In the classification according to the method of fastening to the door, locking devices are divided into 3 types:

- invoices;

- mortise;

- built-in

Depending on the location, types of secret and deadbolts, the lock mechanism also varies. Devices for entrance and interior doors are similar only in some operating principles, but in structure they are different elements.

The generalized door lock diagram has the following structure:

- Housing and cover panel.

- Mask (secret mechanism).

- Crossbars (retractable bolts).

- Executive device.

Common models include a halyard latch (tongue) and a handle. Regardless of the method of fastening, there are always two components: a secret system that recognizes the key, and an executive component that implements the ability to lock.

Structural door lock mechanism

The following types of secrets are distinguished:

- Cylinder. Elements that prevent the lock from being picked are placed inside the cylinder. When the key is inserted into the keyhole, the grooves on it contact the pins, moving them to the level required to move the cylinder.

- Suvaldny. Inside there are plates of complex shape, spring-loaded and placed in one block. The “safe” key, characteristic of this mechanism, has as many teeth as you need to move the levers, the combination of which is individual for each device.

- Disk. The cross-section of the key is almost a semicircle with several notches. Inside the secret there are discs that, when turned, release the locking mechanism of the door lock.

- Combined. Different types of secretions may be present simultaneously. There are versions in which the lever part is placed in the cylinder, which provides better protection against burglary.

Regarding actuators, mechanical, electromagnetic and electromechanical principles of closure are distinguished. The most popular is the first option, the operation of which is based on the insertion of a metal rod from the door into a special groove in the frame.

Installation methods and their features

Locks can differ in the way they are installed on the door (protective structure), have several different types of security mechanisms, be made from a wide variety of materials, and have a huge number of different functions. This is exactly what we will talk about next.

Differences in installation method

When choosing a lock for a new place, and especially when choosing for an old one, a person strives to find out the type of lock in order to start the search at least somewhere.

Often, it is the installation method that is the first sign used to search for a door lock.

Mortise or mortise lock.

If the body of your lock is completely embedded in the door, its bolts protrude from the plane of the moving door leaf, and only fittings and decorative trims are visible from the outside - you have a mortise lock installed.

These are the ones that are found on modern doors in the vast majority of cases today. A mortise lock does not spoil the appearance of the door, and when installed correctly, can withstand heavy burglary loads when attempting to forcefully open the door.

In the group of mortise locking devices, according to the installation method, we can also mention mortise locks. In fact, this is the same mortise lock, which is installed not only (and not always) behind the end plate, but also using front fastening. At the end of the door, the inset lock often does not have visible fasteners.

In a professional environment, the inset method of installing a lock is considered preferable, since it provides a more rigid fit to the lock, which leads to an increase in the protective properties of the structure. For example, this is an example of an inset lever lock on our metal doors.

For installation, a mortise lock requires a certain thickness of the door leaf, and for this reason, in some cases, inserting such a locking device into a particular door is impossible. In this case, to ensure locking, you should use the following type of lock according to the installation method.

Rim lock

If the body of your lock is completely visible from the inside, you need (or have installed) a rim lock.

A rim lock is applied to the door leaf from the inside. The bolts of such a lock often go behind the door frame. And the key itself is either longer to reach through the entire thickness of the door, or the cylinder of this lock requires a through hole through the entire thickness.

Installing a rim lock is obviously a simpler task than the previous type. This is what often plays a role in the choice. Although it must be added that the installation of a lock, as such, in principle, should be done carefully, with a sense of purpose and following the recommended standards and requirements for a specific situation. An incorrectly installed lock will void the warranty and have a reduced service life.

The disadvantages of a rim lock are its specific appearance (it spoils the interior finishing) and the absence of a latch, which is so necessary for the correct operation of the door.

Padlocks

If the lock body of your lock is completely visible (and accessible) from the outside, and the locking of the structure is carried out due to the shackle and external elements (eyes) attached to the moving and stationary parts, it is a padlock.

This is the simplest type of locking device in terms of the locking method, and therefore the most popular in principle. In addition, a padlock can be used where previous types are impossible to install in principle - chests, drawers, bars on windows.

If you still have questions about the topic discussed, or some section seemed insufficiently covered, please leave your comments. We will try to respond promptly and supplement the article.

And to determine your lock model, you can send its photos to our email, attaching the photos and we will definitely respond.

Or write to us via the feedback form.

How does a lever-type door lock work?

The main element that provides protection against forceful burglary is the bolt shank post. The gap between it and the code slot directly affects the protection function.

The time that can be spent breaking the door depends on the number of levers. The most commonly used option is the one with six plates. But the more there are, the more reliable it is. Proper operation is ensured by springs that allow the levers to return to their original position.

