To create various building structures, a special material is used, which is called a profile. It can be seen as a window frame, a base for mounting drywall, facade frame and other elements.

The main requirements for the material are lightness and strength, so an aluminum profile is suitable for such purposes. All types of profiles differ from each other in many respects, including filling, shape, and manufacturing method. But more on that later.

Where is aluminum profile used?

Aluminum strips are actively used in the construction of buildings and interior design. This is facilitated by their enhanced strength. The material is most often used to create load-bearing frames that are sheathed:

- plywood;

- siding;

- plastic cassettes;

- plasterboard;

- glass.

However, stronger steel products are used to assemble solid structures. Stone slabs and other heavy materials are attached to them.

Cladding the façade of a building using an aluminum profile

Features of operation

It should be remembered that the connection using bolts or crab systems is serviceable, and periodically - 1-2 times a year - it is necessary to check the connection and tighten the bolts.

Possible problems

It should be borne in mind that the strength of aluminum is still less than that of steel, and a large rack loaded with preparations for the winter is not the best use for duralumin structures. But all kinds of awnings and canopies, enclosures and light shelving are exactly what aluminum corrugated pipes are intended for. In addition, such pipes do not like large lateral loads - the pipe may bend.

Packaging, transportation and storage

Aluminum profiles can be scratched and even bent during careless transportation or storage. Therefore, when transporting, they should be laid in such a way that heavy objects do not put pressure on them (or fall!). A couple of pieces of wood or a bag of putty weighing 25 kg will not do much damage to large pipes, but a fallen door, window, or steel corner may well leave a dent or bend the pipe.

It’s a good idea to pack products in cardboard and polyethylene, especially if the pipes have a decorative coating. There are no special requirements for the storage of aluminum and alloys. But if you know that this alloy is not resistant to corrosion, store collapsible structures under the roof, or even better, in a garage or shed, and not on the street or in the basement.

Technical characteristics of aluminum profile

Aluminum structures are a more profitable purchase than wooden or PVC profiles. However, on several indicators they still lose. Product characteristics can be formulated as follows:

- Durability. The service life of an aluminum structure reaches 60-80 years.

- Environmental friendliness. When climate changes, the profiles do not change their qualities. Thus, when exposed to heat, many materials release toxic substances. This property does not apply to aluminum.

- Ease. The material is very light, but at the same time has the highest possible strength.

- Plenty of imagination. Aluminum can replicate the texture of any other material. In addition, using anodizing, the material can be painted in any color.

- Fire resistance. The aluminum structure cannot be set on fire.

The material protects the walls of the building well from dampness if used for facade cladding. In addition, using the design, you can shift the “dew point” to the outside, which will further protect the room.

Advantages of aluminum profile compared to other materials

Important! Despite its apparent fragility and lightness, aluminum is capable of supporting massive double-glazed windows and other cladding materials.

Aluminum structures are very light and durable

Purpose

Various systems of aluminum profiles are used for the manufacture of translucent structures, external and internal fences, partitions in public, residential and industrial buildings, as well as in the construction of industrial enterprises and shopping complexes. Windows of various configurations, balcony glazing, entrance groups of external/internal opening, pendulum or rotary type, facade structural or semi-structural glazing - these are the main areas of application of various aluminum profile systems

What should you consider when choosing a profile?

Aluminum profiles are the main parts of load-bearing mechanisms, so they must meet a lot of requirements. So, when choosing, the following assessment requires special attention:

- ultimate strength;

- maximum elasticity;

- the degree of maximum contraction under the influence of temperatures;

- viscosity qualities.

In some cases, corrosion resistance, electrical conductivity and heat resistance also need to be assessed. That is, check whether the profile corresponds to the conditions in which it will function.

In order to end up with a high-quality aluminum profile, you need to choose the right alloy for its smelting, taking into account the level of heat treatment and cold hardening. In addition, an important point is the exact observance of dimensions when creating a profile.

T-shaped alloy construction

Prices for aluminum profiles

Aluminum profile

A few words about the manufacturers

Products from both domestic and foreign manufacturers are widely represented on our construction market. It is generally accepted that the standard of quality is imported products, which has often been confirmed in practice. However, it is worth noting two important points in favor of Russian brands. In 2003, GOST 21519 was introduced, which was compiled taking into account world practice. That is, domestic products in terms of quality, which is strictly regulated, are actually no different from foreign ones.

The second important point is the adaptation of products to local climatic conditions. Not all lovers of imported goods take this into account and often make a mistake. As a result, at a minimum, you have to change the fittings, and at maximum, completely reinstall the entire structure.

