Home » Windows and Glazing » Aluminum profile for glazing balconies and loggias

Although metal-plastic windows occupy a dominant position in the post-Soviet territory, another material is also used for window profiles - aluminum. Nowadays, balcony glazing with aluminum profiles is much more common than wooden windows. And this is no wonder. Aluminum profiles are an order of magnitude stronger than wooden and polyvinyl chloride with a metal base (PVC). It is quite natural that the strength of a material is directly proportional to its service life. In addition, such windows are produced in different colors.

Aluminum profile parameters

The cost of an aluminum profile is an order of magnitude lower than that of plastic structures. It is believed that it is stronger than wooden profiles. As a result, the material under discussion is becoming increasingly popular when glazing balconies or loggias. It can also be noted that aluminum structures are quite compact. This makes them easy to use for glazing. Aluminum profiles can be of different brands and vary in price. They also have some differences in parameters, including:

- Number of block chambers (a larger number of chambers ensures the thermal insulation properties of the profile);

- Profile type – warm, cold;

- Opening type – hinged, sliding or accordion-style;

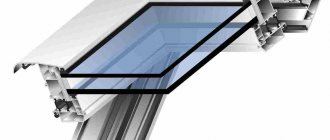

- Double-glazed windows - the ability to install from single-chamber to three-chamber;

- Surface – lamination, metal, different colors.

Balcony glazing price per sq.m. designs

The cost of 1 square meter of “solid” glazing (without the cost of filling) as of November 28, 2019 is from 1,737 rubles/sq.m.

The cost of 1 square meter of glazing with a rotary and/or tilt-and-turn opening (without the cost of filling) as of November 28, 2019 – from RUB 2,296 .

Straight façade of mullion-transom structure

The straight facade of the mullion-transom structure, 6 mm glass in transparent cells and the combined filling of steelite + magnesite plate in opaque cells, allows you to create the appearance of a continuous glass wall from the outside. From the inside, the magnesite plate creates a reliable, impact-resistant barrier along the lower belt of the enclosing structure.

See catalog 3-4-01 <section 1 and 2>

Straight façade of mullion-transom structure

The straight facade of the mullion-transom structure, 24 mm double-glazed windows in transparent cells and the combined filling of steelite + magnesite plate in opaque cells allows you to create the appearance of a continuous glass wall from the outside. From the inside, the magnesite plate creates a reliable, impact-resistant barrier along the lower belt of the enclosing structure. The use of glass units in transparent cells to some extent reduces heat loss and noise transmission through the glazing structure.

See catalog page 3-4-01<section 1 and 2>

Straight mullion-and-transom façade, inward-opening sash

The use of fittings for Eurogroove V.02 “Type 3” allows for swing <section 4> or tilt-and-turn opening of the sash <section 3>, built into a cell in a mullion-transom facade. Any fillings that are possible for embedding into the blind cells of the facade of the ALS B35 system can be built into the sash; the scheme for selecting glazing beads for filling the sash is identical to the scheme for the blind cells of the facade. Page 3-4-02. The use of an additional profile <section 5> on the crossbar allows you to install a standard mosquito net on the opening opening. page 3-04-03 (2)

See the catalog page 3-4-02, page 3-04-03 <sections 3, 4, 5>

Bend the plane inwards up to 90°

The plane bends inwards up to 90°, solid glazing, rotating profiles are installed symmetrically on both sides of the rack

See catalog page 3-4-04 <section 7>

Bend the plane outward up to 90°

The plane bends outwards up to 90°, solid glazing, rotating profiles are installed symmetrically on both sides of the rack

See catalog page 3-4-04 <section 6>

Angle of plane outward 45°

Bend of the plane outwards 45°, fixed glazing, rotating profile installed on one side of the rack

See catalog page 3-4-04 <section 3>

Bend the plane inwards up to 45°

The plane bends inwards up to 45°, solid glazing, a rotating profile is installed on one side of the rack

See catalog page 3-4-04 <section 4>

Bend the plane inwards up to 90°

The plane bends inward up to 90°, the doors open, installation options: on the right side there is a handle on the post side, on the left side there are hinges on the post side, an additional profile is installed on the rotary adapter for the hinges. The use of an additional profile on the crossbar allows you to install a standard mosquito net on the opening opening.