Armor plates cover the most vulnerable places, and the front side with a frame is not only a decorative element, but also protection against forceful hacking.

Purpose of the latch

Today there is a huge assortment of latches to choose from, not only in appearance, but also in size and design. Despite all this, they have one task - to hold the canvas in the closed position.

Some door models have a latch with a lock, which allows you to temporarily lock the door from the inside and prevent entry from the outside. A latch handle for interior doors with a reliable lock is especially important on those doors that divide rooms into heated and unheated ones. This will help prevent the penetration of cold air flow as much as possible.

Also, if the room has an air conditioner, then for it to work effectively the door must be closed. If it is installed without a latch, then in the event of a strong draft the canvas may swing open and hit, for example, a small child. But the presence of a fixing element on the canvas will help avoid injury to the baby.

A good quality latch has the following characteristics:

- Fixes the door leaf and prevents it from opening from touch or light draft;

- Quiet to use;

- Long service life when choosing a high-quality mechanism designed for a large number of working cycles.

The principle of operation of a door lock with a lever secret

The mechanism is based on a set of plates that have shaped cutouts.

The opening scheme is quite simple: the key, with its teeth, aligns these levers in a certain position, allowing you to turn and open the system. If at least one of the plates does not fall into its groove, then the mechanism will remain closed.

The key is the carrier of the code for arranging the required combination of plates, and a high degree of reliability is ensured by the fairly large dimensions of the device and the presence of armor protection. It is very difficult to hack such a system by force.

Tips for choosing a door latch

To choose the right lock for an interior door with a locking latch, you need to pay attention to the following criteria:

- There should be no jamming or extraneous clicks when opening and closing the structure;

- Latches must be selected with medium-hard springs, because weak ones may hold the door poorly or will eventually stop doing so altogether, but installing a mechanism with a tight spring will require great effort to open the door;

- When purchasing a mechanism, it is worth assessing its appearance so that there are no scratches, chips, rust or other defects;

- When opening the blade, the handle should fit comfortably in the hand and be pleasant to the touch.

Particular attention is paid to choosing a latch for the characteristics of the door. If the canvas is very heavy and made of natural wood, then the mechanism must be made of durable material.

When purchasing a handle with a latch, you should pay attention to its design and color scheme so that it matches well with the interior of the room and the color of the canvas itself. It is not recommended to install handles, locks and hinges of different colors.

Before installing a door, you should decide on its function. If it is installed in a bathroom or toilet, it is best to install a lock with a lock, but for a child’s room a magnetic lock, which works absolutely silently, is better suited.

What are the features of cylinder type

In the general scheme, the design of a door lock of this type has the following structure:

- disguise;

- deadbolt and deadbolt;

- body and front frame;

- lever for controlling the latch;

- a strike plate into which the bolts are immersed when locked.

The cylinder inside the box is “frozen” using coding pins. When the key is immersed in the lock slot, it performs the task of arranging them to the required positions, obtaining such a separation line that allows you to unlock the cylinder and move the bolts.

Overhead structures

The design of a padlock can be called simpler. Today they are used less and less. A special feature of the overhead door lock is that, according to GOST, it is attached to the door leaf without additional recess. The system consists of two parts: the main part contains a cylinder and a latch on one side, the well goes out on the back side. The second part is the response panel where the crossbars go.

The mating part is also overhead, so if you do the installation yourself, it must be conveniently placed on the frame exactly opposite the exit of the pins.

Overhead lock model

How to make a door lock

There are craftsmen who like to build something non-standard with their own hands. They will come up with an interesting mechanism for the door too. The easiest option is to make a regular deadbolt from improvised means. But there are mechanisms that are much more complex. You can independently make parts of a door lock or an entire electromechanical locking device.

Alternatively, it could have the following structure:

- bolt;

- actuator from a car lock;

- remote control with keyboard (or other type of secret);

- power unit;

- a certain set of electronics and components (you can use the Arduino platform and the like).

If you need to make a lock for the box with your own hands, then you can get by with a conventional mechanical design in the form of a latch. Or buy ready-made fittings and install them yourself.

The assortment of stores in Moscow, and other cities, allows you to find any parts, so if you wish, you can not only build the latch itself, but also an entire door locking mechanism with coded access or even a sensor that reads fingerprints.

Code lock

Locking devices with a code can be mechanical or electronic. The first option is characterized by ease of installation and further operation. If necessary, it can be easily reprogrammed.

Electronic models require a mandatory connection to the electrical network. Therefore, it is recommended to additionally have an autonomous power source in case of a power outage.

The deadbolt of a mechanical combination lock is activated by pressing a preset combination of numbers. For electronic models, in addition to the secret combination, you can use a special magnetic key.

Electronic shutter devices are considered more reliable. They are often installed on the entrance doors of office centers, entrances of apartment buildings and other public buildings.

