Even the highest quality interior doors require maintenance and periodic replacement of hardware. Considering the frequency of opening and closing the door structure, the handle experiences the greatest load. It's easy to replace the part yourself. The main thing is to understand how door handles work. And also know what is needed to properly dismantle and reinstall the accessory.

Types of door handles

Handles for door blocks are selected depending on the type of room, degree of traffic, ease of fixation, design and price.

There are 2 classifications of locking fittings:

- According to the material. For the manufacture of handles, silumin, tempered glass, aluminum, steel, wood, and metal-plastic are used.

- According to design features. This parameter divides the fittings into rotary, push, and stationary.

- Push models consist of two L-shaped levers. They are connected to each other by means of a steel rod passing through the door leaf. The design is equipped with a tongue that fits into the hole in the door frame and acts as a locking mechanism. Lever handles have an extensive service life and high reliability.

- The rotary type is produced in the form of a ball or button. The standard diameter of the device is 5–6 cm. There is a keyhole in the center. It can be on one side or on both. Knobs are usually equipped with blockers and installed at the entrance to the toilet or bathhouse. They are characterized by insufficient strength and quickly fail. One of the reasons is the many small details.

- Stationary models have the simplest structure and are produced without additional elements. The purpose of stationary fittings is to move the door in space and give it aesthetic completeness. To attach to the door leaf, such handles are applied and fixed using self-tapping screws. Stationary type accessories come in two types - single-sided or double-sided. The two-sided ones are connected to each other by an axial mechanism.

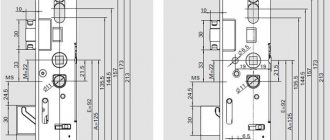

Rotary and push mechanisms consist of the following set of elements:

- sockets or strips;

- retaining ring;

- latches;

- square pin;

- fastener;

- decorative flange;

- limiter;

- springs.

The handles come complete with keys that open and lock the lock. As well as a device for installation and dismantling.

Reasons for dismantling door mechanisms

Door handles are exposed to mechanical stress every day. Therefore, despite the strength promised by manufacturers, the fittings quickly fail and need to be dismantled for subsequent replacement.

Various situations can lead to this need:

- Breakdown - often under the most unforeseen circumstances, when the lock or outside handle of the front door accidentally jams.

- Renovation – when radically changing the interior, door fittings are very noticeable.

- Loss of appearance - the presence of scratches, abrasions and peeling coatings spoil the appearance of the room as a whole.

Types of door latches

High-quality door latches must securely fix the door in the closed state, not emit extraneous noise, and have a reliable locking mechanism.

Modern door latches are distinguished by:

- Structure. This feature divides latches into magnetic, latch, roller, sliding, electromechanical or electromagnetic.

- Installation method. Here you can highlight mortise and overlay elements.

- Availability of additional functions. The devices are equipped with latches or locks.

- The latches require some force to lock the door. After a characteristic click, the door can be opened either by pressing the handle or turning the key. The handle here not only closes and opens the door, but also plays an aesthetic role and must match the interior of the room.

- Roller mechanisms are placed on the door leaf or frame. When the sash closes, a spring roller slides into the hole on the opposite side of the slat and locks the interior unit. This type of latch is installed solo, or works in tandem with the lock. If you use only a roller latch, it will not be possible to ensure reliable fixation of the sash. When you press the device with some force, the door will open.

- Magnetic devices - their operating principle is based on the ability to attract metal objects. Such a locking mechanism can be easily snapped into place and, if desired, also simply swung open. More complex modifications are equipped with a crossbar. You can open a door with such a latch using a rotary or push handle.

- Sliding devices combine the functions of a lock and a latch. Supplied without handle. You can unlock them with a turntable or a key. The latch helps hide the bolt in the latch body. This prevents spontaneous slamming of the mechanism.

- Electromagnetic or electromechanical devices provide the function of remote control of the locking mechanism. Usually installed at the entrance to a protected area. Requires installation of an additional power supply system. Otherwise, in the event of a power outage, the room will remain open.

Electromagnetic latches, in turn, are divided into:

- Normally open. When the power is turned off, they remain in an open state and people can freely leave the premises.

- Normally closed. When the current supply is stopped, the devices remain closed. This ensures the safety of the premises even in the absence of power.

- With locking function. If the power supply is restored, this latch opens. And it remains in this state until it is opened in the standard way.

All types of electromagnetic latches are useful in their own way and are suitable for solving specific problems.

Why do you need to disassemble the door lock?

Doors, for example to a toilet or bathroom, are equipped with handles, which are most often built into locking devices. At the same time, inexpensive accessories are purchased to save money.

But when producing cheap devices, the manufacturer also uses low-quality components. This is the reason that the key may get stuck in the product, or the handle may not work properly, or the tongue may get stuck.

In addition, a disassembled lock will be needed if:

- In the parts of the locking device, mechanical wear is accelerated due to the fact that dust has accumulated in the keyhole.