See catalog page 3-5-02 <section 10> (7)

Bend the plane outward up to 90°

The plane bends outward up to 90°, opening sashes, installation options: on the right sash there is a handle on the post side, on the left sash there are hinges on the post side, an additional profile is installed on the rotary adapter for the hinges.

See catalog page 3-5-01 <sections 8 and 9>

Attachment unit to the interfloor ceiling

The bracket solution used provides a wide 3D range of adjustments to the position of the fixed rack, ensures a minimum gap between the facade and the load-bearing ceiling, ease of installation of the structure and the connection device in the interfloor area.

See catalog page 3-6-01, page 3-7-01

Related Products

- Mounting clip 505700 for gap compensation

Request for a balcony glazing system

See also:

- Structural glazing of facades FC50+SG

- Aluminum facade system FC50+

- Fire partitions FC50+SF

- Window and door glazing system AGS 50 (cold)

- Window and door glazing system AGS 68 (warm)

- System profile processing equipment

Properties and types of aluminum profiles

Once the decision is made to glaze the balconies, aluminum profile glazing will be one of the best options. This profile is corrosion resistant, which greatly increases its durability.

It is believed that such a profile has a service life of about 50 years.

The aluminum structure cannot be affected by weather conditions. As a result, the owner does not have to worry about special care for the product. Regarding fire safety, aluminum is an excellent material for glazing balconies. The design of structures can also be carried out in any design, regardless of the strength of the aluminum. As previously noted, the profile can be warm or cold. Consumers often produce aluminum glazing with a cold profile.

It has a low cost, so it is considered the best glazing option, especially if the balcony or loggia is not used all year round. Cold profiles can also save space. This visual effect is achieved due to the fact that the design has thinner frames. Cold profiles are often used for products with sliding windows. The warm profile has a heat-insulating polyamide insert. It is inserted as an external and internal profile part. This design is slightly wider than a product made from a cold-type profile. Since it has a double glazed window. The only disadvantage of glazing a balcony using a warm profile is the cost of the structure.

Fitting and installation of balcony canopies with the removal of the window sill

Like ebb tides, installation of canopies is carried out starting from the sides of the balcony. To determine the length of the side canopy, measure the distance from the building wall to the corner of the aluminum structure and add 13 cm. 10 cm overlaps the front canopy, 3 cm. – on a bend at the junction with the wall, directed towards the top (attached with dowels to the wall adding rigidity to the wide galvanized canopy).

Trimming corners is carried out similarly to trimming ebbs: the rear (wide) flange is cut off completely, the front protrusion is cut diagonally, leaving a tongue for connection.

Angle of the balcony canopy with extension.

Having adjusted and secured the side parts of the balcony canopy, the front canopy is trimmed. Due to its large length, it consists of two parts. The halves are overlapped and the joint is subsequently sealed with silicone or mastic.

Photo of fastening the front balcony canopy.

The canopies are attached to the window frame with self-tapping screws. Their inner side is inserted into the top plate with dowels. The slab is pre-coated with bitumen mastic for sealing. The inner edge must extend at least 10 cm under the slab.

Since a wide (about 70 cm) galvanized canopy is mounted on a balcony with a 50 cm extension under the window sill, after installation it requires mandatory external and internal noise reduction.

A good option for external noise reduction is to apply a layer of bitumen-polymer mastic to the upper surface of the canopy.

Silencing the protruding balcony canopy with bitumen mastic.

Mastic has the necessary properties to effectively dampen vibrations and noise.

It is convenient to work with bitumen-polymer mastic at almost any time of the year; it is suitable for use in the temperature range from -10 to + 50 degrees and does not require heating.

Bitumen mastic.

The operating temperature of the mastic should be about +15, so it is advisable to keep it indoors until use.

The mastic is applied to the visor using a paint brush or roller in one or (if necessary) two layers.

Work is carried out after bringing the mastic to the desired consistency by adding a solvent and thoroughly mixing. It should be liquid enough to be applied with a roller and thick enough to prevent smudges on the balcony.

The areas where the canopy adjoins the wall of the house are especially carefully coated. It is more convenient to use a brush for this.

Photo of treating the junction of the balcony canopy with the wall of the house with mastic.

Sliding aluminum glazing

Sliding aluminum glazing is a very convenient way to glaze a balcony or loggia. The name already speaks for itself. Convenience lies in the method of opening. Most balconies and loggias in houses in St. Petersburg are quite small in size.

