It often happens that laminate is purchased some time before installation begins. Also, many people keep a small supply of material in case of necessary repairs; these remnants have to be stored for an even longer time. In this case, you need to know how to store the laminate correctly and under what conditions so that it does not lose its original properties.

Laminate is convenient and practical, but it has certain features - it reacts to humidity and temperature changes. This should be taken into account when storing the coating.

To prevent the laminate from deteriorating during storage, you need to know what conditions it needs. If you follow a number of simple rules, even after a few years the slats can be used for installation.

How to properly store laminate

In some cases, laminate is purchased at one time, and installation is carried out much later.

There are also situations when, after installation, excess material remains, which may be useful for flooring in other rooms or for repairs. To prevent laminated panels from deteriorating and losing their properties, storage conditions must be observed. We will talk below about how to properly store laminate so that it is suitable for subsequent installation. The main factors for the destruction of the panel structure are:

- temperature;

- humidity;

- mechanical damage;

- contact with water.

What can harm laminate during storage?

The rules for storing this material are dictated by its composition. The main factors that can harm the lamellas are:

- Temperature changes;

- Direct contact with water;

- High humidity;

- Direct sunlight;

- Mechanical damage.

At high humidity, water is absorbed into the supporting layer of the laminate, consisting of compressed sawdust and adhesive resins. From such an impact they become deformed and the lamellas lose their shape. Contact with water leads to deformation even faster, which will destroy the structure of the lamella in a short time.

It is worth noting that if, after installation, a moisture-resistant laminate is not afraid of light humidity and in some cases it can even be wiped with a damp cloth, then when constantly stored in a damp room, its moisture resistance properties are often not enough to resist its effects.

Temperature changes can also damage the structure of the laminate. Humidity fluctuations are possible even in a completely dry room. In addition, a large temperature difference can lead to the base layer drying out and cracking, or the protective layer to deform, which will also cause further deterioration of the lamella.

Also, do not place slats for storage in rooms where they will be in direct contact with ultraviolet radiation or sunlight. Over time, with constant exposure, the color of the coating may change, the lamellas will fade and become unusable due to their unsightly appearance.

Correct laminate storage conditions

Laminate is a rather finicky material, so the range of conditions under which it retains its qualities is small. Let's look at them in more detail.

At what temperature can laminate be stored?

The effect of temperature on the lamellas is explained by the deformation of the panel under thermal influences. The expansion and contraction of the material during temperature fluctuations contributes to the formation of microcracks in the load-bearing slab of the panel, which in turn affects the strength of the structure as a whole. Therefore, failure to comply with storage temperature conditions leads to a decrease in service life. If there is a significant deviation from the norms, the laminate may become unsuitable for installation.

The optimal temperature is 18 °C. Under such conditions, the material can be stored for quite a long time; this is the recommended value for operation. The minimum overexposure value is 5 °C.

This leads to the answer to a fairly common question: “Can laminate flooring be stored in an unheated room?” It is possible if two conditions are met:

- The room temperature does not fall below 5 degrees.

- There are no sharp fluctuations in air temperature.

However, that's not all. We will consider the basic requirements for the premises below.

At what humidity level can laminate flooring be stored?

Modern models of floor coverings have high water- and moisture-repellent properties. The leader in these qualities is PVC laminate, which is not at all affected by moisture, since it is based on a plastic polymer.

As for ordinary laminate, there are storage and operation limits, beyond which you can get material that is unsuitable for installation. It is unacceptable to stay in a room with humidity above 65% for a long time.

Just like with temperature, excessive influence of humidity deforms the structure of the load-bearing fiberboard.

Laminate requires special conditions

Due to the great popularity of such flooring as laminate, it is purchased not only by professional builders, but also by amateurs. Therefore, problems often arise with its storage.

This type of coating is a rather complex structure, where the safety of each element is important. Otherwise, the assembly may be carried out in violation of the technology, which will certainly affect the quality of the coating in the future.

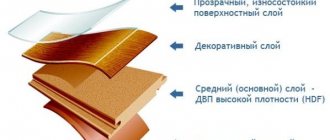

Laminate is a material consisting of several layers.

- The top layer is a moisture-resistant, wear-resistant coating made of a protective film.

- Decorative layer of paper with a wood structure pattern.

- Load-bearing layer, the basis of which consists of high-hardness fiberboard.

- The bottom layer is waterproof, balancing or compensating.

Due to its rather complex structure, the material requires special storage conditions . Violations of these conditions can lead to damage to one or all of these layers.

Not everyone who uses this material stores it correctly. Mistakes are often made when storing laminate flooring at construction sites and store warehouses. Or in places where construction or repairs are directly underway.

This leads to deformation of laminate elements, that is, lamellas, damage to their locks, and cracks. Delaminations may appear on the slats. The top layer may burn out in direct sunlight.

Transportation of material to storage location

Damage to the material can occur not only during storage, but also during transportation. Upon receipt of a shipment of goods, you must check each package for ruptures. The same process must be repeated after unloading the boxes.

- Transportation can be carried out using any type of transport suitable for this purpose, with protection from precipitation and mechanical damage.

- Laminate flooring must not be transported in an open truck, even in intact packages, to avoid exposure to rain or snow.

- The packages must be tightly packed and secured into the means of transportation - the boxes must not “ride”, “bounce” or be subject to other mechanical stress.

FiNEX company presents a range of transportation services:

- Delivery by company transport

- Delivery through transport companies

- Pickup from our warehouse

- Storage of finished goods in the company warehouse

Transportation recommendations:

- It is necessary to transport parquet only horizontally;

- During transportation, the surface on which the parquet board lies must be flat (to avoid falling and damage to the packages).