Another plus in favor of the native manufacturer is the cost. Here you don’t need to overpay for transportation, customs or global reputation. Russia has its own sources of aluminum production, a modern technical base for mass production of certain products and a developed transport system. The lower price is justified only by these three points, but not by worse quality.

Production of curved structures Source al-solution.ru

Classification of aluminum profiles

The material from which aluminum structures are made has several classifications. Including size, production method, exterior and other characteristics. Below are the most significant classifications.

Classification 1. By internal filling

According to existing standards, aluminum profiles are divided into several types. These characteristics are provided for by Russian GOST 22233-2001 and GOST 8617-91. The features of this classification are described in the table.

Table 1. Characteristics of aluminum elements by filling level:

| Type of profiles | Description of the structure |

| Hollow | These are profiles with free space inside. According to the standard, such structures must be equipped with at least one closed side, visible in cross-section. |

| Solid | Continuous structures do not have closed areas. |

| Open ended | The “free” end can be supplied to both a hollow and a solid part. All these varieties are subject to various requirements for the maximum possible discrepancies in form. |

| Semi-closed/semi-loose | Hollow structures can also be semi-open/semi-closed. They are characterized by an incompletely closed cavity (rectangle or circle), on one side of which there is an entrance. However, not every cavity with an open entrance makes the part semi-closed. The area of the profile itself should be significantly larger than the entrance area. |

| Hollow matrices | Semi-open and hollow profiles are made on the same “hollow” matrices, therefore they are additionally combined into one group. There are three types of free matrices: porthole; cruciform; bridge Products that are created on such matrices are equipped with one or more longitudinal welding seams. This is because during the smelting process, liquid metal flows around the bridges to support the frame. The latter serves to indicate the internal contour of the future profile. |

The aluminum profile is welded under high pressure and elevated temperature. Solid profiles are created on solid matrices - these are metal disks with one or more holes.

Classification 2. According to profile shape

Metal structures also differ from each other in their external shape. Each variety has its own purpose of use. For example:

- Frame structures. Suitable for marking door or balcony openings. Can be used as decorative elements in the interior.

- U-shaped part. Such structures are used as load-bearing structures when installing massive slabs. They are wider than frame ones. The narrowest side is often the bottom or top edge.

- L-shaped element. Used as a “edging” for decorative items. It can also be used to separate incompatible types of coatings from each other.

U-shaped metal part

The aluminum profile is secured using clamps or brackets. This assembly makes an excellent frame. Panels of any nature are attached to the weightless profile on top - glass, plastic, acrylic or vinyl. Any other modern material can be used as cladding. It will look quite stylish in a matte silver aluminum frame.

Classification 3. By production method

Aluminum profiles are created in one of two ways, each with its own nuances:

- Cold formed. The profile is made of thin aluminum strips no thicker than 4 mm. They are bent in the required directions, the metal does not heat up in any way during the process.

- Pressed. They are made using special pressing mechanisms under pressure and high temperature. The products obtained in this way are hardened and aged. The press can also create materials without heat treatment.

Classification 4. By area of application

From the current production, finished profiles are sent to various spheres of life. The main purposes of the structures are discussed in the table below.

Table 2. Grouping of aluminum strips by purpose and features of the following categories:

| Purpose of the product | Characteristics |

| Construction and architectural | The profiles of this group are used for the production of doors, shutters, shelves and racks for stores. Barrier structures are assembled from individual planks. The material is created from AD31-35 grade alloy. |

| Transport | They are used in the production of sea/river vessels, land vehicles, and in aircraft construction. Also used in the assembly of elevator structures and railway equipment. The strips are made from alloys A1, D5, D6 and others. |

| Universal | This category includes universal elements - channels, angles, tees. They are made from both aluminum and stronger metal alloys. |

| Electrical | This group of profiles is used for the production of parts for heat exchangers, radiators, air conditioners and other equipment. The equipment is mainly assembled for industrial enterprises. |

First of all, aluminum profiles are valued for the fact that they make it possible to assemble lightweight and reliable structures. Installation is also simplified due to special technical holes, which are required to be supplied with any aluminum strip.

Classification 5. By staining method

Aluminum slats can be painted in one of three ways:

- Based on finished material. The profile is powder coated in the desired color.

- Decorating. It is a coating that imitates other textures. For example, wood, marble and others.

- Anodizing. During the painting process, a colored oxide film is formed on the surface of the alloy.

