Today, not only city dwellers, but also the majority of country property owners prefer metal structures as entrance doors. In theory, they are much stronger, more reliable and durable than their wooden or plastic counterparts. But in fact, many solid-looking metal doors from the budget segment can be opened with a can opener, and a crowbar for them is a universal key. Not everyone can afford to install a massive, expensive structure, and high cost is not a guarantee of appropriate quality.

Therefore, craftsmen who have welding skills and the appropriate tool base prefer to make such doors themselves. In this situation, you can be confident in the strength of the frame, and in decent parameters of noise absorption and thermal insulation, and also give the appearance in the general style. FORUMHOUSE users have also mastered the process and are sharing the results. We study their experience and prepare a metal door.

Metal entrance doors - constructive

In a typical version, a metal door consists of a frame, a leaf, hinges and mounting elements (plates, eyes, pins). You cannot do without certain costs for materials and components, but a self-made door will cost much less than a purchased one. The exact list of consumables depends on the design, dimensions and purpose - if for a utility unit a simple frame with lining and a latch is sufficient, then to enter the house the door must be multi-layered, with effective locking fittings and decorative cladding. In the second case, an approximate set of what is needed looks like this:

- Metal corner (from 5 mm) or profile - for the box;

- Metal corner or profile pipe - for the frame, stiffeners;

- Sheet of metal - for power sheathing (optimal thickness 2-3 mm).

- Thermal insulation material (mineral wool, polystyrene foam, EPS or PSB);

- Components – hinges (preferably with bearings), seal, peephole, lock/locks, handle, etc.;

- Finishing – wood, forging, plastic (for the inside there are various panels or laminate).

One of the most important stages is measurements; if you make a mistake, the installation of the door will become much more difficult in the future, so you should adhere to certain recommendations:

- All measurements are taken not from the finishing layer, but from the rough wall;

- There should be a groove left between the frame and the opening, the standard one is 2 cm (for alignment and installation seam);

- The gap between the box and the canvas on the hinge side is 3 mm, on the lock side – 5 mm.

Having a working drawing with dimensions or at least a sketch will be a good help; not everyone’s imagination is developed enough to imagine the end result in their mind. Fortunately, there are plenty of quite workable drawings on the Internet, although drawing and drawing are also difficult.

Finishing

Making a metal door with your own hands is not all. It must be formatted accordingly. With blocks installed in outbuildings it is quite simple; as a rule, they are painted. But if we are talking about a door at the entrance to a residential building (apartment), then it is advisable to decorate it. The choice of option is at the discretion of the owner, and some recommendations will help with this.

How you can finish the canvas:

- Solid materials - multi-layer plywood, fiberboard, vinyl plastic, wooden lining, laminate, MDF followed by varnish coating (colorless or with tinting components).

- Leatherette and leatherette are used to cover the sash.

- The water door to the apartment can be covered with decorative film. Since the impact of atmospheric factors is minimal, this finish will last a long time. And taking into account the low cost and simplicity of design, it is one of the best solutions.

Experience is the best assistant

But the best assistant is the experience that the participants of our portal generously share.

dronduletusFORUMHOUSE Member

I welded simple doors for installation at the dacha; I’m not a pro, the door is my third welding experience (after grilles), so maybe I did something wrong, there are some mistakes.

The frame was made from a 20×40 mm profile pipe, a 3 mm thick metal sheet, mineral wool as an insulator, and MDF finishing.

Since it is necessary to cook the frame on a hard, flat surface, and the craftsman did not have a suitable cooking table, he used beams placed in the same plane. He also used clamps to maintain the geometry of the product; some of them slightly “grab” the elements to the cooking table during the welding process. dronduletus made the door in several stages.

I cut the pipe to size, did not observe the 45⁰ angles, since the welding was carried out end-to-end, assembled the frame, beat off the diagonal, grabbed it, checked it, and secured it with clamps. I welded the frame and welded the stiffeners.

The sheet for the sheathing was cut taking into account allowances for overlap along the entire perimeter (1.5 cm), and secured to the frame with clamps. I first welded it from the inside of the frame - from the middle to the edge, using clamps (about 2 cm in increments of 15-20 cm). To make the sheet less sticky, cook it diagonally - opposite sides in different directions. Afterwards, I welded the external seams in the same way, cleaned them with a grinder, and welded them along the stiffening ribs in the same order. It was possible to get by with just one rib, but the sheet turned out to be curved. Next, I welded the “pocket” for the lock - I cut a groove in the end, and scalded it around the perimeter with profile scraps.

