A cylinder lock is a lock whose working part is a cylinder mechanism (the so-called “cylinder”).

The cylinder mechanism is the coded part of the cylinder lock, which ensures secrecy and moves the bolts, which can only be turned in the case when a standard (own) key is inserted into the hole inside the cylinder.

Initially, each manufacturing company patented and manufactured such a mechanism (core, or “larva”) of its own standard size, but from the second half of the twentieth century they began to produce a teardrop-shaped body with end fastening, thanks to which such blocks (larvae) from different manufacturers are now interchangeable.

What is he like?

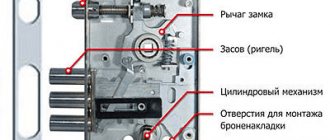

Cylinder locks received this name because of their working part - it has the shape of a cylinder. It is based on interchangeable or code mechanisms. Moreover, they are standard, since the larva has a standardized size. The device also has a locking system and a deadbolt drive. The supplied key opens the lock using a deadbolt drive.

Design components include a metal housing, spring-loaded locking and contact pins, a cam and a key. It should be taken into account that such locks can be not only pin, but also disk. Car locks are most often equipped with a frame secret mechanism - all these are cylinder locks.

How to choose the right lock

Cylinder padlocks are considered to be more resistant to freezing. And their mortise “brothers” are not recommended for outdoor service, but are excellent for doors with heavy loads, as well as entrance and interior doors made of different materials - wood, plastic, metal, glass.

When choosing a cylinder lock, you should find out from the seller information about the characteristics of the material from which the lock is made. The stronger it is, the more difficult it is to open the door by selecting a key, drilling or knocking out the lock. The quality of the lock is also important - you need to find out whether breakdowns are possible and how realistic it is to repair it. The lock can be equipped with additional functional capabilities, for example, installing a gear mechanism, recoding, etc.

If it is necessary to change the lock, the cylinder mechanism allows you to change only the cylinder, and not the entire device. Moreover, even a non-professional can do this; it is enough to have a minimum of skills and a small number of tools. By the way, when choosing a new cylinder, it is better not to do it at random, but to take the old mechanism with you.

Types

Several types of these devices can be distinguished. Thus, there are single-row pin systems - they can be coded or locking. The material for production is most often steel or brass. The 2-cylinder lock also belongs to the pin type. This mechanism requires a double-sided key.

You can also select models with rotary pins. There are rotary code pins here. Such solutions are very widespread. Another type is cross-shaped locks. The key and the hole are made in the form of a cross. The pins are located inside the mechanism. There can be several rows of them - each with two or more pins.

The most reliable type is milled locks. Here the rows of pins are placed in different planes. This several times increases the possible options for secret combinations for those who will try to hack them.

Types of cylinder locks

There are different modifications depending on the internal configuration of the pins. For example, there are single-row models that come in both classic locking systems and with code systems. Such devices are usually made of steel and brass. Two-way models require the use of appropriate keys. The presence of a two-row system does not double, but significantly increases reliability. You can also find a cylindrical lock with pins that rotate. However, this option is less common compared to cross-shaped locks. Such models can be recognized even by a quick inspection of the keyhole - as the name implies, it has a cross shape. The key itself is distinguished by the same feature. According to experts, the most reliable mechanism is the one whose key has conical milling at the end.

Pin lock device

The secret part of the cylindrical locking device is enclosed in a metal housing. The secret part is based on pin elements. They come in locking and coded versions. The first are elements that simultaneously interact with the key from the kit, as well as with the pins of the locking pins. Locking pins are code elements adjacent to the pins that ensure the rotor is locked relative to the housing.

The most important component of a cylinder lock, from a mechanical point of view, is the rotor. It represents a movable core, due to which the mechanism can interact with a person and the locking system. There are holes inside the rotor in which locking and combinational or secret pins are installed. In order for the locking system to take its basic value when closed, the design provides springs that return the pins to their places.

The principle of operation of the lock, its advantages and disadvantages

The cylinder lock works by moving and locking the lock bolt in different operating modes. The secrecy of the lock is ensured by a corresponding mechanism, which is a specific combination of pins that interact with a specific key. The secret mechanism (aka larva) is located in a standard case, so larvae made by different manufacturers fit perfectly with each other. Cylinder locks are very popular, but specialists who understand the specifics of how a lock works can pick it in less than a minute.

The operation of the lock is ensured by the smooth functioning of the entire mechanism. The cylinder, which is a replaceable part, contains code and locking pins (or pins), and as a result of their interaction, the rotor is blocked. The pins are blocked by return springs, and the driver moves the bolt, causing the lock to open.