Despite the variety of colors and painting methods, most buyers choose a regular unpainted profile.

Powder coating of aluminum systems

Classification 6. By use in installation

Regarding the use of aluminum profiles in the assembly of structures:

- Connecting for polycarbonate. It is used when installing transparent polycarbonate structures. These can be greenhouses, gazebos, canopies and arches, stops, awnings in parking lots and other structures. In this case, polycarbonate sheets no thicker than 2.5 cm are attached to aluminum strips.

- Tortsevoy. Used for installation of structures of any shape and size, including non-standard ones. The difference between this profile is that it is protected from the accumulation of liquid in the cavity. For this purpose, there is a drainage channel and a small steel plate with curved edges inside.

- Click profile. Frames and light boxes are assembled from such unusual materials. The anodized alloy click profile snaps into place and turns into a glowing frame. Such designs perform well in outdoor advertising.

- LED profile. Aluminum LED profiles are used to construct basic or decorative lighting. Such strips are also called LED. This is an ordinary metal profile that is painted using anodizing. An LED strip is inserted inside it. The profile is supplied with a white or transparent cover.

LED LED profiles are now very popular and are used everywhere. Thus, similar designs decorate store shelves, kitchen units, stairs and railings, bathrooms, roads and sidewalks.

LED profiles, design principles

Classification 7. According to the level of thermal insulation

Depending on the conditions under which the aluminum structure will be used, two types are distinguished based on qualitative characteristics. They are described in the table below.

Table 3. Classification of aluminum profiles according to quality:

| "Warm" | "Cold" | |

| Description | These strips are additionally equipped with rubber inserts and thermal pads. Fiberglass reinforced. The thickness of the gaskets is adjustable, due to which you can change the level of thermal insulation. Due to the good additional layer, such profiles have high-quality sound and heat insulation. | There are no thermal inserts in such designs. It doesn't retain heat at all. Therefore, it is used in places where it is not necessary to maintain a comfortable microclimate. There are practically no fittings, so the design is very light. If necessary, glass with a thickness of 4-6 mm is mounted on it. |

| Where is it used? | The products are used for installing partitions and windows in offices, rooms and private homes. These can be industrial premises or subsidiary farms, verandas, loggias, balconies. | A “cold” profile can play the role of an office partition or stained glass window. |

According to sectional shape

Solid aluminum profiles

1. A solid profile has no closed cavities.

2. Hollow profile. This is a profile with at least one closed cavity in a perpendicular section.

A hollow profile can also be half-open (half-closed) with a partially closed cavity, for example, a rectangle or circle.

In addition, there is an “open-ended” profile. This “end” can be either a solid or a hollow profile.

The dimensions of these profiles are specified in the current standards. Read more about what aluminum alloy profiles exist in the article on our website “Manufacturing aluminum profiles for every taste!”

Also, these standards list all existing configurations of aluminum profiles. Read more about the use of various types of profiles in the architectural and construction industry in the article on our website “Aluminum profiles in glass structures: where and why is it used?”

Aluminum profiles for glazing loggias

Glazing a balcony is a mandatory procedure to protect the room from dust, wind, and precipitation. On a glazed balcony, you can hardly hear the noise from the street and you don’t feel the sharp temperature change from “street” to “home.”

You can glaze the balcony using plastic, wooden or aluminum structures. Aluminum has become especially popular in recent years because it has several important features.

Glazing of loggias using aluminum structures

Pros and cons of aluminum for glazing balconies

Aluminum structures as part of balconies have both disadvantages and advantages. There are much more of the latter, which is why the material is so popular in this area.

Table 4. Advantages and disadvantages of finishing the balcony with aluminum slats:

| Advantages | Flaws |

| Lightness of designs. Aluminum glazing does not place additional load on supporting structures. In addition, for the sake of such elements you will not have to expand and strengthen the fences. Strength. Aluminum alloys can bear a load 7 times greater than natural wood. Long service. The material will last a long time because it does not change under the influence of temperatures and moisture. Aluminum profiles cannot develop mold, corrosion or cracks due to drying out. Ease of maintenance. Profiles do not require specific care. They do not need to be regularly coated with protective mixtures, like wood. It is enough to occasionally wipe the surface with a damp cloth and lubricate the moving parts. Low cost. Due to the low cost of the material, using aluminum for glazing is more profitable than other materials. | Active thermal conductivity of aluminum profile. Because of this property, it is impossible to provide a climate on the balcony that would be the same all year round. There are options with thermal inserts, but they cannot compete in thermal insulation with PVC sheets. Aluminum expands when exposed to high temperature. This feature must be taken into account during installation, since the frames will change in size. This feature may cause some inconvenience. The cold profile freezes in sub-zero temperatures. Because of this, the doors that should open are blocked. |

Aluminum is a metal alloy, which affects its ability to transmit heat. Without additional elements, it does not delay it at all. The aluminum structure creates cold bridges, so the unprotected balcony quickly cools down. Additions in the form of inserts help reduce heat loss. And the thermal insulation qualities increase significantly.

