When purchasing plastic windows, we count on their long and trouble-free operation. I would like to avoid unpleasant surprises in the form of warped frames or cracks in them after several months or years. A properly selected profile for plastic windows is the key to the strength and durability of the entire structure. What types of profiles exist, how to choose the right one and what to pay attention to?

Types of profiles for plastic windows

GOST 30673-99 specifies the classification of a profile according to its design features.

By class (by wall thickness)

Based on the thickness of the external and internal walls, profiles are divided into the following classes:

- A – the thickness of the outer walls is from 2.8 mm, the inner walls are from 2.5. The best indicators of strength and thermal insulation among all types.

- B – external walls from 2.5, internal walls from 2.0. Compared to class A, they retain heat worse and are more susceptible to deformation.

- C – all profiles that do not fit the parameters of classes A and B. There are no strict requirements for them. It is not advisable to use this type for window frames in apartments.

In non-residential industrial premises, frames from the so-called object profile are often installed. It is thin, does not retain heat well, is easily deformed and therefore is not suitable for an apartment. It happens that unscrupulous companies offer cheap windows made of such material. The “objekt” marking on the protective film will help you recognize deception. Based on other signs, it is difficult to identify a fake at first glance.

Width

The profile has different widths:

- 58 mm is the most common, most often installed in apartments and houses.

- 70 mm – profile width for windows in high-rise buildings or buildings located in cold climate zones.

- 90 mm – premium class with the best sound insulation and insulation characteristics. Piece products, which are not in the assortment of most companies that install plastic windows.

By number of cameras

The number of air chambers in it depends on the thickness of the profile:

- The 58mm has a maximum of three cameras.

- In a product 70 mm thick there can be from three to five.

- With a width of 90 mm, the norm is six chambers.

The more internal chambers, the higher the thermal insulation and noise reduction rates. But in reality, the difference between frames, for example, with a 3- or 4-chamber profile is insignificant.

The corporate profile is uniform in structure and color. To ensure its authenticity, look for the manufacturer's markings on the inside. In addition to the company name, there should be numbers indicating the shift number, date of manufacture and other data related to production.

A few words about double-glazed windows

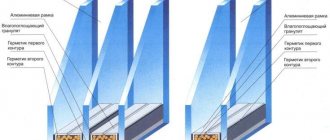

An important aspect is the number of chambers between the glasses in a double-glazed window. They should not be confused with profile cameras.

- For glazing of unheated rooms (balconies, summer terraces) single-chamber double-glazed windows are used.

- For living rooms, a double package is optimal - three glasses separated by two air chambers.

- In cold winter conditions, three-chamber structures are used. They have the best thermal insulation performance, but transmit less sunlight and weigh more. It makes sense to install such windows in the northern regions.

Read about all the intricacies of choosing the elements of a plastic window - profiles, double-glazed windows, seals, fittings - here.

USEFUL INFORMATION: Which fittings are best for plastic windows: reviews, rating 2022

Quality matters when choosing a profile

An important point when choosing a plastic profile, in addition to the stated characteristics, is the quality of the product itself. Profile production is a complex technological process that requires constant monitoring of production and inspection of the finished product. The ExProf* company is the largest Russian manufacturer of profile systems for windows, producing a whole range of type A profile systems with different installation widths. Type A is the highest in profile wall thickness according to GOST.

Photo: class “A” profile is stronger than class “B” profile. The thickness of the walls affects the strength of the profile and welding in the corners of the window structure. All exprof profiles for climatic operating conditions are produced in class I (universal), that is, suitable for use in any climate from the subtropics to the Arctic.

Reinforcing profile for plastic windows

This is a metal insert inside a plastic frame. It increases the rigidity of the structure, since plastic has low elasticity. Without it, the frame will expand in the summer under the influence of temperature, which will lead to jamming of the sashes - they will simply no longer fit into the designated opening. In winter, gaps form between the window elements due to their narrowing.

In Russian climatic conditions, where there are significant temperature differences between summer and winter, only reinforced frames are used.

Structurally, the reinforcing profile is a contour made of galvanized stainless steel. There are two types of circuits available:

- Closed, or O-shaped.

- Open, U- or G-shaped.

There are several important points to note:

- Manufacturers sometimes refer to O-shaped reinforcement as “warm” reinforcement. However, this is not true: the thermal conductivity of metal is higher than that of plastic. Therefore, the more it is in the frame, the worse it will retain heat.

- O-shaped reinforcement is called closed, but to compensate for temperature changes in the dimensions of the metal, a technological break is necessarily made in the circuit.

- A frame with a closed contour is stronger, while a frame with an open contour is lighter and warmer.

According to GOST, the wall thickness of the reinforcing profile must be at least 1.2 mm for standard systems and at least 1.5 mm for colored and frost-resistant structures (painted plastic heats up more).

