The market offers different models of locking mechanisms for installation on entrance doors. They differ not only in design, but also in their operating principle. The main purpose of locks is to protect your home from intruders. Therefore, before purchasing such a product, it is recommended to study the structure of the lock of different models intended for the front door.

Types of locks

There are many options for locks, each of which is produced in accordance with the relevant GOST. There are several main criteria by which different types of fittings differ.

For example, a lock for an entrance door block may look similar in appearance to a lock for an interior door. But overall these are two completely different bolt mechanisms with different components.

- Built-in. Such products are a component of the door block. They are mounted into the door leaf at the production stage. Built-in shutter mechanisms are most often used in the manufacture of steel doors;

- Mortise. Such devices are embedded inside the canvas and can additionally be connected to a handle. Most models of mortise lock structures are suitable for both entrance and interior blocks;

- Overhead. This is the simplest lock option for doors installed in the entrance opening. Installation is carried out directly on the surface of the canvas. Most models do not include a door handle. Such products can be easily installed independently without the help of a specialist.

Overhead products

Such shutter devices are rarely used, as they are less reliable. The main feature of the device is its installation on the surface of the door without recessing into the leaf.

Its design consists of 2 elements:

- The main one is a cylinder with a latch on one side of the door. On the second there is a hole into which the key is inserted;

- The second element is a response panel installed on the end of the door frame. It includes crossbars when closing the door leaf;

The counter plate is also of the overhead type. When installing it yourself on a frame, it is necessary to ensure convenient placement of this part. The bar must be fixed exactly opposite the exit of the crossbars.

Mortise and built-in lock options

Modern built-in and mortise locking devices are used today more often than conventional overhead structures.

The main difference between mortise products is that the main element is cut into the canvas. Outside there is a hole and a handle for opening/closing the door. The fastening areas are covered with a decorative panel.

According to GOST, mortise gate structures are inserted into the end part of the blade. The counter part, made in the form of a plate, cuts into the box from the opposite side. This installation principle is used for door blocks made of different materials.

The structure of the built-in type lock, intended for the front door, has a more advanced design. Their main difference is the use of a large number of crossbars. Moreover, they can be placed both on the side, and above, and below, which ensures complete blocking of the door structure in the entrance opening.

Built-in models are mounted inside the door leaf directly during the production of door blocks. This is their main difference from mortise structures. It is quite difficult to remove such a lock on your own.

Interior models

If we consider the question of how the design of door locks works, we should definitely consider interior models. The design of a standard interior door lock can be divided into a separate category, since, unlike previous models, these products have a special design.

The circuit of such a door lock is combined with a handle. In this case, in addition to the latch, there is an outlet to the handle, which sets the halyard tongue in motion due to its connection with a rectangular cross-section rotary pin. Depending on the type of handle, such mechanisms are divided into three categories:

- rotary round;

- nobs;

- push.

Types of locks for interior doors

The design of an interior lock is almost completely identical to that of a mortise lock, but here the exit under the handle often has more space. It is impossible to make a high-quality lock on a door with your own hands without certain skills, but understanding their structure will be useful for every owner.

Design features

The design of any shutter device includes the following components:

- Larva;

- Crossbars;

- Tongue;

- Door knob;

- Response panel;

- Decorative strip.

Models for interior units are often limited to only a latch. They do not have a secret mechanism. And entrance structures must have reliable shutter fittings.

Therefore, all locks are divided into separate categories according to the degree of secrecy of the locking mechanism. The reliability class is characterized by the number of possible combinations of the device secret itself. The more of them there are, the more difficult it is to open the lock using master keys.

Many manufacturers also produce special locking mechanisms that are burglar-resistant. Some of these models can only be opened using the original key.

Products with a secret

In order to improve the quality of protection of their possessions, owners are looking for all sorts of ways, including the use of special tricks that will make the lock scheme unique and prevent hacking using standard methods.