Proper storage of parquet is the key to its quality. It is very important that products are stored correctly both at the supplier's warehouse and at your home. It should be remembered that wood is a hygroscopic material. Such materials are susceptible to the influence of moisture contained in any building. Wood requires stable humidity and temperature.

How to choose a place to store laminate flooring

Let’s consider what necessary parameters the premises must have for the entire storage period:

- temperature not lower than 5 °C;

- humidity not higher than 65%;

- protection from sunlight;

Laminate placement

Some placement tips:

- The boxes are laid over the largest area, that is, lying down. It is strictly prohibited to place packages on their sides, as in this case there is a high probability of damage to the locks and the impossibility of subsequent stacking.

- It is necessary to leave a distance from the walls and ceiling of at least 1 meter. The height of the stacks should not exceed 5.5 meters. A taller stack will put more pressure on the underlying boards.

- Any possibility of water ingress and mechanical impact must be excluded, therefore placing packages near batteries and unstable structures is not recommended.

Suitable storage locations:

- storage room;

- glazed balcony;

- warehouses;

- garage or cottage in the warm season in the absence of moisture penetration.

- basement;

- unglazed balcony;

- garage or cottage in the cold season.

The remains of the unpacked laminate must be tightly packed in a box, additionally wrapped in plastic wrap. Storage is carried out in a warm, dry place in a horizontal position.

Laminate shelf life

The maximum time that laminate can be kept depends on two factors:

- conditions under which storage occurs;

- wear resistance class of panels.

The higher the class, the longer the service life the manufacturer guarantees, however, the price will be higher. If the conditions are met, the shelf life approaches the service life, which is on average 10-15 years.

Accommodation Tips

It is also important to correctly place the laminate in the room where it will be stored. There are several rules for this:

- Packs of laminate should be laid lying down, over the largest area. Do not place them on their sides or vertically, as this will damage the locks.

- The distance between the packs and the walls, as well as the ceiling, should be at least 1 meter. The height of the stack should not exceed 5.5 meters, otherwise there is a high risk of mechanical damage from the strong pressure of the laminate found below.

- Wrap the packs with foam insulator, which can protect them from possible chips and impacts.

What does laminate consist of?

The laminated panel consists of several layers. If even one of them is damaged, the service life is sharply reduced; in some cases, further installation is not possible at all.

- The bottom layer serves as a stabilizer for the entire slab and gives rigidity to the structure. On modern models it also serves as protection against moisture.

- The base layer is the main part. It is represented by a thick wood-fiber board, on which a lock is profiled for fastening the boards together. Even slight damage to the locking system precludes the use of the lamella.

- Decorative. The appearance of the laminated coating depends on it. Can imitate wood structure, reptile skin, stone, etc.

- Top protective layer. Increases resistance to moisture and sunlight, and to some extent prevents deformation from mechanical contact with the surface of the laminate.

We summarize how to properly store laminate flooring, what conditions must be observed, and what room is suitable for this:

- optimal temperature - 18 °C, minimum - 5 °C;

- humidity level - no higher than 65%;

- avoiding exposure to direct sunlight;

- exclusion of exposure to precipitation and mechanical damage during transportation and storage, even if the packaging is intact;

- storage is carried out in a horizontal position in stacks no higher than 5.5 meters;

- suitable premises: glazed balcony, storage room, specialized warehouses, garage in the warm season.

We hope that our recommendations will serve you well and your laminate will last a long time without the slightest complaints.

A little about laminate

Laminate is a multilayer coating, quite durable, which is sold in stores packaged in packs of several lamellas. But, despite its reliability, the material needs to be treated with care. The fact is that if you damage even one layer of this coating, you will no longer be able to install it correctly , and it will serve much less than what the manufacturers claim.

Laminate is a multilayer material

The laminate consists of 4 layers.

- Top protective layer , which allows the coating not to fade in the sun and is not to some extent afraid of exposure to moisture and mechanical damage. It is made on the basis of synthetic resins. Sometimes it also plays a decorative role - the surface can imitate the grooves of wood.

- Decorative layer, which is responsible for giving the coating a certain color. Usually represented by paper with a design printed on it. It hides under a protective top layer, and therefore is not afraid of water.

What is laminate

- Base or load-bearing layer , which is responsible for the strength and thickness of the lamellas. It is on this part that the reliability of the material will largely depend. The layer is usually made from high-density fiberboard. It is in this layer that a lock is cut out, allowing the individual covering strips to be securely joined together.

- The bottom layer is stabilizing . Increases the rigidity of each lamella, protects the material from below, and prevents the boards from deforming.

Comparative table of properties of laminate and linoleum

If all layers are made with high quality, then the laminate has a certain level of sound and heat insulation properties, has some moisture resistance, and is not afraid of moderate mechanical influences.

Laying laminate

On a note! The higher the class of the laminate, the higher the strength and resistance of the coating to external influences. However, the higher the quality, the higher the price of the material.

The strength of laminate is much higher than that of wood, since crystallized wood is pressed tightly

Laminate also has its drawbacks, which, however, do not reduce its popularity. It’s just that in some special-purpose rooms other types of coating will be installed. Laminate is afraid of:

- excessive amount of moisture (except for moisture-resistant type of coating);

- strong mechanical impact;

- exposure to certain chemicals.