I welded the box from a 40x40 mm corner, used a 100x50mm channel for the threshold, and when cutting the segments I added gaps not only for the hinges and the lock, but also up and down (4 mm each). As a protection against those who like to profit from other people's goods, I welded additional plates/plugs over the place where the crossbar will fit the full width (on both sides). I welded metal strips to attach the box to the wall (two on top and three on the sides). It protected not only from knocking out the bolt, but also from removing the door from its hinges.

dronduletus

I welded pieces of corner 8 cm wide inside the door, on the back side of the frame, lifting it 8 mm from it - these are anti-removal crabs.

I welded the canopies in a horizontal position - placing the canvas in a box and placing a 2 mm thick steel plate between the canopy and the canvas, so that the seal could be glued on afterwards and avoid friction. I welded the canopies at a distance of 25 cm from the edge of the canvas to the center of each canopy, having previously checked the level and secured with clamps.

Since the walls are old and the condition of the brick leaves much to be desired, I abandoned conventional anchors and used pins only to fix the threshold (channel). The frame was secured with studs 25 cm long (diameter 12 mm) and chemical anchors. After installing the frame, I hung the door and drilled holes for the bolt. I laid insulation in the door cavity, covered everything with MDF panels, and painted it.

Connecting the door leaf to the frame

- Just as with the previous assembly, the seams should first be “tightened” by welding. The final connection is made only after checking the correct installation.

- We drill holes for inserting a key and, if necessary, a peephole.

- To attach the hinges, you need to step back 20 cm from the bottom and top of the door.

- Raise the door (it’s easier to do this together). We fasten the canopies in such a way that the lower elements (the pins are attached to them) are attached to the frame, and the upper ones, called counters, are attached to the door leaf.

- All loops must be located strictly along the same axis. This is not easy to do - you will have to take measurements many times. Otherwise, if an error occurs, the door will warp.

- It is better to hang a massive door not on 2, but 3 hinges.

- Lubricate them immediately so that the door opens easily and does not creak.

Entrance metal structure

Even if the door will be upholstered or decorated with decorative panels in the future, it should be treated with an anti-corrosion compound or painted. For painting metal, it is better to use the so-called “hammer” enamel, made on an alkyd-styrene base.

Useful tips for beginners from experienced ones

Another portal participant did not photograph the process, but his observations will be useful to anyone who is planning to start making a door.

outsiderForumHouse Member

I also welded the doors; I didn’t take any photos during the process, but I’ll tell you the details. I did this with my father-in-law, they welded a bunch of these doors as a sub at the factory.

DIY metal door, life hacks and conclusions:

- It is better to take hot-rolled iron for cladding; cold-rolled iron has tight geometry and right angles;

- To weld the hinge plate to the box with a clamp, you need to hold it lightly and immediately release it. When the seam cools, the plate will bend with the required gap. All loops are scalded after fixation;

- If you make a special device (as in the figure), pressing the sheet to the corner during welding will avoid “bubbles”;

- To prevent the door leaf from touching the frame during operation, the hinges are welded so that the hinge axis is on the edge of the sheet;

Intermediate draft result in the photo.

Master81 welded two metal doors - double and single (255x110 mm and 210x0.72 mm), and, looking at his creation, it is clear that he is “on the short end” with metal.

The box was welded from a corner five millimeters thick, six is possible, but four is undesirable, the frame is made of a 40x20 mm profile pipe. The manufacture of the structure did not cause any difficulties.

Master81FORUMHOUSE Member

I measured the doorway, minus a centimeter from the width and length, cut the corner straight with a grinder, first assembled the frame, then the frame for the door.

Another of our craftsmen, a FORUMHOUSE member from Moscow with the nickname oss, has already made the sixth metal door, if you count garage doors. The canvas is three millimeters thick, the frame is made of a 50x40x3 mm profile pipe, like most, but he approached the issue of safety thoroughly. Armor plate, internal plate, lever lock with four bolts, protective curtain in the hole. These improvements have increased the cost of the product, but peace of mind is more valuable. What oss lacks in photos, it makes up for with an optimized assembly process and helpful tips.

ossFORUMHOUSE Member

Before this, I made doors using different techniques, including first tying, and then tacking and assembling the frame. The sequence chosen this time seems more optimistic.

The optimized version looks like this:

- I started with the front vertical profile, made a frame, secured the lock in the frame, checked how it worked;

- I made a rear vertical profile, immediately welded the anti-pullers (behind the hinges);

- I assembled the entire frame from profiles using tacks;

- I cut out the trim along the frame (with an overlap of 20 mm);

- “I baited” the sheet, scalded it with oven mitts in increments of 150 mm;

- In the racks of the box (trimming) I cut out grooves for the crossbars and anti-removals;

- I welded a box with gaps (3 and 5 mm);

- Welded the hinges.