The advantages of cylinder locks are:

- small key size;

- ease of operation;

- ease of replacing the lock if it is found to be faulty or the keys are lost;

- the ability to improve the lock itself and complicate its mechanism if necessary.

The design also has disadvantages:

- simple design to the point of primitiveness;

- low resistance to mechanical burglary;

- If the lock was installed incorrectly, a burglar can easily tear it out.

Operating principle of the pin mechanism

The essence of the mechanism is to block the lock rotor with pins that are controlled by a spring block. Any manipulations are implemented in relation to the body.

When the key enters the keyhole, each slot corresponds to a code pin. The latter are recessed to a certain depth. During the process of opening the lock, the combination pins and support elements line up between the core and the body. As a result, the core rotates easily. In this case, the code pins remain in the core, and the support pins remain in the body.

If you try to open the lock with an incomplete, foreign key, the pins will not line up. Accordingly, the rotor will not be able to turn.

The reliability of a cylinder lock is directly proportional to the complexity of the pins. The more intricate the algorithm for their location, the more difficult it will be for hackers to break into the system. But it is now almost impossible to open these locks using pins.

Disadvantages of cylinder locks

Of course, there are also disadvantages to this system that are important to consider when purchasing. First of all, this is a relatively low level of resistance to hacking. Moreover, this applies to both the so-called quiet and forceful methods. Especially when it comes to inexpensive models of initially low quality. However, we can talk about a low level of reliability only in the context of comparison with more advanced modern devices of other types. Against their background, of course, not every cylinder lock can successfully compete. On the other hand, large manufacturers have not yet abandoned this concept, regularly increasing the technical reliability of such mechanics.

Disc cylinder locks

The mechanism of these products is implemented on the basis of a set of disks. Each item included in the set has a unique cutout. The key has the same slots. During the opening process, each disc moves towards the core. If the key matches the lock, it will turn.

The secret part of the mechanism sets the discs at certain angles. The grooves in the discs create a channel, and when turned, the locking part will move. The key to such a lock has the shape of a rod sawn along with slots of various shapes - a semicircular key.

How cylinder devices are hacked

Unfortunately, the cylinder of a mortise lock is also its weakest part - attackers use many methods to break into the mechanism. Here are some of them:

- Hacking with a master key: picking up a key to a lock with a modern mechanism is almost impossible, but thieves use special locksmith keys, plus technical devices, such as a bumping machine. True, this option may also be ineffective: the technology provides for a complex secret: grooves, grooves. Therefore, to open a mortise mechanism with a latch, it will take a lot of time, which attackers most often do not have.

- Breaking out the cylinder: select a key of suitable size that will fit into the well. Then they hit it with a hammer - all the parts (pins, pins) are knocked down and the canvas opens. But this method is suitable if the lock is old or made of fragile material. You can protect yourself from such a break-in by purchasing a durable mechanism or choosing a lock with a non-standard connector.

- Drilling is an effective hacking method. You can only resist by choosing a device with a mechanism made of high-strength materials.

- Knocking out: using physical force and available materials, the mechanism is broken. The solution is to purchase strong structures.

The strength of the material is the main factor protecting the room from unwanted penetration. But you also need to remember that a mortise lock should be easy to use and last a long time.

Classification

There are several ways of classification according to various criteria. So, based on the way the lock is located on the door leaf, you can distinguish the invoice and mortise door options.

The cylinder rim lock has one connector. On the other side of the door leaf there is only a handle. The mortise lock has a through connector - it can be opened and closed with a key from both sides. Such mechanisms are equipped with two types of cylinders - key and key, as well as key and handle. Options with handles are more convenient, but the first method is considered safer. A key inserted into the hole from the inside will not allow the lock to be opened from the outside. Most often they buy a cylinder mortise lock.

In addition, the cylinders have different lengths, it depends on the thickness of the door leaf. When choosing such models, it is important to consider the size. A small cylinder will sit too deep in the blade body. This is not only unaesthetic, but also very inconvenient. The door will be difficult to open due to the fact that the key does not reach the mechanism.

If the cylinder is too large, it will protrude beyond the edges of the connector - this is also a serious drawback. This design is much easier to hack. If an armor plate is installed on the cylinder lock, if it is located in the housing, then the cylinder may not fit into the slot for it.

Cylinders are classified by how they are positioned on the body. There are central and extreme locations.

Replacing the lock cylinder

A cylinder mortise lock with a latch is convenient because, if necessary, it is not necessary to dismantle the entire device - it is enough to replace the cylinder. You can replace the lock cylinder yourself by following the proposed algorithm:

- Open the door, find the screw on the bar near the cylinder at the end.

- Unscrew the screw.