With access and skill in handling equipment, screw locks are made, the main highlight of which is the unusual shape of the key. The more non-standard its head, the more difficult it is to open the lock.

With the development of technology, time is no longer spent working with old mechanisms, which means that you can successfully use them without inventing something new. Old complex mechanisms are perfectly resistant to modern methods of opening.

Using a padlock with two locking pins, each with an individual location, is also an excellent choice.

Lock mechanism

The key component of the locking device is the cylinder, which ensures the blocking of the door block in the entrance opening, preventing unauthorized persons from entering a private house or apartment.

There are several options for secret devices.

Level

Such products are equipped with the most reliable secret. Levers are located inside such mechanisms. Special “butterfly” keys are used for them. When they are turned in the keyhole, the bolt mechanism is raised to the set coding level.

Cylinder

These are standard locks, the secret part of which is made in the shape of a cylinder. Inside the cylinder there are pins designed to lock the bolt device in the closed state. Special notches are made on the key, which, according to the established pattern, move the pins, making it possible to rotate the bolt mechanism.

Crossbars

Crossbar-type models are equipped with a latch on the reverse side. Today they are considered less reliable and are therefore rarely used. The operating principle of such a device is based on pulling back two bolts located inside the lock using a key or latch.

Disk

This option is also not reliable enough, but disk structures are used more often than transom ones. The key resembles a rod, cut in half, on which several notches are made. When you turn the key, discs spin inside the locking mechanism, forming a tunnel and the mechanism is released.

Crusades

This is the most unreliable version of the locking mechanism with a cross-shaped key. The cylinder of such a lock can be opened with any Phillips screwdriver or other similar objects.

Features of the design of the lever lock

Many people are interested in how a lever-type lock designed for installation on the front door works.

The design of lever locks includes the following elements:

- Levers are spring-loaded plates equipped with special grooves;

- Rod (transverse) bolt;

- The cylinder is a special hole into which the key is inserted.

All plates are in different positions, so they can only be turned with a “original” key, the teeth of which have similar locations. The degree of reliability of the device is directly proportional to the number of plates equipped in the shutter mechanism. The more there are, the better the protection.

Operating principle

Levers are a set of plates with figured cutouts. The scheme is simple: under the influence of the key, they line up in clearly defined positions in order to turn the key and open the system. But if at least one plate does not fit into its groove, the mechanism will not work.

The key plays a certain role as a code, and it is difficult to hack such a system by force. A high degree of reliability and durability is determined by the large dimensions of the mechanism.

If you follow all the rules for assembling the product, it will be difficult for even the most experienced burglar to hack it.

Design of cylinder mechanisms

Shutter mechanisms for entrance doors equipped with cylinder mechanisms can be overhead or mortise.

All elements of the locking system are located in the lock body. Such devices can be single-sided or double-sided. In the first case, you can open the door leaf with a key only from one side. The second option involves opening/closing doors on both sides only with a key.

The order of actions that must be performed when opening the cylindrical mechanism:

- A key is inserted into the groove of the lock cylinder. In this case, the frame of the device itself remains motionless;

- Then, when you turn the key, the pins rise, acting as the main closure mechanism of the structure;

- The key patterns must completely match the positions of the pins so that all secret elements match completely.

Code lock

Locking devices with a code can be mechanical or electronic. The first option is characterized by ease of installation and further operation. If necessary, it can be easily reprogrammed.

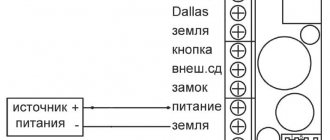

Electronic models require a mandatory connection to the electrical network. Therefore, it is recommended to additionally have an autonomous power source in case of a power outage.

The deadbolt of a mechanical combination lock is activated by pressing a preset combination of numbers. For electronic models, in addition to the secret combination, you can use a special magnetic key.

Electronic shutter devices are considered more reliable. They are often installed on the entrance doors of office centers, entrances of apartment buildings and other public buildings.