Window bars are often installed by owners of apartments located on the first floors, as well as residents of the private sector. In addition, the structures are very popular among summer residents, since in winter their houses remain unattended and become easy prey for thieves. Today, in a review from the HomeMyHome editorial team, we will talk about all the varieties of such products, what materials they are made from, as well as installation features.

Forged lattice with additional space for flower pots

Window bars: requirements and tasks

Protecting residents from unauthorized entry by uninvited guests is the main task of the products. In addition, they must also perform a decorative function, since owners want their homes to look beautiful and well-maintained not only from the inside, but also from the outside.

The grilles can be either forged with elaborate elements or almost invisible made of polycarbonate. The price of the finished structure directly depends on the material, design and complexity of the work.

Today, the authorities have lifted the ban on installing bars on the windows of residential apartments, but in private recommendations they still advise making one sash hinged or removable, and the key should be nearby. This will help you react quickly in case of unforeseen situations.

Swing gratings

Advice! Since uninvited guests can be not only adults, but also teenagers, whose fragile physique allows them to penetrate through a narrow hole, the recommended spacing of the rods should be no more than 15 cm × 15 cm.

Based on the above, we can summarize that window bars must meet the following requirements:

- strength and wear resistance;

- reliability and durability;

- installations in accordance with regulatory documents.

The main purpose of window bars is security and decorative.

Required Tool

For those involved in repair work, there will be no problems with preparing the required tools. The following units will be needed:

- grinder or reciprocating saw;

- welding machine;

- chalk for marking;

- roulette;

- metal square;

- hammer;

- brush;

- primer;

- dye;

- brush;

- fasteners;

- solvent;

- hammer drill

Not everyone has a welding machine at their disposal, so you can rent one at a hardware store.

What materials are window grilles made from?

Window grilles are made from different materials, each of which has its own pros and cons. Let's look at them in more detail.

Most often, gratings are made of metal

Metal

Typically, the following types of metal are used for gratings:

- steel , it can be forged well, but is not strong enough. Rods 1.5 cm thick can be easily cut with a special tool. A product made from rods 2 cm thick will be more reliable, but such elements look bulky;

- reinforcing bars , elements with a thickness of 1.4 cm are similar to ordinary metal with a cross-section of 2.0 cm, they can only be cut by hydraulic shears. The only disadvantage of such products is that they cannot be used to make elegant curls. The lattice will have clear shapes;

- Special steel is the most reliable material. From it you can make the thinnest rods, which are not inferior in strength to reinforcing steel. In order to hack such a grille, attackers will need a plasma cutter.

Irregular bars look great on windows; their openwork patterns sometimes mislead burglars. It seems to them that it is quite difficult to break such a “broom”. This design should only be ordered from an experienced specialist. He will be able to correctly calculate the sketch and make a stable lattice.

Extruded grilles match the architecture of the building

Types of profiles used for the manufacture of gratings

The following types of profiles are used for gratings.

| Image | Profile type | Description |

| Bar | It has a round cross-section, the structures are quite durable. For gratings, a cross-section from 1.2 cm to 2.0 cm is used. | |

| Square | The profile, the edges of which are 1.2, 1.4 and 1.6 cm, is quite durable and quite attractive in appearance. | |

| Band | The flat profile has a cross-section in the form of a rectangle, the width of which can reach 2.0 cm, thickness - 0.6 cm. Simple elements are made from it, inferior in strength to a rod and a square. Their main advantage is their low cost. |

Polycarbonate

Metal grilles are bulky, and not every owner can order ornate designer forging. This is where polycarbonate plastic slats come to the rescue. These are lightweight products that provide a sufficient degree of protection for housing without disturbing the appearance of the building.

Polycarbonate grilles look aesthetically pleasing and elegant; they differ from metal ones in their configuration; the material does not interfere with the passage of ultraviolet rays and the view from the window.

The main advantages of polycarbonate gratings include:

- high strength;

- resistance to mechanical loads;

- impact resistance;

- durability;

- resistance to weather factors.

Advice! It is advisable not to install polycarbonate on windows facing south due to constant exposure to ultraviolet radiation.

The standard width of the polycarbonate strip is 6 mm, this is enough to provide protection not only from burglary, but also from falling pets or children. Even cleaning a window at height is much easier with this design. The maximum load reaches up to 500 kg.

Tree

There are more than enough advantages to wooden gratings, let’s highlight the main ones:

- decent appearance;

- the ability to paint the structure in any tone, this is a significant plus especially for private and country houses;

- the ability to give the structure any shape;

- the possibility of making a grating with your own hands.

Among the characteristics of wood, the only thing worth noting is the need for periodic protective surface treatment. A properly made grille will last for decades.

How to paint a grille

Ready-made gratings sold in hardware stores are already painted. The need for painting arises if the grille structure was made on its own or the metal began to rust in some places. In this case, many homeowners are trying to find out how to remove the grill from a window for painting. This is only possible in two cases:

- overhead grille, installed with bolts;

- The design is hinged - it can be removed from the hinges.