Laminate classes

Conditions and shelf life of laminate in packaging and without

Nowadays, laminate is considered almost the most popular flooring. It is easy to install, aesthetically pleasing, quite durable and not too expensive. Compared to natural wood floors, it is easier to maintain. Modern types of laminate are quite water-resistant, which allows you to wash the floor without fear of the coating lifting. Laminate floors are often purchased in larger quantities than are needed for installation. This is done in case some part of the floor needs to be replaced. But in order for the material to remain suitable for further use, you should know how to properly store the laminate and what conditions are required for storage.

Counting laminate squares per room

Now let’s count how many squares are in a pack of laminate. If you know the area that should be covered with flooring and how much laminate is in one package, as well as its exact parameters, then you can accurately calculate how many packages you will need. Let the area of your room be 50 m2. And you have chosen a laminate with the following parameters: eight slats in a pack and the total area of the slats in the pack is 2 m2.

Thus, after making simple calculations, you will get how much laminate you need for a given room: 50 / 2 = 25 packs or 25 * 8 = 200 laminate planks. Knowing the installation method, you can calculate how much you need to increase the amount of material. Let the installation method be chosen straight, which means a margin of five percent is required: 200 * 1.05 = 210 laminate planks.

In this article, we looked at such questions as: how many squares are in a pack of laminate, how many pieces of laminate are in a package, and how much laminate is needed per room in order not to buy too much and not be left without material.

Despite the apparent simplicity of this issue, there are many pitfalls and subtle nuances here; if you do not take them into account, you may find yourself in an unpleasant situation when you have to run around the shops as hard as you can and look for the one missing strip.

Having this information, you can safely buy the necessary material in the right quantity, which will allow you to avoid unnecessary expenses.

Purchasing flooring

- To ensure that the floor covering is not damaged before it is laid on the floor, it requires proper storage and careful transportation.

- When purchasing, you need to pay attention to the tightness of the packaging. If it is broken, such a product could already be exposed to high humidity. Which, in turn, could negatively affect the quality of the product, its shelf life, or even lead to damage to the laminate.

- For long-term storage, packages with laminated panels must be placed at a distance of no less than 1 meter from the wall. In addition, they must be located on a flat surface, always in a horizontal position. Do not stack other heavy materials on pallet packages. This can lead to deformation of the future floor covering.

- To store already opened packages, the laminate is placed in small stacks, approximately the same height as in the original packaging. Next, they are hermetically packaged in film and sealed with tape on all sides. This is necessary so that evaporation and high humidity, which inevitably occur in an apartment during renovations, cannot damage the pallets.

- If the factory packaging remains intact, the laminate is stored directly in it, and if the bags are removed, the material can be packed in them again, wrapped with tape, creating an airtight seal.

Long-term and short-term storage of laminate flooring is practically no different. In the places where it is located, drafts are not allowed, and there should also be no sources of heat or high humidity. Do not store heavy objects nearby (if they accidentally fall, they can damage the laminate). You should also not place heavy tools or bags of building materials on top.

If after laying the floors there are several laminated panels left, they must be stored in the same conditions: sealed and kept at room temperature, avoiding high humidity and overheating. This could be a mezzanine or a storage room.

Conditions for laminate installation

The conditions for laying this type of coating differ little from the conditions for its storage. First of all, it is worth remembering that the material cannot be used in a room where the air temperature is negative. It is important to adhere to the rule that the air must be heated to +18 degrees.

Certain conditions must also be met during installation.

Also, there should not be a high level of humidity in the room. Otherwise, the laminate will quickly begin to deform and collapse - it will go in waves, rise, and the joints between the individual lamellas will be clearly visible.

Installation of laminate diagonally

Also, laminate is a very demanding coating regarding the evenness of the rough base. If you neglect this, the material will quickly begin to “walk” under your feet and creak when moving over it. Also, during installation, a soft substrate is placed under the laminate, and all debris from under it must be thoroughly swept away.

Do-it-yourself laminate laying technology

Laminate is a coating that is of high quality and has a fairly long service life. Even individual lamellas left after repairs can be stored for a very long time. There is no point in throwing away or selling the remaining coating after finishing the repair - it is better to save it. It also happens that there is a need to repair the coating - replacing one or two lamellas. This is where the saved material comes to the rescue.

Source

It often happens that laminate is purchased some time before installation begins. Also, many people keep a small supply of material in case of necessary repairs; these remnants have to be stored for an even longer time. In this case, you need to know how to store the laminate correctly and under what conditions so that it does not lose its original properties.

Temperature storage conditions for laminate

Proper storage of laminate flooring is not only about observing air humidity levels. Temperature is of great importance.

The optimal temperature indicators are the same for both storage of laminated panels and for their operation. This is +5°C - +30°C with air humidity not exceeding 65%. Too dry air is also harmful for laminated coatings - the panels may dry out.

Those people who install laminate flooring in their dachas argue that if it has not been damaged on the floor during the winter, then nothing bad will happen to its remains if they are in the garage, in conditions of low temperature. But this is a mistaken opinion. This material is very sensitive to changes in temperature and humidity. As a result of storage in such a place, it will become deformed, begin to delaminate and crack. Subsequently, such material will no longer be suitable for laying on the floor.

GOST 32 – 304 – 2013 regulates how to store laminate. For this purpose, closed, dry and clean rooms with a temperature above +5°C and humidity not exceeding 65% are used. Unheated rooms in which such indicators are maintained even in winter can be used to store laminate flooring. This GOST limits the shelf life of this material in such conditions to one year.

Preparation for storage

Storing laminate flooring for a long time will not be difficult, but the panels need to be prepared for such savings. The preparation measures are simple - you should go through the laminated boards and immediately remove the damaged ones. These will only take up space. Similar preparation applies to unpacked packs.

