A high-quality and reliable window sill will always be a wonderful interior decoration and a convenient stand for indoor plants, which does not exclude its most important function as part of a window unit. Its importance lies in the fact that it, together with the sashes and window frame, is designed to ensure the long service life of the plastic window. You should not think that only window sills made of the same material are suitable for plastic windows. Their variety is quite large and they can be made from:

- Plastic (PVC);

- Solid wood;

- Natural or artificial stone;

- Acrylic compounds.

Modern models of window sills

Plastic

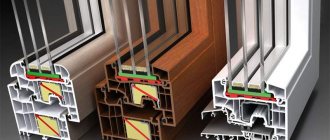

This type of window sill is most often chosen for plastic windows, because they fit perfectly with the main texture of the window. If there is a colored film on the frame with an imitation of any decor, then it can also be applied to the window sill. The wide distribution of plastic models can be explained not only by the variety of designs, but also by other advantages, which include:

- Simple manufacturing and low cost of production;

- Ease of installation;

- Unpretentiousness to care procedures;

- Optimally smooth surface without unevenness;

- Resistance to ultraviolet radiation (yellowishness does not appear on the surface and it does not fade);

- Durability;

- The windows themselves do not need to be painted the same color as the window sill and vice versa.

However, plastic samples have not only positive, but also several negative qualities. Among their disadvantages, it is possible to identify the low thermal stability of the entire structure (it is prohibited to place overly heated objects on them to avoid melting the base), low maintainability (if dents, cracks and chips appear, it is easier to replace the window sill block). Thus, knowing about these significant disadvantages, it will be easier to follow safety precautions when handling, which will clearly extend the life of the structure.

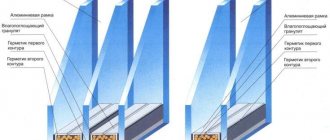

At the same time, most of the questions may lie behind the quality criteria of the plastic itself. The chambers of the product should not be very thin, and it is also preferable to use models with the minimum possible distance between the walls - it is the chamber structure that is responsible for the overall strength of the structure. It is very easy to check the strength - just press on any part of the product and make sure that strong deflections do not appear and there is no characteristic crack.

Thus, plastic models are perfect for those who are looking for practicality and do not want to frequently clean and repaint. Also, they are suitable for lovers of unusual decor - using a special adhesive film, the window sill can be decorated to look like stone or wood.

Wooden

These models are in second place in popularity after PVC models. Wooden window sills must be selected based on several criteria - color, thickness, size and wood used. Oak base is considered the most durable, but also the most expensive. Alder and pine are a little cheaper, but this material is too soft. Beech base is considered the best option, because this type of wood is strong enough to resist mechanical stress, looks great, and its price is very reasonable.

Wooden models have their own advantages:

- They are very pleasant to the touch, you feel contact with living material;

- Durable in use;

- Increased strength - the array has a solid structure that can withstand heavy weight, and such products can be restored when chips and scratches appear, as well as when fading;

- External elegance - a wooden base looks good in almost any interior;

- Large range of shades and the possibility of painting the surface.

Again, such products also have certain disadvantages. First of all, these include poor moisture resistance. This quality can be improved through the use of hydrophobic compounds, however, without sufficient treatment, the tree will constantly gain moisture from the air. Another disadvantage is the need for care. Wood surfaces require regular maintenance, and their coating needs to be renewed at some intervals. The third drawback is the average level of resistance to mechanical stress (if the window sill is based on soft wood, then dents and scratches will become commonplace). And the final disadvantage is usually a fairly high cost.

For wooden products, the class of wood will be of great importance (“A” is considered the best, but in classes “B” and “C” there are too many eyes from branches). It is better to give preference to hard varieties. Also, you should check in advance for factory defects and chips. However, if you wish, you can purchase a fairly budget version of the window sill and bring it to life yourself.

Stone

Their main positive properties are increased strength and durability. They have virtually no wear, they do not risk getting dents if handled carelessly, and they do not need to be regularly coated with paint or varnish. Their undoubted advantages include:

- Excellent ability to withstand temperature changes and high humidity;

- They have a massive and stylish appearance;

- There is a wide range of colors and textures on sale.