- If the locks have handles, the cylinder can be easily reached; if without, you need to insert the key into the slot, turn it counterclockwise until it stops and pull it towards you.

- Then move the key and handle slightly in the opposite direction so that the lever moves down - then the cylinder will easily come out of the body.

- The new cylinder is inserted into the mechanism by the handle, or by inserting a key into it. Monitor the position of the lever - it must be completely secret.

- Try to close the mortise lock with the latch, moving it backwards and forwards so that it closes freely.

- Replace the screw.

- Check the work.

To replace the cylinder of the rim lock, the body must be removed from the blade. Then everything is the same as with the previous one - find the screw, take out the old cylinder and replace it with a new mechanism.

In order not to make a mistake with the size of the cylinder, it is recommended to purchase a new one with an old mechanism or measure its size.

Latch lock

This is a fairly convenient and functional solution. These mechanisms are closed using mechanical action. The latch acts as an auxiliary element in the locking mechanism. The latch may have a latch in the form of a tongue or not have one at all. A cylinder lock with a latch is most often used in industrial and residential premises.

False handles can be used on entrance or interior doors. They do not carry any functional load, they are decorative elements. The whole comfort is that when changing the interior, to replace the handle you only need to choose the right color.

The handle designed for the front door is made in such a way as to withstand any external negative influences. The element is made from high-quality durable materials. There are push and turn handles.

The best candidates for purchase

Very high-quality and burglar-resistant cylinder locks are produced by these European companies: MOTTURA, ABLOY, CISA, ABUS, KABA, MUL-T-LOCK.

Motura is an Italian company. It is recommended to pay attention to the Champions series. The trick of these locks is that a magnet is used inside the key, which attracts the pin to itself. This makes it much more difficult to open with master keys. The other side of the coin is problems when the key is lost. More precisely, there are no problems, you will get a duplicate at ANY AUTHORIZED SERVICE CENTER upon presentation of a client card with a personal number.

Motura Champions 48 series locks are considered the safest, the issue price is 5500-6000 rubles. Those that are simpler: Motura Champions 31 series range from 2100 to 4500 rubles.

ABLOY is a Finnish company that produces cylinder locks of two standards: FIN and DIN. The FIN standard applies exclusively to Finnish and Swedish locks. I recommend paying attention to such series as ABLOY Classic, ABLOY Pro, ABLOY Protec. It is noteworthy that ABLOY Protec locks use a unique DBS disc locking technology, which prevents these locks from being opened by bumping. Cost: from 200 rubles for Pro and up to 5000 for Protec.

CISA offers RS3 and AP3 cylinder mechanisms. Good locks, have decent protection against force impacts, be it bumping or drilling. The price for RS3 ranges from 4,500 to 6,000 rubles. AP3 will cost slightly less: 3000 - 4300 rubles.

Traditional hacking methods

If the attackers do not use master keys, but simply knock out or tear out the cylinder, then this operation will take a maximum of a minute or two. To protect against such exposure, experts recommend installing armored linings on the outer part of the door. The ideal option is a mortise magnetic cover that protects against acts of vandalism and burglary. It will not allow the cylindrical part of the lock to be knocked out or pulled out.

It is better to choose a door with linings, this will be a plus. During the process of making steel doors, installing the trim will be easier than after the door is ready.

The armor plate must be mortise - it is more difficult to remove. It is secured from the inside. Overlay armor is weaker. It dismantles faster.

Pros of a cylindrical mechanism

Such models are easy to use. The mechanism is not particularly difficult to use, and the keys are compact in size, which is also a plus. Also, if a fault is detected in the cylinder itself, it can be replaced. Today, manufacturers produce standardized cases for models of this type, so it will be enough to update only the core. There is another advantage. You can install such a lock on a door with the expectation of future improvement. As experts note, the design of most cylindrical mechanisms is fully subject to modernization with technological improvements.

Manufacturers

Despite the huge number of offers on the market, there are very few reliable products. The Elbor and Guardian mechanisms have long been popular in the Russian Federation. These companies make quality products, but they lack technological innovation. If you want a more modern lock, reliable and functional, then you should pay attention to models from Kale and Abloy. However, their cost will be much higher.

For example, a cylinder lock for solid doors model CY001T from Abloy will cost about six and a half thousand rubles. The element is made of brass with hardened steel inserts. Resistance to lock picking is about 15 minutes, which is quite good.

Security properties

Not every cylinder mechanism has a high degree of protection against burglary. At the very least, we can talk about differences in the level of secrecy between different models. According to regulations, security qualities must correspond to the degree of potential danger against which a particular lock is designed to protect. Although the cylinder mechanism is not certified in Russia, information on the security class can be found in the markings. Today there are four degrees of protective properties.

