The construction market offers doors from many manufacturers that have different opening designs. Hinged doors were initially very popular, so their design is of interest to many apartment owners. How to install an interior swing door with your own hands so that it works for a long time without deformation or modification?

Appearance of a classic swing door

Where are double-leaf (double) doors used and where to install them?

You can install double doors wherever your heart desires. But, there are a couple of conditions: the doors must correspond to their intended purpose, that is, external doors must be installed outside, and interior doors must be installed indoors.

The second condition is the width of the opening where you install the door. If it is double, then there are no problems, but if it is single, then it is necessary to widen the opening. Here you need to be careful, since this is a redevelopment and expanding the opening from a single or one-and-a-half to a double, especially in a load-bearing wall, is necessary after agreeing on the redevelopment and the appropriate permission from the BTI.

Expansion of a doorway in a load-bearing wall requires permission and appropriate strengthening of the opening

Let's assume that you have a double doorway, or you have taken all the necessary actions and, with the permission of the BTI, expanded your opening or created a new one. If you have an old double door installed in your old double opening, it will need to be removed first, so let's start there.

Types of doors by design

A solid wood box has the following advantages:

- low thermal conductivity;

- high strength and frost resistance;

- durability;

- environmental friendliness;

- opportunity to implement different design ideas.

At the same time, wooden canvas has the following features:

- unprocessed raw materials quickly absorb moisture;

- presence of cracks and knots;

- flammability.

To reduce absorption, the board is dried, treated with hot steam and impregnations.

Massive doors

Before making wooden doors, it is recommended to determine the features of the production process. The dacha can be protected from robbers by a massive canvas, for the manufacture of which thick tongue-and-groove or planed boards are used. The resulting structure is strengthened with horizontal or inclined jumpers.

To make a massive door, dense wood is used

To make a massive entrance door, cedar, larch or oak are used. This type of wood is characterized by a dense structure and textured pattern.

If the project of a summer cottage includes a bathhouse, then linden and pine are used to arrange the opening. The bathhouse must be used after treating the wood with an antiseptic.

Paneled doors

To make paneled fabric, boards and beams obtained by gluing lamellas are used. Then the workpiece is covered with veneer. Before constructing the canvas, a drawing is prepared. It indicates the configuration of the panels. It can be the same or different. Glass can be used instead of wooden elements.

Paneled doors are most often installed indoors

To equip the vertical and transverse elements, you will need to glue the timber. To make the canvas, a floorboard of appropriate thickness is used. To fix individual elements, spikes are used.

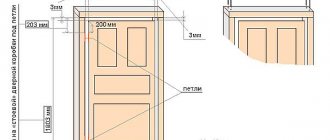

Door assembly diagram

If a panel is used to make the canvas, you need to consider:

- The reliability of the product is directly affected by the number of cross-sections;

- a homemade box is formed from timber, and a lath or plastic is used to make a panel;

- glazing bead is used to fix panels.

Since the paneled door is thin, it is considered the best option for creating an interior doorway.

Panel doors

The panel box is made of fiberboard, veneer or laminate. The frame is assembled from boards. Fiberboard, MDF or chipboard sheets are used as a shield.

Panel door design

The canvases under consideration are classified into the following types:

- solid - filled with beams fastened together;

- hollow - made from side and transverse beams. Lining is used for cladding;

- small-hollow - have different fillings.

To create a high-quality canvas yourself, the frame is first covered with plywood. The material is laid in 2 layers. Size of 1 layer – 24 mm. This technology prevents deformation of the coating.

What is a swing door made of?

So, when dismantling the door, we found out what it consists of, let's repeat and analyze it popularly:

- The door leaf is the door itself.

- Door frame - bars (mostly made of MDF or wood, if the door is more expensive) of a special shape, which are attached to the doorway; the door closes into the frame.

- Door trim covers the mounting joints between the frame and the edges of the wall.

- Door hinges are what the door hangs from in the door frame.

- An additional strip is not always a required attribute; it is used to block a wide doorway (the photo below shows where it is).

- Locks, latches, handles...

What does an interior door consist of?

Now we will find out how to dismantle the old double door, if there is one.

Features of wood of various species

When producing wooden doors, you need to know the advantages and disadvantages of the material. The final result depends on this. The main difference between wood is its hardness. Soft woods are easy to work with, but are less resistant to moisture. This material is suitable for interior doors. It is difficult to process hard wood with hand tools, but the material is more resistant to moisture. This wood is suitable for making entrance doors.