Of their disadvantages, first of all, it is worth mentioning too much mass, the possibility of chips, the repairability of which will be very doubtful. Also, these products are not cheap at all stages of their “life” - production, delivery, and installation will be expensive. They will be the best choice for those who appreciate classic design and massiveness.

Window sills can be made not only from natural stone, but also from artificial stone, based on acrylic. This material is distinguished by an abundance of textures, colors and shapes.

Window sill-tabletop

This model can be made from various materials, which were described above. Its idea is to combine the surface of the window sill with the table, which is used to save space in the room or to free up additional work space in the kitchen. At the same time, the material is selected in direct dependence on how the working surface will be used further. Artificial or natural stone is suitable for kitchens, and plastic or wood will look good in a living room. And if it is planned to additionally install a sink into the countertop, then its surface should be durable and thick, plus resistant to moisture.

Which material to choose

The product range is presented in the following categories:

- Plastic window sills. The most popular type among buyers. Available in various colors, easy to install and operate;

- Wooden window sills. It is distinguished by its visual appeal, but in operation the material does not show its best side. Natural wood is subject to wear and tear due to moisture. However, it is appreciated by customers due to its environmental friendliness;

- PVC window sills. They may well compete with a tree. They are easy to install and easy to operate. Thanks to lamination, it provides high wear resistance to damage and service life;

- Chipboard window sills. The quality is somewhere between wood and PVC. Despite the presence of a protective film, moisture still seeps through it. As a result, the material swells and becomes unusable;

- Stone window sills. Perhaps the most unpopular material due to its cost. It is distinguished by durability and visual “richness”.

There are several brands of window sills on the market that are most popular among buyers. These are products from the Danke, Crystallit and Moeller brands.

Let's tell you more about each of them

Existing types of designs

Today, this range is quite wide and starts from traditional and standard, and ends with exclusive options. The latter include shaped structures, which can have any complex shape that can be suitable even for windows with non-standard geometry. It is possible to make all kinds of curls, bends, and monograms on the product - it’s just a matter of taste. There are also radical design solutions that feature raw edges of wooden boards - their natural uneven edge will perfectly complement the interior of a dacha or country house.

Arc-shaped structures have become popular in the wake of the construction of new types of residential complexes, in which semicircular window blocks are used. Bay windows also apply to rounded windows, but they will have corners at the joints. Although, the design can always be increased if desired, if the wall thickness allows. Then it can be used for a desktop or tea table. The size of the window sills can also be adjusted for maximum comfort. However, it is worth remembering that the width limitation is the protrusion from the wall to the cornice (the distance from the window sill to the curtain/blind must be at least 2 centimeters). The heating radiator should be covered no more than halfway in order to ensure the circulation of warm air in the upper direction.

Constructive color solutions can be different, but glossy or matte textures are more popular. The gloss is visually quite impressive, but the dirt on it is very noticeable. The matte surface is less dirty and unpretentious in the process of care, but loses in aesthetic terms.

In order to avoid the appearance of condensation on the window, the window sill design must have the proper length and surface width, and also be correctly placed relative to the battery. If you cannot achieve half the opening size for the battery, you will have to use ventilation grilles.

Or maybe it’s better to buy Danke?

Unlike Meller Danke, window sills were originally supplied from Ukraine, where they were produced at the plant of the same name. But a few years ago, the company opened a new plant in Russia in the Bryansk region, which is now focused on supplying window sills throughout our country.

The production of Danke window sills is also patented and has all the necessary environmental certificates. An environmentally friendly PVC mixture is used as the mixture from which the window sill board itself is made. But the laminated coating differs among different Danke lines. In total, there are 3 types of window sills in the manufacturer’s collection: Danke Comfort (the cheapest), Danke Standard (frosted window sills) and Danke Premium (premium window sills). For Danke Comfort window sills, regular PVC lamination is used, for Danke Standard 2-layer ELESGO® lamination, for Danke Premium window sills they use the same lamination as for Meller window sills - this is a 4-layer premium ELESGO® coating.