Oss recommends installing one combination door lock instead of two different types.

Taking measurements

Welding a metal structure

Even when using standard drawings to assemble an iron door, you will need to take measurements. Ideally even, symmetrical doorways simply do not exist. Therefore, it is necessary to be extremely careful when taking measurements.

One measurement will not be enough - you need to take measurements three times and then select the smallest number obtained. The door leaf should be measured at the top, bottom, and middle.

The height of the opening is determined in exactly the same way. If the old doors have not yet been removed, it is easier to measure them.

In most cases, the width of the canvas is a multiple of 10 cm - its width can be 70, 80 or 90 cm. Please note that the size of the future opening should be 1.5-2 cm smaller than the size of the opening itself. The remaining cracks are subsequently filled with polyurethane foam. After all, it will be difficult to insert and perfectly align a door cut exactly to the size of the doorway.

Immediately determine which direction they will open. According to SNiP, entrance doors must necessarily open outward, so that in the event of an evacuation or transfer of a sick person, it can be opened without hindrance. In this case, it will also be possible to save useful space in the hallway.

How to correctly measure the width of an opening

The opening side is selected taking into account comfort and convenience. Traditionally, doors are made right-handed so that upon entry they can be opened with the right hand. But this option can be changed taking into account specific circumstances.

After all, the door should open so as to occupy a minimum of free space without creating interference. In apartment buildings, the location of neighboring doors is also taken into account.

Conclusion

In a forum thread dedicated to making metal doors yourself, the opinion was expressed that the costs of homemade products would be significant, and the savings would not be so significant that the game would be worth the trouble. However, for skilled hands, the manufacturing process is quite feasible, and the ability to choose decent materials, and not guess what’s inside the purchased structure, is an important factor. Therefore, while some are talking about the feasibility, others are doing and sharing real experience to make the task easier for beginners.

You can learn how to save on wooden entrance doors from the article about transforming budget blanks. How to insulate an already finished metal door is also on our portal. The video contains an overview of popular new doors from the famous exhibition.

Subscribe to our Telegram channel Exclusive posts every week

Insulation

insulate an iron door welded from metal with expanded polystyrene, polystyrene foam or mineral wool. When using polystyrene foam, sheets 4 cm thick are sufficient. Too much density of the material is not needed - after all, the load on it will be small. You will need to purchase 4 square sheets of 1 m wide.

When purchasing polyurethane foam, choose a composition with minimal expansion, otherwise the foam will simply squeeze out. We apply it around the perimeter of the frame, stepping back slightly from the edges. Next, polystyrene foam is laid. All seams between sheets, cracks between foam plastic and a metal corner should also be sealed with foam. It can be replaced with Moment glue or any other suitable adhesive composition.

Installation of insulation

Mineral wool or stone wool has a significant disadvantage - these materials can absorb moisture. A metal door with this type of insulation will quickly rust. For apartment buildings this is not critical - there is not much moisture in the entrances. But it is highly not recommended to insulate a street door with mineral wool.

If in the future the door will be finished with self-adhesive film, there is no need to cover the insulation with chipboard. Any irregularities will be immediately visible. Replace chipboard with furniture-grade moisture-resistant plywood. It is attached to the metal using self-tapping screws through pre-drilled holes.

Metal door covered with film, trimmed with molding

You can decorate a door covered with film with moldings - decorative strips made of metal or polymer materials, painted to resemble wood, stone, silver or gold.

What is necessary

We will make an iron entrance door from a profile pipe and sheet metal. To work, you will need a flat work surface, a welding machine, a drill, an angle grinder, it’s a good idea to have a level (laser level) and something to measure - a carpenter’s square, for example.

Standard metal doors. This is roughly what we will do

Materials you will need:

- profiled pipe 40*40 mm, 40*20 mm;

- a sheet of metal 2 mm thick, the size of a door leaf;

- metal hinges are powerful enough to support a weight of about 100 kg;

To “ennoble” the door, you will need metal paint (preferably hammer enamel), a wooden batten, insulation (foam or mineral wool), plywood, OSB or other similar material, plastic or any other finishing material, a door peephole, a lock.

The procedure for manufacturing metal structures

A do-it-yourself iron door, regardless of its diagram and drawing, is assembled according to one algorithm. Initially, individual elements are made.