The first class is minimal and is not recommended to be used as the main barrier to an attacker. Even the second class is justified if it is planned to be integrated into a door that is not the only security line. For city apartments, for example, it is recommended to use lock models of the third and fourth security classes.

Master key [edit]

Master key lock

is a type of drum pin lock that allows the lock to be opened with two (or more) different keys.

This type is often used for door locks in multi-tenant commercial buildings such as office buildings, hotels, student housing, and warehouses. Each tenant is given a key that opens only their own door, called a change key

, but the second key is

a master key

that opens all doors, and is usually kept by the building manager so they can enter any room in the house. construction.

In a master key lock, some or all of the shaft holes in the lock have three pins instead of two. Between the drive pin and the key pin there is a third pin called the spacer pin

.

So each pin line has two cut points

: one where the drive and spacer pins meet, and the other where the spacer and key pins meet. This way the lock will open with two keys; one aligns the first set of shear points, and the other aligns the second set of shear points. Locks are made in such a way that one set of cut points is unique for each lock, and the second set is identical for all locks. The more reliable type of mechanism has two separate toggle switches, each of which is opened with one key.

More complex master key lock systems are also produced, with two or more levels of master key, so there may be sub-master keys that open only certain subsets of locks, and a top-level master key that opens all locks.

About the selection of cylinder locks and cylinders

The cylinder lock system is a product of precision metalworking technology and appeared at the end of the 19th century.

Locks of this type are very common nowadays because of their ease of use (miniature key, low rotation force) and replacement (if necessary, not the entire lock is changed, but only its secret part - the cylinder, colloquially known as the cylinder, liner or insert). General description of cylinder locks

The cylinder lock system is a product of precision metalworking technology and appeared at the end of the 19th century. Locks of this type are very common nowadays because of their ease of use (miniature key, low rotation force) and replacement (if necessary, not the entire lock is changed, but only its secret part - the cylinder, colloquially known as the cylinder, liner or insert).

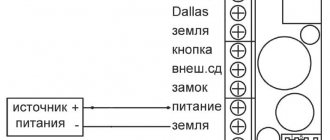

In fact, a cylinder lock consists of two parts - the bolt drive (mechanism) and the secret replaceable part (cylinder). Mechanisms and cylinders from different manufacturers can be combined with each other in different combinations.

The article will talk in detail about the drive mechanisms, additional protections and the cylinders themselves.

At the end there is a comparative rating table. Lock mechanism

The lock mechanism serves to transfer force from the cylinder to the locking elements (crossbars) and fix them. In addition, the lock mechanism may contain additional elements - latches and their drive from handles, drives for additional bolts and even additional locking devices (dual-system locks).

In the simplest locking mechanisms presented by STEAL (KALE, Ritko), there are no tricks other than the drive of the bolts and the latches with handles. But the more complex movements from Mottura and Cisa have more complex and specialized devices.

Door lock Mottura 85.571Q Cisa lock with smooth drive

Cylinder Cisa RS3

Smooth drive

– implemented, for example, in locks: Cisa 56.505 and in the cylinder part of two-system Mottura 54 series. A feature of the smooth drive is the absence of jerks when opening and closing the lock. The bolts do not extend abruptly, but synchronously with the rotation of the key. The advantages of a smooth drive are minimal force when rotating the key and, to some extent, greater protection from forceful methods of hacking (drilling). There are no places in the smooth drive mechanism that can be drilled to open the lock.

Protection against removal (knocking out or breaking) of the cylinder

– implemented in Mottura 85.571Q and Mottura Gorillino 87.377.Q locks. The principle of protection is that the lock jams when the cylinder is removed. This makes breaking, tearing out or knocking out the cylinder meaningless.

Protection against clogging of crossbars

– implemented in the already mentioned Mottura 85.571Q and Mottura Gorillino 87.377.Q – a special strip supports the bolt group when the lock is closed and prevents the bolts from being driven in.

It should be noted that it is on cylinder locks that the anti-panic

– the lock closes in one movement of the handle from any side and opens in one movement from inside the apartment.

More information about the Mottura Gorillino lock 87.377.Q Cylinder

The cylinder is a device that ensures the transfer of force from the key to the lock mechanism and at the same time a secret element. It is the precise mechanics of the cylinder that is responsible for recognizing the key on the “friend/foe” principle. All the cylinders we use are of the Europrofile type and are all interchangeable in different mechanisms.

The cylinders offered by the company STAL have a body color of “matte nickel” and two drive versions - with a key on both sides or with a rod for a turntable on the flat side. The spinner can be of any color corresponding to the fittings.

A “naked” cylinder, without additional reinforcements, is, alas, very vulnerable, so it requires additional protection - an armored lining.

