Installation of doors made of aluminum profiles is a rather specific process that takes a bit of time from professionals. But an inexperienced user risks making many technical errors, as a result of which various problems will appear during operation:

- Distortions;

- Condensation formation;

- Ice;

- Drafts;

- Mechanisms jamming, etc.

Once such troubles are discovered, either adjustments and partial repairs, or complete dismantling and replacement of components will be required. It probably goes without saying that such events are not cheap and take a lot of time. Therefore, we strongly recommend inviting experienced workers with the necessary tools and skills to conduct events. After all, even the most reliable glazed aluminum fire doors will become unusable if installed incorrectly and used in the same way.

Advantages of aluminum profile doors

Manufacturing doors from aluminum profiles has a number of undeniable advantages:

1. Aluminum resistance to water vapor and water. Hence:

- the aluminum door will not swell or lose its shape;

- it can be washed using detergents.

2. Aluminum is practically not subject to corrosion. The result is the durability of the door, its excellent appearance throughout its entire service life. 3. Static stress does not accumulate in aluminum.

4. Possibility of use in any climatic conditions. Aluminum doors feel great at temperatures from -80 to + 100 °C.

5. Aluminum tolerates direct sunlight very well.

6. Aluminum is a very light metal. At the same time, it has good strength and is not subject to deformation. It is not for nothing that aluminum is the main material used in shipbuilding and aircraft construction. If the planes turn out to be strong and durable, then there is nothing to worry about getting out the door.

7. The appearance of aluminum profile doors is also important. They are beautiful, elegant and fit perfectly with the architecture of modern buildings.

8. Such a door is an excellent alternative to ordinary interior barriers. Thanks to glass inserts, the space seems wider. The room is filled with bright light. Such a door gives the interior originality, making it stylish and sophisticated. Glazing is used both single and double.

9. Wide variety of shapes. Aluminum doors are not necessarily a traditional rectangle. Modern aluminum doors emphasize the integrity and harmony of the appearance of the building. Hence the presence of soft, streamlined, rounded door shapes.

10. An undeniable advantage is the variety of colors. It is possible to choose an aluminum profile for doors of almost any color. The paint can be either glossy or matte. An interesting solution is one door, made in different colors on the outside and inside. This allows the door to fit most harmoniously into the interior of a separate room. Moreover, the main door accessories, such as latches and hinges, are made in the same color.

11. Aluminum doors have a high level of sound insulation. Leave the noise and bustle of the city outside the door, plunge into silence and comfort.

Groups of doors made of aluminum profiles

According to their design, doors made of aluminum profiles are divided into two groups:

1. Cold doors. The profile does not contain thermal inserts. Similar door structures are used for unheated rooms or in those parts of buildings where there is no need to separate the cold zone from the warm one. Main objects of application:

- entrances to public places, such as banks, shops;

- vestibules, stained glass windows;

- office partitions.

2. Warm doors. A profile of this design is equipped with a thermal insert. In addition to the thermal insert, there is a double seal along the entire contour of the sash. Warm doors perfectly retain heat and prevent the penetration of cold air. It is used when necessary to separate zones of a room into cold and warm, or at the entrance to heated rooms. Typically used as an entrance door for a residential building.

Rules for posting comments

You can leave your opinion about the video posted on the portal.

If you are interested in the services of the company that posted the video, go to the company's page.

Forbidden:

- Advertising messages are prohibited.

- The use of HTML tags and scripts in JavaScript and VBScript is prohibited.

Messages with offensive and obscene content are prohibited.

All messages are reviewed by the administrator and, in case of violation of the rules, are deleted without warning or explanation.

Aluminum heated entrance doors are the key to heat conservation. This design is mainly placed on the balcony and is quite popular.

Warm aluminum entry doors can be really warm if you install them correctly. In this article we will tell you how to install warm aluminum entrance doors.

Only before installation should you know about all the advantages and disadvantages of this design and only after that make a final decision.

Types of doors made of aluminum profiles

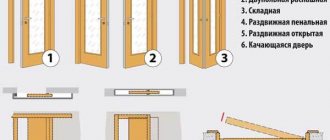

There are several types of doors based on the opening method:

1. Swing. Standard door type. It is installed in the door frame. Fastening to the door frame is carried out using side hinges. A swing door can only be opened in one specific direction. This type of door is usually used inside offices, residential buildings and apartments. This is the simplest option for an interior door.

