Energy-saving double-glazed windows are framed in a multi-chamber profile, the thickness and filling of which determines the heat transfer resistance of the enclosing structure.

To choose the right translucent design, the consumer should study the types of profiles of plastic windows.

What it is?

The profile of a plastic window is the main structural element of a translucent structure, which serves as a supporting frame and frame for a double-glazed window. The part is manufactured by extrusion from polyvinyl chloride mass in a factory. The thickness, number of chambers, as well as the presence of reinforcement are determined by the requirements of regulatory documentation and the operating features of the future structure.

Profiles for PVC windows can be fixed - mounted directly at the ends of the opening in the wall, or opening - on loop hangers or on roller supports. Opening doors are equipped with handles and locks for ease of operation, increasing user comfort and safety.

Stand (installation) profile

A detail that is often overlooked when installing plastic windows. If a replacement profile is included in the delivery, it is usually already attached to the frame. Its functions:

- Protects the frame from damage during transportation.

- Strengthens the structure and prevents it from freezing in the lower part, where the window block adjoins the wall.

- Provides reliable fastening of the window sill and ebb.

Dimensions of the stand element:

- Standard length is 6 meters.

- Width – from 2 to 4 cm.

- Height – from 2 to 3 cm.

Read more about choosing and installing a stand profile here.

Requirements of regulatory documents for PVC structures

The requirements for plastic windows are regulated by clause 5.5 of GOST 30674-99 “Window blocks made of polyvinyl chloride profiles”, as well as technical conditions that are developed individually by each manufacturer. According to the text of the regulatory documentation, all profiles for PVC windows must meet the following basic requirements :

Before the manufacture of each new type of profile, design and technological documentation must be developed, in which the geometric parameters of the products are indicated, and thermal engineering calculations are also performed.- Materials must meet strength conditions and also withstand temperature changes when seasons change.

- It is recommended to make all window profiles white, or add pigment to the viscous mass during production.

- When manufacturing bent PVC structures, the minimum radius of curvature must be at least 5.5 times the thickness of the product.

- Designs must meet sanitary, hygienic and environmental requirements. The materials from which the profiles are made should not cause irritation to the respiratory tract when heated.

Despite the existence of state standards, many manufacturing enterprises often set their own, more stringent requirements for their products, which increases their popularity among consumers, since such steps are part of their marketing policy.

Metal-plastic windows

The thermal insulation and sound-absorbing characteristics of PVC structures are comparable to those of wooden products, and in some cases even exceed them. At the same time, plastic windows are much easier to manufacture, which, coupled with the low cost of the material, makes them much more affordable.

The main material used for the manufacture of metal-plastic windows is polyvinyl chloride, which in turn consists of ethylene and chlorine. Both materials are of natural origin: ethylene is obtained from petroleum, and chlorine is part of ordinary kitchen salt. PVC structures are airtight - they retain warm air in the house in winter, and in summer they do not allow cool air to leave the room.

Wood-look windows have become very popular for private homes.

Metal-plastic windows are resistant to any type of atmospheric influences, do not collapse or degrade from household chemicals, and if used correctly, do not require complex maintenance, repairs or additional finishing. A high-quality profile used for glazing residential buildings does not change its color, maintaining its original color throughout the entire service life of the window. More detailed information - here

Specifications

Each product that goes on sale is supplied with a quality certificate. The document specifies the following technical characteristics of the profiles:

- Overall cross-sectional dimensions.

- The length of the shipping mark intended for cutting.

- Mounting width of the product's support foot.

- The thickness of the outer and inner walls of the profile, on which the strength of the finished window depends.

- Landing dimension for installing double-glazed windows.

- The number of closed cameras inside the profile (usually from 1 to 6).

- The range of permissible temperatures in which the product can be operated.

- If there is a seal installed on the profile, the reliability class of the polymer flexible material is (A, B, C).

- Guaranteed service life subject to normal operating conditions.

In addition to the listed technical characteristics, each profile for PVC windows has 3 certificates - for compliance with technical specifications, current GOST, fire and environmental requirements. These documents are issued by government agencies based on the results of full-scale tests.

dimensions

When contacting a company engaged in the production of PVC windows, the consumer is offered several options for profiles that differ in the width of the product and wall thickness:

- There are 3 standard sizes plastic window profile:

- 58 mm. Standard economy class product. The profile has been repurposed for installation in technical rooms, on verandas and terraces. Inside the supporting element of the frame of a window with these dimensions, from 1 to 3 cameras can be installed.