Therefore, it is very important to install glazing that will not take up useful space. Sliding aluminum windows are sashes that are installed on the balcony parapet and slide left and right along a guide, similar to a sliding wardrobe. This method of opening windows is very ergonomic, silent and convenient.

Nashchelniki

Flashings are also an important part of the structure, which makes it possible to protect the installation seam from exposure to moisture and the sun, which protects it from deformation and destruction. As a rule, they perform primarily an aesthetic function; the balcony will have a beautiful appearance.

Product quality

As a rule, the reliability and durability of all products directly depends on the quality of materials, the work of craftsmen and the quality of components. As a rule, companies that deal with turnkey glazing select only the highest quality components. Often these are quite moving elements, the quality of which directly determines the durability of the entire structure. Installation of high-quality fittings is also a fairly important part of the glazing of balconies, included in the category of components. Caring for it is quite simple - you just need to lubricate the moving elements from time to time and ventilate the room so that humidity does not affect the operation of the mechanisms.

Sliding glazing of gazebos and verandas

Sliding glazing is relevant not only for a balcony or loggia. Sliding sashes are also often used for glazing verandas and gazebos. In the case of glazing a gazebo or veranda, the doors can be made from floor to ceiling.

This way you get a kind of sliding doors. It's very convenient and beautiful. In warm weather and no rain, you can move the doors to the side and enjoy fresh air, and closed sliding doors will also help you hide from bad weather.

Hinged aluminum glazing

When sliding glazing is installed on a balcony, the question arises of how to glaze the sides of the balcony. In this case, you need to build on the width of the balcony itself. If the width of the balcony is more than a meter, then sliding doors can also be installed on the side.

But when the balcony is narrow, it is not convenient to make rolling sashes that are too small. In this case, either fixed windows or casement aluminum windows are usually installed. Opening such a window will occur according to the same principle as for metal-plastic windows. Of course, a casement window is more practical in terms of ease of cleaning.

Aluminum glazing from floor to ceiling

Aluminum sashes can be installed not only on parapets. There are situations when the parapet is in disrepair. Or when it is important for the customer to install panoramic glazing. In this case, we propose to make floor-to-ceiling glazing with aluminum. In this case, the old lattice parapet is dismantled, and the lower and upper parts of the glazing are manufactured separately.

The upper doors can be sliding or hinged. The lower ones are made deaf. Moreover, the filling may be different. If you do not need to make panoramic windows, then the lower part can be filled with a sandwich panel. This is a special opaque filling.

If there is a need to make transparent windows from floor to ceiling, we recommend using glass with a special film or triplex for the lower part of the glazing. Panoramic glazing is a winning solution for those who like a well-lit room.

Facade aluminum glazing

Aluminum glazing is now especially popular for glazing the facades of new houses under construction. It is also called mullion-transom glazing. This method is of course primarily of interest to developers. Because the point of such glazing is that aluminum racks are attached inseparably along the entire façade of the house. However, in most cases, developers install cold glazing.

And if you need to insulate your balcony, then simply removing the old frames and installing PVC windows will not work. In this case, it is necessary to replace the cold façade glazing with a warm one, without affecting the existing racks.

Advantages of glazing balconies with aluminum

One of the features of glazing balconies using aluminum profiles is the ability to choose an option that best suits your needs and is affordable. In cases where aluminum framing is used during installation - glazing of balconies, reviews regarding such performance are ambivalent.

Some expected the balcony to be warm, while others were happy with a cold one, but it provided protection from wind, dust and bad weather. But with any option, it is worth noting the advantages that glazing provides:

- reducing dust, dirt and noise in the apartment;

- creating an additional buffer between the apartment and the street, even if cold glazing is installed;

- providing protection from external influences (wind, rain, snow) when on the balcony.

- the ability to choose an option at a price that matches your planned budget.

I would like to separately highlight the advantages of the Provedal profile . These include:

Resistance to temperature changes and non-corrosion thanks to high-tech aluminum alloy.

- Strength is more reliable due to the use of a special structure profile.

- The quality of the fittings used: the glazing is protected from external opening and sudden opening by strong gusty winds.

- Well-honed operating mechanisms: smooth operation, quiet opening, elimination of drafts, freezing, and precipitation on the balcony are ensured by rubber inserts and a brush-type seal.