When talking about wood species, it is worth considering the resin content of the material. Larch takes first place in this regard. A product made from it will withstand dampness for a long time. Resin protects against rotting.

The following requirements apply to choosing a board:

- minimum number of knots;

- wood moisture content no more than 15%;

- perfect evenness.

For outbuildings, used material taken from the dismantling of old buildings is suitable. It is better to make beautiful doors to the house from a new board.

Hardwood

- Birch is quite hard and difficult to process, but has an attractive texture.

- Beech is characterized by increased strength, but deforms when humidity changes.

- Alder is soft and rots quickly in high humidity.

- Oak is hard, tends to split, but is resistant to dampness and beautiful.

- Walnut has an interesting texture, is easy to process, and is not afraid of moisture and mechanical stress.

- Maple is moderately hard, can be processed well, and has moderate resistance to moisture.

For the manufacture of wooden entrance doors, oak or beech is most often used.

Conifers

- pine is considered the most popular . Soft wood is easy to process, but does not withstand moisture well. The material is best used in the manufacture of wooden interior doors.

- Larch is characterized by a beautiful texture and high resin content. Solid wood perfectly resists moisture, which makes it possible to use the board for assembling entrance doors.

- is knotty, lighter and softer than pine, and slightly inferior in strength.

Removing an old double door

The door is dismantled quite simply. The first step is to remove the door panels. It is worth paying attention to the hinges on which they are attached; they may or may not be removable. The door can be easily removed from removable hinges: you need to open the door 90 degrees and, lifting it, remove the upper part of the hinges from the two pins. If the platband on top prevents you from removing the door, you must first dismantle it.

I recommend: How to replace wooden windows with plastic ones in a wooden house

If the door is not on removable hinges, you need to unscrew one of the hinges from the door leaf or frame.

Fixed butterfly door hinges

After the door panels are removed, you need to dismantle the door trims.

If the platbands are old, you can use any available tool for dismantling: an ax, a hammer and/or a crowbar.

Relatively new trims are attached mainly to thin finishing nails; finding them on the door is not difficult. Such platbands can be removed directly by hand, using something to pry them from the side.

Modern trims are attached to finishing nails

The next step is to dismantle the door frame. Again, if it is old, then we use a hacksaw to saw through the vertical posts of the box in the middle and use a crowbar, removing parts of the posts one by one. At the same time, if you are not going to repair the walls, then you need to be careful not to damage the walls, especially if they are not concrete, but, say, plaster.

If the door you are dismantling is relatively new, then most likely it is attached with self-tapping screws from the end of the door frame into the wall and additionally with mounting foam. You need to unscrew the screws, cut through the foam with a knife and dismantle the box.

Installing a door is quite a troublesome, complex and time-consuming task. Installing a sliding door is much easier than a swing door, especially if you purchase a kit for self-assembly, these are commercially available. Now let's look at the types of platbands and methods of fixing door bars.

Painting

At the next stage, the finished structure is processed and decorated. It is recommended to adhere to the following plan:

- processing the coating with sandpaper or a grinding machine;

- impregnation of wood with antiseptic. The first layer should dry well. The processing is then repeated;

- the canvas is covered with a special putty, which can be replaced with a primer. In this case, the canvas is processed 2 times. But each applied layer must dry well. This will take about 2 days;

- Paint, varnish, and stain are used to finish the coating. The stain must be applied over the primer. Taking into account the desired shade, the appropriate number of layers of stain is applied. Each layer will take 4 hours to dry. To fix the result, the stain is coated with two layers of varnish.

To finish the door, paint, varnish, and stain are used

Experts advise treating the door with special protective agents against moisture and pests . If the door leaf will be installed in an apartment, then it is coated with a fire retardant. To perform a more complex decoration option, you will need the help of a specialist. Read more about painting and treating doors in the article “Painting wooden doors.”

Types of platbands and ways to cover boxes

Platbands can be:

- corner or

- invoices.

Corner (L-shaped) and overhead casing

Corner ones are installed in the groove of a box block, overhead ones are nailed to the bars with finishing nails or glued (in rare cases).

Overlay platbands can be:

- flat or

- rounded,

- There are also milled trims, but they are difficult to install with your own hands.

Depending on what kind of casing you have, it can be sawed and joined differently:

- at right angles (for flat platbands),

- at 45 degrees (for rounded ones).

Also, depending on the platbands, the door frame bars in the corners are sawn and joined:

- at 45 degrees or

- perpendicular.