(see below) Selection of mechanism

The choice of lock mechanism is carried out depending on the specific customer requirements for functionality and price. The simplest mechanisms only perform locking and latch fixation, more complex ones allow you to connect vertical rods, and the most complex ones feature a smooth drive, protection against knocking out the cylinder and other options mentioned a little earlier. The price is proportional to complexity, reliability, protective properties and convenience. More expensive mechanisms are more durable, well made, less vulnerable to attackers and more convenient to use.

It is not recommended to combine mechanisms and cylinders with large differences in price and quality.

Defense must be balanced. Selection of cylinder

The choice of cylinder is carried out (as in the case of the mechanism) depending on the specific wishes of the customer. The simplest models have a minimum of protective and secret functions and are very vulnerable. More complex models have a lot of additional protective elements, are more reliable and durable, but, alas, also more expensive. A comparison table is provided at the end of the article.

Weaknesses and strengths of mechanisms and cylinders, parameters for comparison

Operational reliability and wear resistance

Wear resistance depends on the quality of the materials of the parts, their compliance with each other in rubbing units and on lubricants.

Reliability in operation depends on the quality of manufacturing of parts, as well as on the thoughtfulness of the entire design and on the quality of assembly. These parameters are very important for both the lock mechanism and the cylinder. Firstly, reliability and wear resistance characterize the lock’s fault tolerance – a very important consumer quality. Secondly, the secret element (cylinder) depends on wear resistance - wear of its parts makes it more vulnerable to master keys and key selection. Force burglary

Force burglary can be aimed at both the lock mechanism and the cylinder. The mechanism is vulnerable to drilling - if the type of mechanism is known, then by drilling it at several critical points, in some cases you can try to rotate it without affecting the cylinder holding it. Protection can be either the installation of carbide plates that make drilling difficult, or the use of soft drive locks, as well as hiding a specific lock model. For the sake of truth, it is worth noting that drilling the lock mechanism is far from the most common hacking method - firstly, without knowing what type of mechanism is installed, it is impossible to calculate vulnerable points in advance, and secondly, drilling is a rather noisy procedure and can attract the attention of neighbors.

Forceful cylinder cracking includes knocking out, tearing out, breaking and drilling.

The cylinder is effectively protected from most misfortunes by a mortise armor plate. In addition to it, the cylinder itself (carbide elements are installed in it), as well as the lock mechanism, also resists these methods. In particular, the anti-knock protection implemented in Mottura locks with the “Q” index in the article eliminates everything except drilling. Armored linings

Additional protection of the cylinder mechanism from forceful hacking methods is provided by the protection of the cylinder. Almost all locks provide for the installation of this type of protection. It should be noted that cylinder protection (also called protector, defender or armor plate) comes in two fundamentally different types, namely overhead and mortise. Overlay protectors (Kale, Ritko) are installed directly on the outer sheet of metal or on the exterior trim. Mortise locks (Mottura, Cisa, DiSec) are placed directly on the lock body, and a hole is made for them in the outer sheet.

Overhead cylinder protections are, by and large, decorative. Although they protect the cylinder from drilling, they can be easily torn off with a simple lever tool, such as a crowbar or a large screwdriver, or knocked down with a blow from a sledgehammer or chisel, which is what attackers do quite often. Unlike overhead ones, mortise cylinder protections cannot be pryed off with a lever tool, since they are recessed into the door leaf. It will also not be possible to knock them down, since the impact will be transmitted not to the fastening screws, but to the outer sheet of the door through which the protector body passes. Some of the protections also have a rounded body that prevents them from being grabbed and attempts to pull out the fastening.

Installation of overhead cylinder protections is simpler, there is less metal in them, and therefore their cost, compared to mortise ones, is lower.

But only mortise armored linings can provide a truly decent level of protection. The STAL company does not use overhead protection options on its products. Key selection

A method that is effective only for the simplest and very worn cylinders.

The essence of the method is that due to large tolerances (allowed by the manufacturer or resulting from wear), not only “original” keys begin to fit into the cylinder, but also keys with a similar pattern. Simple master keys

Thanks to American cinema, most customers have formed a persistent image - a certain thief or law enforcement officer can, after rummaging around in a lock with a crooked wire for 2-3 seconds, this same lock can be easily opened. In reality, everything is much more complicated.

