home

> Glazing of facades

> Glazing systems

> Spider glazing

Advantages Examples Calculation Application Our work Bonuses Prices Guarantees

Calculate the project

The construction company carries out spider glazing of the facades of various buildings and structures, having a staff of highly qualified specialists, modern equipment and tools for timely and high-quality completion of work.

Types of glazing where the spider system is used

Panoramic glazing

The variety of aspects in the practical application of the spider glazing system allows us to cover all typical designs of modern buildings. The materials on which this system is based are capable of providing protection from UV rays and have high heat capacity. Using an aluminum profile and specially treated glass, the spider system guarantees enhanced strength characteristics of the entire SPK.

Cable glazing

Point glazing technology, in which glass is attached to the supporting frame using a system of tension structures (cables). It is the most advanced technology and allows you to create the most transparent facades.

Glazing of entrance groups

Decoration of building entrances with translucent systems with an aluminum frame. The glass entrance looks very stylish and gives the building a richer look.

* The service is provided for a complex order of facade glazing.

Glazing of canopies

Decoration of building canopies with translucent structures. Protects the entrance area from precipitation and serves as an excellent decorative element.

* The service is provided for a complex order of facade glazing.

Do you have questions about spider glazing?

Leave a request on the website or call and our specialists will advise you in detail on your project.

To get a consultation

Components of planar glazing

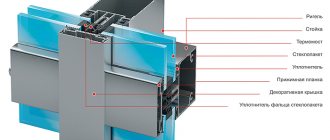

Planar glazing includes glass panels, which can be of different sizes, a load-bearing subsystem and spyder mounting brackets.

The type of brackets used depends on the type of system, the material used and the substructure. There are four types depending on the number of bolts attached to the bracket. Stainless steel is used for the manufacture of metal elements, and various materials are used for the supporting subsystem, for example, glass, steel, wood, aluminum. Planar glazing can use laminated glass, solar control glass, triplex glass, energy-saving glass and other types of glass. The production of load-bearing glass elements is made from tempered glass having a thickness of at least 6 mm. Its quality is checked using the “HST” test, which guarantees its long-term operation.

According to the technology, with spider glazing, minimum tolerances of less than 1 mm can be allowed; deviations not exceeding 0.3 mm are possible for the holes made. Glass, like stainless steel, can be classified as one of the most durable, inert and corrosion-resistant artificial materials.

Features of spider glazing

Video about fire glazing

The main feature is the absence of load-bearing frames between the glass panels. Thanks to this, the effect of lightness and airiness of a huge building is created. The frame is invisible, and the structure itself has high strength characteristics.

When installing a spider glazing system, the number of frame nodes is minimal, so the interior spaces look lighter and more spacious. Glass can be installed at different angles. This helps to create translucent structures of almost any shape.

Advantages of planar glazing

There are a number of features that distinguish the spider glazing system:

- Variety of shapes and sizes of facades.

- Lightweight structures with increased glazing area.

- High light transmission rate.

- Strength, reliability, durability of fasteners.

- High installation speed.

- Low cost of maintenance.

Spider glazing price per sq.m.

In the technological process of installing a spider system, traditional load-bearing frames between panels are not used; double-glazed windows are directly mounted with special devices: rods and spiders.

specializes in performing work on spider glazing of facades at a low price per sq.m., guaranteeing customers high quality installation and further operation.

| Name | Unit. | Price |

| Domestic “fitting” mount | per m2 | from 13,000 rub. |

| Foreign "fitting" mount | per m2 | from 15,200 rub. |

Disadvantages of planar glazing

Some chaos. A large number of types of fastening elements and facade shapes introduce difficulties at the design stage. There are no unified projects. Each facade is individual.

Facade glazing in general, and the spider variety in particular, are developing dynamically. New types of fastening elements and connection units are appearing. Structures are constantly becoming lighter, reducing the cost per square meter of façade.

Similar articles

- Stained glass glazing of facades: modern Spider

.

...

In modern urban conditions, stained glass

glazing

allows you to visually expand the space and increase the amount of light. Read more - Comparison and rating of subsystems for ventilated…

Metal cassettes harmoniously combine with stained glass windows,

glazing

, and also create a technogenic style for the facade of the house. Read more - Insulated panels

New entries.

Stained glass glazing

of facades. Thermal engineering calculation of the outer wall of a building with a ventilated facade. Read more - Installation of ventilation facades: step by step about insulation technology...

New entries.

Stained glass glazing

of facades. Thermal engineering calculation of the outer wall of a building with a ventilated facade. Read more - Which is better: siding or plaster?

Stained glass

glazing

of facades. Thermal engineering calculation of the outer wall of a building with a ventilated facade. Anti-aircraft lamp - what kind of design is it? Read more - Plastic panels

New entries.

Stained glass glazing

of facades. Thermal engineering calculation of the outer wall of a building with a ventilated facade. Read more

Aerial monumentality.