In all other cases, you will have to remove the grate with a grinder. Therefore, you will have to suffer and paint the grill on the window. The process is simple and includes cleaning the iron from rust, applying a primer to prevent metal corrosion, and painting itself.

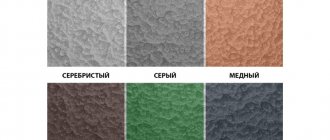

The paint should be powder - it is resistant to ultraviolet radiation, temperature changes, and perfectly protects the grille from corrosion. Costs from 360 rubles. for 1 kg. Warranty for about 20 years. An alternative could be alkyd enamel - the quality is almost as good as powder paint.

Classification of window grilles according to manufacturing method

The gratings are classified according to the manufacturing method, which determines the strength and durability of the structure.

Forged and welded

Recently, forged products have gained great popularity; they are most often made to order for installation in private houses and apartments located on the lower floors.

The gratings are made by cold forging from ductile structural steel. It should be noted that they have low strength, so if the issue of protection comes first, it is better to give preference to another material.

Forged structures are divided into the following types:

- regular , for their manufacture they use a round or square rod with a side of about 20 mm. They have excellent strength, but one significant drawback should be noted - their rough appearance;

- irregular designs look elegant and aesthetically pleasing, openwork patterns will scare away a burglar, he will not risk breaking such a bundle;

- mixed type - the strict classical design contains ornate elements and some artistic disorder. Opening such a structure is not difficult for a burglar.

The welded grating is made of high-strength reinforcing steel. It is not as flexible and plastic as structural one, so the products have a more strict, conservative shape. Scraps of material in the form of curls act as small figured accents. A skilled craftsman can make an elegant openwork composition out of them.

Scale on weld seams is removed using a grinder, on which a cleaning wheel is placed. After which the decorative grille is painted. You can make such a design at home with your own hands if you have a semi-automatic welding machine at your disposal. Moreover, it is not necessary to use reinforcing steel; a special stainless steel rod with a cross section of 6 mm will also work. High-strength material can be bent with a pipe bender over a large radius.

Advantages of welded structures:

- low cost;

- simple manufacturing technology, respectively, high production speed;

- high strength.

Among the shortcomings, one can highlight only a less beautiful appearance than that of forged elements.

Cast

Many owners of private houses assume that the strength of cast grilles is comparable to forged ones and give an analogy with car wheels. However, this opinion is wrong. She's much shorter. To open it, a burglar only needs to have a crowbar or a crowbar.

One of the advantages of the products is their beautiful appearance. Manufacturers can pour any patterns at the request of the customer. Most often, such grilles are installed in offices located on busy streets. An alarm system is often connected to them.

Types of window grill designs

Window bars can be installed both from the inside of the house and from the outside. The right choice will help not only protect your home from unauthorized guests, but also decorate it.

Removable and non-removable

Removable grilles are installed in the window opening using through bolts, their optimal number is 8 pieces. They are often chosen by owners of wooden houses with thin walls into which it is not possible to install more reliable fasteners. If necessary, the structure can always be removed without damaging the building façade.

Fixed or stationary grilles are attached to the wall using anchors. This is the most reliable model of protection against burglars. To open it, the Ministry of Emergency Situations will take up to 3 minutes, but in case of emergencies, such as fires, such a duration can be fatal for the residents of the house.

Swing and sliding

Designs with swing doors are very similar to antique shutters. The cost of such gratings is two times higher than stationary ones, but they are more convenient. The leaves are mounted on a common steel frame and are closed with locking and swinging devices. A burglar cannot open them, but for the specialized services of the Ministry of Emergency Situations, one minute will be enough.

Everyone is used to seeing sliding grilles in small shopping centers, but not in private homes, especially since their reliability is low. They are made from strips of metal fastened crosswise to each other; it is not difficult for an attacker to open the system. However, this is a good and inexpensive option for country houses that remain unattended by the owners for the winter. The damage there is caused not by thieves, but by homeless people who have nowhere to sleep. It is unlikely that they will open the grate.

Sliding grilles can be mounted both inside and outside the house. The panels are closed with a secret lock, which is installed inside the side parts of the frame. This type of structure can be opened immediately, so it will not become an obstacle to exit in case of emergency.

Roller shutters

Roller shutters consist of a box with guides to which the canvas is attached. The design completely covers the window opening, while access is limited not only to thieves, but also to light and drafts.

Roller shutters are divided into the following types:

- steel - most often they are used in shopping centers. This is reliable protection against uninvited guests;

- aluminum , their main advantage is ease of control. Even a child can raise and lower the system, and the sound insulation of the structure is quite good;

- roller grilles - they are used in stores to protect goods. These are transparent structures through which the entire contents of the pavilion can be seen.

Finishing

The installed structure necessarily requires additional processing - at least painting. It’s better to also treat it with an antiseptic, which will protect the metal from corrosion.

Using paint, you can hide welding areas, this is especially true if you have abandoned decorative elements that can hide them.

The paint also serves as a protective coating that protects the metal from weather and moisture, thereby extending the life of the structure.

In the photo you can see a design option for the grille.

For sliding structures, you need to additionally install runners with which it can move.

