They try to make the front part of the building as presentable and aesthetically attractive as possible. One of the currently popular ways to implement such tasks is facade glazing. This type of finishing gives the building its characteristic glass lightness and modern appearance, and on the inside it makes the room lighter and visually more spacious.

Facade glazing is used in the construction of office complexes, sales centers, retail establishments, as well as in the construction of private houses, for example, in the loft style.

Advantages and disadvantages

Finishing the façade of a building with glass has the following strengths:

- First of all, this is an original appearance, realized using glass of different shapes, colors and degrees of light transmission.

- The high level of natural light during the day allows you to significantly save on electricity, and working in daylight is much more comfortable.

- Facade glazing is made using high-strength types of glass and high-quality profile systems, which, together with modern installation technologies, allows us to implement reliable structures that are resistant to any natural phenomena.

- The use of energy-saving glass and the correct glass unit formula ensure high sound-absorbing and heat-insulating properties of the façade of the building.

- The design is easy to maintain and repair; if the integrity of one of the sections is damaged, only the damaged element is replaced, without dismantling the components of the profile system.

Disadvantages of glass facades:

- Finishing facades with glass requires the participation of a team of experienced, highly qualified specialists and sophisticated equipment;

- Compared to other design options, facade glazing is noticeably more expensive, especially if you use high-quality branded profile systems and double-glazed windows;

- In order for the glass facade to maintain its aesthetic properties, it must be washed regularly.

Arrangement of facades

The design of the system is made using several elements:

- a supporting frame made of aluminum or steel supporting profile, to which double-glazed windows will subsequently be attached;

- tempered glass or facade double-glazed windows, which are attached to a metal base by applying an adhesive-sealant to them and using high-strength adhesive tape.

To construct a façade, increased rigidity of the building frame is required. There is often a need for special preparation of the frame before starting work on its glazing. Gaps and cracks formed on the façade between glass blocks must be of a minimum size. The deflection of interfloor slabs should also be kept to a minimum.

The outer surface of the building does not have cracks and gaps into which dust and dirt could get clogged, due to which the operational characteristics of the structure are significantly increased. In terms of the degree of moisture resistance, sound insulation, thermal conductivity and duration of use, the glazing of houses is not inferior to ordinary light-transmitting facades, but at the same time it significantly benefits in aesthetic terms due to its solidity.

Warm and cold facade glazing

Profile systems for cold facades are made of either plastic or aluminum, but the latter option is more common, which is noticeably cooler than PVC structures. The translucent filling in cold facades is, as a rule, single glass or a single-chamber double-glazed window, which uses ordinary glass with low energy-saving characteristics; dried air is used as a filling gas.

The cold glazing profile itself is rarely thicker than 5 cm, and the number of insulated chambers in it does not exceed four (usually 3).

Warm facades are constructed from a wide frame profile with a cross section of 5-10 cm. Plastic products contain at least 5 chambers, in which thermal insulation materials are additionally used. In aluminum structures, profile systems with thermal breaks are used, which helps reduce heat loss during the cold season.

Energy-efficient double-glazed windows with two or three chambers, different thicknesses of glass and spacer frames are installed; Inert gas (argon, krypton) is used as a filler.

What is it like?

Cold facade glazing is a very profitable option when arranging large industrial buildings, retail sites, entertainment centers, as well as small premises such as balconies and loggias. This solution will help give the facade an attractive appearance, as well as protect the interior space from negative external factors, be it moisture or direct sunlight. The main materials from which such structures are made are metal, wood, plastic and aluminum.

Facade systems made of aluminum have gained the greatest popularity both in CIS countries and around the world. Such structures have a sufficient margin of safety, as well as relatively low weight and a pleasant appearance. It should be borne in mind that the level of thermal insulation of such a design is very low, and all because with cold facade glazing a simple single-chamber double-glazed window is used. Also, energy-saving properties directly depend on the quality of the assembly, the aluminum profile itself and the fittings used.

Types of facade glazing and glass fixation systems

There are two main methods of finishing facades with glass: framed and frameless. Frame glazing includes structural, semi-structural and mullion-transom glazing. Panoramic, modular and cable-stayed options are considered frameless.

Mullion-transom glazing of facades

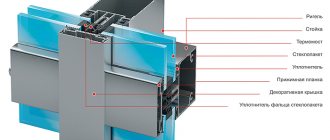

The frame of such systems is formed from vertical metal racks and horizontal crossbars. The main load falls on the vertical elements - transverse crossbars are necessary to prevent longitudinal deformations of the structure.