Box

There are no problems with it, but provided that all measurements and cutting of blanks are made correctly, in strict accordance with the drawn up drawing. It is not difficult to weld individual parts into a single structure of the correct geometry. You just need to work on a perfectly flat, hard surface and constantly monitor the angles. Once the jamb is assembled, all seams are carefully polished with a diamond disc.

It is mandatory to weld hinges and fastening strips with drilled holes to the box. Using the final details, it is fixed to a wall made of any material.

Door leaf

If the “one and a half” scheme is chosen, then all technological operations for the small blade are absolutely identical, with the exception of the peephole and the door lock. But upper and lower stops should be provided for fixation in a stationary position.

Product cladding

Whatever method of finishing the door you choose, first it must be protected from corrosion - primed and painted. To do this, you need to remove slag from the welds, clean them and degrease the entire surface, and then apply 2 layers of primer. After drying, paint the product 2 times, starting from the back.

You can decorate your entrance doors in the following ways:

- insulate the inside with polystyrene boards, placing them on glue, and cover them with plastic panels;

- screw the outer and inner wood lining, in particular lining, with self-tapping screws;

- cover the canvas with leatherette, laying a layer of insulation under it;

- buy and install a ready-made kit for MDF doors.

You can make platbands from iron and paint them the same color

The finished product is installed in the entrance opening using anchor bolts, and the cracks are traditionally sealed with polyurethane foam. Here it is important to maintain horizontal and vertical lines so that the door closes well and the loot is not “piled up” inside the apartment. To hide the foam, the outside and inside of the box is lined with platbands made of wood, metal or plastic. The correct painting of the door leaf is described in detail in the latest video:

Slope fastening

The appearance of our door is still far from ideal - polyurethane foam and pieces of broken plaster stick out from all the cracks. It is necessary to bring the entrance structure to perfection by making slopes.

Of course, the doorway can simply be plastered over. But it is quite difficult to perfectly align its corners. It is much easier to install slopes - to decorate the part of the wall framing the door frame with panels, for example, made of MDF, laminated or veneered chipboard.

To do this, it is enough to correctly mark, cut out the parts and attach them to the wall.

There are three ways to install slopes:

- using polyurethane foam

- on plaster mortar or special glue called liquid nails

- on a pre-assembled frame

Slope fastening

After fastening the slopes with self-tapping screws or gluing with liquid nails, the platbands are attached. The screws are recessed a couple of millimeters deep and then sealed with putty matched to the color of the platbands.

We measure and make a sketch

Before starting work, you need to make sure that the walls are made of brick or concrete. It will not be possible to install a welded metal door into an opening made of plasterboard or thick plaster. If the results of measurements of the width and height turn out to be more than 1.5 × 2 m, when drawing up the drawing, it is necessary to provide for the installation of an additional frame covered with iron on the side or on top of the door frame. The sketch indicates the dimensions of the door, the height of the hinges, lock and peephole, and the distance between the stiffeners.

Self-production of iron doors - drawings, materials and installation instructions

Despite the fact that there are many models of entrance doors on sale, in some cases it is quite difficult to choose the right option. Some are not satisfied with the dimensions due to the non-standard opening at the installation site, others are afraid of hidden defects in the product, and others are embarrassed by the high cost of the kit.

Making a metal door yourself, with proper organization of the process, has a number of advantages. For example, you don’t have to worry about the quality of the design; it can be assembled according to any acceptable drawing, and there won’t be any problems with the design - there are many techniques. In addition, the costs of assembling and finishing the block will be minimal.

Let's start welding: step-by-step process

The correct welding of metal doors depends on the condition of the opening. Therefore, it is puttied, plastered, and adjusted to the size of the door frame indicated in the drawing. The position of the sides is checked by a level.

Assembling the door frame

To be on the safe side, the opening is measured again. If there are no errors, proceed to making the frame:

- Blanks are cut from a 40x40 pipe, taking into account that the size of the box is 1.5 cm smaller than the opening. This will avoid difficulties when welding the door.

- The workpieces laid out on a flat surface are grabbed together.

- Angles, matching diagonal sizes, and horizontal elements are checked.

- If there are no distortions, complete the welding. The seams are cleaned with a grinder and a grinding wheel.

- For fastening to the wall, three eyes are welded on each side with holes for anchor bolts made from a 40x4 mm metal strip. For reliability, it is also advisable to place a couple of pieces on top and bottom.

We weld the door leaf

Beginners are recommended to make metal sheathing with a thickness of 2 mm or more, since a thin sheet can easily be burned through with insufficient experience. The order of assembly of the canvas:

- Frame elements are cut from a 40×20 pipe so that it is 3 - 5 mm smaller than the door frame on each side.