I washed down the box bars at 45 degrees and perpendicularly

This is done for symmetry, so that both the box and the casing are cut at 45 degrees; box at right angles and platband. Perpendicular is a little easier.

Now about the necessary tools.

Main types of doors

In terms of their structure, door leaf manufacturing technologies differ in design. They look different in appearance, although they can be made of the same materials.

Option No. 1 - paneled door structures

The most classic model is paneled. They are decorative and very diverse in appearance.

The main features are the presence of:

- wooden frame - strapping;

- jumpers located vertically;

- panels - figured planks from solid wood.

Sometimes panels can be partially replaced with glass or other decor.

This design is durable and has good sound insulation. It is resistant to changes in humidity, even if it is made of wood, as it consists of separate components. The fibers in them are multidirectional and compensate for temporary deformations that occur due to moisture or dryness.

Panel doors, due to the fact that they are made of natural wood, can have a high price and are heavy, which requires strengthening the fastening during installation

In this case, you can compromise and opt for a pine product. This is light wood, and modern coatings allow you to tint the surface as required by the interior design.

Paneled doors are also made of MDF or can be combined, using different materials, which allows you to choose an option that is suitable for price and appearance.

Option No. 2 - panel doors

A fairly budget-friendly type of door structure is panel models. They consist of elements such as:

- frame made of solid wood;

- sheathing, for example, MDF sheets;

- surface decor: veneer, laminate, PVC;

- filler.

The frame is usually made from pine or spruce bars - this is an inexpensive, light, but durable wood. MDF is a man-made material, but it is made from natural ingredients.

Finishing veneer makes the door more beautiful, although it increases the cost. Lamination and PVC film as decoration are quite impressive, although doors with such a coating are cheaper.

For sound and heat insulation, there is a filler inside the panel doors. The most economical and lightweight is the cellular one, it is made of MDF

Option No. 3 - side doors made of MDF

Drawbar models are very popular. They are a prefabricated structure.

Tsar doors consist of: tsar - transverse strips and vertical posts. Horizontal elements are alternately inserted into the side ones using longitudinal tongues and grooves.

Drawer doors, due to inserts of different widths made of glass and metal, are varied in design and look modern

Each MDF part is covered with a protective film or laminated before assembly, so they have no edges and moisture will not get inside.

Option No. 4 - molded models

There is another modification of prefabricated doors, which is conventionally called molded. To be precise, door moldings include platbands, extensions, flashings, thresholds, and vertical pillars of the frame.

By design, the door models are made of molded elements, which is why they are called that. Most often, these are two or three vertical racks, with elements made of glass or MDF panels inserted between them

The parts, as in draw-bar models, are covered with a protective layer before assembly and have no edges.

Required Tools

To cut the door frame bars you will need the following tool:

- Or an electric miter saw, which allows you to get a better cut and speed up the work process.

Miter saw

- Or a hand saw with a fine tooth and a miter box.

Hacksaw and miter box

- Also, a miter box and a hacksaw can be a single tool, almost a miter saw, but with a manual drive.

Miter box with hacksaw

What other tools and materials will be needed to assemble a double door frame:

- hammer;

- screwdriver;

- chisels, 2 pieces - wide, about 20 mm and smaller, about 10 mm;

- wood drill 3 mm;

- self-tapping screws 3.5*50-60 mm;

I recommend: Where should the door to the pantry open?

Step-by-step manufacturing instructions

Any step-by-step plan for manufacturing a door involves assembling a shield. If the installation of the canvas in the bathhouse is planned, then a simple assembly of the shield is carried out. To fix the boards, transverse and longitudinal elements are used. A warm box for the home is made taking into account aesthetics. The assembled shield is polished.

Making a door from solid wood

The step-by-step plan for assembling the canvas includes the correct choice of consumables. To make a shield, you will need tongue and groove boards more than 25 mm thick. Then the consumable material is cut into pieces.

The tongue and groove boards must be smooth and without grooves on the front sides

When assembling the shield, it is recommended to take into account the direction of the annual rings. To connect tongue and groove boards, a tongue-and-groove lock and wood glue are used. If the consumable material is non-grooved boards, then they are assembled using glue .

The work is carried out on a large surface area. The assembled coating is pressed with clamps. If the shield is dry, it is processed with a milling cutter. To ensure good sound insulation, it is recommended to assemble a shield from several layers of boards. The resulting structure is clamped with clamps.

Array gluing

Traditional methods of tying boards in solid wood doors

For tying, crossbars are used, installed at the top, middle and bottom of the covering. Markings for grooves are made on the canvas. The recesses made should be ½ the thickness of the consumable material.