If you are a builder or architect, spider glazing is a real technological gift for you! The absence of metal profiles in the design, as well as any other types of frames that cut through the surface, makes spider glazing systems impeccably smooth and gives the building facades a monumental effect. But not the heavy and solid look that stone carries, but that special airy monumentality that can only be achieved with the help of glass. Planar glazing undoubtedly has a great future and virtually limitless potential. After all, it provides complete carte blanche to architects, allowing them to create real masterpieces. Take advantage of this opportunity and order spider glazing from!

Stylish ergonomics

What is important for owners of offices and business centers when it comes to equipping the premises? Ergonomics and efficiency! These are the advantages that planar glazing provides. The absence of profiles on glass partitions will not only save you useful space, but will allow light to spread unhindered. Even if you have a small office space, equipped with partitions from , it will look spacious and bright.

And not just to look: a bright, sunny office has not only aesthetic value, but also quite material benefits for the owner. After all, the more intense the natural light in the room, the lower the cost of electricity. In addition, freed from frames and profiles, spider glazing adds a sense of spaciousness to office employees. Transparent, almost invisible glass borders do not cause a cage effect, which has a beneficial effect on the psychological comfort of workers and, as a result, on labor productivity.

Are you interested in spider glazing that is optimal in cost and quality? Just contact us - and Glass Architecture LLC will provide you with this ratio. Moreover: since we provide our clients with free measurements for spider glazing, its price becomes even more reasonable.

has its own production, which means that we are responsible for every centimeter of glazing. The company takes the entire scope of work, from design to installation, into its own hands - all you need is the desire to have the perfect glazing of a facade or room. And, of course, contact us. Do it right now!

To the load-bearing structures of the building

Attaching spider systems to the load-bearing elements of a building is the most affordable method of installing glazing, since in addition to fastening fittings it does not require the construction of additional load-bearing structures. In this case, the connectors of the beam brackets, connected to the glass modules via hinge connections, are attached with anchor bolts directly to the load-bearing parts of the structure.

The scheme for fastening spider glass blocks using this method looks like this:

Advantages:

- Easy to install.

- Low price.

Disadvantages: tying the system to rigid structural elements limits the possibilities of using spider glazing. This gap is easily filled by using this method in combination with others.

To metal racks

Attaching spider systems to metal racks is the most common method of installing glass structures. To implement glazing, additional columns of various sections are made from stainless steel or aluminum, which in turn are attached to rigid elements of the supporting structure. Then the spider elements of the glass modules are fixed on the installed metal stands.

The assembly diagram for spider glazing using this method is as follows:

Advantages:

- The ability to create designs of a wide variety of shapes.

- Affordable price.

- Simplicity and ease of installation.

Flaws:

- The need to use additional supporting elements limits the free space.

- Metal racks to a certain extent reduce the light transmittance of the structure.

To the cable-stayed system

Attaching spider structures to a cable-stayed system is an expensive method, which, however, is widely used by designers to create an unusual “industrial” interior or exterior of some buildings.

Spider glazing in this case is fixed using vertical tension rods and stainless steel cables, which are connected to beam brackets (spiders) through horizontal tubes. The cable-stayed system, in turn, is connected by point fastenings to the load-bearing parts of the structure.

The fixation diagram for the elements of a spader system of this type is presented below.

Advantages:

- Unique design.

- High level of transparency.

Flaws:

- High price.

- The need for accurate calculations of load-bearing structures.

- The problematic nature of glazing structures of complex geometric shapes.

Advantages of the spider finishing system

The spider system of facade cladding has a number of undeniable advantages, analyzing which many property owners decide on such finishing.

These include:

- the ability to implement non-standard architectural techniques;

- construction of lightweight modernized structures to replace bulky facades with massive walls;

- safe installation of tempered glass panels;

- resistance of products to environmental influences;

- quick and uncomplicated installation, allowing to reduce the construction time of the building;

- a minimum number of load-bearing structures, which reduces material costs;

- practicality and long service life with a minimum of maintenance and service costs;

- natural lighting due to the light entering the room, which will reduce energy costs;

- simple repairs if necessary;

- ease of use of the panels and easy maintenance of the finish.

Visually, the spider system is a solid surface with almost invisible seams that do not in any way affect the architectural appearance of the house. The sealants used in the process increase the level of thermal insulation of the facade and protect the building from moisture.

Swivel mount

Maintaining the required balance allows the use of a hinged mount that can take on the action of loads. The manufacture of a hinged bolt head compensates for possible deformations of the facade glass, without creating tension in the places where the spiders are attached. It is envisaged to use two hinge bolts for vertical glass panels, and four fastening points for inclined ones.

Support structures and glass have different expansion characteristics, therefore, to prevent glass from breaking, glass panels must move freely relative to the support structures. This can be achieved by using stainless steel bolts. The bolt heads are attached to steel segments, and washers and gaskets made of elastic material are used to avoid metal contact with the glass surface.

At the joints of the panels, the seams are sealed with high-quality sealants. They must have stable fixation, resistance to ultraviolet radiation, moisture and air tightness. The seam cavity must be filled tightly and consistently.