- 70 mm. A product with increased thermal characteristics. Installed in most living rooms of apartments and private houses. Manufacturers place 4 to 5 cameras inside the profile.

- 90 mm. Energy-efficient premium design with 6 closed chambers inside. Provides the highest heat transfer resistance and can be installed in regions with a harsh northern climate.

- Wall thickness The profile of a PVC window depends on the class of the product, according to the European classification:

- Class A. The outer walls of the structure must have a thickness of at least 2.8 mm, internal walls - 2.5. As a rule, most window structures are installed in residential premises and are made of plastic with a thickness of 3.0 mm.

- Class B. Refers to economy class window units, which can also be used in civilian buildings, provided there are no special requirements. The outer wall is made with a thickness of 2.5 mm or more, the inner wall - from 2.0 mm.

- Class C. The simplest profiles for installation in technical rooms, or when installing windows inside a warm contour (for example, in the presence of a glazed balcony). The thickness of the outer and inner walls is not standardized.

Depending on the width of the product and the thickness of its walls, the strength of the finished structure, durability, wear resistance, and, accordingly, the retail price depend. The most expensive products are considered to be profiles with a width of 90 mm, class A.

Video description

This video provides an overview of the Mont Blanc profile:

VEKA

“Germans” has been the undisputed sales leader for many years. Colored and white profiles up to 91 mm wide are created. The quality of the plastic is so high that it does not turn yellow when used and under the influence of ultraviolet rays. There are 3-4-5-6-7-chamber profiles.

Pros of the manufacturing plant:

- high level of quality;

- wide range of models;

- “immunity” to negative influences;

- models have been developed for various climatic zones;

- There are profiles made in color.

The downside is the high cost of products from this brand.

What types of plastic windows are there?

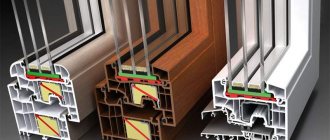

In addition to the width of the products and the thickness of their walls, the profiles used in the manufacture of PVC windows are also classified by the number of chambers and the presence of reinforcement. Each of these parameters is described in detail below.

By number of cameras

Based on the number of internal closed chambers, there are 6 types of plastic profiles for window units.

- Single-chamber . They are used extremely rarely, since such structures not only do not satisfy the thermal characteristics, but also do not provide the necessary strength. They are used when installing blind windows in sheds, storage rooms and other utility rooms.

- Two-chamber . The cross section of such a profile is divided by a plastic partition approximately in the center of its width. The windows are suitable for installation in boiler rooms, basements or attics. As a rule, they are supplied for the installation of single-chamber double-glazed windows or single glazing.

- Three-chamber . Standard economy class designs. Provide resistance to heat transfer at outdoor temperatures down to – 10 °C. Most often, they are used for glazing residential buildings and apartments in the southern regions of our country.

- Four-chamber . The products belong to the middle price category and are installed in the central zone of the Russian Federation. 4 closed spaces provide sufficient structural strength for the manufacture of windows with dimensions of more than 1500 x 1500 mm, as well as balcony doors. Often, 4-chamber windows are used by developers when glazing residential areas under construction as part of the implementation of a development program.

- Five-chamber . The most popular elements for window units, which are ordered by consumers individually. 5 closed chambers are optimal for operation in areas with the coldest five-day temperature - 28 ° C.

- Six-chamber . Exclusive products with a thickness of 90 mm. 6-chamber frames are characterized by impeccable energy efficiency and high retail price. They are mounted on the upper floors of high-rise buildings, and are also used as structural elements for reinforced panoramic windows.

If it is necessary to replace windows in an apartment, experts recommend giving preference to 4 and 5 chamber profiles. In the case of equipping unused spaces that do not have strict thermal requirements, it is sufficient to use 1-3 chamber structures.

When purchasing a profile for a window frame, you should not confuse the number of chambers with the number of enclosed spaces in a double-glazed window, which ranges from 0 to 2, depending on the number of glasses in a single block (from 1 to 3).

By the presence and form of reinforcement

PVC products used for window structures must meet strength conditions, which is especially important when installing translucent structures on upper floors, or when the product area is large. In such cases, manufacturers provide several types of profile design:

Non-reinforced – structures that do not have increased strength requirements.