2. Pendulum. Due to its design features, such a door opens both inside and outside the room. The door is fastened to the ceiling and floor. Almost always, swing doors are equipped with a closer, allowing them to return to their original state after opening.

3. Sliding or sliding. The door moves to the side when opened. The door leaf is attached to special carriages. They ride along a special rail attached to the ceiling. A great option for saving space. A swing door can only open if there is free space behind it. But the sliding door moves along the wall and will open in any case, no matter what is behind it. This type of door is used indoors or at the entrance to shops and supermarkets. There are sliding doors: left or right; double-leaf or single-leaf. For a double-leaf door, the following options for movement of the leaves are possible:

- both doors move along the same guide;

- each leaf is equipped with an individual guide;

- move inside the wall or move along it;

- sliding doors equipped with folding doors. When such a door is opened, the doors fold. The folded sash slides into the wall.

Sliding doors are suitable for openings of any height and width. It is possible to use both lower and upper guides. The use of upper guides allows for absolutely silent door movement.

4. Foldable. The door folds like an accordion. Very convenient design, takes up minimal space. Very wide range of applications:

- dining room;

- kitchen;

- living room;

- library;

- wardrobe;

- crockery or book display.

5. Carousel. They are used at entrances characterized by increased throughput. Using a revolving door is guaranteed protection against pollution and drafts. Revolving doors are produced in three types:

- non-automatic. Open manually. The visitor has to push the door in front of him;

- semi-automatic. They always rotate;

- automatic. They react to the approach of an object and begin to rotate.

I would like to include automatic doors in a separate group. They are installed at the entrances to shops, hotels or other public establishments. A special sensor reacts to the approach of an object and sends a signal to open the door.

Doors are classified according to their purpose:

1. Fire protection. Possible design options:

- deaf;

- partially glazed;

- They are entirely made of glass.

Heat-resistant glass is used. The fire door is an all-aluminum structure. The internal lining of profile structures is carried out using fire-resistant silicate strips.

4. Explosion-proof.

Choosing a door made of aluminum profile

The choice of such external characteristics of the door as color, shape, size depends entirely on the preferences and wishes of the client. However, there are a number of nuances that it is advisable to pay attention to:

- Hand painting of the profile is not permitted. The paint should lie in an even layer. Drips and roughness are unacceptable.

- The minimum width of the thermostat is 20 mm. Aluminum jaws should be provided with notches to hold the thermostat.

- Make sure the kit includes door hinges and not window hinges. The use of window hinges is unacceptable; they are less reliable.

- The seal material is silicone or EPDM. Other seals crack at the first frost. In the corners of the box, the seal must be securely glued. The joining of the glass unit with the seal is absolutely smooth, without waves. The presence of cracks and gaps is unacceptable.

- Corner brackets must be mounted on pins. Coating them with sealant is mandatory.

- The beads are located on the inside of the door and fit tightly one to the other.

Educational films "ALUMARK"

Use of templates, tools and equipment

Templates significantly reduce the time for profile marking and ensure accurate and high-quality assembly of translucent structures.

F50 series. Post-transom system for the manufacture of facade structures. The façade rack template is intended for processing the rack profile for the subsequent installation of the crossbar block. The template is made of aluminum alloy; the template has a screw clamp for drilling the workpiece.

S70 series. System for the production of warm window and door structures. The window sash template is designed for assembling the corner connection of window sash profiles. The template is made of aluminum alloy; the template has a screw clamp for drilling the workpiece.

Please note that the profiles and components shown in the films may differ from those actually existing in the TBM trade program. Work to improve the Alumark aluminum building system continues and the replacement of certain types of components with new, more advanced ones is carried out routinely.

Installation of doors made of aluminum profiles

Most often, to install doors with aluminum profiles, they resort to the services of professionals. Representatives of the manufacturer do not limit themselves to delivering the door to the buyer’s home. Even if they do not do the installation themselves, they will definitely advise who is best to contact. However, many buyers prefer to install aluminum profile doors with their own hands. It's not as difficult as it seems at first glance. Patience and strict adherence to installation instructions guarantee a positive result.