Sliding grilles must be equipped with a burglary-proof mechanism, since opening such a structure is much easier than a stationary one.

Runners can also be visually hidden using decorative elements such as flower pots.

Features of choosing window grilles

Consumers face a difficult choice of the correct design of window bars. All criteria must be taken into account. It is also important to contact a trusted manufacturer. We have collected key expert tips to help you choose the best product.

By resistance to burglary

If burglary resistance is a priority when choosing a window grill, experts advise the following:

- install welded structures. They are cheaper than forged ones, but are not inferior to them in strength;

- gratings made from rods with a cross-section of 16 mm or more are more reliable;

- removable structures are attached to the outside of the window with bolts and can be dismantled, while stationary structures are mounted in the window opening. They cannot be removed.

Another selection criterion is the location of the grille:

- external - the structure is mounted on the outside of the building on a window block or on a wall;

- internal - installation is carried out between the frames or in front of the window unit, provided it opens outward.

According to decorative qualities

In terms of decorative qualities, pay attention to the following designs:

- forged ones are one of the most expensive, but also beautiful products, they harmoniously fit into the architectural design of the building and become its real decoration;

- for the upper floors, polycarbonate gratings are a real godsend, they do not spoil the appearance of the house and do not interfere with the passage of solar flow, but, at the same time, they are reliable protection;

- The decorative frame of the window, especially in wooden houses decorated in the Russian style, is wooden grilles .

Cost of metal products

If you decide to buy bars, then the question will soon arise - where to buy bars for windows? Typically, specialized hardware stores sell all kinds of metal products to protect windows. However, we should not forget that there are private craftsmen who can adjust the price and please the buyer with a good discount.

It is worth paying attention to a company that takes measurements of windows for free before accepting an order. You should read reviews, compare prices, and talk to previous customers.

If there is a need to purchase inexpensive metal gratings, you can take unpainted products, as well as products made by welding the rods. In this case, the quality will strictly correspond to the price of the product.

The price range for metal grilles for windows is quite wide. The complexity of the design, the material used, and the popularity of the craftsmen also have a huge impact.

The approximate price of window bars varies from 1,500 to 4,000 rubles per square meter.

The nuances of installing window grilles

Installation of gratings can be done in different ways and depends on the material of the structure. Most often these are anchors or metal “ears” driven into the wall.

External and internal installation

If installation is carried out in a window opening or in concrete, metal pins are first driven into them. A grate is welded to their ends, which protrude several centimeters above the slopes. For a wooden surface, the installation is slightly different:

- Eyelets are attached to the frames.

- Screws are screwed through their holes. They will hold the grate.

Installation of the grille in a house made of laminated veneer lumber is carried out overlay; holes for self-tapping screws are first drilled in the wall.

Installation can be performed both outside the building and indoors. The second option is more reliable, since access to the grille occurs only after the attacker breaks the glass. In order for the structure to hold firmly, it is necessary to use high-quality embedded parts:

- paws - they are made from metal strips measuring 40 mm × 4 mm;

- anchors made of rod with a thickness of 12 mm. They are installed into the wall at a distance of 15 cm to 25 cm. Embeds of longer length can be used only during the construction process; they should be welded to the reinforced concrete wall frame.

It is important! The most important thing in fastening gratings is their reliability. For window structures of standard sizes, a certain amount of fasteners should be installed: 1-2 elements on the bottom and top, 2 times more on the sides. There should be at least 8 mortgages in total, the distance between them is about 70 cm.

Features of fastening metal structures

Installation between window openings

The third installation option is between the glasses; it is used quite rarely. It is first necessary to weld steel strips with drilled holes for fasteners to the metal. They are attached to the window opening using powerful anchors of a suitable cross-section; pulling them out of the wall is quite problematic.

Suitable garden grilles

Depending on the features and installation options, window elements come in several types.

Removable models are a one-piece option. In critical cases, such a structure can be removed from the window, however, due to the tight twisting of the elements, such manipulations are extremely difficult. The likelihood of elimination does not have the best effect on the strength of the product in further operation.

Stationary type options can be tightly attached to the facade. This type of protection is one of the most durable. It is almost impossible to open this model plan, since they have an impressive thickness and also meet the required fire safety standards.

The disadvantage is that in an emergency, the owners will not have the opportunity to get out of the house through the window opening, so it is better to combine such products with various other grating options.

Hinged grilles have one or a pair of flaps, which can be easily removed if necessary. Installation of products is carried out using high-strength fastening, which goes quite deep directly into the wall surface. The sash closes with a special latch.

If tiny rods are used in the manufacturing process, then it is impossible to open such elements. In this version, the rods are cut with a special tool for working with metal.

Sliding window grilles are the most convenient to use models. Closing and opening them is quite simple, and the unusual placement of the rods gives them the ability to fold like an accordion. This type of element reliably protects window openings and doors.

One disadvantage is the simplicity of design and the impossibility of creating an attractive pattern. In addition, the reliability of protection that such a design provides is average, since for the uninterrupted functioning of the mechanism, rod-plates are used that can be easily broken.