They are used for the manufacture of windows with dimensions up to 1.8 x 1.5 m, which are installed in buildings that are not exposed to the pulsating component of wind load.- With reinforcement from a U-shaped profile - standard window structures that are widely offered by manufacturing companies to fill standard openings in apartment or individual buildings, as well as in offices and small shopping centers.

- With square pipe reinforcement - reinforced profiles that can be mounted on sites with increased requirements for the strength of the window frame.

- With reinforcement from carbon plates - expensive products of a higher price category, inside of which rigid plates made of aramid fibers are installed. They are distinguished by impeccable thermal characteristics, without reducing strength.

When choosing a profile with reinforcement, the consumer should take into account that such a product must consist of at least 4 - 5 chambers in order to prevent the formation of a cold bridge.

Accessories

Reliable fittings must meet the following requirements:

- Wear resistance. It is characterized by the number of cycles (opening/closing) until the end of which the mechanisms will properly perform their functions. For high-quality products, this figure is never less than 10,000 cycles.

- Ease of maintenance . Elements of common types of fittings are easy to replace if damaged, which cannot be said about exclusive products.

- Anti-corrosion qualities . Components and mechanisms made of metal should not rust after contact with moisture. Ideally, stainless steel is used, but such fittings are not cheap, so coated options are increasingly found, the service life of which is not nearly as long.

- Ease of use . The opening elements of the block should open easily without backlash or distortion, without making unnatural sounds.

Designs with increased protection

Anti-burglary fittings are distinguished by a locking mechanism in the form of pins and strikers and are designed to prevent entry into the room by opening the sash from the street. Such mechanisms are useless if an attacker breaks the glass.

To protect against such burglary, special roller shutters were developed. Unlike conventional roller shutters, they are installed directly into the opening, and not on the facade. This does not spoil the appearance of the building, but slightly reduces the translucent glazing area.

Useful hardware functions

- Microlift . An additional mechanism for supporting large opening elements in order to reduce the load on the hinges and prevent sagging of the sash.

- Child protection . It is mounted into the frame profile or directly into the handle, preventing the child from opening the sash on his own.

- Reclining position regulator. An additional element of the tilt-and-turn mechanism, which allows you to fix the sash during ventilation.

A separate category includes special ventilation elements - supply valves, overhead ventilators and similar devices. They are installed to ensure the required level of air circulation in the room, which after installing PVC windows may turn out to be excessively airtight.

The best manufacturers

- Maco. The Austrian company mainly specializes in the production of rotary or tilt-and-turn products. The company's product range is very wide and includes modifications with five levels of burglary protection.

- Roto. A German manufacturer, which is remarkable in that it provides a ten-year guarantee for its products.

- Winkhaus. The company has been operating in the hardware market for more than 50 years. Simple and easy to install products.

Which is better to choose?

Taking into account the above classification, as well as the requirements for profiles for plastic windows, when equipping a typical home, experts recommend paying attention to the following types of profiles:

- Width – at least 70 mm.

- The number of chambers is from 4 to 6; before choosing, you should study a sample of the cross-section of the profile so that all the chambers are located one behind the other, which ensures that the entire product is included in the work.

- Wall thickness - class A.

- The permissible temperature difference is no less than -30 to +50 oC.

- Guaranteed service life – from 25 years.

- Reinforcement - steel U-shaped channel. When installing a window on a balcony, it is better to avoid reinforcement, as it reduces the thermal parameters of the structure.

- The width of the landing plane is not less than for a 2-chamber double-glazed window.

One of the most important criteria for choosing a PVC product for a window block is the popularity of the brand, the year the manufacturer was founded, which determines the work experience, as well as the presence of positive reviews from satisfied consumers on online forums.

Rating of the 5 best manufacturers

There are many profiles on the market for the manufacture of PVC windows from manufacturers who compete fiercely with each other in terms of quality and optimal price.

Each consumer can make a mistake in their choice, which will affect the operation of the installed structure.

To help property owners, below are the names of the most popular manufacturing companies on the market that produce plastic window profiles.

As a rule, individual profiles are not supplied for retail sale from the factory, since these enterprises work under contracts with window companies. Thus, the prices given below are indicative and may be adjusted depending on the number of products ordered, the dealer’s internal pricing policy and other parameters.