Product advantages

The exhibited designs are used virtually everywhere. The production of aluminum doors takes place in factories. In addition, you can construct such a product with your own hands using iron profiles. Among the advantages of similar structures are the following:

— Corrosion resistance. Moreover, at the production stage the metal is additionally processed with special means.

— Easy to maintain and install.

- Safety. The fact is that the processed profiles do not emit any harmful substances and also do not contain heavy metal salts.

— The production of aluminum doors is happening rapidly.

Also, such windows and doors fit perfectly into any interior.

How to make doors from aluminum profile

How to make doors from an aluminum profile with your own hands. Let's consider a structure in the form of a frame, covered with durable material along the internal perimeter.

The figure shows the structure of the door and its components.

1. Square or rectangular profile. 2. Aluminum plate. 3. Material (heavy-duty mosquito net, fabric, polymers). 4. Door hinge. 5. Handle with lock. 6. Self-tapping screws with hex head screws DIN 7504K. 7. Expansion rivet.

I

– corner connection using connecting angles

II

– end connection using angles

Aluminum profile door manufacturing technology

1.

According to the drawings, we trim aluminum blanks of the required size at a given angle.

2.

We will produce embedded products for connecting workpieces (corners, corners).

3.

We will connect aluminum profiles.

4.

Fix the door hinges to the frame profile with expansion rivets.

We select and install the hinges in such a way that the door leaf fits tightly to the door frame and closes the gap between the frame and the door. 5.

Attach the door handle to the assembled frame.

6.

Along the perimeter of the door frame, we attach the aluminum plates with self-tapping screws with a hexagonal head DIN 7504K.

7.

Inside the frame, into the grooves of the profile, insert a heavy-duty mosquito net and secure it with a rubber seal.

Instead of mesh, you can use durable fabric or polymer material. 8.

We will hang the doors on the door frame.

Assembled doors according to the proposed scheme have a number of advantages:

- - weather resistance

- - lightness, strength and durability

- - good appearance

- -possibility of use in any climatic conditions, with a wide range of temperatures and exposure to sunlight

- - ease of manufacture

We install the structure

Aluminum doors are sold with a full set of mounting elements. Installing them is not difficult at all and you can do it yourself.

To mount the door structure yourself, you must follow the following procedure:

- dismantle the old door and related elements;

- We insert the door frame into the prepared opening and fix it around the entire perimeter with wedges;

- using a level, we achieve the ideal horizon of the entire structure, adding linings of the required size;

- in the frame we drill holes for dowels with a diameter of no more than 1 cm, which we place at a distance of 30 cm from the edges and in the middle on the side elements, and 30 cm from the edges on the top and bottom;

- we screw in the dowels, starting from the side frame on which the door hinges will be installed;

- You can completely tighten the dowels only after you make sure that the vertical and horizontal lines are maintained;

- after this you can hang the door leaf;

- We fill the voids between the door frame and the wall with polyurethane foam, after wetting the structural elements with water.

That's the whole installation. If you did everything correctly, the aluminum door will not cause you any trouble.

See also:

Tips in the article “How to assemble a corner sofa” here.

Aluminum door. Installing a hidden door hinge and adjusting it in the video:

Types of aluminum doors

Depending on the nature of the opening, doors made of aluminum can be used: hinged, pendulum, radius, revolving, or combined. Well suited for small spaces. Options for designing and installing entrance doors with fully movable leaves or with one fixed part are possible.

The manufacture of doors, especially for buildings where there is a high volume of people moving through entrance openings, must meet a number of requirements, which is ensured not only by compliance with GOST and other standards, but also by the quality of the material.

Stages of product production

The production of doors from duralumin profiles in most cases takes place in a specially equipped workshop. The process itself is not complicated and does not require much time. There are several steps in the production of the presented designs:

1. Heating of duralumin ingots at the highest temperature in a special furnace. After which the metal is pressed and cut into elements of a given length. All this is done automatically. But you need to watch the process so as not to get a defect.

2. The manufacture and installation of aluminum doors is done only after all parts have been treated with an anti-corrosion compound.

3. Creation of fastening corners with which the profiles are connected.

4. Frame assembly. At this step, the heat insulator is laid (if necessary).

5. Inserting double-glazed windows.

In principle, creating the presented designs is not difficult. If you decide to make doors at home, then it is enough for you to purchase duralumin profiles.