Theoretically (I emphasize!) you can open any lock with master keys. What one person has done, another can always break. This is, in general, an axiom. The question is how much time it will take, what tool will be used and how talented and trained the “operator” will be in his field. If the simplest cylinder mechanisms can really be opened within a maximum of 1-2 minutes, then opening even average-level cylinders can take hours even for an experienced thief. Highly qualified master key specialists, who can open cylinders more complex than “English” ones, are no more common among thieves than neurosurgeons are among ordinary people. Their qualifications are worth accordingly, and they also do not use their skills often - the risk must correspond to the reward. If you don’t have a branch of the Pushkin Museum in your apartment and a cylinder of at least an average price category is installed, you don’t need to worry about master keys. It should be noted that in addition to thieves, there are also specialists in the special services. But they also need to be “interested.”

Protection against traditional master keys has been developed for a long time and is widely used by manufacturers.

To protect against master keys, traps are made in the form of locking elements of complex shape. Also, the work of the master key is complicated by small keyholes, complex hole profiles and security elements located in several rows. Automatic and “bumping” master keys

Automatic master keys (vibration picks, pickguns) are devices that allow you to open cylinders using vibration instead of careful and delicate work with a traditional master key. The principle of operation is to create a shaking in the cylinder mechanism, during which the locking elements open, and try to catch the moment when the opening corresponds to the position of the correct key. Theoretically, all cylinders built on the principle of code pin + support pin + spring are vulnerable. But only the simplest cylinders are really vulnerable to such devices. Traditional methods of protection against pick guns are also very effective against pickguns - the traps jam the movement, and miniature wells of complex shape do not allow the working part of the tool to be inserted and moved. Multi-row cylinders are also very resistant to vibration (impact technology) - the method is not new, but has recently received wide publicity on the Russian part of the Internet and in some media, thanks to the efforts of competing manufacturers. Not only a detailed description of the method is published, but also detailed instructions (including videos) for making “bump keys” for various locks. Falsifications cannot be avoided, and as a result, owners of simple and inexpensive locks, of whom the majority, come under attack.

Only cylinders built on the principle of code pin + support pin + spring are vulnerable to “bumping”. The essence of the method is that, using a specially prepared key blank, a blow is struck simultaneously to all the secret elements of the cylinder. The transmitted impulse, without moving the code pins, causes all the reference pins to bounce at the same time. The rebound is large enough that the resulting clearance allows the cylinder to rotate. Externally, “bumping” looks like this: a prepared blank is inserted and its head is lightly tapped with the handle of a hammer or screwdriver. Simultaneously with the blow, the burglar tries to turn the key.

It should be especially noted that the method is unstable and does not provide a 100% guarantee of opening. The more complex the cylinder, the less consistent the results become. Some cylinders can only be turned in a certain direction, some do not turn at all, and some stop opening after several successful attempts.

Standard methods of protection against master keys complicate, but do not eliminate, “bumping”.

Cylinders without springs (for example, EVVA) are completely not subject to “bumping”, as well as cylinders with special devices specifically against this method. There are also a number of cylinders (for example, Mul-t-lock Classic), for which “bumping” is possible, but the result is extremely unstable - not every sample can be opened. Another group (in particular Cisa RS3 and Mottura Champions with magnetic elements), although theoretically vulnerable, has not been opened in practice (video fragments of opening Mottura cylinders available on the Internet are falsification, since a key blank with a previously known position and polarity of the magnet was used, as well as same with a known depth of groove under the magnet). Exotic methods and fairy tales

Separately, it should be noted both exotic methods of opening and breaking cylinder locks, and legends that have no connection with reality. From the exotic (not found in practice, although theoretically possible), it is worth noting the method of destruction with acid - it is claimed that by pouring acid into the cylinder, you can break it by dissolving its locking elements or the springs that hold them. In practice, this method is practically impossible, since any metal, when exposed to acid, forms salts, which, by covering the material, protect it from further exposure to acid. One pour obviously will not be enough; the acid must be supplied in portions (preferably in a heated form), and in the intervals the formed oxides must be cleaned or washed out. Well, if you take into account that most manufacturers, even in fairly simple cylinders, use steel and/or cupronickel parts, which are extremely difficult to dissolve with acid, then you don’t have to think about this method.

As for fairy tales and legends, here we should first of all remember liquid nitrogen.

Some storytellers, taking advantage of the gullibility of the listener, tell scary stories about how, with the help of one thermos of liquid nitrogen, the hinges of steel doors are broken, and the locks simply crumble into dust. Let's all say a LIE! Firstly, the metals used in locks, cooled to the temperature of liquid nitrogen, do not become brittle like glass. Yes, their plasticity decreases, but they do not crumble upon impact. There is no need to confuse metals and, say, rubber. Secondly, it is almost impossible to cool even a small piece of metal to the temperature of liquid nitrogen in domestic conditions. Even if we do not take into account the fact that the cooled element (for example, a cylinder) is practically inaccessible for heat removal (the available surface area is too small), then attempts to “pour nitrogen into the lock” will be comparable to attempts to pour water onto a red-hot frying pan - nitrogen flows immediately will evaporate and splash, mostly without even contacting the surface. A song about “secrecy”

In Russia, many sellers of doors and locks base their sales policy on the active exploitation of the concept of “secrecy”. At the same time, “secrecy” is measured by a certain number, instilling in the customer that the higher this number, the “cooler” the lock (cylinder). This is a very gross mistake, or rather, a deliberate lie.