In total, the Danke collection includes 11 decors for Danke Premium, 3 decors for Danke Standard and 7 decors for Danke Comfort. Window sills are produced in widths from 150 to 700 mm, the maximum window sill length is 6 meters. The window sill has a unique beveled kapinos (spout) shape.

Finding the right size

The width of the surface of the window sill directly depends on the thickness of the wall and the depth of installation of the window in the block. To do this, you need to measure the distance from the PVC guide under the window frame to the end of the wall inside the room. It is not the rough level itself that should be taken into account, but rather the finishing - tiles or drywall added to the wall thickness. Next, the length of the protrusion beyond the wall edge is added to the measured width.

It is possible to ensure air circulation from the battery not vertically upward, but into the interior of the room. This type of arrangement will distribute heat evenly. If the protrusion is too small, the heated air will pass along the window block and heat the glass, which will lead to the creation of condensation. At the same time, a window sill that is too wide will interfere with the heating of the walls near the window. Thus, the recommended protrusion should be 50-60 millimeters.

As a rule, the standard window sill should extend beyond the boundaries of the slopes by 50-80 millimeters, so the length of the window sill itself should be calculated with a margin of 100-150 millimeters.

The window sill can also be equipped for a complex window structure - a semicircular or U-shaped balcony. In this case, a separate product is placed under each window included in the block and all elements are secured using special connectors.

In any case, in order not to make a mistake with the sizes, it is preferable to use the services of a professional.

Advantages of choice:

- Economical. Low price compared to analogues made from natural materials;

- High quality. In no way inferior in positive properties to stone and wood;

- Aesthetic appeal. The color palette will allow you to choose a product that suits your interior;

- Practicality and durability. Thanks to its structure, the material will not “sag” over time; the rays of the sun, drops of water and scratches are not a hindrance to it.

The company also has components, which allows you to get the window sill of your dreams on a turnkey basis without searching for missing parts. Products have quality certificates and a guarantee of up to 10 years. Environmentally friendly, pleasant to the touch, inexpensive and high quality.

One of the best manufacturers is the Danke brand.

Plugs for window sills

The window interior element in question will not have a finished look and will look aesthetically ugly and rude if it is not provided with appropriate plugs. A little thing like that can make all the difference. With the help of plugs, the part will acquire a finished appearance, and dirt and dust will not settle in its end part. Among other things, the clamp-plug will provide:

- Preservation of heat (will stop cold air);

- Full tightness of the structure;

- Easy and strong fixation of the product.

Plugs are selected taking into account the shape, thickness, width and length of the product. It is recommended to purchase plugs directly with the window sill board so that they fit the specific model. If you intend to purchase separately, then you should first take measurements of the ends of the window sill boards. Naturally, the best plug is made by the supplier who produced the window sill itself, and their shapes can be quite different. Existing types of plugs:

- Shape - they can have various bends (called kapinos) and are selected individually by the buyer to fit the board shape.

- Color – as a rule, they have the same color as the board itself. However, there may also be decorative options made in a different color scheme. In this way, you can symbolically place accents on individual parts of the interior.

- Length – this standard parameter is 700 millimeters. This value may vary depending on the dimensions of the window sill board for which the plug is selected.

Window sills provided with plugs will last much longer, give the main product a finished look and easily fit into the overall design of the room. In addition, with their help, the product itself will be securely fixed in the window block.

How to choose the right plastic window sill

If it's time to replace a window sill or an entire window unit, you need to know in advance what to ask the seller. This is a guarantee of the safety of the material and its long service life, and the absence of unpleasant problems with defects. PVC window sills have long ceased to look like a white rectangle: their unique decor, design, and individual size help them become the main accent in the room.

How to make PVC window sill boards

PVC is an abbreviation for polyvinyl chloride, which is used as a basis for chambers, window sills, and small parts. By adding stabilizers and softeners to polyvinyl chloride, it is made pliable. Pigmented paints are gradually mixed into the mass, coloring it in the desired color. All PVC products are regulated by GOST 30673-99. The finished mass is poured into a mold, where it is left to harden.

