What is a cylinder lock, types of structure

According to the GOST standard, a cylinder lock is: “a mechanism that moves and fixes the lock bolt in working positions and ensures the secrecy of the lock through a secrecy mechanism, i.e. a set of specific combinations of pins (plates, disks) corresponding to its own key.”

These mechanisms have different forms:

- Cylinder.

- Circle.

- A drop.

- Triangle.

The door hardware market offers cylinders with a European standard mechanism: they have a certain size and are made of a brass profile. Cases are made for them.

There are two types of cylinder mechanism:

- Pin.

- Disk.

About the "larva"

This word can be found very often when mentioning castles. They call it the very cylinder mechanism in question (due to its shape and external design).

The cylinder mechanism is the most important part of the entire mechanism, since it is responsible for the correct combination that allows you to lock and unlock the deadbolt. If you come across the word “core”, do not be alarmed - in this case we are talking about a synonym for larva and both of them mean the same thing.

Replacing the mechanism

Initially, manufacturers of such locks used different designs, which led to incompatibility of parts. Subsequently, it was decided to abandon this, and if your cylinder breaks, you can replace it with a model from any brand and country of origin. These components are interchangeable.

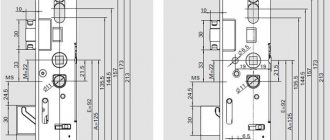

Pin cylinder lock device

A pin lock, mortise cylinder (cylinder, volute) is a mechanism based on a core with a connector. It has code channels in which there are code pins (their height determines the number of slots on the key) and a spring that pushes the code pins out of the channel. The code pins are located in a profile, thanks to which they do not fly out. There are also support pins.

When the key enters the hole, each slot corresponds to a code pin, which is recessed to a certain depth (height). When unlocked, the code and support pins are exactly in line between the body and the core, and it (the core) turns easily. In this case, the code elements remain in the core, the support elements with springs remain in the housing. That's the whole working principle.

The cylinder shape (cylinder) adopted by the European standard is called: DIN standard mechanism.

Pin cylinder lock parts:

- The body is the outer part of the lock in which all the parts are located.

- The key is an independent unlocking part, with the help of which the secret is opened when the leash is turned.

- The cylinder or rotor is a replaceable part of a lock with a connector. It contains pins.

- Code pins or pins are parts of the locking mechanism.

- Locking pins or pins - together with code pins block the rotor.

- Return springs - they are used to lock the pins.

- Leash - with its help the bolt moves.

Essential elements

The locking mechanism itself is located inside the lock shell: the thicker its walls, the less opportunities an attacker has to get to the secret filling. Crossbars are bolting elements of the system that secure the locking of the device. When in the closed position, they are located in special holes in the frame. When you turn the key, the bolts come out of these niches, releasing the bolt from fixation. The number of such elements depends on the degree of reliability of the device and its model.

The lock bolt is an executive element of the locking system that keeps the door closed. When the door is closed or unlocked, this part moves into or out of the door frame body through the strike plate. This design element of the system has holes for the unhindered movement of the bolts.

The lock system lever ensures that the cylinder mechanism is activated when the key is turned. The locking system is attached to the door leaf thanks to the front face plate. This detail also performs decorative functions. The locking device is started by turning the key.

Disc cylinder lock device

A door disc lock is a type of cylinder device whose mechanism is represented by a set of discs. Each disc has a uniquely shaped cutout. Corresponding slots are made on the key.

When unlocked, the mechanism disks move deeper towards the core. If the key fits, it turns easily. The secret of the lock places the discs at a certain angle, their recesses create a channel with a balance - turn and the bolt moves.

The key is a lengthwise sawn rod with slots; it is also called a semicircular key.

Cylinder padlocks with this mechanism are less susceptible to freezing. It is not recommended to install a mortise disc lock outdoors. They are suitable for fabrics with heavy loads. Suitable for entrance and interior doors made of metal, wood, plastic, glass.

Types of cylinder mechanism

There are several classifications based on different criteria.

By location on the canvas:

- Overhead – has one connector. On the other side there is a handle.

- Mortise door lock - its connector is through, that is, the key can be used on both sides. The cylinders of this lock are of two types: key+key, key+handle. The second type (with handles) is more convenient, but the first type is safer: if you insert a key into the slot from the inside, the lock cannot be opened from the outside.

In addition to these characteristics, there are cylinders of different lengths, the size depends on the thickness of the blade. When purchasing, you need to consider the size or you may encounter the following problems:

- The cylinder is small and will be located deep in the housing. This is ugly and inconvenient - the door will be difficult to open, because the key will not reach the mechanism of the device.

- A large cylinder - if it protrudes beyond the edges of the connector, this will make it easier for attackers: it’s easier to break. If armored pads are installed in the housing, the cylinder will not fit into the socket.

Cylinders are classified according to their location on the body: central and outer.

Cylinder locks with latch

The mortise lock with a latch is functional and easy to use.

Cylinder locks with latch latches are closed under mechanical action. It is an auxiliary element of the locking mechanism. The latch is available with or without a tongue lock, with one or two handles. Such locks are often used in residential and industrial premises.