Assembly diagram

Holes are cut using a router. It is more difficult to cut grooves by hand. For this you will need a chisel. A rubber hammer is used to insert the cross member. If you plan to apply a drawing to the resulting shield, first trace its outline using a pencil according to the template. A cutter is used for cutting.

The cutouts are milled according to a previously drawn pencil drawing.

Then the canvas is painted with pre-treatment with an antiseptic. Markings are made on the canvas and the box for installing hinges. The markings for the handle and lock are done in the same way. The last stage is hanging the canvas into the opening.

Treatment with antiseptic and varnish

Manufacturing of a panel door

The instructions for making a shield sheet allow you to use finely filled boards. Experts distinguish 3 methods for assembling such a design:

- preliminary assembly of the frame with subsequent filling of its internal space. Using this technology, you can create a solid or finely filled shield;

- separate production of the shield with its subsequent fixation into the frame. The last stage is covering with finishing material;

- The manufactured shield is mounted in a frame and lined.

To assemble the canvas using the first method, primary tying is carried out. It will determine the size of the future door. The structure uses timber with a cross section of 30×120 mm. Consumables are cut to fit the dimensions of the future structure.

The next step is choosing the type of connection in the corners. Experts advise using the “half-tree” method. Accurate marking of future grooves is an important stage in shield assembly.

Connection diagram of frame elements

All grooves are coated with glue. The connection of the timber is carried out on a flat but large area. If the glue has dried, the connections are fixed with dowels. To do this, make through holes with a diameter of 8-10 mm.

Plywood or fiberboard is used to cover the frame. The markings are made and the frame is removed. The frame returns to its original place. It must be pressed against the facing material treated with glue.

Plywood or fiberboard is used for cladding

MDF is used to fill the interior space. It is glued to the bottom sheet of finishing material. But first the glue must dry well. At the same time, it is recommended to prepare consumables for the outer lining of the canvas.

Internal filling gives the canvas rigidity

If you need to glue 2 sheets, then the first sheet is fiberboard, and the second is laminated material or SF. The resulting structure is sent under the press.

You can cover the door with natural wooden slats. They are fixed to the frame. The holes made are filled with a mixture of glue and sawdust. If the surface is dry, it is treated with sandpaper. All corners and ends are processed with a milling cutter. The handle and lock are cut into the finished door leaf, and the hinges are fixed. The door is mounted in a corresponding frame.

A frame door is made using a similar method - the interior space is additionally reinforced with beams. But before starting work, accurate calculations are carried out and a drawing is prepared.

Making a paneled door

To make a paneled door, you will need special carpentry tools and experience. The components of the structure are made of plywood and solid boards. A drawing is pre-prepared, on which 4 panels are marked.

Paneled door in section

The frame is made of timber. It is pre-processed with a milling cutter. Then a groove is made on one side of it. Tenons are cut out on the crossbars, and the edges are processed with a router. Panels and mullions are inserted into the grooves.

Panel door assembly diagram

The end part of the coating, which will extend to the end of the canvas, must be flat. Slots are made in the vertical elements to assemble the structure.

To make panels, plywood or chipboard is used. Some panel elements are replaced with glass. In this case, glazing beads are additionally used. Panels with a flat plane are mounted and framed with glazing beads.

Otherwise, the panels are processed with a router. In this way a relief configuration is created. Plywood is used to make panels. Each element of the future canvas is treated with an antiseptic and dried.

Milling scheme 1

Milling scheme 2

All parts are assembled into a single structure on a flat surface, and each spike is coated with special glue. Step-by-step door assembly:

- gluing crossbars into the grooves of vertical beams;

- installation of mullions;

- installation of the remaining panels;

- gluing vertical beams;

- fixing glazing beads for finishing.

To install the tenons into the grooves, use a rubberized hammer. The canvas is padded from the sides. A construction angle is used to check corners. The covering is compressed with clamps.

Markings are made on the canvas for installing hinges and a handle with a lock. Installation of fittings is carried out after completion of finishing work. Acrylic paint or varnish is used for finishing. To obtain a dark finish, stain is used.

Assembling a double door frame

The very first thing you need to decide is where the door will open and on which side the porch will be.

Where is the narthex at the door frame

The second thing is to prepare a quiet, clean and spacious place so that no one walks there and you can safely put the entire door frame there.

Measuring the top bar

You need to measure and cut the top crossbar, to do this we add up the two panels in width, add the gaps between the panel and the frame on both sides and another one between the two panels, and also add two times the thickness of the vestibule.