- With all the variety of advantages, cold glazing of a balcony with an aluminum profile has also received a number of disadvantages, and all of them arise under the influence of low temperatures.

- Glazing is not intended to protect against cold.

- Icing of frame structures, making it difficult to open them.

- Increasing heat transfer from a warm apartment through the balcony to the street.

- Reduced noise insulation due to leaks formed by sliding systems.

Installation of “cold glazing” glass on the balcony

Carrying out this work requires accuracy and caution. Glass can easily chip or crack even from a minor impact. Contact of glass with hard surfaces should be prevented by placing and resting them only on previously placed towels or other soft materials. To avoid cuts, you should handle them with gloves.

Suction cups are used to move large glass panes. Basically, these precautions apply to the installation of blind sashes. Glasses that open during installation do not require removal of glass.

They start with glazing the blind side sashes. They operate in the reverse order of disassembling the frames before installation.

Installation of side glass “cold glazing” of the balcony.

The glass is placed in place, namely on rubber backings, which are fixed in the “grooves” of the aluminum frame. You should make sure that the glass sits on the rubber; if it slides onto the aluminum frame, it can get chipped or cracked.

The glass is fixed with aluminum U-shaped profiles (glazing beads), which snap into special grooves in the frame.

Beads for fastening glass in aluminum frames.

In this case, it is necessary to take into account some points. The top bead is installed first, then the bottom and side beads. This is done taking into account the asymmetry of the shelves; the inner one has a more curved shelf at the end (to fit into the groove), the outer one has a flatter one - for snapping.

Compliance with this point is fundamental, since at first glance the glazing bead seems symmetrical, and its incorrect installation during assembly can result in unpleasant consequences.

Then a rubber seal is inserted around the perimeter of the frame. It easily fits into the small gap between the glass and the glazing beads.

Photo of installing rubber seals on aluminum windows.

The next step is to install the sliding front sashes.

Installation of aluminum sliding doors on the balcony.

Glass from the factory is marked with numbers from left to right. The outer shutters are placed on the outer guides of the profile, the middle ones - on the inner ones. The sashes are first inserted into the upper profile, then their bottom is pushed into place and lowered onto the lower guide.

After installing all the sashes, the latches are adjusted, which, before twisting and installation, are inserted into their corresponding grooves and can then change their position in height.

Adjusting the sliding window latches on the balcony.

To make adjustments, you need to have a set of small hexagons with you.

Type of cold glazing with offset

Glazing option, thanks to the displacement of the window frame by 25-30 cm from the parapet towards the street, allowing you to expand the space of the balcony. An additional bonus of this option will be a comfortable wide window sill. Apartment owners have adapted to using it not only as a springboard for growing plants, but also as a work surface or bar counter.

In terms of design, the implementation of the extension from an aluminum profile in cold glazing makes it possible to block the openings of balconies even in those houses where serious loads on the structures are contraindicated. Where it would not be possible to arrange a removal using PVC frames, aluminum glazing can easily and reliably cope. Removal is the reason for the rise in cost of cold aluminum glazing, since the additional steel frame required for its installation will require additional costs.

Conclusion: Before glazing a balcony with an aluminum profile, you should decide for yourself which type of glazing is more preferable (cold or warm), and also decide on the design (frameless or framed: sliding, swing), carefully study all the features of each type and make balanced choice.

And in this video you can watch how to glaze a balcony with aluminum. It demonstrates all the main stages of work.

Danke window sills: a harmonious addition

Danke window sill is a perfect design, an elegant and reliable addition to the window. Impeccable, high quality, durable and pleasant to the touch.

Advantages of Danke window sill

- Wear resistance. Thanks to this property, you can easily move any objects along the surface of the window sill without scratching it.

- Service life – 10 years.

- Excellent moisture resistance is a guarantee that Danke plastic window sills are not at risk of delamination and swelling from dampness or moisture. Neither spilled liquid nor rain will affect their condition.

- Heat resistance. You can put a hot cup of tea on the windowsill, this will not affect its surface in any way.

- Thanks to its ideal smoothness, caring for such a window sill is greatly simplified. Removing stains without streaks is real!

- Modern design. The inclusion of special stiffeners provides the necessary strength.

- Resistance to sunlight will preserve the original design and color.

By purchasing Danke window sills, you are purchasing a high-quality, easy-to-maintain, beautiful, wear-resistant analogue to a natural stone window sill.