The internal configuration is special: the body itself is empty, and inside it resembles a honeycomb, with stiffening ribs directed at an angle. Improvised honeycombs inside the structure and vertical stiffening ribs allow the upper wall not to bend under weight, withstand the constant pressure of heavy objects, but at the same time be easily cut with cutting tools to fit the desired size. Thanks to the combination of additives in the PVC mass, the window sill will easily withstand bends and will not break under heavy load.

With proper use and care, a plastic window sill can last up to 10 years. Promising a long service life, manufacturers indicate a minimum threshold. In practice, they can last up to 50 years!

Marking of the finished product

Before sale, the manufacturer must label the product, encoding key technical indicators in the designations. According to GOST, there must be a marking on the window sill indicating:

- production date;

- a type of PVC construction;

- dimensional parameters;

- basis for manufacturing;

- general installation recommendations;

- production batch number;

- product operating characteristics.

Before purchasing, in addition to labeling, you need to ask for certificates of conformity for the product category.

Features, advantages and types of PVC window sills

In the comparative table you can evaluate the quality of polyvinyl chloride products and then decide whether it is worth ordering.

| pros | Minuses |

| High fire-resistant properties. | Impacts from heavy objects leave dents. |

| Increases thermal insulation and protects against drafts. | The glossy surface is unstable and scratches remain. |

| Unpretentious to cleaning. Resistant to repeated wet cleaning, the surface will not be erased. | The front side cannot be round in shape with smooth corners. |

| Moisture-resistant surface, does not deform. | The dark film accumulates light and over time the PVC becomes deformed due to severe overheating. |

| Mounted separately from the window frame. You can replace it with another one at any time. | |

| You can sit on them and place heavy objects; depending on the internal structure of the canvas, they can withstand weight up to 400 kg per 1m2. | |

| Various uses: shelf, work table, relaxation area, bench. | |

| Durable PVC does not delaminate, does not turn yellow, and does not deform from the sun and heat from radiators. |

Useful tips when purchasing

Most buyers naively believe that the main function of window sills is only an aesthetic component. However, they are an important part of the entire window system, protecting the room from the penetration of cold air currents and maintaining the proper level of microclimate. Accordingly, when purchasing a window sill board, you should pay careful attention to the following properties:

- Appearance - the product should not have scratches, chips or other defects, because then they will have to be constantly hidden behind a curtain.

- Material of manufacture - its selection will depend on the financial capabilities of the buyer and general design preferences. The least expensive options are plastic options that are resistant to moisture and can withstand sufficient mechanical damage and various types of deformation. The most expensive options are made from natural stone and they are able to visually introduce notes of nobility and a certain luxury into the overall interior.

- Sections - when choosing a window sill, you need to pay attention to its ends. Plastic products have stiffening ribs, with the help of which the structure is provided with resistance to various loads. The more there are, the higher the reliability of the product;

- Installation method - the most unpretentious to install - PVC models. Their installation can be done using different methods, but the easiest way is to place them on cement or an adhesive base. Wooden window sill blocks are characterized by hygroscopicity, which means their installation on a wet base is prohibited. The best solution for them is installation on foam pads or iron brackets.

Price and sizes of window sills for plastic windows

The window sill is not only an important decorative part of the window, but in many cases it is also functional.

After all, it is needed not only to visually separate the window from the wall, but it provides a warm air layer between the window and the wall, protects from moisture, and hides the battery, which is often located under the window sill. In addition to the above, it can be used as a table, fireplace cover, flower or bookshelf, storage space.

- wooden;

- plastic;

- stone.

Advantages of plastic window sills

Recently, these plastic products have gained ground from their counterparts. What is the reason for such popularity?

- Ease of installation.

- Low weight with high strength.

- Resistance to chemicals and ultraviolet radiation.

- Resistant to scratches, impacts, dirt and heat (within reasonable limits).

The secret of such plastic window sills is that they are covered with a thin film (65 microns). Due to this, the cleaning procedure is greatly simplified. Dirt does not eat into them; just wipe the surface with a wet cloth and it will shine. The surface of the PVC window sill is resistant to chemicals, for example, if you need to wash the windows and detergents get on the surface, nothing bad will happen.