Note! If the panels are in their original packaging, then its integrity should not be violated; it was created in order to preserve all the consumer qualities of the material throughout the entire shelf life.

If you need to preserve material for a long time, you need to follow these rules:

- Place the packages in a horizontal position on top of each other.

- It is better to concentrate them in the center of the room.

- The room must be heated.

- It is necessary to limit access to material for pets.

- Humidity – no more than 60%.

- It is not recommended to store laminate in a vertical position - this can cause deformation of the panels.

Where to store unused laminate

For the unused part of the coating, choose a place where these materials will not interfere with anyone. It is better if the remains of the laminate are constantly in one place - frequent movements will not do it any good.

It is not advisable to store laminate flooring in rooms with high humidity (bathroom, toilet, etc.). Also, do not allow water, snow or other liquids to come into contact with the pallets.

Special locks on the panels, which are made to connect them together, should not be subject to deformation or break off. They are quite fragile, and during storage you need to pay great attention to this, since if the locks are damaged, installation will be impossible.

What can damage the material?

When ensuring proper storage of laminate flooring, the first thing you need to do is recognize its enemies by sight. The most dangerous thing for this coating is moisture. Most grades of laminate flooring are water intolerant. There is no need for high humidity in the storage room.

It is also worth paying attention to transportation, because it is important not only how to store the laminate, but also how to deliver the material to the place of storage. Important Features:

- Packages should only be transported in a closed car to avoid precipitation on the panels.

- Packages should be stacked on top of each other, but ventilation and secure fastening to the board must be ensured if the material does not occupy all the space.

- Heavy objects should not be placed on top of the packs, which will lead to deformation of the panels or their locking joints.

- It is recommended to transport packages on pallets.

Laminate shelf life

Laminate floors have different qualities and, accordingly, shelf life and use. Laminate is divided into classes, and the higher the class, the more durable and wear-resistant the material from which it is made. But no one can give an exact time for how long laminate can be stored. It all depends on the conditions under which it will be kept and operated.

Typically, the shelf life of laminate flooring is limited to 8 - 10 years, if all the standards described above are followed. High-quality floor coverings that are resistant to moisture can be stored without sealed packaging, simply covered with film.

The service life of laminate varies from 3 to 20 years. In order for it to maintain its appearance for many years, you need to choose the right classification. If you plan to lay floors in institutions where many people wear street shoes every day, you need a wear-resistant material of a high strength class, and a lower class is suitable for an apartment.

Packaging and labeling of solid parquet

Package

The packaging must be intact. It is recommended to open the package when laying the parquet boards begins.

- Solid and engineered boards are packaged in bundles for ease of counting, storage and transportation.

- Modules and units are packed in corrugated cardboard packaging, 4 pcs. in height, thickness 19.8 mm and 5 pcs. 15.5 mm thick in height.

- Molded products (plinth) are packed in bags and film according to the meter, according to the order.

General storage rules

- air humidity up to 65%;

- storage temperature is not lower than +5°C and not higher than +30°C;

- there should be no drafts during storage;

- Do not allow water or other liquids to come into contact with the laminate;

- when storing, the distance to the walls must be at least 1 meter;

- It is unacceptable to store heavy objects on packages with laminate;

The correct selection and storage of laminate will allow the floors to look beautiful in the apartment and in the country for many years. Use the tips above and save significant money on your new flooring purchases.

How to store peeled horseradish at home: tips

Pre-prepared sauces and seasonings with horseradish lose their taste, pungency and sharpness, and horseradish is famous for this. Therefore, everyone tries to keep it fresh for as long as possible in order to use it as needed.

In addition to taste, horseradish has other benefits, including medicinal properties. It helps cope with colds and replenishes the supply of vitamins in the body. The essential oil contained in horseradish also evaporates over time; to prevent this from happening, you need to properly prepare the crop for storage.

What roots can you use?

Preparing horseradish roots for long-term storage begins with sorting. For this purpose the following are selected:

- Solid, smooth, healthy roots - they can be processed later than others;

- Peeled horseradish should be white or milky in color.

For culinary purposes, it is better to use the varieties “Valkovsky” and “Atlant”, observing the terms of its ripening, usually 3 years. To prevent the roots from deteriorating, they should not be placed next to other crops and should not be wetted.

Harvesting

Having harvested on time, the roots will be juicy, spicy and stored longer. Roots should be dug up according to the characteristics of the variety, usually in October. If you delay cleaning for another month, the roots will become brittle and brittle, so it will be more difficult to dig them out. When harvesting, you need to follow the following rules:

- Dig strictly at the specific time indicated on the package of seeds;

- Pay attention to the leaves. When they begin to dry out, you can begin to extract the roots, after cutting off the leaves;

- The roots are carefully removed from the ground using a fork so as not to touch them;

- Only large specimens are taken for storage, smaller ones are left in the soil until next year;

- When all suitable roots have been extracted, those remaining in the ground are covered with straw to protect them from frost;

- All roots are inspected for damage and left for one day in the fresh air so that the horseradish dries out.

Methods for storing peeled horseradish

There are many ways, it all depends on its quantity, conditions of detention, individual preferences. Most housewives prefer to store the roots in a peeled form to make their work easier in the future, reducing the cooking time. Let's look at the most common methods.

Frozen

The freezer is a suitable option for keeping fruits, vegetables and other products fresh for a long time, without heat treatment and thereby leaving all the benefits in them. To do this, the selected horseradish is cleaned and left to shake a little. Next, the roots are cut into slices or grated. The prepared horseradish is placed in bags or containers and placed in the freezer. If necessary, break off the desired piece and use it.