Installation of metal lathing with insulation

Balcony glazing methods

Using an aluminum profile, you can glaze a balcony using two different methods - standard and insulated. The structure of the material itself is the same in both cases:

- Standard. The air temperature on the balcony and on the street differs only slightly, but the design will be as light and cheap as possible. This option is used in regions with mild climates or in garden houses.

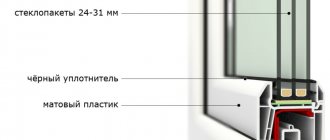

- With insulation. Aluminum profiles can be insulated using additional profile elements. These can be double-glazed windows, energy-saving glass and other parts with enhanced thermal insulation.

Insulated structures will cost slightly more than conventional ones. The future owner will have to pay extra for thermal insulation. But even in this state, an aluminum profile will be much lighter and more durable than plastic and wood.

Windows with aluminum profiles: types of designs

This unique metal allows you to create a variety of window configurations. They can be framed or frameless, with sliding or hinged doors. Detailed classification is presented in the table below.

Prices for metal-plastic windows

Window

Table 5. Varieties of window structures based on aluminum profiles

| Construction type | Description |

| Frameless | The window has upper and lower guides, and on the left and right there are free edges of the glass. There is no frame, so the window opening is covered only with transparent glass. This allows sunlight to freely enter the room. This design looks aesthetically pleasing, but provides almost no protection from sounds from the street and temperature changes. |

| Frame | Sliding glazing with frames is more insulated than frameless. Sliding windows on four sides are equipped with aluminum slats in the form of a frame. There are also two guides at the top and bottom, between which the window moves on rollers. It is important to mount and position the frame correctly, otherwise it will get stuck between the guides and let in cold air from the street. Hinged These are ordinary window structures that are installed on balconies. They are not as convenient to open as sliding ones. They swing open into the room, so there must be free space for manipulation. However, with swing structures it is possible to provide better thermal insulation and noise protection. |

| Remote | The frame on a loggia or balcony is moved forward by 30-40 cm. It turns out that the balcony expands outward, which is why the room becomes more spacious. The window sill turns out to be very wide. This design is very functional and attractive. At the same time, it does not create a large load on the structure. Used in both old and new homes. Due to the removal of the structure, its cost increases, since additional reinforcement will be required for the removed frames. |

Video - aluminum windows, pros and cons

Types of windows by number of fittings

Aluminum window profile is a multi-component system that includes a lot of auxiliary parts. These are various fasteners, inserts, gaskets for thermoregulation. In this regard, the profile is classified according to the following parameters:

- the nature of the compaction (middle or along the vestibule);

- type of installation of fittings (terminals or screws);

- number of thermal chambers (from 3 to 7); thickness (inserts from 2 to 3.5 cm);

- a type of thermal bridge (the gaps between the frames are filled with dense material or foam).

If hard special material is used as filling, the thermal insulation will be lower. Nylon, nylon, propylene and dederon are used as such layers.

Aluminum structures in the creation of facades

Such profiles make ideal ventilated facades - light, durable and easy to install. The aluminum structure is reliable enough to withstand the weight of insulation, cladding and resist the effects of precipitation. The ventilated facade subsystem includes several elements.

Video - how the façade system is assembled. Assembly of the structure

Bearing profile

This is an aluminum strip, which may have a different cross-sectional shape. It depends on the specific “role” in which this element will be used. The following forms are distinguished:

- T-shape or U-shape. The main element in the assembly of a suspension system for finishing houses. It is designed to support insulation and finishing materials, but will not withstand additional weight.

- U-shaped. Able to take on increased loads. In this regard, it can only be mounted on a reinforced bracket. Can also be installed on floor slabs.

- L-shaped. A curved strip used to trim window and other openings. Not designed to bear loads, used only to cover difficult areas.

- F-shaped and H-shaped. They are used to treat windows, arched structures, and parapets.