Installation of the mechanism

For installation, you should prepare a hammer, drill, screwdriver, awl, square, pencil and carpenter's knife in advance. The latch is installed at a height of 1 meter, because it is at this height that door leaf manufacturers install a wooden block for greater structural rigidity. From the bottom of the canvas, the required height is marked on both sides and marked with a pencil and square.

A latch is applied and a place for the handle is determined. You need to start drilling the hole from the end of the door using a feather drill. After which the hole is leveled using a drill or chisel to the required size.

A latch strip is applied to the end part of the blade and veneer is cut along its perimeter, after which a chisel is used to select the depth of the strip. As a result, it should lie on the same level as the door.

Holes for the handle are drilled on the sides of the canvas, and then carefully leveled with a chisel. Now you can begin installing the latch and fixing the strip with screws.

To install the handle, unscrew one locking screw and loosen the second one slightly. The handle is inserted into place so that the central pin is in place. The second part of the handle is put on and the locking screw is tightened, after which the handles are attached to the door leaf using self-tapping screws and the decorative trim is put on.

Finally, the striker is installed. To do this, you need to slightly cover the door leaf and mark the size of the tongue with a pencil, then drill a hole for it and screw the strip into the frame.

Structure of a cylinder lock system

Level lock diagram.

The cylinder locking mechanism can be applied or mortise. It has a secret device in the middle. These door locks are manufactured:

- one-sided, they can be opened with a key on only one side;

- double-sided, these locks have two cylinders and cannot be opened from the inside without a key.

In order to close a home with such a lock, it is necessary to perform certain actions: a key is inserted into a hole that has a limited protrusion. This hole is in a cylinder, part of which always turns, but will only do so when the proper key is inserted. The rest of the device will remain motionless - this is the body. The executive device is the pins. They serve to lift the key. Their position will determine whether the constipation is open or closed.

The door lock will open only when all coded elements are completely aligned.

Disassembling the door latch

The design of a door handle on an interior door with a latch is not simple; the design has many elements and some of them may fail, after which disassembly of the mechanism will be required. This happens in the following cases:

- Mechanism jamming or creaking;

- The need to clean the locking mechanism or lubricate it;

- If necessary, replace some parts of the mechanism;

- The need to completely replace the latch.

Dismantling work may vary slightly depending on the type of mechanism installed. But if there is a push and turn mechanism, the procedure will be as follows:

- The decorative trim is removed from the handle. Depending on the installed model, you will need to pry it off with a knife or unscrew the screw;

- The handles are removed and the tetrahedral pin is pulled out;

- Unscrew the fastening element from the end of the canvas and remove the latch.

When the mechanism is disassembled, the reasons for its malfunction are determined:

- Creaking or jamming is the result of lack of lubrication or dust. In this case, it is necessary to clean the mechanism and lubricate it;

- Rust. The elements are cleaned and coated with a liquid with anti-corrosion properties;

- Broken spring or tongue. Carry out a complete replacement of parts;

- The mechanism is worn out. They are replacing it.

Before installing the latch, you need to decide what type of latch is needed and only after that proceed to choosing a product based on color, quality and price.

Types of secrets

Mechanical secretions are manufactured in various versions:

- In the shape of a cylinder. The basis is a special part - a cylinder. In the middle there are pins - elements that prevent the lock from being picked. This type of castle is called an English castle. It is the most common.

- Coded. It opens when you enter the key by typing the required numbers.

- Suvaldny. Finding several teeth on the key that determine the number of levers.

- Electronic. It is created on a drive built inside.

Tools and materials

To install the mechanism you will need the following materials:

- handles of any shape (round, in the shape of the letter “G”) – 2 pieces;

- cylinder mechanism with spring;

- fastening screws that connect the cylinder mechanisms;

- crossbars;

- sockets for closing cylinder devices – 2 pieces.

In addition to materials, the work requires a small set of tools:

- a simple pencil;

- roulette;

- drill;

- office knife;

- chisels at 0.1 and 0.2 cm;

- feather drill 2.3 cm;

- drill 0.2 cm;

- crown 5.4 or 5 cm based on the thickness of the door;

- masking tape;

- hammer.

If you don’t have any of the listed tools at home, you will have to buy more. Their cost is low, and they are always useful on the farm.

Installation of interior mortise locks

Types of mortise interior locks differ in their functionality. This depends on the presence of blockers and secret parts in their composition.

The locking devices under consideration consist of the following elements:

- Planks: front, return

- Pens

- Lock (lever or key)

- Bolt, tongue (roller, magnetic)

- Internal part that provides snapping, locking

- Cylinder, lever locks. For interior locking devices, they are used when particularly reliable locking is needed.