Dried

Convenient, practical and common storage method. It is quite difficult to put all the desired products in the freezer, since its size is strictly limited, dried horseradish does not take up much space and, moreover, it can be stored at temperatures from +5 to +25°C. Before sending horseradish to dry, it needs to be prepared - peeled and cut into thin slices or grated. After this, you can send the root vegetables to dry.

There are three ways to dry roots:

- In the oven - place the horseradish on parchment. The temperature should be within 50°C;

- In an electric dryer;

- In the sun, horseradish is placed in one layer on the surface and covered with gauze. The main thing is that the weather outside is warm and sunny.

When the horseradish is completely dry, it is placed in a glass or plastic container, tightly closed and stored along with other spices for 1-2 years. If stored properly, horseradish will not lose its taste and will remain just as beneficial for the human body.

Canned

Russian cuisine is famous for its preserves, including canned horseradish. Horseradish is grated and all kinds of spices and vegetables are added to it. This field is laid out in sterile jars and stored for up to 6 months. The most common options with:

- Citric acid. To do this, 1 kg of horseradish is washed, peeled and allowed to shake a little. At this time, prepare the marinade separately. Place 1 liter of water on the fire and add salt and sugar 30 g each; when the brine boils, remove it from the heat and add 20 g of citric acid and pour in the previously grated horseradish. Everything is thoroughly mixed, placed in sterilized jars and tightly closed with a lid. The amount of sugar can be reduced or not added at all, then the horseradish will be sharper;

- Vinegar. Just like in the first recipe, horseradish is prepared and grated. If desired, you can pass it through a meat grinder. For 1 kg of horseradish you will need 1 liter of water. Place the water on the fire and let it boil. Then add 40 g of salt and sugar and 1 tbsp. vinegar. The resulting marinade is poured over horseradish and allowed to stand for 10-20 minutes, then put into jars and closed;

- Beetroot. The sauce is prepared as follows. Horseradish is ground. 1 liter of water boils, and 30 g of salt, 50 g of sugar and 50 ml of vinegar are added to it. The resulting brine is poured over horseradish and beet juice is added. After mixing thoroughly, the sauce is placed in sterile jars and placed in the refrigerator.

Benefits of horseradish

The root vegetable contains a large amount of vitamins. In addition, it contains minerals, dietary fiber and organic acids. All this improves immunity and promotes better functioning of internal organs. Horseradish is used as a base for sandwiches, as a sauce for meat or fish. It is added during the marinating process. A wide variety of recipes will allow you to choose something for every taste.

Inspection upon purchase and transportation

When purchasing a product in a store, be sure to check the integrity of the plastic packaging. If in the future you are going to store the material and not immediately lay it down, then the whole package will protect it from unnecessary factors of unwanted influence. In addition, a torn film may indicate that the board is damaged.

Pay special attention to the shape of the corrugated gasket in the tongue and groove area, as well as at the corners of the board. If damage is visible, this is a reason to demand that the pack be replaced.

After the packs are selected, we begin transportation to the storage location. Cargo should be transported horizontally, on a flat surface in a tilt vehicle or closed body. Such conditions will avoid the risk of mechanical damage to the material in transit. Most of all, laminate is afraid of excess humidity and physical influences.

During transportation, moisture must not get under the protective film of the packaging. Avoid placing any heavy objects on top of laminate pallets.

conditions, temperature and humidity according to GOST

Laminate is a popular and economical flooring material, and everyone who came across it should have understood that its main enemy is moisture. It causes it to swell and become deformed. Let's look at how to properly store laminate flooring if you have unused packaging left or you had to postpone laying it indefinitely.

What is laminate?

This flooring is a chipboard (chipboard) coated with a special decorative layer. In the first layer of the laminate there is a protective film based on melamine or acrylate resin, under it there is decorative paper, on which, in fact, a textured pattern is applied, and only then thick chipboard. The thickness of the entire laminate board is usually 8-12 mm.

For the manufacture of the chipboard itself, formaldehyde or acrylic resins can be used; the second option is more environmentally friendly, and the first, when heated above 26 degrees, can produce harmful fumes. Although this is regulated by GOSTs, still pay attention to this when choosing a material.

Under the chipboard there is another one - a stabilizing paper layer; this bottom layer in some models may also have a soundproofing function.

How to store?

Now that we imagine what this flooring consists of, we can, in principle, understand what it is afraid of.

Standard requirements for this material:

- Horizontal storage.

- The distance from the walls and ceiling to the stack is at least a meter.

- Closed, dry, well-ventilated area.

- It is strictly prohibited for water to get inside the packages, so when purchasing, check the integrity of the top plastic packaging of the boxes with the material.

- Do not stack other heavy materials on top of the laminate packages, do not step on the packages, or allow heavy objects to fall on the packages or the panels themselves. The height of stacks separated by pallets, according to GOST, should not exceed 5.5 meters.

- After transportation from a warehouse or store to the installation site, do not install it immediately; let the material rest for several days in the conditions in which it will be installed and used.

- It is recommended to install at temperatures above +18˚C.

- Optimal operating conditions coincide with the average requirements for residential premises: +18-20˚ C, humidity about 65%.

- Excessive dryness is also harmful; it can cause the panels to dry out.

Very often the question arises: is it possible to store laminate flooring in an unheated room, for example, in a country house, on a balcony, in a garage?