Montblanc

The plant is based in Elektrostal, Moscow region, the company has been supplying products to the domestic market since 2001 . The range includes standard products with a width of 58 and 70 mm, with 3, 5 or 6 chambers and U-shaped channel reinforcement.

Average retail price - 450 - 500 rubles / m.

Salamander

The brand was founded in the 70s of the last century in Germany. For more than 12 years, a plant producing plastic window profiles of this brand has been operating in our country. The company's assortment includes most types of products with a thickness from 58 to 90 mm.

Average retail price - 520 - 570 rubles / m.

KBE

Also known throughout the country, the company has been supplying raw materials and finished window structures for civil facilities for more than 20 years. The company specializes in the production of economy-class profile products for glazing of warm or cold contours.

Average retail price - 400 - 480 rubles / m.

Rehau

A German company that over the past 20 years has made successful investments in the construction of several factories in the Russian Federation, including in the Moscow region.

The company's products are in high demand from window manufacturing companies, as well as individuals and sales agents.

Average retail price - 450 - 600 rubles / m.

Full information about Rehau windows here.

VEKA

The Russian enterprise, known throughout the country, was founded more than 15 years ago. It has its own full-cycle production facilities, including an extruder for profiles. The plant specializes in the production of mid- and high-price products.

Average retail price - 550 - 700 rubles / m.

Read more about Veka windows in the article at the link.

Video description

In this video, watch a review of the Salamander Streamline profile:

- Stylish and sophisticated appearance. Such windows will be an excellent decoration for almost any room.

- There is specialized control of dealers.

We will certainly note the presence of a minus. The price of such windows is 34-41% higher than that of other manufacturers.

KBE

The German company has won special recognition in our market. There are also factories in Russia that create profiles. There are standard models with a profile width of 59 mm, 71 mm, 89 mm, 128 mm.

Positive characteristics:

- high-level quality guarantees a long service life;

- affordability;

- wide variety of models.

Each buyer will be able to find a model that will suit his needs and financial capabilities.

MONT BLANC

Budget, but very high-quality products, which are known very well to Russian buyers. At the current time, a line of seven different types of profiles up to 120 mm is offered. There are three-chamber and five-chamber options.

Main advantages:

- affordable cost;

- high performance;

- a fairly wide range of various products for any conditions and climatic features.

Consequences of the wrong choice

Not every owner of a residential property knows how to choose the right profile for making PVC windows. In case of errors, a number of negative consequences may occur during the operation of the installed structure:

- Inconsistency between the thermal characteristics of the product and the required climatic parameters in the room.

- Deformation of heavy sashes when torn off.

- Vibration of a window structure under the influence of the pulsation component of wind loads at a height of over 30 meters.

- Vibrations and insufficient sound insulation due to the small number of closed chambers inside the product.

- Unjustified expenses when purchasing a profile with maximum characteristics.

Before placing an order, you should consult with a professional, present him with architectural plans of the premises, and also draw up technical specifications so that he can select the optimal profile at a reasonable price.

Connecting profile

Designed for joining individual frames that make up a single glazing structure, which are attached at a certain angle. It is needed if you need to glaze a complex broken structure with large windows: a winter garden, a loggia or a partition.

Depending on the required location of the elements to be connected, there are different types of connecting profiles:

- With connection angle 0˚.

- With docking at right angles – 90˚.

- With variable rotation angle, or simply rotary.

- Companies that produce connecting elements unify them with the products of well-known companies (KBE, Rehau, Veka), so choosing the right profile for the frame is not difficult.

Color profile

Many people don’t like the usual white plastic windows precisely because of their uniform design. However, there has long been a way out of this situation: windows made of colored plastic. Technologies make it possible to obtain a profile of any color, but shades of brown are the most successful: this is how different types of wood are imitated.

Products of the desired color are obtained in several ways:

- Lamination in bulk - color is added at the manufacturing stage, and a protective film is applied to the surface of the element to protect it from sunlight. The cost of such a window is from 14 to 21 thousand rubles.

- Film lamination - the white profile is covered with a multi-layer durable film that imitates expensive wood species. The film can also be applied to the ends of frames, as well as to fittings, such as hinges. It costs less than the previous option: from 9 to 17 thousand rubles. out the window.

- Painting with acrylic paints. The most budgetary method: from 7 to 18 thousand rubles.

- Application of colored plexiglass melt using an extruder. From 15 to 20 thousand rubles.

USEFUL INFORMATION: Multifunctional glass: what is it