- Breakage of the components of the locking mechanism (poor rotation of the key in the cylinder) can occur due to lack of lubrication.

- A foreign object that has gotten into the locking system prevents the front door from operating in the required mode.

- Without dismantling the mechanism, it will not be possible to pull out a broken key stuck in the cylinder of the product.

- The latch handle is faulty.

To avoid replacing the entire mechanism, it is better to eliminate minor faults in a timely manner and carry out periodic repairs on your own.

Necessary tools for work

It is impossible to carry out repair work on the reconstruction of the interior unit without a set of tools.

The kit includes the following types of carpentry tools:

- Measuring. To do this, use a square and a tape measure.

- Marking. This requires a pencil, chalk or pen.

- Cutting. You need a chisel and a crown.

- Cutting machines. You may need a drill and a set of drills.

- Fixing. A screwdriver is also required for installation.

Experts recommend using only high-quality tools. Otherwise, the final result may greatly disappoint the master.

Door handle options

The range of components for doors is very wide. Over the years, such a detail as the handle has undergone a lot of changes, but remains as before an important part of any door.

For entrance door structures, three types are used:

- The rotary round handle is installed together with the mortise lock and serves to open the latch. The action is carried out by moving clockwise or counterclockwise around its axis;

- The pressure mechanism is made in the form of a lever and performs the same functions. According to users, it is the most convenient and is suitable for both interior and exterior doors.

Stationary handles are no less common and are made in the form of a bracket or a ball. They do not open locks and serve more of a decorative function.

In the latter case, repairing the door handle comes down to its complete replacement, since it does not have complex collapsible components. For the most part, it is enough to tighten the fastenings if the structure becomes loose.

Disassembly procedure

Removing and disassembling the door handle is quite simple. This requires a minimum set of tools and theoretical knowledge about the structure of the mechanism. You can dismantle the handle of the interior unit yourself. The main thing is to properly prepare your workspace:

- Inspect the handle and determine the type of locking device.

- Secure the door in a stationary position.

- Pry up the decorative flange and pull it off.

- Expose the fastening parts of the structure.

- Unscrew the fixing parts located under the decorative flange.

- Use a screwdriver to press in the spring pin located inside the housing.

- Pull the handle while pressing on the pin.

- Unscrew the fastening bolts.

- Separate the inner and outer parts of the locking mechanism.

- Pull out the handle and flange.

If, in addition, you need to remove the latch, then unscrew the screws on the side of the door block. Then the bar and the mechanism itself are removed.

Briefly about the main thing

The handle of an interior door is usually used several times a day. In this regard, the part often becomes unusable due to physical wear and tear. In such situations, door handles must be replaced. Before purchasing and installing a new mechanism, it is necessary to dismantle the old product. To complete this work quickly, without damaging the door, you need to stock up on a set of special tools, and carry out all stages in strict accordance with the step-by-step instructions.

Lock with handle

This is a simple and common type of locking device.

It can be in the form of a simple latch or a more advanced design that requires the use of a key. Before removing the lock, remove the handle, decorative trim, and unscrew the fastening screws. After dismantling the handle, access to the internal mechanism of the device opens. Then unscrew the plate at the end part, remove all the components and the lock tongue. To do this, push them inward and take them out through the hole located in place of the handle.

How to properly remove the handle

So, let's move directly to the main topic of our article. But before that, I would like to point out that it is not always necessary to remove a door accessory in order to bring it into proper technical condition. Sometimes the handle just gets loose and needs to be fixed. To do this, press out the decorative flange with a knife or screwdriver, after which it must be turned. The fasteners will open and are tightened with a screwdriver. But if the task is to remove the handle, then the fasteners must be unscrewed after opening the flange.

Purely structurally, push and turn handles consist of two main elements. This is, for example, an L-shaped handle, which is a separate element. And the second is the same handle only with the axial part, which is an integral part. Therefore, after the fasteners have been removed, the handle is removed from the pin. In this case, the second handle with the axial part must be held with your hand. After which she is pulled out of the door leaf.

There are other types of handles in which the pin is a separate element. Disassembly of these models is done in exactly the same way. The only difference is that both handles are removed at the same time, and the pin is pulled out separately. After which the decorative strip located at the end of the door leaf is dismantled. It is secured with two self-tapping screws. And only then the lock itself is pulled out from the end of the door.

Push-type door handle with pin Source palladium.ru

The rotary handles are removed almost exactly the same way. But they also have their own nuances:

- First, the ball knob, which is a separate element from the entire lock, is held on the pin by a small spring-loaded pin. Therefore, to remove it, you need to press on this pin with the key that comes with the door lock.

- Secondly, when you remove the ball, you will find a bar underneath it, secured with two screws. They need to be unscrewed. After which the opposite ball can be easily removed.

The lock itself is removed in the same way as in the case of overhead models - through the end of the door leaf. Please note that the height of the door handle, here we mean the height of its installation, has strict standards that take into account the ease of use of this device. Therefore, you should not rearrange them higher or lower, of course, unless you have some physical abnormalities.