Secrecy is a very vague concept. Very often, a certain number of key or lock combinations declared by the manufacturer or independently calculated by the manufacturer are taken as secrecy. This is fundamentally wrong. The number of combinations, firstly, can be calculated by different methods with completely different results (or artificially inflated without changing the quality of the product). Secondly, it is simply impossible to compare secret mechanisms from different manufacturers based on this parameter, since the resulting number in different cases shows completely different parameters, in other words, the results have different dimensions. The number of combinations is simply a certain number that indirectly (very indirectly) characterizes the accuracy of manufacturing parts, the number of secret elements, the probability of repeating a key and the possibility of expanding master systems. At the same time, for example, the operational reliability and resistance to master keys of a lock with 10,000 secrets can be much higher than that of a lock with a declared 10,000,000 secrets.

Based on the above, you can try to formulate a very convenient concept of “secrecy” as a set of parameters such as: resistance to master keys, probability of opening with similar keys, operational reliability (wear resistance) and, partly, resistance to mechanical stress.

That is, the term “secrecy” can only be considered and used as a complex parameter. Substituting the term “number of possible combinations” with the term “secrecy” misleads the customer. In fact, the number of possible combinations has very little to do with the actual useful characteristics of the cylinder. Key protection

It is not directly related to the properties of the cylinders, but is an additional safety factor. Cylinder manufacturers limit the distribution of blanks and the possibility of duplicating keys, which prevents attackers from making copies of them. The simplest method of protection is duplication upon presentation of the lock owner's card. A higher level – duplication only in specialized workshops and only upon presentation of the lock owner’s card. The maximum level of protection is duplication only at the manufacturing plant or representative office.

Comparison table of cylinder mechanisms

In the table, popular cylinder mechanisms on the market that we do not have in our assortment are indicated in gray. These models are provided for comparison.

| Exploiter reliability | Drill protection | Key selection | Lockpick protection | Resistance to "bumping" | Key protection | Overall Cylinder Rating | Warranty (years) | |

| English type | 1 | 1 | 1 | 1 | 1 | 1 | 6 | 1 |

| KALE perfo | 1 | 1 | 2 | 2 | 3 | 1 | 10 | — |

| Mul-t-lock 7*7 | 2 | 2 | 2 | 2 | 2 | 1 | 11 | — |

| CISA Asix | 3 | 2 | 2 | 3 | 2 | 1 | 13 | — |

| CISA Astral | 3 | 3 | 2 | 3 | 2 | 2 | 15 | — |

| TITAN i6 | 3 | 3 | 2 | 3 | 2 | 1 | 14 | 2 |

| TITAN K 56 | 3 | 3 | 2 | 3 | 2 | 1 | 14 | 3 |

| Mul-t-lock Interactive | 5 | 3 | 3 | 2 | 3 | 2 | 18 | — |

| Mul-t-lock Classic | 5 | 4 | 3 | 3 | 4 | 2 | 21 | — |

| MOTTURA CH. thirty | 3 | 5 | 3 | 5 | 5 | 3 | 24 | — |

| MOTTURA CH. 28 | 4 | 5 | 3 | 4 | 4 | 4 | 24 | — |

| MOTTURA CH. 38 | 3 | 5 | 3 | 5 | 5 | 4 | 25 | — |

| KABA Matrix | 5 | 5 | 3 | 5 | 5 | 4 | 27 | — |

| KABA Expert | 5 | 5 | 3 | 6 | 5 | 4 | 28 | 4 |

| EVVA ICS | 5 | 5 | 3 | 6 | 6 | 5 | 30 | 6 |

| CISA RS3 | 5 | 5 | 3 | 6 | 5 | 5 | 29 | — |

| EVVA 3KS | 5 | 5 | 3 | 6 | 6 | 5 | 30 | 10 |

| EVVA MCS | 5 | 5 | 3 | 6 | 6 | 5 | 30 | 10 |

Explanations for the columns:

- Exploiter

reliability : Five points. Performance and durability as assessed by the service department. - Drilling protection

: Five-point. The presence of elements that prevent drilling or make drilling ineffective. - Key selection

: Three-point. 1 - possible; 2 - unrealistic even for heavily worn ones; 3 - impossible - Protection against master keys