The individual structures of the aluminum subsystem are connected by special strips. The latter is attached between the two ends of adjacent parts.

Important! When connecting aluminum structures, it is important to consider thermal expansion. To do this, a gap of at least 5 mm is left between adjacent planks to control seasonal deformation.

Installation of suspended facade systems

Support bracket

A device on one side of which an aluminum profile is attached. The opposite side of the bracket is mounted to the wall. There are 2 types of parts:

- Simple. Suitable for fastening conventional profiles in the shape of the letter T. It does not have additional reinforcement, therefore it cannot withstand excessive loads.

- Reinforced. Profiles with square and U-shaped sections are mounted on it. Equipped with reinforced shelves, so it can withstand heavy loads.

Insulation and vapor barrier

A mandatory element in the installation of aluminum cladding is insulation. As a rule, for the purpose of insulation, a layer of mineral wool with a density of up to 120 kg per cubic meter is used. The material blocks out extraneous noise from the street well.

To protect the insulation from liquid penetration, a membrane vapor barrier is used. It sends water out if it accumulates inside and blocks it from coming back. Condensation settles between the outer cladding and the wall, after which it is dried by air currents.

Insulation layer

Connecting elements

The brackets are connected to the wall using anchors. To connect the bracket and profile together, use metal screws. The insulation also requires fastening - it is nailed to the wall using disc-shaped dowels.

Calculating the required quantity

Knowledge of form factors and types of profiles for drywall are useful, but not sufficient. In order not to purchase unnecessary parts, you need to be able to accurately calculate the number of parts for the planned structure frame. To simplify the task, a small diagram is drawn indicating the sizes and types of profiles.

Wall

When finishing walls with plasterboard, the calculation of the required number of elements begins with measuring the height and length of the covered area. The resulting value is multiplied by half and the required footage for guide-type profiles is obtained. If there are openings in the wall, their size along the perimeter is also summed up.

Installation of the profile on the wall Source obustroeno.com

Installing profiles

Aluminum strips are mounted on brackets strictly at right angles vertically or horizontally. The structures are connected to each other with self-tapping screws. The main thing is not to forget about the gap that is created to ensure safety during seasonal deformation of aluminum.

Bending or cutting of the supporting structure may also be required during installation. Bending aluminum is quite difficult. To do this, use hand tools or a professional machine. If you need to change several elements at once, it is advisable to order work from a professional.

Prices for bending machines

Bending machine

Aluminum façade cladding

Aluminum can act not only as an element of a supporting structure. Ventilated facades are often covered with panels made from this material.

Aluminum panels: what is it?

Panels can be square, rectangular or more complex geometric shapes. Such finishing will cost the home owner quite a lot, but it will be reliable and strong. Each aluminum panel consists of three layers:

- two layers of durable aluminum alloy;

- homogeneous mass as a spacer, which is located between layers of aluminum.

Thanks to this structure, the panels are resistant to fire and have a long service life. Instead of aluminum trim, sheets of porcelain stoneware, various alloys and other materials are also used.

Important! Often designers use elements whose length is many times greater than their width. Such elements are called linear panels.

Cladding an administrative building with aluminum panels

Prices for composite panels

Composite panels

Installation Methods for Aluminum Trim

Aluminum alloy panels can be installed using two methods:

- Open. The aluminum cassette is equipped with bent edges with small notches. Thanks to them, it is fixed on top of the profile using self-tapping screws.

- Closed. The panel is equipped with only the top curved edge. The lower half has grooves that snap it into the cassette below. The initial row of finishing cassettes is attached to the façade guide.

The aluminum facade looks very stylish and interesting. It decorates the building and provides it with additional strength, as well as protection against heat loss.

Aluminum profiles in the interior

Aluminum profiles together with panels are an excellent design solution for creating an “apron” for a modern kitchen. This material with a silver surface is suitable for interiors in the style of:

- techno;

- minimalism;

- loft.

Aluminum structures look good in the kitchen interior

Alloy facades are very easy to clean, so they can be easily cleaned of grease and other contaminants. Such a convenient surface will make life much easier for the housewife, who already has to constantly clean a small kitchen. At the same time, aluminum does not change its shade if it comes into contact with hot steam or boiling water.

Aluminum will also be an excellent ally in bathroom renovations. It is suitable for arranging wardrobes. Aluminum strips in the shape of the letter H are optimal for arranging doorways. They give structures rigidity and strength.

Aluminum goes well with glass, not only in variations with window openings. Such metal structures look good in the interiors of living rooms, bedrooms and bathrooms.