- After welding, the angles and diagonals are checked.

- A stiffening rib is welded vertically, dividing the frame into two equal parts. In each half, two sections of profile pipe are installed horizontally.

- The sheet of iron is marked so that it overlaps the box by 1 cm at the top, bottom, on the side of the handle, and at the hinges - 0.5 cm.

- Since tightness is not required, the sheathing is welded to the frame in short sections at equal intervals, alternately on each side, so that it does not “lead.”

We weld the hinges

Before installation, the canopies are lubricated with grease or other similar lubricant. This will protect them from damage during welding. Then:

- the installation location of the canopies is selected at a distance of 20 - 25 cm from the lower and upper edges of the canvas;

- so that the trim does not touch the door frame when opening, the hinge is installed in a slightly raised position;

- check that the canopies are in one straight line and scald;

- the frame is installed in the box, leveled, and the mating parts of the canopies are welded.

To strengthen it, it is recommended to weld metal plates (ears) to the hinge bodies, overlapping the frame. After welding, they will distribute the load more evenly.

We cut in the lock and door handle

To install the lock, two rectangular holes are cut in the opposite walls of the profile pipe at a height of 1 meter from the floor. To make the lock flush, the cutout is made longer on the outside. Two plates are welded into it from the inside, in which threaded holes are made for screwing the lock ears with bolts. On the contrary, a hole is made in the profile pipe of the door frame for the crossbars (tongues) and latches. After fitting, a place for the keyhole is outlined. It is first drilled and then bored to the desired shape with a round file.

After installation, a decorative trim and a lock handle are installed on the outside. If the peephole is placed in the center, you will have to drill a vertical stiffener. Therefore, it is more expedient to move it to the side.

We insulate and line the door

It is best to insulate a metal entrance door with foam plastic 40 mm thick. The use of mineral wool is undesirable, as it absorbs moisture and then shrinks. After 2 years it completely loses its properties.

Rectangles are cut from polystyrene foam slightly smaller than the space between the stiffeners. After gluing them, the remaining cracks are filled with polyurethane foam. The insulation is covered with plywood on top, secured with rivets, and covered with veneer or wallpaper. Cladding is also done with laminated or plastic panels or clapboard.

The outside of the doors can also be finished with panels, but it is easier and more reliable to cover them with hammer paint in the following order:

- the surface is cleaned with a metal brush or an attachment on a grinder;

- degreasing is carried out with a solvent;

- a primer corresponding to the type of paint is applied:

- Using a brush, roller or spray gun, apply 2 - 3 layers of paint.

Installing the door

Installation procedure:

- The frame installed in the opening is aligned with the level gauge using wooden wedges;

- holes with a depth of at least 15 cm are drilled through the eyelets in the wall;

- fastening is carried out with anchor bolts or driving in metal rods with a diameter of at least 12 mm, followed by welding to the eyes;

- the door leaf is hung.

The gaps between the frame and the slopes are filled with mineral wool and filled with polyurethane foam. After a day, the excess foam is cut off, and a layer of cement-gypsum mortar is applied on top. It will protect the foam from destruction, as it is afraid of light.

Preparation stage

Work should begin by dismantling the old door and completely cleaning the opening. Only after a thorough examination of the condition of the base can one conclude whether it is suitable for installing a metal structure or not. It may be necessary to narrow (expand) it in accordance with the required dimensions and further strengthen it. The latter is typical for buildings made of cellular concrete, wood, as well as other materials with a significant degree of wear. Consequently, the necessary technological operations are carried out.

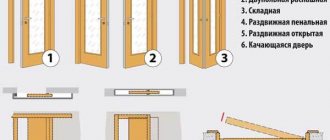

After obtaining a passage in the wall with the correct geometry, you can begin taking measurements. Based on this, a drawing of a metal door is developed. In addition to determining the dimensions of the frame and sash, you should also choose a design diagram. First of all, in which direction is it more convenient to open the canvas, where is it better to install locks, hinges (their number) and fittings (handle, peephole) on it. Sometimes it is advisable to make a “one and a half” version. In it, the small sash is rigidly fixed, but if it is necessary to temporarily expand the opening (for example, when moving large loads), it is easy to open it.

Materials and supplies are being prepared. When working with iron, welding will be required. Plus, a hammer drill (electric drill with a chipper) and a grinder. Everything else is ordinary household tools, a square, a tape measure. It’s a little more difficult with materials; you’ll have to choose.