Features to Pay Attention to

In addition to the technical characteristics of the plastic window profile discussed above, there are several consumer indicators that must also be considered. This is, first of all:

- number of chambers in cross section;

- width of the system for installing double-glazed windows;

- manufacturer of window materials.

It is also important to find a good installation supplier company that employs qualified craftsmen. Unless, of course, you are going to install the window yourself.

Number of profile cameras

There can be two types of prefabricated plastic elements in the window design. The first is a load-bearing window frame made from the main profile. The second type is an opening plastic sash for installing double-glazed windows. In both cases, the profile structure is hollow and in its cross-section consists of chambers separated by partitions, which can be from 3 to 7.

The greater the number of chambers, the higher the structural strength and the higher the performance characteristics. Each wall and partition performs a specific function and therefore the position and thickness of the profile elements are calculated mathematically based on experimental data. The most popular designs in central Russia have 5 chambers .

Profile width

The installation width of the frame determines which profile can be installed in this window and the number of cameras in the internal section. Both of these indicators greatly influence the thermal and sound insulation characteristics, the overall weight of the structure and the cost of the window.

Single-chamber double-glazed windows in the classic version of two glasses have a width of 58 mm and must be installed in a profile of the appropriate section. For two-chamber structures, the profile width must be at least 70 mm. Accordingly, 3-chamber – 90 mm and 4-chamber 110 mm. The last two types of windows belong to the “Premium” class and are installed only in the Far North.

Connecting profile

Designed for joining individual frames that make up a single glazing structure, which are attached at a certain angle. It is needed if you need to glaze a complex broken structure with large windows: a winter garden, a loggia or a partition.

Depending on the required location of the elements to be connected, there are different types of connecting profiles:

- With connection angle 0˚.

- With docking at right angles – 90˚.

- With variable rotation angle, or simply rotary.

- Companies that produce connecting elements unify them with the products of well-known companies (KBE, Rehau, Veka), so choosing the right profile for the frame is not difficult.

Additional (expansion) profile

It is used to increase the size of the window frame when the thickness of its plastic part is not enough taking into account the insulation or finishing of the walls or ceiling. Most often, this element is used for glazing balconies and loggias.

Important! It is strictly not recommended to use an expansion profile only to adjust the frame to the size of the window opening. No matter how competently the additional element is selected and installed, such a design will still be inferior to a monolithic frame in terms of thermal conductivity and strength.

Additional profiles are produced with a width of 2 to 10 cm. The grooves in them are arranged in such a way that to obtain the desired height, parts can be combined: simply insert one into the other. For example, to expand the frame by 8 cm, two extensions 4 cm thick are used. The standard length of the element is 6 meters.

For an insulated balcony, an extension is selected that is identical in quality to the main frame, including with the same reinforcement. Without it, the window block will not have the necessary rigidity.

USEFUL INFORMATION: Panoramic window: in an apartment and a private house, pros and cons

Despite the fact that the extension is fixed on the frame by snapping into grooves, additional fastening to it with self-tapping screws is required. Without this, after a few months a gap will form at the junction.

Glazing thickness

Cross-section of a double-glazed window.

A double-glazed window, as mentioned above, occupies about 90% of the area of the entire window. Today, there are three types of double-glazed windows, differing in the number of glasses installed in them:

- Option with one glass . Not suitable for installation in residential buildings due to the presence of insufficient characteristics of such a double-glazed window. The main flaws in the design of single-glazed windows are poor heat retention, as well as the lack of protection against condensation forming on the glass. With the onset of the cold season, such disadvantages can contribute to the cooling of the room, as well as the formation of an impressive layer of ice on the glass.

- Double glass design . It is the most optimal solution for installation in an apartment or private house due to its good price-performance ratio. The so-called crying of windows is practically eliminated, and heat in a glazed room is retained much better than when using a double-glazed window, which contains only one glass.

- A solution that includes three glasses . With installed triple glazing, you can achieve not only the greatest heat savings, but also maximum protection of the apartment from all kinds of noise entering its territory from the street. Triple glazing has only two disadvantages - high cost and heavy weight.

From the above information it follows that for most buyers the best option would be to purchase double-glazed windows, which will contain three glasses. If you lack funds, you can opt for double-glazed windows, which have the best price/quality ratio.

Stand (installation) profile

A detail that is often overlooked when installing plastic windows. If a replacement profile is included in the delivery, it is usually already attached to the frame. Its functions:

- Protects the frame from damage during transportation.

- Strengthens the structure and prevents it from freezing in the lower part, where the window block adjoins the wall.

- Provides reliable fastening of the window sill and ebb.

Dimensions of the stand element:

- Standard length is 6 meters.

- Width – from 2 to 4 cm.

- Height – from 2 to 3 cm.

Read more about choosing and installing a stand profile here.