You can see the work we have completed, as well as a variety of pleated curtains and Danke window sills, photos of which are posted on our website.

Design Features

Glazing of balconies and loggias from aluminum profiles can be done in two versions - frameless and using ready-made structures.

When a new multi-story building is being built, ready-made frames are often used. Their production is carried out in production facilities using specialized equipment.

Installation of finished products is carried out quickly, using pre-developed technology. Frameless structures are used when cold glazing is carried out according to the original design. Often the work is done with your own hands, without involving outside specialists.

Translucent structures: panoramic view and more

Advantages of translucent structures from:

- Aesthetic compliance of translucent enclosing structures with the highest demands. Exquisite style and naturalness.

- The use of the most modern materials and technologies helps us achieve excellent noise insulation performance and the highest resistance to external influences.

- The aluminum profile is malleable for processing. This gives unlimited creative freedom and the opportunity to implement a variety of design solutions.

- Maximum illumination.

Our company’s specialists install translucent structures taking into account the smallest details. We calculate all possible nuances, which is the key to successful completion of the assigned tasks.

We also offer translucent canopies, roofs, soft roofing, decorative elements, aluminum balcony railings, canopies, metal tiles, glass tinting and painting of parts.

Cold or warm

When choosing an aluminum profile as a structural material, you need to know that this metal has high thermal conductivity.

In winter, aluminum, unlike wood, does not retain heat. The temperature on the balcony will be approximately the same as outdoors.

Emphasizing this feature, consumers and experts gave this solution the name “cold glazing.”

Moreover, this design has the following positive properties:

- light weight and environmentally friendly;

- strength and durability;

- ease of use.

To this list we must add the cost, which is noticeably lower than that of plastic or wooden products.

Homeowners who want to have warm glazed balconies should not be upset and refuse to use aluminum construction.

To implement an all-season project, you need to use a special profile that has thermal inserts.

Thanks to such inserts, the aluminum structure transmits a minimum of heat to the street. Plus, energy-saving glass or double-glazed windows are used.

All of the listed techniques and methods ensure the creation of comfortable conditions on the balcony at any time of the year. Numerous reviews confirm this.

Installation of window sills for cold glazing of a balcony

Installation of aluminum frames begins with the installation of window sills, which are mounted around the perimeter of the welded metal structure.

Photo of the process of installing window sills on a balcony with removal.

Installation begins from the side. Using a tape measure, measure the distance from the wall to the outer cladding (which extends several centimeters above the metal frame) and reduce it by 5 mm. The gap is necessary to compensate for the thermal expansion of the window sill and to install end caps on it. The resulting size is transferred to the window sill and, using an electric jigsaw or a hacksaw with a fine tooth, it is cut.

The window sill is adjusted to the opposite side in the same way.

Having placed the window sill slabs at the installation sites (if the welding of the frame is done correctly and the rectangular geometry of the structure is observed - the window sills are flush against the outer cladding), we take the size of the front window sill, it is equal to the distance between the side slabs minus 5 mm.

At the corners, the window sills can be joined with trimming at 45 degrees (there are special connectors for this), however, this option is more expensive, because the window sill is not fully used, and significant parts of it are cut down and thrown away, but it is more beautiful. This is especially noticeable on balconies with extensions, where window sills up to 60 cm wide are used, and for many, economic feasibility is an important criterion when choosing a particular design solution.

Adjustment of window sill slabs.

Plugs are put on the ends of the prepared window sills, and the window sills are laid out around the perimeter. When installing them, three conditions must be met:

- The distance from the outer edge of the window slab to the protruding outer skin should be minimal and approach 0. Small gaps are allowed if the geometry of the welded balcony frame is violated. In this case, the window sills are still placed at right angles to each other and to the wall of the building, and the resulting gaps are closed from above with galvanized window sills.

- Relative to the front, the side window sills should be located in the same plane, at an angle of 90 degrees.

- Since aluminum frames are installed directly on the window sill slabs themselves, the latter are mounted with a clear alignment of the transverse and longitudinal levels.

The window sills are screwed to the metal frame around the perimeter from the outside with metal screws, which are hidden by the aluminum frame, with control of the longitudinal and transverse level. The level is adjusted as necessary using plastic or wooden wedges placed between the window sill and the metal structure of the balcony on which the inner edge rests.