: Five-point. The ease with which an average craftsman can open a cylinder with a pick. 1 - minutes; 2 - 10-30 minutes; 3 – from 30 min. up to an hour; 4 - more than an hour; 5 - only in theory, never encountered in practice; 6 - we do not open it within a reasonable time. - Resistance to “bumping”

: Five-point. 1 - easy to open; 2 - opens often; 3 - sometimes; 4 - rare, isolated samples; 5 — no cases recorded; 6 - fundamentally unopenable. - Key protection

: Five points. 1 - in any workshop; 2 — own profile “STAL”; 3 — duplication in service centers; 4 — duplication in the server center with the obligatory presentation of the card and key; 5 - duplication at the manufacturer or representative office. - Warranty (years)

: Warranty provided by the STAL company for this type of cylinder.

And finally, some quotes:

If only you wouldn't chase cheapness... (Alexander Sergeevich Pushkin) The miser pays twice (folk wisdom) I'm not rich enough to buy cheap things.

(Henry Ford) © Author: Anton Budkovsky © STAL 01/30/2006-05/14/2019

Burglary resistance classes of door locks

According to GOST 5089-2011, there are 4 burglary resistance classes of locking devices for entrance doors. The category is assigned based on the time required for unauthorized opening. The burglary resistance class must be indicated in the passport for the door or in the documentation of the lock itself.

Let's consider the meaning of each group:

- Class I - the easiest versions to crack. Unlocked with hairpins, pins, paper clips. The burglar will need 5 minutes. Locks are only suitable for utility rooms where material assets are not stored.

- Class II is a more complex level found in economy-type entrance doors. A beginner will not be able to handle the lock, but a professional will take less than 10 minutes . Typically, such versions are installed in apartments provided that there are two locking devices of different types (lever and cylindrical), as well as another lockable door in the entrance.

- Class III is a mechanism of increased complexity, which will take a professional 20-30 minutes . Suitable for installation on the entrance doors of an apartment or private house if there is another lock of at least II class.

- Class IV is a device of the highest level in terms of burglary resistance. The security guard will spend at least 30 minutes hacking . The mechanism successfully resists special devices and electrical equipment. It can be used alone on the front door of an apartment or cottage, and when paired with a 2nd or 3rd class lock it makes the home even more impenetrable.

If you notice an error, a non-working video or link, please select a piece of text and press Ctrl+Enter .

0

Difference between locks by type of installation

Types of locks are classified according to the installation method, which affects the design of the front door and the complexity of installation. Eyelet padlocks are only used on sheds and utility rooms, so we won't cover them here. For entrance doors of apartments, houses, administrative and other buildings, locks of three types of installation are used.

Invoices

The simplest option from an installation point of view. All you need to do is drill holes for the hardware and tap them. The door leaf and frame of the leaf remain almost intact. Among the disadvantages of locks of this type is that a strong inner wall of the door (opening into the apartment) is required, otherwise it will not be possible to securely fasten the locking device.

Padlock.

Typically, entrance doors have a steel sheet on the outside (street) side, and on the room side they are finished with MDF panels. Attaching a lock to a chipboard is a bad idea. Chinese doors, consisting of two layers of metal, are also not suitable, since the thickness of the iron 0.6-0.8 mm is not sufficient for reliable fixation in the material. Entrance doors with 1.5 mm thick iron sheets inside and outside are an expensive purchase, but only on them can a rim lock be securely attached.

Overhead versions are also less attractive due to the aesthetic component. The entire device is located outside the sash and can spoil the view (especially if there are several locks).

A rim lock installed on a metal door.

The presence of an overhead locking device involves placing it at the edge of the canvas so that the bolts go as deep as possible into the counter part. This makes it impossible to install on entrance doors with a double or triple rebate, which implies the presence of several steps for additional sealing contours.

Mortise

Such models are placed inside the sash by insertion. A hole is cut from the end of the blade into which the lock body is inserted. The latter has a decorative plate covering the slot.

Mortise lock.

Installing such a lock is more difficult, but it is located inside and does not spoil the appearance of the front door from the side of the room. At the same time, the sash serves as protection for the lock, completely covering its body.

Mortise lock installed in the door.

Deposits

This is an advanced version of a mortise lock, only a hole is cut out at the end of the blade, not for the entire body, but only for the exiting bolts. The lock itself is installed at the door manufacturing stage and placed inside.

Inset lock.

Smaller holes in the canvas frame increase the strength of the structure. The locking mechanism is securely closed and does not spoil the appearance of the door. But when the lock breaks, you will have to significantly disassemble the inside of the sash to replace it.

Inset lock installed in the door.