It is most convenient to take gaps of 0.4-0.5 cm, since less will be more difficult to work with, and more is not necessary.

Top strip width = (door leaf width * 2) + (gaps * 3) + (rebate thickness * 2).

Total, for example, (2 canvases of 80 cm each) + (3 gaps of 0.5 cm each) + (2 thicknesses of the narthex of 3 cm each), we get 167.5 cm.

“Having measured 7 times,” we cut off the crossbar.

We measure the racks

The length (height) of the racks consists of the height of the door leaf, the gap between the door leaf and the top bar, and the gap between the door leaf and the floor.

Again.

The height of the racks = the height of the door leaf (generally 200 cm) + the gap between the leaf and the top bar (0.5 cm) + the gap between the leaf and the floor (1-1.5 cm).

For example, 200 cm + 0.5 cm + 1.5 cm = 202 cm.

“We measure 7 times” and cut off the posts.

Choosing grooves for racks

We apply the rack to the crossbar perpendicularly, the way they should be, align the side edges of the rack and the crossbar strictly flush (every mm is important here). We mark the location of the recess of the protruding part of the door block on the crossbar on both sides. We check the dimensions again and, if everything is correct, select these places with a hacksaw, chisel and hammer, carefully!

Box assembly

We insert the post into the groove on the crossbar, press it firmly and evenly with one hand (or hold it with another person) and use a screwdriver and drill to drill holes through the posts into the crossbar to the length of the screws.

Here it is important to drill evenly so that the drill does not drill through the block from the side or go to the side, into its front part. We tighten the screws. The box must be aligned tightly, with a minimum of gaps.

Having assembled the box, we proceed to marking and installing door hinges.

Preparatory work

Before installing swing doors, the first thing you should do is prepare a place for the door: remove the old door with the frame and cover up all existing holes and cracks. After this, the opening for the future door is measured. Usually the opening has a standard size, but sometimes a standard door has a slightly wider opening. Then you need to use wooden beams, install plasterboard sheets, and also use fiberboard.

Any gaps larger than 2 cm are sealed. When building up the opening, extensions are used. These are panels made of various materials: wood or fiberboard, the installation of which is not difficult.

Installing door hinges with your own hands on a double interior door

It is important not to confuse where the hinges on the doors will be located. Place the assembled door frame in place (at least against the wall) and the door, and mark the places for the hinges lightly with a pencil), taking into account where the doors will open. Also check that the top/bottom of the door is correct.

I recommend: Deformation of a plastic window: what to do?

It is best and most convenient to use removable hinges; it is also important not to confuse the hinges when purchasing; they come in right and left.

From the top bar on the doorway of the box, taking into account the gap between the top bar and the canvas, we mark the places for the hinges. This will be 20.5 cm and 180.5 cm. On the door leaf we mark without a gap, that is, 20 and 180 cm (if the door is 200 cm high).

We apply the hinges, moving them 1.5 mm towards the axis from the door, that is, the axis should not be pressed tightly against the door and frame.

The door hinge should protrude 1.5 mm from the door block and leaf

We trace the outline of the loop with a pencil, remove the loops and cut out a place for them using a chisel and hammer.

Cut out the space for the loop with a chisel and hammer

It is important to first go along the contour with a chisel, cutting through it, as well as on the side, where the axis will be, and then select the entire place for the loop. Closer to the axis, you need to choose less material, a third of the thickness of the hinge, and on the other side, the hinge should be flush with the door and/or frame. That is, the loop should be slightly raised on the axis side. If this doesn’t work, you can put something on the side of the axle, the same selected material.

Having carefully chosen the material for the hinges, we fasten them with self-tapping screws, having previously drilled the holes with a wood drill. It is advisable not to use the screws that came with the hinges; they are very soft.

Necessary materials

To make a wooden door with your own hands you will need the following materials:

- dry tongue and groove board;

- self-tapping screws;

- wood glue.

During the purchase, the thickness of the boards is selected taking into account the installation location of the door leaf. For an interior door, 25 mm thick wood is sufficient. For the front door, use a 50 mm thick board. After purchasing, it is advisable to dry the wooden blanks by laying them on a flat surface using pads.

Additionally, a mortise lock, hinges, handles, and a viewing peephole are purchased for the wooden entrance door. For an interior door, it is enough to take hinges and a handle with a latch.

Installing a double door

Now it's time to install a double door. It takes two people to work!