Classification by materials

Wood, aluminum, and PVC are used to produce modern window blocks. Each type of material has its own advantages and disadvantages, features and limitations in use.

Tree

The best and most expensive types of wood for the production of window profiles are oak and larch; alder and pine are also used. The high cost of wooden structures is associated not only with the use of natural wood, but also with the peculiarities of the technological process. The material for window profiles needs careful processing (drying, impregnation with antiseptics, painting, varnishing), and in the manufacture of the product, high precision and skill play a key role.

Advantages of wooden windows:

- environmental friendliness;

- good heat-shielding properties;

- maintaining natural air exchange between indoors and outdoors;

- aesthetic natural appearance.

Flaws:

- the possibility of warping and swelling if the production and installation technology is violated;

- low fire resistance;

- high price.

Aluminum

Since metal is not able to retain heat, aluminum profiles are mainly used for cold glazing of balconies or utility rooms, when there is no possibility or need to install warm glazing.

There are “warm” aluminum windows. A special thermal liner is placed in the profile, which provides high thermal insulation properties of such window structures.

The advantages of aluminum profiles include:

- strength and durability;

- ease;

- resistance to external influences;

- fire resistance.

Minuses:

- low heat-protective properties of the “cold” profile;

- high price of the “warm” option.

Polyvinyl chloride

Reinforcing U-shaped profile for structural rigidity

PVC profile has become most widespread for the production of modern windows, due to its low cost compared to wood and aluminum and excellent heat-shielding and operational properties. The main competitive advantages of PVC:

- high level of thermal insulation;

- ease of manufacturing and installation of finished products;

- high resistance to the influence of precipitation and chemical reagents;

- the ability to produce products of various designs and shapes;

- affordable price.

The main disadvantage is flammability, like all plastics. All other user complaints in most cases are related to the choice of low-quality products or installation errors.

Starting profile for slopes of plastic windows

Needed for attaching plastic slopes to the base and joining them together. This is a kind of plastic bracket mounted at attachment points.

The variety of their types is due to the methods of installing the panels. The types of starting profiles got their names from the Latin letters that their sections resemble:

- I-variety. Installed in any position so that the long central shelf is perpendicular to the surface on which the slope is mounted. Plastic panels are attached to a short profile shelf.

- The F-variety has two short shelves and one long one. It serves not only for fastening slope panels, but also covers the joint. With it there is no need for a decorative corner.

- L-profile is the most versatile and popular. Installed perpendicular to the plane of the window, with a wide shelf against the wall. The narrow transverse part is adjacent to the window frame, and a strip parallel to the opening masks the junction of the frame and the slope.

- The P-variety is very similar to the previous one, but has two wide shelves, which allows the element to cover a wider seam.

These starting elements are attached with screws or glue. With their help, it is easy to install plastic slopes without the complex procedure of leveling the window opening with plaster.

Color profile

Many people don’t like the usual white plastic windows precisely because of their uniform design. However, there has long been a way out of this situation: windows made of colored plastic. Technologies make it possible to obtain a profile of any color, but shades of brown are the most successful: this is how different types of wood are imitated.

Products of the desired color are obtained in several ways:

- Lamination in bulk - color is added at the manufacturing stage, and a protective film is applied to the surface of the element to protect it from sunlight. The cost of such a window is from 14 to 21 thousand rubles.

- Film lamination - the white profile is covered with a multi-layer durable film that imitates expensive wood species. The film can also be applied to the ends of frames, as well as to fittings, such as hinges. It costs less than the previous option: from 9 to 17 thousand rubles. out the window.

- Painting with acrylic paints. The most budgetary method: from 7 to 18 thousand rubles.

- Application of colored plexiglass melt using an extruder. From 15 to 20 thousand rubles.

USEFUL INFORMATION: Multifunctional glass: what is it

Advantages and disadvantages

In terms of frequency of use, such designs are less popular than three-chamber ones. But they have a lot of advantages, for which they are valued :

- Price. This is the most important selection criterion. The budget profile with two cameras, especially from a well-known and trusted manufacturer, makes it possible to get excellent quality without overpaying.

- Light weight. Heavy windows are more difficult to install; old or dilapidated walls need to be additionally strengthened. Light weight avoids these difficulties.

- Environmental friendliness. Plastic windows are safe for residents and pets.

- Durability. If there are no violations during the production of the profile and installation of the window, then the structure will serve for a very long time.

- Tightness. Despite the small number of chambers, high-quality sealing ensures good tightness.

- Fire safety. The material from which the profile is made allows windows to be installed in rooms with high air temperatures.

- Convenience and ease of maintenance.

- Variability of shapes and colors. The profile allows you to make a window with any opening mechanism.

Minuses:

- A small number of cameras.