Let's turn to GOST 32-304-2013. It states that such floor coverings can be stored in dry, clean, closed areas at a temperature not lower than +5˚C and a relative humidity not higher than 65%. If your unheated room maintains such constant parameters during the winter season, then it is quite suitable for storage.

By the way, the shelf life under such conditions is limited by the same GOST to 12 months.

And, lastly: to transport laminate, use closed vehicles, excluding precipitation from getting on the transported material.

saveton.ru

Proper storage

When purchasing material in advance, worry about where it will be stored. For more information about storing material, watch this video:

Long-term storage of laminate should be carried out in a room that meets certain requirements:

Pallets should be placed at a distance of at least 1 m from the wall. It is not recommended to place heavy objects on top of laminate packaging. It is strictly forbidden to store packaging with a laminated board in a vertical position.

The conditions for short-term storage of laminate are similar to long-term storage. If you plan to immediately lay the material, then before laying the laminated board should rest in the conditions of future use for at least 2 days.

To solve the problem, You can build such a convenient structure for storing and preserving potatoes with your own hands in winter and create the right temperature for it...

In every apartment (regardless of the number of rooms) there is not enough space to store things. After all, the point is not only that the premises are sometimes not enough, but also…

In recent years, heated floors have become increasingly popular both among owners of private houses and residents of high-rise buildings. They provide good and…

Is it possible to store laminate flooring on the balcony in winter - Laminate flooring and all about it

Laminate is a popular and economical flooring material, and everyone who came across it should have understood that its main enemy is moisture. It causes it to swell and become deformed. Let's look at how to properly store laminate flooring if you have unused packaging left or you had to postpone laying it indefinitely.

What is laminate?

This flooring is a chipboard (chipboard) coated with a special decorative layer. In the first layer of the laminate there is a protective film based on melamine or acrylate resin, under it there is decorative paper, on which, in fact, a textured pattern is applied, and only then thick chipboard. The thickness of the entire laminate board is usually 8-12 mm.

For the manufacture of the chipboard itself, formaldehyde or acrylic resins can be used; the second option is more environmentally friendly, and the first, when heated above 26 degrees, can produce harmful fumes. Although this is regulated by GOSTs, still pay attention to this when choosing a material.

Under the chipboard there is another one - a stabilizing paper layer; this bottom layer in some models may also have a soundproofing function.

How to store?

Now that we imagine what this flooring consists of, we can, in principle, understand what it is afraid of.

Standard requirements for this material:

- Horizontal storage.

- The distance from the walls and ceiling to the stack is at least a meter.

- Closed, dry, well-ventilated area.

- It is strictly prohibited for water to get inside the packages, so when purchasing, check the integrity of the top plastic packaging of the boxes with the material.

- Do not stack other heavy materials on top of the laminate packages, do not step on the packages, or allow heavy objects to fall on the packages or the panels themselves. The height of stacks separated by pallets, according to GOST, should not exceed 5.5 meters.

- After transportation from a warehouse or store to the installation site, do not install it immediately; let the material rest for several days in the conditions in which it will be installed and used.

- It is recommended to install at temperatures above +18˚C.

- Optimal operating conditions coincide with the average requirements for residential premises: +18-20˚ C, humidity about 65%.

- Excessive dryness is also harmful; it can cause the panels to dry out.

Very often the question arises: is it possible to store laminate flooring in an unheated room, for example, in a country house, on a balcony, in a garage?

Let's turn to GOST 32-304-2013. It states that such floor coverings can be stored in dry, clean, closed areas at a temperature not lower than +5˚C and a relative humidity not higher than 65%. If your unheated room maintains such constant parameters during the winter season, then it is quite suitable for storage.

By the way, the shelf life under such conditions is limited by the same GOST to 12 months.

And, lastly: to transport laminate, use closed vehicles, excluding precipitation from getting on the transported material.

Source: saveton.ru

kosmohard.info

Performance characteristics of laminate for unheated rooms

Many users are interested in the question of whether it is possible to install laminate flooring in their country house. Of course, this is possible, but the material for the flooring must meet the following characteristics:

- High strength and wear resistance of the coating. This is very important, because the floor in a country house will become stained much more often than in a city apartment. According to consumer reviews, it is recommended to select products of at least class 33 for this purpose. Such materials have a high cost and a long service life, so the price of the coating is very justified. Choose laminated panels from a well-established manufacturer.

- Harmlessness of the materials used for human health. Laminated panels are partially made from artificial raw materials, so the buyer should pay attention to the emission class e0 or e1. Such coating options are considered absolutely safe for humans.

- Long period of operation. This characteristic depends on the production technology and the quality of raw materials. The guaranteed service life of laminated panels from some manufacturers is 20 years.

- The flooring material that will be used in the country should not be afraid of humidity and sudden changes in temperature. Most of the technical characteristics of laminated panels are confirmed by quality certificates of the corresponding type.

- The floor covering may suffer from exposure to freezing temperatures in winter, so laminated panels must be frost-resistant. The minimum thickness of products is 1 centimeter. Thicker materials are subject to additional treatment with a special moisture-resistant impregnation. This is an ideal material for use in an unheated country house.

- Laminate has different colors and textures; its surface can imitate ceramic tiles, natural wood or stone texture. This variety allows you to choose the flooring material to suit any interior.

The indicated advantages of laminated panels are not yet enough for its use in the country. It all depends on the region where the construction site is located, the duration of winter and negative temperatures.

Is laminate flooring afraid of frost?

When choosing laminated panels for a garden terrace, many users are interested in the question of how this type of flooring tolerates the influence of negative temperatures and whether it is afraid of frost. In fact, the material does not show sufficient resistance to negative temperatures. This is due to the fact that the product consists of several layers, which are fastened together using special glue.