The inner edge of the window sills is fixed with self-tapping screws on the bottom side. To do this, drill a longitudinal corner of the railing (profile pipe), on which the window sill rests from the inside, and a self-tapping screw is screwed through it into the lower shelf. The length of the screws is selected such that when tightened they do not pierce the front side, but pull the window sill, breaking through only its lower shelf (wood screws 35 mm long are suitable).

Attaching a window sill to an old balcony railing.

If there is no level on the old railings or their slight curvature of a few centimeters (in this case, the old railings were not removed and the frame was “unwelded” based on them), these unevennesses are compensated for by pads. Wedges are placed on the supporting corner, and the window sill is pulled to the corner through them. This compensates for the curvature. The distance from the support corner to the window sill is filled with polyurethane foam (for its final fixation). The photo shows this distance; it is equal to the thickness of the linings.

The outer perimeter cladding protruding above the window sill is cut flush with it.

The mounting film is removed at the end of all construction work.

Features of purchasing a profile

When ordering aluminum structures, it is worth remembering that different manufacturers put marks on their products that help installers determine where is the bottom and where is the top, left and right side.

They can be indicated by special arrows. At the time of purchase, you should remind the seller to have them supplied. Otherwise, the sides may be mixed up during the work process. This risks dismantling the structure and performing installation work again. Few are willing to sacrifice precious time and effort.

Just installing windows takes a beginner almost the whole day. For an experienced master, a few hours is enough. Additional time will be spent on dismantling the old structure, exterior and interior decoration. The photo shows one of the options for this finish.

Preparatory work

When using lattice fencing, its external finishing is carried out before installation work begins. Also at this stage, insulation is carried out. Interior finishing is carried out after installing the window frames. The top of the fence must be horizontal. Otherwise, leveling the structure will cost more than the cost of the frames.

When installing a structure on a parapet made of concrete or brick, its top must be leveled with cement mortar. Interior finishing and insulation are carried out after installing the window sill.

Pipe stands are installed in the case of a hanging balcony that does not have an upper ceiling. They are able to take on the weight of the mounted structure, transferring the load to the canopy. If the length of the balcony is more than 4 m, an additional pipe stand is installed in the middle of the long side.

The outer corners should be filled with polyurethane foam, then the excess should be cut off and covered with galvanized strips. Weld seams are smoothed using a grinder. The supporting frames are made of steel corners. They can be painted only after cleaning and degreasing. The lower frames are made taking into account the skew of the balcony slab. It is necessary to ensure that the junction of the upper and lower frames is horizontal.

The canopy should be installed along the top line immediately after cleaning the room. This stage of work must be completed before installing the frames. The canopy is installed regardless of the type of glazing. It ensures water drainage from the structure.

Installation of windows and cladding of loggia

After all, after installation work is completed, there will be much less free space. Consequently, it will be more difficult to cladding the outer part of the loggia. After completing the finishing work, you can begin glazing the loggia with an aluminum profile, i.e., begin installing the balcony frames.

However, there are several reasons why glazing with aluminum profiles should not be done independently. The first reason is that employees of specialized companies have the necessary skills and know all the nuances of installation. The second reason is that when work is performed by representatives of a specialized organization, the customer is provided with a written guarantee for the product.

Disadvantages of an aluminum system

Provedal glazing has the following disadvantages:

- The doors are susceptible to freezing and can become clogged with snow drifts.

- The system is intended only for glazing spaces without heating.

- Sound insulation is low.

- Insufficient degree of tightness.

- The Provedal aluminum profile is characterized by low heat retention in the space of an apartment or house.

Insulation and finishing work

After completing the exterior finishing work and installing windows, the room is insulated. These works are performed regardless of which profiles were used. In any case, the balcony should protect the apartment from the wind and retain heat in the room. Polystyrene foam or mineral wool are often used as insulation. The inner side is lined with a thick cellophane film, the outer side is lined with a wind barrier.

The ceiling and floor must also be insulated. The insulation on the floor is polystyrene foam, on top of which boards are laid. If the issue of tiles is being decided, then an additional system of heated floors must be installed. The ceiling can also be insulated with mineral wool, especially if the apartment is on the top floor. Interior decoration of a balcony is most often done using plasterboard. This material is subsequently puttied and painted. For enhanced insulation of the room, you can use wooden lining, which can be easily varnished.