A translucent or opaque filling is mounted into the supporting structure, which is pressed from the outside with a special profile, after which it is covered with decorative overlays. Warm buildings are filled with double-glazed windows with two or three chambers; in cold versions, single-layer glass is usually used.

As a rule, the thickness of the visible part of the profile on the inside does not exceed 5 cm, which in most cases is sufficient to ensure the required design rigidity of the structure. Decorative overlays on the outside can be painted in any color that matches the overall design of the building. In warm mullion-transom systems, special thermal inserts are used, by adjusting the width of which it is possible to equip the facade with double-glazed windows of varying depths.

Semi-closed mullion-transom facades

A variation of the previous glazing option, in which one of the joints (vertical posts or horizontal crossbars) is fixed with sealant without clamping strips and painted over in the color of the glass. When using this assembly method, maintenance of the facade becomes significantly more complicated, for example, in the event of damage to one of the double-glazed windows, but externally such structures, as a rule, look more attractive.

Structural glazing of facades

Structural glazing Shuko

Basically, structural facades have a mullion-transom system, made with a number of features. There are no load-bearing structural elements on the outside of the structural systems, which is why the façade of the building appears monolithic and appears to be made of solid glass.

The main frame is located inside the room, and only glass or opaque filling is located outside. The joints between the glazing elements are minimal and practically invisible from the street, the same applies to opening elements, if they are provided in the facade. The tightness of the junctions and the fixation of double-glazed windows in the structure is ensured by a special sealant.

Structural facades look quite impressive, but there are a number of points that need to be taken into account:

- Assembly is quite complex and labor-intensive, which significantly affects the final cost of the structure.

- It is advisable to use a steel supporting profile, since aluminum products, due to their lower rigidity, can only be used for low-rise buildings.

- Structural facades involve the use of double-glazed windows of a special design: the outer glass is larger than the inner glass.

- The outer glass must be made of tempered material. In addition to increasing the impact resistance of the glazing, tempering makes the translucent filling more resistant to solid particles (for example, sand), preventing possible erosion.

- Since part of the load falls on the glass and, in particular, on the junctions between the blocks, it is necessary to use a high-strength weatherproof sealant.

Semi-structural glazing of facades

As with structural structures, the entire load-bearing frame is located on the inside of the building, however, in addition to adhesive sealant, thin clamping strips are used to fix the double-glazed windows. Their thickness is several mm and when painted to match the glazing, they are practically invisible from the outside.

Compared to the structural option, semi-structural facades are easier to install and subsequently maintain. Double-glazed windows can be installed on the inside of the building; in addition, it is easier to design systems with complex geometry and opening elements. This makes glazing more reliable, while simultaneously reducing its cost and expanding the variability of design solutions.

Panoramic

This type of facade glazing is characterized by the installation of continuous glass from floor to ceiling within one floor. There are no horizontal joints inside and outside the premises, which imposes a number of requirements on the double-glazed windows used. For panoramic façade systems, it is advisable to use reinforced, laminated or tempered glass.

Modular

The modular facades are based on the same mullion-transom system. Ready-made blocks (modules) are manufactured in a factory, after which they are delivered to the construction site and installed.

This assembly option allows you to integrate a number of systems (for example, air conditioning) at the production stage, which is much easier to do in a factory environment.

Spider glazing of facades

A type of frameless cold glazing, since this method allows the use of either single glass or single-chamber double-glazed windows. The name of this assembly option is associated with the shape of the main fastening element, which in appearance resembles a spider.

The central part of the fastener (head) is fixed on the elements of the supporting structure; these can be vertical posts or a concrete base. Fastening is carried out using an anchor, threaded connection or welding. A special rod is fixed at the corners of the rectangular glass unit, to which one of the legs of the spider-like fastener is mounted. As a result, one spider holds four adjacent double-glazed windows.

In spider facades, there is no external frame, as well as clamping strips, which makes it possible to significantly increase the light transmission of the building walls.

Cable-stayed glazing of facades

A more complex version of spider glazing, in which the function of the supporting frame is performed by a complex structure of tensioned cables and braces holding the translucent filling.

As a rule, such an implementation of a glass facade requires complex preliminary calculations. The rigidity of a cable structure differs significantly from that of a profile structure. There may be backlash and deformation in it if all wind or seismic loads that are possible at the site of construction of the building are not taken into account.