Hazel handles are used for entrance and interior doors. There is no functional feature in it, it is rather a decorative element. The convenience is that when changing the interior, in order for the locking device to fit into the image, you just need to choose a handle according to the style.

Handles for entrance doors are resistant to external influences and are made of durable materials (compared to interior door handles).

Depending on the type of handle pressed, there are:

- Push (for entrance doors).

- Pivot (for interior doors).

The push handle is also suitable for interior structures. The choice depends on the buyer's preferences.

How to choose a cylinder lock

In addition to such a criterion as the size of the larva, when choosing, you need to pay attention to the following characteristics:

- Protection – you need to ask your sales consultant how durable the material was used to make the lock. The difficulty of opening it when bumping, drilling, or selecting a key depends on this.

- Quality - how accurately the mechanism is built, whether there have been cases of breakdown, how repairable the mortise lock with latch is.

- Additional functionality: recoding, installation of a gear mechanism, “anti-panic” and others.

The safety of the premises depends on how conscientiously the manufacturer adheres to these characteristics. The more reliable the device, the higher its cost will usually be.

Replacing the lock cylinder

A cylinder mortise lock with a latch is convenient because, if necessary, it is not necessary to dismantle the entire device - it is enough to replace the cylinder. You can replace the lock cylinder yourself by following the proposed algorithm:

- Open the door, find the screw on the bar near the cylinder at the end.

- Unscrew the screw.

- If the locks have handles, the cylinder can be easily reached; if without, you need to insert the key into the slot, turn it counterclockwise until it stops and pull it towards you.

- Then move the key and handle slightly in the opposite direction so that the lever moves down - then the cylinder will easily come out of the body.

- The new cylinder is inserted into the mechanism by the handle, or by inserting a key into it. Monitor the position of the lever - it must be completely secret.

- Try to close the mortise lock with the latch, moving it backwards and forwards so that it closes freely.

- Replace the screw.

- Check the work.

To replace the cylinder of the rim lock, the body must be removed from the blade. Then everything is the same as with the previous one - find the screw, take out the old cylinder and replace it with a new mechanism.

In order not to make a mistake with the size of the cylinder, it is recommended to purchase a new one with an old mechanism or measure its size.

So

There is no clear answer to the question of choosing a lock - it is argued by the many individual characteristics of the door, the value of the protected object and the available budget.

It is believed that lever locks are easier to crack intellectually, but they provide reliable fixation of powerful massive doors.

The cylinder “English aristocrats” are the reliable elegance of secret technologies, assembled in the lock mechanism. And they are given additional anti-vandal resistance by armor plates and armor linings, which prevent physical damage to the “secret” of the lock.

Share:

All reviews To category

How cylinder devices are hacked

Unfortunately, the cylinder of a mortise lock is also its weakest part - attackers use many methods to break into the mechanism. Here are some of them:

- Hacking with a master key: picking up a key to a lock with a modern mechanism is almost impossible, but thieves use special locksmith keys, plus technical devices, such as a bumping machine. True, this option may also be ineffective: the technology provides for a complex secret: grooves, grooves. Therefore, to open a mortise mechanism with a latch, it will take a lot of time, which attackers most often do not have.

- Breaking out the cylinder: select a key of suitable size that will fit into the well. Then they hit it with a hammer - all the parts (pins, pins) are knocked down and the canvas opens. But this method is suitable if the lock is old or made of fragile material. You can protect yourself from such a break-in by purchasing a durable mechanism or choosing a lock with a non-standard connector.

- Drilling is an effective hacking method. You can only resist by choosing a device with a mechanism made of high-strength materials.

- Knocking out: using physical force and available materials, the mechanism is broken. The solution is to purchase strong structures.

The strength of the material is the main factor protecting the room from unwanted penetration. But you also need to remember that a mortise lock should be easy to use and last a long time.

Useful properties and disadvantages

A distinctive feature of lever locks is their massiveness and the strength of the body and internal parts. In fact, all lever locks require mortise installation, that is, they are additionally protected by the external planes of the door leaves. Only the profile key hole is accessible from the outside.

Heavy series locks are equipped with additional rods that allow you to organize door locking in three directions: traditionally - sideways, additionally - up and down.

The level of secrecy of the lever lock increases:

- a large number of plates with a decrease in their thickness - this increases the transverse size of the lock body;

- the complexity of their configuration, the presence of false grooves, systems for protection against force and recognition of master keys;

- installation of an additional armor plate (1.5-2.5 mm) protecting the body.

Among the inconvenient aspects of using lever locks, we highlight:

- the key sizes are relatively large;

- a through hole for the key lets in light, sounds, air;

- the relationship between a specific lever mechanism and keys; if the lock is broken, it requires its complete replacement;

- large size of “secret” plates, which simplifies hacking.

There are lever locks equipped with a special mechanical recoding mechanism. At the moment of its activation, it reads the profile of the key inserted into the keyhole at that moment. Then the lock works in normal mode with this set of keys.