Some time after installation, under the influence of frost, the glue loses its initial properties, as a result of which numerous cracks appear on the surface of the coating. Ultimately, this can cause the material to rot. Insufficient frost resistance is also associated with the use of paper in the manufacture of laminated panels. This element is impregnated with special moisture-repellent compounds, but it can also deteriorate due to the influence of negative temperatures.

How to increase the frost resistance of laminate?

If laminate is used to install flooring in a country house, then the property owner can provide high-quality protection for the flooring from the influence of negative temperatures. To do this, it is necessary to lay insulation before installing the floor, which will prevent the penetration of cold from the base. Another protective measure is the correct selection of a substrate with minimal thermal conductivity. This flooring technology is also in demand in ordinary heated residential premises.

The use of thermal insulation allows you to create comfortable conditions for human living. For an unheated cottage this is the most popular option. To prevent moisture from entering the structure of the material, before laying the thermal insulation, a polyethylene film is spread on the base.

Operation and storage of parquet and parquet boards

When using parquet, seasonal changes in microclimate play an important role.

In summer, relative air humidity is high (more than 60%) and the size of the parquet planks increases (“expanding”), which leads to the squeezing of varnish and putties out of the cracks and raising the edges of the parquet planks. To avoid these unpleasant consequences of changes in seasonal microclimate, you should reduce the humidity using air conditioners or turn on the heating. Relative humidity can be measured with a thermohygrometer.

In winter, when the heating is on and the relative air humidity is low (less than 45%), the parquet rivets become smaller and the parquet cracks and cracks appear. To eliminate these consequences, it is necessary to reduce the temperature and increase the humidity. The temperature can be changed using an air conditioner, and the humidity can be increased using a humidifier or open water tanks.

The deformation of parquet staves when the season changes can be very significant, for example, when the relative air humidity changes from 30% (winter, room with central heating and without additional humidification) to 60% (summer, autumn) at a temperature of +20 * C, the equilibrium moisture content of the wood changes by 5%.

A change in absolute humidity by 5% may change the size of an oak stave (width) by 0.8 mm (420x70x15mm is the size of a parquet stave). Most often, dimensions change at the ends of the rivets.

It is not allowed to cover the parquet with waterproof materials for a period of more than 5 calendar days. (for example cellophane).

If the varnish layer is damaged, it is recommended to renew it to protect it from moisture.

Varnished parquet should be removed using a vacuum cleaner and wiped with a well-wrung-out cloth. To partially renew (revitalize) the varnish coating, you can use special chemicals for the care of parquet floors. These chemicals are added to water and the parquet floor is wiped with a well-wrung out cloth, previously soaked in this mixture.

Flooding the parquet with water is not allowed. The ingress of water leads to warping and swelling of the parquet. Chemical defects can also appear on the parquet floor.

Pets, hairpins, etc. significantly reduce the service life of the varnish coating (usually 3-5 years) and leave stains, dents, and scratches on the wood.

Mechanical damage to the parquet is also unacceptable (damage to the varnish coating and changes in the mechanical properties of wood are detrimental to the parquet floor)

To store parquet, it must be shrink-wrapped. Optimal microclimate conditions must be observed: temperature 14-24*C, at 45%-60% relative air humidity.

Before laying parquet on site, you should unpack the film and give time (1-2 days) for the parquet to accept the microclimatic conditions of the room.

Parquet is afraid of mechanical damage.

Water ingress is detrimental to parquet.

When storing parquet, laying it, operating it, you should also remember that there are the most hygroscopic species, such as beech, pear, campass (the so-called capricious species) that most quickly respond to changes in microclimate and stable species - oak, merbau, etc. In stable species, such as As a rule, the clearest geometry and dimensions are compared to capricious ones. When laying capricious rocks, you should use anhydrous glue or glue with a low water content, otherwise cracks will form after laying and a “boat” effect will appear.

Do not forget that parquet flooring requires maintenance during use. You cannot fill it with water or cover it with film. Operation must take place under the conditions stated above.

Which laminate to choose for your dacha?

The main criteria for choosing a laminate for a summer house are:

- strength characteristics;

- panel thickness;

- flooring color and pattern;

- price.

Let's take a closer look at each selection criterion. Particular attention must be paid to the strength of the material, because dachas are considered unheated houses, and besides, the load on the floor in such rooms will be much greater than in an apartment. At the moment, there are 6 strength classes of laminated panels. In our case, it is necessary to select a floor covering of at least class 32. Such materials will ensure the reliability and strength of the floor and high performance characteristics.

An equally important characteristic is the thickness of the panel, the minimum value is 1 centimeter. In addition, the material must be able to withstand moisture well. Water that gets into the structure of the product expands under the influence of negative temperatures, which leads to destruction of the product.

For finishing the floor in a country house, it is best to choose dark laminated panels. This tone of the coating will help hide numerous dirt that remains on the floor after walking in shoes. The most popular solution is considered to be flooring with an imitation oak texture.

Many users try to save money on purchasing flooring, but this is not possible when installing laminate flooring in the country. For good, high-quality and durable laminated panels you will have to pay a considerable amount of money. Here it is necessary to use moisture-resistant products, and they are much more expensive than standard analogues. If the country house is designed for the owners to stay in the winter, a heating system is installed in it. In this case, you can use ordinary inexpensive laminated panels.

For an expensive country house, instead of laminate, it is recommended to use solid larch flooring or moisture-protected parquet. Such floors look beautiful in any residential interior; they have high moisture resistance and durability.