Plastic window sills are not afraid of water (rain from an open window or water from a flower pot), they have a certain vapor permeability. You can easily move pots across its surface, store various things, or use it as a tabletop, all because the layer of film that protects the surface is almost impossible to scratch.

Plastic window sills can withstand quite high temperatures, for example, if you put a hot glass on it, no circles will remain. PVC window sills are sold both ready-made and to order. As a rule, finished products have lower prices and are used in standard buildings where windows have standard sizes.

If the window sill has non-standard sizes and shapes, it must be ordered strictly according to measurements. In this case, you can choose not only its size, but also its color. Naturally, such a unique work will have a higher price than the standard version.

Installation of plastic window sills

As a rule, when installing a plastic window, a PVC window sill is also installed, but it happens that this is a separate task.

In this case, you can call a specialist to measure the dimensions and install the desired option. If you plan to install it yourself, it is necessary to take correct measurements. First, measure the length of the opening and add at least 6 centimeters to the resulting figure, because it is necessary that on each side the window sill protrudes beyond the slopes by at least 3 centimeters. The width is calculated on the basis that the window sill must be placed under the window at least 2 centimeters and protrudes from the outside by no more than 6–7 centimeters. This is the case if there is a battery underneath it. This width of the window sill will allow air to circulate unhindered; if it is wider, warm air may not rise to the window, and it will fog up.

This PVC product can be attached in different ways. Below are the main ones.

- Polyurethane two-component foam (the most common method).

- Glue and spacers.

- Special bracket (necessary if the width of the window sill significantly exceeds the width of the opening).

- Special staples.

PVC window sills, their features and prices

Moeller.

Germany. These products consist of 30% wood flour and 70% PVC. They are flame retardant, not exposed to sunlight, have high scratch resistance, can be installed in rooms with high humidity (saunas and baths), and can withstand pressure of 428 kg. Meets international environmental standards. Sold in a variety of colors from standard white to mahogany or marbled. Price from 260 rubles per linear meter. Elex. Russia. They are produced in Russia, have a pleasant appearance, are easy to clean, have high resistance to temperature, wear and scratches, and are made from environmentally friendly materials. The price starts from 60 rubles per linear meter.

Installation of window sills

Installation of window sills for plastic windows will require the installer to have maximum knowledge of construction processes. Before starting the entire procedure, you will have to fully prepare the window unit, remove debris from the opening, and ensure dust removal. Due to the fact that the window sill needs to be buried in the wall in the area of the slopes, cutting is carried out in their plane using a hammer drill. Next, it will require masking during finishing. The fastening method should be selected depending on the material of the product and involves several different solutions:

- On the adhesive composition - first, markings are made to place the panel relative to the window frame, after which the structure is applied to the adhesive base or sand-cement mortar, and then the height is adjusted so that the panel fits tightly to the installation point in the frame.

- Using iron brackets, a wooden block-type gasket is installed on the window, which is secured using sand-cement mortar or screws. Next, iron brackets are screwed to the canvas, after which the panel is installed in the window block and screwed to the wall under the window using self-tapping screws. The gaps between the bars are filled with polyurethane foam, and the joint between the frame and the canvas is strengthened with sealant.

- Using pads - the window sill is mounted in the opening, after which the free space under it is filled with blocks or wedges that serve as spacers until the canvas goes under the frame, reaching the maximum density level.

IMPORTANT! Regardless of the type of fastening chosen, the board is installed with a slight slope of 3-5 degrees relative to the interior. This condition is necessary in order to ensure the drainage of condensate from windows or from water that may flow onto the surface when caring for indoor plants.

Danke window sills – German quality

A German brand that produces premium window sills with unique lamination of the Elesgo standard. To create their samples, they use plastic in combination with a special acrylic coating. It is applied to the surface of the product, making the window sill much stronger and more resistant to high temperatures and moisture.

The Danke product line is presented in 13 color options, most accurately recreating the structure and appearance of natural stone and wood.

Instead of an epilogue

Despite the wide range of existing models of window sills for plastic windows, it is better to purchase these products from trusted brands. Companies that respect their reputation will always be able to provide quality certificates for their products. In addition, when purchasing, you should pay attention to the conditions in which the product is intended to be used - the density of the material and sensitivity to ultraviolet radiation will be important properties. Thus, a competent approach to purchasing and high-quality installation of the product will be the key to long-lasting operation while maintaining the same visual and quality characteristics of the material.