Having installed the box in the opening, we secure it with spacers made from the remains of the same door bars or wood. We fix the box in the opening approximately as in the picture (you won’t get it so beautifully, but it doesn’t matter, the main thing is to fix the box). This is quite a difficult job.

Fixing the door frame in the opening

Having placed the box as level as possible (from all sides and from the inside too!), we drill holes in the box right through and a small recess under the head of the screw (here you will need drills, one slightly thinner than the screw, the other as wide as the head), so that the head fits into the box.

Fastening the box with screws through and through

If the wall is concrete, then we mark the places where the screws will be screwed in. We remove the box and drill holes for the dowels. We install the dowels and the frame in place, tighten the screws, use self-tapping screws about 100 mm long, first fix the frame and hang the door leaf. It is important that the screws are tightened and do not stick out and damage the canvas.

We check whether the door leaf closes; if not (most likely not), we move the frame further into the level using wedges and tightening or unscrewing the screws. We ensure that the door closes well and tightly and that the necessary gaps are maintained.

When the door is open, you can relax a little and get to the fun part.

Changing the height of the door leaf

Most often, this need arises after laying carpet flooring. If the gap between the upper part of the door leaf and the rebate is sufficient, then a washer can be located between the bouts (canopies) of the detachable hinge. However, the rubbing surfaces must be thoroughly lubricated with oil.

If the gap in the upper ledge is too small, then the upper quarter of the door frame can be planed. This is more convenient than cutting the door leaf. After all, after trimming, the height of the canvas will remain irreversible. The top quarter of the frame must be carefully sanded to ensure the door closes smoothly.

Foaming the seams

The entire distance between the box and the opening must be foamed with foam. This is a simple and interesting task, the main thing is to foam the entire space and after drying, cut off the foam with a knife.

The following are the stages of installing extensions, door frames and → locks, but this will be discussed in other articles on the site.

Leave your tips and comments below. Subscribe to our newsletter. Good luck to you and good luck to your family!

Preparing the doorway

Typically, installation openings during construction are made according to standard dimensions, and doors are made accordingly for them. In such cases, additional materials for installing the door are not required.

But sometimes the dimensions of the opening do not comply with building codes and regulations (SNiP). An opening that is too large is narrowed using a mounting block, a wooden board, a gypsum fiber sheet (GVL) and a fibreboard (DFB). Leave a gap for foam of no more than 20mm. The opening is sealed on each side no more than 40 mm, otherwise the joint between the opening wall and the frame beam will not be covered with a platband.

If you have to increase the doorway by more than 40mm on both sides, then add-ons are used.

Panels are called panels made of wood, fiberboard, MDF, veneer of various thicknesses and different installation methods. Their installation is not difficult.

Measure the distance from the edge of the box to the wall. Using a hacksaw or jigsaw, cut an additional strip of the same length, taking into account the groove. Insert the extension into the groove and secure it with mounting foam in different places, waiting for the foam to dry completely.

If the maximum width of a standard factory panel (230mm) is less than the thickness of the opening wall, use a connecting strip, which allows you to connect several panels and create a doorway without installing a frame.

When preparing a doorway, be sure to check the floor level. The building level is applied horizontally inside the installation opening parallel to the walls. Marks are placed on the walls of the opening on both sides, which are used as a guide when installing the box. The distance from the floor to the mark shows the difference in height between the sides of the box. This difference should not exceed 3mm.

How to install glass swing doors

Swing-type glass doors are often found not only in public buildings, but also in apartments and private houses. Pendulum glass doors are inserted into the prepared opening without a door frame. The device with the rotation mechanism is located at the top of the doorway and on the floor.

This design of glass swing doors allows the installation of panels of significant dimensions without fastening to the walls.

When installing glass swing doors with a lower support from a hinge or closer, it is necessary to check the alignment of the upper and lower supports, which is very important for uniform distribution of the load on the rotating mechanism and its long-term uninterrupted operation.

There are designs of swing-type glass doors with side-fastening hinges. Most often, this type of glass doors is installed in the dining room, hallway, hall, living room, and as partitions in the shower room.

When installing swing doors, you need to remember that the radius of the area covered by the leaf passes on both sides of the door. It is necessary to provide free space for the movement of the door leaf and prepare a flat floor surface.

How to seal cracks

In order to ensure additional stability of the structure, and to insulate a house or room, it is necessary to fill all the cracks with polyurethane foam.

Before starting work, cover the face strips with masking tape. We moisten the cracks with water and fill them with foam. After hardening, we trim the protruding bubbles of the sealant with a construction knife and tear off the tape along with the splashes adhering to it.