Installation technology

- To ensure that the coating lasts longer, you should prepare the surface in advance. It can be leveled with screed or plywood and additionally insulated with mineral wool or extruded polystyrene foam. Differences should not exceed 2 mm per meter.

- In order to reduce humidity, it is imperative to lay waterproofing made of polyethylene film on the floor before starting work. It should be laid overlapping each other and the walls. The joints are taped to ensure tightness.

- Lay the underlay on the floor end to end and secure it with tape.

- Laminate flooring for a dacha must be laid with the maximum possible temperature gap near walls and other obstacles. During a change in humidity, it will greatly change its linear dimensions, so it should have enough space to float freely on the substrate.

- The rooms must be separated from each other by a gap with a threshold.

- The standard wedges that come with the kit are not suitable for installing laminate flooring, as they leave a gap of only 10 mm.

- You can make your own limiters of the same thickness of 20 mm from scraps of plywood or old boards. Such a gap will be enough, and it can be hidden by a plastic baseboard.

- The first row is assembled in the usual way, by joining the panels using locks. The last panel in the row is cut taking into account the required gap.

- The second row begins to be laid with trimmings to move the joints. They must move at least 30 cm.

- First, the second row is completely assembled, and then it is connected to the first.

- Before joining the panels, you need to coat the locks with a special glue-sealant for laminate flooring. It is simply applied evenly from the tube to the end and the panels are pressed against each other. The excess should then be removed with a clean cloth before it dries.

- The last row is cut to width and joined in the usual way. To simplify this process, you can use a special Z-shaped clamp.

The instructions in this video will show you how to lay laminate flooring in a country house.

Sealing seams

If you are going to lay laminate flooring for a mid- and premium-category cottage, you should know that many manufacturers apply a layer of wax to the locks at the factory. This protects the joints from moisture penetration from below and above.

Note! The presence of a wax layer does not negate the use of a vapor barrier for the base.

If the joints are not treated in any way, then you should separately purchase a special water-repellent Click Guard sealant and manually process each end before joining.

When combined with this, the laminate uses a water-resistant backing, then you can significantly increase its use in harsh environments.

Laminate storage?

Laminate storage - if you do not plan to install the laminated flooring immediately after purchase, then you should take into account the rules for its storage. Laminate flooring should be kept in a consistently warm, dry environment. High humidity in the air, and especially not allowing water to come into contact with the product, is not allowed. The material should be kept away from heaters and drafts, places where heavy objects can fall onto the coating. The laminate should be stored in its original packaging, preferably in the middle of the room at a distance of at least 1 meter from the walls. Laminate packages should only be stored horizontally. Particular care should be taken to protect locking installation systems from deformation.

Storing laminate immediately after purchase should involve placing it at room temperature for two to three days. This is necessary so that the product adapts and takes the appropriate form for the individual microclimate. Then, you can begin installation. We invite you to read interesting articles about laminate flooring. You can order beautiful, high-quality laminate flooring at affordable prices on the Laminat-Parquet.net and at Laminat- Parquet centers. net & Laminate Hut .

More Questions Answers

How to make a laminate floor? This is perhaps one of the most important questions asked by anyone who wants laminate flooring. For laminate flooring to last a long time, it must be installed correctly. In other words, you need to follow all the rules and take into account the requirements, in this case the laminate will be laid correctly and efficiently.

Laminate Aqua Step Mini differs from other types of laminate due to its water resistance and original design. Moreover, Aqua Step laminate is the only one that can be installed in the bathroom or kitchen. As for the design, the slats look like natural stone or ceramic tiles, and the board is so pleasant to the touch and natural in appearance.

Parquet boards in Kiev, where to buy - of course, in the Laminat-Parket.net & Khata Laminata . By purchasing products from us, you are purchasing high-quality floor coverings from world brands, and this is a guarantee of quality for many years.

The online laminate store Laminate-Parquet.net is open for customers around the clock, without holidays, weekends or breaks. Purchases with delivery to your destination can be made from any city in Ukraine at any convenient time. In our online store you can find a huge selection of branded, stylish floor coverings.

Laminate flooring in Nikopol can be ordered online on the Laminate-Parquet.net .

Since all floor coverings cannot be laid on a bare floor, the question of how thick the underlay under the laminate is is relevant.

How to extend the life of laminate flooring?

The service life of a coating, in addition to its class, depends on many other factors. What needs to be done to ensure that a floor covered with laminated panels lasts as long as possible?

- After delivering the material to the installation site, it must be kept indoors for 2-3 days. If the material is planned to be stored for some time, then for this purpose it is necessary to select a dry room.

- Of great importance is the level of preparation of the base, which must be smooth, without bumps or dents.

- The installation process must fully meet the requirements set out in the manufacturer's instructions.

- The product class is selected in accordance with operating conditions.

- Maintenance rules must comply with the recommendations developed for each class and type of laminated panels.

- In a room with laminate flooring, it is advisable to maintain air humidity in the range of 35-65%.

Sources

- https://kakxranit.ru/stroika/kak-xranit-laminat.html

- https://laminatepol.ru/6376-hranenii-laminata.html

- https://pol-exp.com/kak-hranit-laminat/

- https://relaminat.ru/pri-kakih-uslovijah-hranit-laminat.html

- https://setafi.com/poly/laminat/kak-hranit-laminat/

- https://GuruPola.ru/napolnye-pokrytiya/laminat/kak-khranit.html

- https://www.Laminat-Msc.ru/info/articles/sroki-sluzhby-laminat/