Additional attention needs to be paid to

Labeling and quality certificates are not the only things you need to pay attention to when purchasing window sills. When purchasing these products, it is recommended:

- Give preference to products from time-tested brands;

- Make sure there is a protective film;

- Obtain from the seller information about the manufacturer’s warranty obligations;

- Check the number of stiffeners - it is advisable that the distance between them does not exceed 35 mm;

- Find out the maximum load that the product can withstand.

If window sills are ordered together with windows, then all this information must be obtained from the manager, and then checked when delivering the products to the site.

The minimum thickness of the top wall of a plastic window sill should be 3 mm, the vertical stiffeners - 1.5 mm, and the bottom wall - 2 mm.

Crystallit window sills – versatility in everything

Crystallit is considered the second most popular Dante brand

The base taken by the manufacturers is rigid PVC coated with Elesgo acrylic film. The products have a solid structure with thick walls, so the material does not change its physical properties over time.

The color palette is presented in 30 shades, has a glossy and matte structure.

Crystallit window sills are suitable for installation in any room, even in children's rooms, since they undergo quality control at all stages of production and are created from environmentally friendly elements.

- Traditional motifs - classic white window sill;

- The wood-like decor is made in different colors, from oak to wenge. It will be a great addition to the window in your own office or living room;

- Decor “natural stone” - the material is distinguished by an elegant appearance and high-quality texture, presented in three colors, from snow-white to sand;

- The “Original” decor is perhaps the best of the company’s offerings. Matte and glossy products amaze with their brightness and richness. Red, orange and green shades will be the perfect complement to the bright design of the room.

How to choose a color?

The easiest way to decide on the color of the window sill is to look at the window. Since the frame will be the closest piece, it is logical to make both parts the same color. Example: a white plastic window with a snow-white PVC window sill.

At the same time, color is more important than material - that is, a MDF or acrylic board would be suitable for white PVC windows - why not? Moreover, the last two have much wider possibilities for decorating and adjusting the shape.

Another option is a combination with slopes. That is, the window can be white, and the slopes around the perimeter and the horizontal slab can be gray, beige, black. The appearance of such an assembled structure resembles a portal and actively attracts attention - an excellent way to decorate a window without using curtains.

Don't forget about the radiator: if you are going to cover it with a grille, make a solid composition with a window sill - it will look harmonious. The best option for finishing in this case is wood.

The photo shows a plywood window sill

On the other hand, you don’t have to match it with something: you can focus on it. For example, a wooden covering combined with a white window. Or white paired with black.

The location of the window also has its influence on the choice of colors: in a kitchen or bedroom, for example, a window sill can serve as a table and it is logical to make it match the rest of the furniture in the room.

Window sills made of acrylic stone

Acrylic is also called a “warm” imitation of stone. Mineral elements in its composition account for approximately 65%, and the remaining 35% of the substance are resins and pigments. When heated above 150 C°, the material becomes plastic and can be given any shape. The texture of the composite is completely smooth, without pores - that is, a 100% moisture-resistant material. It is not afraid of condensation, dirt, mold. An acrylic window sill will not swell when exposed to water, will not deform, or become cracked. The composite has a seamless joining technology, a huge color base, and its plasticity makes it possible to create objects of any shape. This surface is easy to care for, keep it clean, and small scratches can be sanded even yourself, without calling a specialist.

An acrylic window sill will look good in any room, but more often it is installed in the kitchen (for example, turning into a worktop or bar counter).

Disadvantages of the material

Instability to strong impacts, susceptible to scratches. However, all damage can be completely repaired. Another drawback is the complexity of installation. To install the stove you need to call a specialist.