- Decorative retaining linings on the outside and at the end of the door leaf

- Retainer with pinwheel or locking key for locking.

Materials and form factor:

- Handles: regular or round in the form of a ball, in the center of which there is a hole for a key

- Material: alloys of steel, bronze, aluminum, copper, brass or cheap soft alloys. Some products have tongues made of plastic

- Decorative parts (levers, overlays) are made by stamping, forging, casting

- One-piece or individual outer covers in a variety of designs.

The life of a knight in his home

The history of the Middle Ages shows that the life of knights in castles, especially in an era of fragmentation, can hardly be called calm. Peace, if it was concluded, was fragile, and storming the fortress was commonplace. The description of a medieval castle suggests that such a structure primarily served a defensive function and was not very cozy inside .

In winter, the castles were heated by fireplaces, but this provided little protection from the cold and dampness. The walls often froze through. Latrines were often separate wooden structures located on the outside of the walls. Their use in the cold season was problematic.

The inhabitants of the castle often had to neglect hygiene, and unsanitary conditions reigned inside. Water from wells was used mainly for cooking and was used for drinking by livestock.

Few people thought about the comfort of the inhabitants when designing the structure, but it was this approach that helped many representatives of the feudal class avoid the capture of their fortresses, plunder and death.

Malfunctions

If the mechanism is faulty and the tongue does not move, the force applied to the handle will have no effect - it will only damage the internal parts. In such cases, it is necessary to remove the locking device, disassemble it and check the internal part.

A possible reason for the tongue not fitting tightly into the response hole when the handle is fully pressed is wear on the lever that sets the latch in motion. This type of failure is common in cheap soft metal locks or when the lever is frequently pressed too hard. To repair the mechanism, it is necessary to disassemble it and wind the wire around the frayed part or replace it.

If the lever turns but the tongue does not move, the retaining part is broken. Exit: change the corresponding part.

Jamming, jamming of the key, handle, failure of the latch - the reason is always in the internal part, except for cases when the tongue jams due to skew or deformation of the blade. In the first case, you will have to disassemble the mechanism, in the second, you will have to widen the groove for the crossbar or bring the door leaf into proper condition.

The reason for the breakdown of the plate (level) lock may be an extended spring that pulls the plates. The mechanism needs to be disassembled and this part replaced.

KEYS

By changing the shape and location of the pins of the toggle security mechanism, you can get locks with different keys. All locks can be opened with one key or each with its own. A system is also possible in which a group of locks with different individual keys can also be opened with one common key. A hospital, a factory, a university, or a large institution may require a “master” common key that fits all the locks. A person working in any room only needs to have a key to that room. The person responsible for the floor needs a common key for all doors on a given floor. The building's security chief needs a higher-ranking general key that opens all the locks in the building (Fig. 4). If there is a shared key, the locks become somewhat less reliable, as their degree of secrecy decreases. This is the price of convenience associated with the fact that all locks with different individual keys can be opened with one master key.

If all tenants of, for example, an apartment building need to have access to some common area (say, a laundry room), this room is equipped with a special lock that can be opened by a known number of individual keys, although they are all different.

Manufacturers and models of interior mortise locks

ABLOY

Finnish company. Products are mainly in the middle or high price range. Certified products, popular in the countries of the European region.

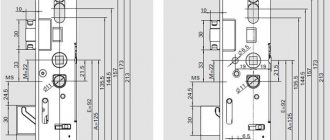

| ABLOY 2014 | ABLOY 2018 | ABLOY 4238 |

| Type | ||

| Interior, toilet, bathrooms | Interior, toilet, bathrooms | Interior |

| Principle of operation | ||

| Key lock (Euro cylinder), reversible latch | Key lock (Euro cylinder), reversible latch | Tongue roller, handle |

| Bolt output | ||

| 11 mm | 14 mm | 5 mm |

| Sideliness | ||

| Universal, right/left | Universal, right/left | Universal, right/left |

| Equipment | ||

| Handle, shield, end plate, rotary button, strike plate | Handle, shield, end plate, rotary button, strike plate | Handle, shield, end plate, strike plate |

| Center distance (A) | ||

| 72 mm | 72 mm | – |

| BackSet (removing the hole from the lock end plate) | ||

| 45 mm | 45 mm | – |

| Opening | ||

| Key, rotary button | Key, rotary button | Pen |

Functions

Locking devices of the presented type perform the following tasks: opening/closing, blocking and unlocking.

Mortise interior locks have the following options:

- Holding in the “closed” position (mechanisms without security, magnetic, roller)

- Locking from the inside using a locking mechanism and a pinwheel

- Double-sided locking with a choice of key or latch from the inside

- Opening with a round handle (knob), equipped with one- or two-sided locking using a key cylinder located in its center.