Installation

Structural facades are installed either in a two-sided way or in a four-sided way. Double-sided installation is performed according to the following algorithm:

- First, the post-transom system is installed. Vertical elements are installed, securing them to the upper and lower ceilings, then the crossbars are mounted. Some systems are assembled without crossbars; in such structures there are transverse fasteners only in the places where the glass adjoins the ceiling.

- Fasteners (clamps) are inserted into the U-shaped groove on the sides of the glass unit.

- Double-glazed windows are placed on support pads and fixed with self-tapping screws through clamps to the outer end of the frame profile.

In addition to mechanical fasteners (clamps, self-tapping screws), double-glazed windows are attached to sealant - all joints are coated with it. After installing the glazing, the seams of the structure are filled with thermal insulation materials and sealed with a decorative layer.

Four-sided installation is carried out without any mechanical fasteners. The glass unit is glued on all sides to the supporting structure with sealant.

What kind of glass and double-glazed windows are used?

More than 90% of the area of glass facades is occupied by a double-glazed window, and the level of heat and sound insulation of the room mainly depends on its qualities. For glazing facades, glass is used, which is characterized according to several criteria.

Number of cameras in a double-glazed window

The most affordable double-glazed windows with one chamber, at the same time, the convection heat loss inside the room will be less, the more sealed sections the double-glazed window contains. However, an increase in the number of chambers implies a corresponding number of glasses, which ultimately leads to an increase in the total weight of the double-glazed window and the structure as a whole. For example, a square meter of a single-chamber double-glazed window, each layer of which consists of a 4 mm sheet, will be approximately 10 kg lighter than a double-chamber one made of the same material.

Energy efficiency indicators

The energy efficiency of a double-glazed window is determined by the presence on one of the glasses (usually on the outside) of a special coating that reflects infrared (thermal) radiation into the room. Thanks to this coating, glass transmits more than 90% of light in the visible spectrum from the street, while simultaneously reflecting up to 70% of heat back into the room.

In hot weather, the energy-saving surface prevents direct sunlight from heating the rooms, and in cold weather it significantly reduces the transfer of heat from the inside of the building to the street. The coating reduces losses only in the infrared spectrum of radiation - the energy-saving layer does not affect the other thermal insulation characteristics of the glass.

The use of an energy-saving coating makes it possible to reduce the heat loss of a single-chamber double-glazed window by 50% in comparison with a double-chamber glass unit, the glass in which does not have an insulating layer, while the weight of a single-chamber glass unit will naturally be less.

Soundproofing

The degree of noise absorption is especially important in buildings whose façade faces busy highways, railway lines or active construction sites. The greatest soundproofing effect is achieved by using glass of different thicknesses located at different distances from each other.

For single-chamber products, glass with a thickness of 6 mm for the outer layer and 4 mm for the inner layer is used. As a result, each layer dampens vibrations of a certain frequency, which gives a noticeably greater effect than when using glasses of the same thickness.

Increasing the number of cameras with the simultaneous installation of different glasses increases the level of soundproofing of the room, but more in the high frequency range. Low frequencies, such as railway noise or thunderstorms, are absorbed noticeably less well.

Tinting and polarizing coating

The use of such solutions is relevant in cases where it is necessary to exclude the transparency of glazing in one of the directions (usually from the street).

Tinting absorbs part of the spectrum of light flux, providing almost complete opacity of the facade in bright daylight. Polarization works on a different principle: the light flux from the outside easily penetrates into the room, but the internal contents of the building remain hidden to an outside observer.

Service

Like any element of a building, facade glazing, despite its reliability and durability, requires maintenance and sometimes repair. During operation, the rubber seals lose their elasticity, the sealing of the openings is compromised, the metal frame is slightly deformed, and adjustment of the fittings of the opening elements may also be required.

When installing cold systems, building owners often have a desire to change the glazing to warm ones or install double-glazed windows with a high level of noise absorption. All repairs or maintenance of glass facades must be carried out by specialists, this will ensure their durable and safe operation.

Useful video about the types of facade glazing:

Subscribe

Profile material

- Plastic is highly durable and economical. It has excellent heat-saving function. In addition, it is easy to install and has high sound insulation.

- Aluminum is widely used in building glazing. The material is quite strong, durable and easy to install. Its superiority is much higher than that of plastic or wood, and it fully complies with all GOST requirements. Aluminum is a less expensive option on the Russian market. Its system is easy to install. But it also has its drawbacks. Since it is primarily a metal, it tends to freeze at low temperatures.