Comparison table - how acrylic stone window sills meet the requirements:

| Requirements | Compliant | Does not match |

| Strength, wear resistance | Withstands heavy weight and does not delaminate | Not resistant to impacts, easy to scratch, but easy to restore to original appearance |

| Life time | Almost unlimited | |

| Low requirement for special care | Due to the absence of pores, it does not absorb water or dirt. Easy to wash | |

| Permanence under sunlight | Doesn't change the appearance at all | |

| Environmental friendliness | Absolutely safe for health | |

| Stylistic compatibility with room design | Goes well with any windows. Warm to the touch You can give it any color or shape you want. Can be used in any room style |

By clicking on the link, you can see various examples of window sills made of acrylic stone.

Window sills with VPL coating

Window sills in an apartment are most often subject to mechanical and other influences. In order to avoid damage to them, we recommend ordering VPL coating.

VPL is a film that can provide the necessary protection against scratches during window sill operation. In addition, the appearance of window sills covered with this film will not be affected at all by temperature changes, ash ingress, leaving a mug of boiling water, etc. You will also be pleasantly surprised that this design is not afraid of moisture and various chemical influences, including alcohols.

Window sills Moeller (Germany)

Recently, in the production of window sills, LIGNODUR material produced by the Möller company, which has existed since 1947, has been increasingly used. These window sills are extremely common today in Germany and are gaining popularity in Russia. Their dense core is made from a mixture of wood flour and PVC mass using special technology under high pressure. Its surface is not sensitive to scrapers, stains, scratches and sunlight. They are ideal for any room. You can buy a plastic window sill inexpensively from our company.

Buying a window or which window sills are best to choose

Everyone, with the exception of lovers of high-tech style, sooner or later has to decide which window sills are better. We assume that readers realize that all the typical models pushed by dealers are not that good, otherwise this review would not have appeared. What are the disadvantages of typical window sills? If we take plastic windows, then the profile is flimsy. It does not withstand not only serious loads, but also exposure to high temperatures. Who wants to drop the ash from a cigarette once and be left with a damaged windowsill? The Werzalit advertisement demonstrates exactly this situation, and we decided to make inquiries.

Moeller window sills – a new look at the usual

Window sills of this brand are distinguished by a qualitatively new level on the market. The material, made using the latest technologies, consists of a mixture of wood chips and PVC microelements. This combination makes the products fire-resistant and resistant to chemical damage.

Compared to the standard structure, these window sills have a lower coefficient of thermal expansion. This property makes the products universal for installation in any room, including saunas, baths, and swimming pools. From a technical point of view, this texture allows it to withstand a load of over 400 kilograms. When covering window sills, KLEIBERUT polyurethane adhesive is used.

Features of choice:

- High strength and reliable protection from external factors. You can dance on it in a group, sunbathe and shower. The quality will remain unchanged;

- Rich color palette - a wide range of colors for every taste, designed in classic wood tones;

- Environmental safety - all materials undergo quality control, which is confirmed by European certificates;

- High service life - manufacturers guarantee that the products will provide comfort and coziness to your home for 40 years.

To conclude our review, we provide a comparative description of the main technical parameters of all three brands (the “result” column contains data obtained after personal testing of samples by our company for compliance with the parameters declared by the manufacturers):

Non-standard option for combining materials

Requirements for safety, environmental friendliness, and the absence of toxic elements in plastic alloys prompted manufacturers to come up with an unusual idea. They began to add a wood component to the PVC mass. Combining materials increases strength and resistance to impacts and deformation, and reduces weight. The scope of application is quite wide: kindergarten, school, hospital and all institutions where safety and low toxicity are needed. Regarding the price, everything is affordable, the outer surface is made of wood and tinted brown. If the customer wants his own color scheme, then film lamination will help create the ideal option.

Manufacturers and their features

Our catalog contains products from major manufacturers:

- Tecton . Feature: production of textured and veneered structures from solid softwood. They have high strength and are practically not subject to deformation.

- German Danke are premium products. Production is carried out using a unique technology developed by the company's employees. The advantages of the product are its environmental friendliness, resistance to dampness, abrasion, scratches, and ease of care.

- Buying plastic structures from the German manufacturer Moller means getting a structure of impeccable quality, resistant to temperature changes and damage. The products contain PVC and wood flour.

- The plastic window sill of the Russian manufacturer of Stained Glass is equipped with decorative protective films, which allow not only to protect the structure from the negative effects of external factors, but also to add shine.