In the system, each camera has its own function. The two-chamber element has one central compartment and one external one. The outer compartment acts as a heat insulator and drainage device, creating an air gap. All other functions fall on the central cavity - condensate drainage, a base for a reinforcing liner, a place for fastening fittings. Such versatility reduces the service life of the product. - Limited range of uses. The profile is not recommended for installation in regions with frosty winters, as well as on large windows.

Attention! This option is great for glazing loggias and balconies.

Reviews from real users

The advantages of designs with two cameras in the profile are noted:

- budget;

- light weight;

- high-quality thermal insulation for “cold rooms”;

- fire safety;

- environmental friendliness.

Cons:

- poor thermal insulation at low temperatures;

- not all companies produce a similar version of profiles.

Finished products are not produced; windows should be ordered according to individual sizes.

Here you can read a real review about the use of a double-chamber plastic window.

Manufacturers of profiles for PVC windows: rating

The variety of window profiles makes choosing difficult. On the one hand, I want the quality guarantee that well-known manufacturers provide. On the other hand, it is undesirable to overpay for brand popularity.

All brands, with the exception of Salamander, are manufactured in Russia according to Western standards and using imported equipment. Therefore, the quality of products of the same brand produced at different factories may differ slightly in quality.

Manufacturer rating based on reviews:

- Veka. A German company, profile systems are produced at factories in the Moscow region, Novosibirsk and Khabarovsk. There is an ISO 9001 certificate, the products are awarded the German RAL quality mark. The buyer can choose from 6 types of profiles with 3, 4, 5 and 6 chambers with a width of 58–90 mm.

- Rehau. A company from Germany has been producing profiles in Russia since 2002 at a certified plant in Gzhel. The leader in the number of products produced per year, it offers 7 models with 3, 5 and 6 chambers and mounting widths of 60, 70 and 86 mm.

- KBE. A German company with factories in Voskresensk and Khabarovsk. 7 modifications of profile systems, there are 3-, 4-, 5- and 6-chamber options, width – 58, 70, 88 and 127 mm. With the same level of quality, KBE frames will cost about a quarter less than Veka and Rehau products. The manufacturer issues an Official Partner Certificate to the best window assembly companies.

- MONTBLANC. The manufacturer is an international company with 4 factories in the CIS. Produces 7 models from 58 to 120 mm wide with 3, 4, 5 and 6 chambers.

- Salamander. The entire profile is produced only in Germany, so it costs more than competitors with Russian factories. It has an attractive design; there are 3 types of profile systems with a width of 60 and 76 mm.

- Grain. Domestic manufacturer with a plant in Ufa. The line includes 6 types of profiles with a width of 58 and 70 mm with 3 and 5 chambers. The most famous models are Vector70 and Vector58.

- Expr. A large Russian company that produces profiles adapted to the conditions of Siberia using German and Austrian equipment. Offers 9 types of profile systems: 2-chamber for balconies and 4-, 5- and 6-chamber with widths of 70, 101 and 118 mm. 4 types have a built-in ventilation system.

- Proplex. Russian company with a full production cycle from profile manufacturing to final assembly. The structures were designed jointly with Austrian developers. The line includes 6 models with 3, 4 and 5 cameras with a width of 58–127 mm.

- Deceuninck. A Belgian concern with a factory in the Moscow region produces 5 types of profiles, 3-, 5- and 6-chamber, 60–84 mm wide.

- Kaleva. Moscow profile manufacturer and window assembler rolled into one. Offers 2 classic models and 3 designer ones with the same mounting width of 70 mm and 4–6 chambers.

- Wintech. A Turkish company that makes profiles and accessories for them using German equipment has a certificate of conformity. The line includes 6 models with a width of 50–80 mm and a number of cameras from 3 to 6.

When choosing, beware of fakes and purchase only from trusted sellers. A high-quality profile is the key to the reliability of a plastic window.

How to choose a suitable plastic profile if you need warm windows

To figure out which profile to choose for PVC windows with high energy efficiency, you first need to understand how heat is retained indoors. Fittings, double-glazed windows and, of course, the profile system are responsible for this process. Most heat is lost through the translucent filling, so you need to take care of this part of the window structure first. However, without taking into account the characteristics of the profiles, it is impossible to complete this task, since there are 2 ways to increase the energy efficiency of windows:

- Install thick double-glazed windows

- such integration is only possible in structures assembled from profiles with an installation depth of 70 mm. The number of internal cameras in such windows is usually 5-6 pieces. - Install single-chamber double-glazed windows with selective coating

- such installation does not require a powerful profile. However, the use of 3-chamber systems with an installation depth of 58-60 mm will lead to heat leakage in the area of the sashes and frame, so a 5-chamber profile would be the best option.

To produce warm windows with any type of double-glazed windows, it is necessary to use profiles with increased installation depth for assembly. Otherwise, the energy efficiency of the structures will be insufficient to maintain a comfortable temperature in the interior.