Disassembling a lock in a round handle

It will not be easy for an unprepared person to deal with such a lock. Therefore, experts advise strictly adhering to the recommended procedure. First, remove the cover from the handle. Then you need to:

- press the pin;

- release the handle;

- unscrew the screws;

- take out the secret of the lock.

If you subsequently have to reassemble the lock, you need to remember, or better yet, photograph all stages of the procedure. Otherwise, there is a danger of getting a non-working design at the end.

How to disassemble a lock on an interior door - necessary tools

Dismantling and complete disassembly of the lock located in the door between rooms is possible if suitable devices are available. For different mechanisms, the required list may differ, but most often the following are required:

- screwdrivers (Phillips and flat-tip) or screwdriver;

- tweezers or thin pliers;

- small brush or toothbrush;

- kerosene or WD 40;

- a piece of fabric;

- sharp object - needle, awl;

- an adjustable wrench (or a set of small diameter wrenches);

- oil for lubrication.

Electromagnetic

The structure of an electromagnetic lock includes a control unit, a powerful magnet and a metal plate. All parts are attached in an overhead manner. Before removing the electromagnetic type lock, you should turn off the power to the device. Then you need to unscrew the bolts and disconnect the mechanism.

Thus, understanding how to remove a handle or lock from an interior door, this work will not seem difficult. To change door hardware, you need to know the design of the locking mechanism, have the right set of tools and at least minimal experience. Then you won’t have to call a specialist and waste extra money and time.

What is required to disassemble the locking mechanism?

Before you start disassembling, prepare yourself by finding the right tool. If the breakdown is simple, a set of screwdrivers, an awl and a lock key will suffice. Remove the mechanism from the door, prepare lubricants. If they are not available, use sunflower oil. However, remember that this is only a temporary measure, and you will still need to purchase a special lubricant.

Experts advise preparing your camera. You can also use a smartphone with a photo function. This will be needed to record the disassembly process. If you have any difficulties with assembly, you will remember the sequence from the photographs. You can go to a professional with pictures, who will tell you what the problem is.

Tools that will be useful in disassembling the locking mechanism

Possible problems with the latch tongue

The most common situations are when the latch:

- does not retract completely when the handle is pressed and does not open the door;

- remains in the groove of the strike plate and does not respond to pressing the handle;

- stuck inside the lock body;

- moves normally, but does not fix the door leaf when closing.

Each of these problems has its own causes, the proper identification of which determines the further performance of the locking device.

Important! In many cases, when a lock jams, you can restore its functionality yourself or call a locksmith who has the necessary experience and specialized tools.

Situations when the latch does not hide completely, but when acted upon by the handle, moves away from the groove in the door frame or strip for some distance, most often arise due to:

How to extend the life of a lock

Timely maintenance of the mechanism and its minor repairs will help ensure the locking device of the interior door has the maximum possible service life. Maintenance consists of partial or complete disassembly of the product, timely cleaning of accumulated dust, chips and other contaminants, and replacement of worn-out parts.

In some cases, the owner has to deal with lever and cylinder mechanisms that have a certain degree of secrecy and a more complex design. To service them and replace components you must:

- Unscrew the screw securing the handle with a hex key, and the screw securing the cylinder at the end of the door using a screwdriver. After inserting the key into the hole, it is easy to pull it towards you. When resistance appears, turn the key until the tongue of the cylinder disengages from the mechanism.

- Unscrew the screws securing the decorative trims with handles and disconnect them. Remove the handles, pull the square out of the mechanism, remove the mechanism body.

- Unscrew the screws securing the housing cover and remove it. Clean the hole for the housing at the end of the blade from dust and chips. Inspect the handle mechanism, lubricate the return springs and travel stops. Check the operation of the cylinder and lubricate it by adding oil using a syringe.

- Clean the internal elements of the mechanism from dust and chips using a brush. Check the position and condition of rods and springs. If necessary, replace worn out parts. Apply oil to moving parts. Place the cover in place and tighten it with screws.

- Reassemble the mechanism in the reverse order, securely fasten all elements with clamping and mounting screws. Check the ease of movement of the crossbars and latch tongue when the doors are open, and the tightness of the closure of the door leaf. If necessary, adjust the position of the strike plate.

In the event that the owner is not confident in his capabilities, does not have sufficient knowledge and experience in disassembling different types of locking mechanisms, or the necessary tools for the job, he can always turn to specialists from a specialized company for help.

Reasons for disassembling fittings

The technology for assembling/disassembling door hardware is not a complicated procedure. Therefore, installation/dismantling work can be done independently.

The main reasons for the need to dismantle door handles:

- The fittings have become loose; the fastening bolts need to be tightened;

- The handle is cracked or broken due to significant physical activity;

- The locking mechanism has failed;

- New, more modern models of fittings have appeared on the market;

- The owners decided to renovate and update the interior of the premises;

- Due to low quality, the fittings quickly lost their attractiveness: the paint peeled off, large scratches or chips appeared on the surface.