If you are tired of a well-worn old wooden door or have fallen into disrepair, and installing a new one yourself seems like a problem to you, then you are mistaken. Next, we will walk you through step-by-step how to install a wooden door with your own hands, plus you will receive 5 tips from a practitioner on how to operate entrance and interior wooden doors.

It is advisable to install wooden doors in a wooden house after the shrinkage of the structure has been completed.

How to install?

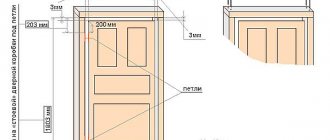

Before installation begins, as described above, the old door is dismantled. Then you need to take the necessary measurements and remove unnecessary elements from the opening.

In a private house

Wooden house

When installing in a wooden house, it is important to pay attention to some points:

- Strength. Wooden structures visually look very durable. But when a metal structure is installed in the doorway, the area next to the door frame weakens and there is a risk of a gap through which dust and wind will penetrate;

- Shrinkage. After a house is built from wood, its foundation is subjected to severe pressure. For several years, the structure shrinks and therefore window and door openings change in size;

- Correct installation. If the installation of metal doors in apartments and brick houses eliminates the destruction of openings, then the passages in wooden houses weaken and can even crack. Therefore, the process of installing the front door requires care and painstaking work;

- Exploitation. It must be remembered that during use the tree can change under the influence of temperature changes and high humidity.

Doors to wooden structures should be chosen that are more massive than doors to panel and brick houses.

For installation in a log house, one of two installation techniques is used:

- The first technique is installation using bars. The timber is inserted into the grooves at the ends of the passage. They put a lock on it.

- The second technique is to install a door in a log house using a casing. Doors made of wood and metal are installed in the casing. It is recommended to install a passage in a house made of timber no earlier than a year after completion of construction. During this period of time, the main part of the wood will dry and shrinkage will be completed.

Foam block house

Now let's look at the installation of entrance doors in houses made of foam blocks. This material belongs to lightweight concrete, it is quite soft

When installing a structure in a foam block, it is important to remember that it stands on the foundation and not on the block

Doors to houses made of aerated concrete are installed in one of three ways:

- on anchors;

- on a metal frame;

- on a wooden frame.

Entry products can be installed both indoors and outdoors. The external door is matched to the external facade of the room. They must have special reliability and thermal protection. Internal entrance doors are installed inside the house. The quality of an internal door depends on the material and fittings.

The positive side of frame houses compared to timber houses and other wooden structures is that they do not require shrinkage. Therefore, after laying the walls and completing repair work, you can install the entrance door to the frame house.

In "Khrushchev"

Choosing entrance structures for a Khrushchev building is not an easy task. There are two ways to install door products in such apartments:

- Expansion of the opening. In this case, it is necessary to make competent measurements so that the new entrance doors do not disturb the neighbors, since in “Khrushchev” buildings the entrances to the living space are located close to each other;

- Making doors to order. This method is preferable since the passage does not have to be enlarged.

Metal entrance doors installed in apartments differ from doors in a cottage or country house. The differences lie in operating conditions. After all, the doors in apartments are installed on landings indoors and are not in contact with the street, while the doors in cottages are street doors and are exposed to external factors.

Plastic entrance doors deserve close attention. They began to be used in private households relatively recently. Previously, such doors were installed in shops and office buildings. They can also be installed at the entrance to a garage or utility room.

Metal-plastic products have quite a large number of positive qualities. They are environmentally friendly, not exposed to chemicals, easy to maintain, have relatively low flammability and an affordable price.

To produce such input products, metal-plastic profiles are used, consisting of several air chambers and stiffeners. Profiles are found entirely in plastic or using metal reinforcement. Metal mortgages connect parts of the door frame to each other. Frames come in any geometric shape.

There are two types of plastic entrance door covering:

- Blind - made using steel sheets, as well as sandwich panels.

- Transparent. This filling is most often mixed. The upper part is filled with double-glazed glass, and the lower part is blank. Glass comes in a variety of varieties, both transparent and frosted, colored or even stained glass. Doors can also be of different colors.

Installation of platbands

Installing wooden doors with your own hands also involves installing platbands. This design looks beautiful, it turns out complete and stylishly decorates the interior.

Having purchased the necessary material, you should take measurements and cut the products based on them. The peculiarity of the installation is that the edges are cut at an angle of 45 degrees. The platband is fitted to the installation site and attached using pins and nails.

During the installation of interior wooden doors and trims, indentations may appear at the place where the nails are installed. They are easy to disguise with mastic.

Doors for a bath: designs, choice of materials, instructions for self-assembly and installation

Windows to the bathhouse: sizes, types, features, construction installation technologies

The plastic window does not close - causes of problems and their elimination

Types of doorway casings

The window frame allows you to strengthen the walls in the openings and prevent their curvature. If the distortions have already occurred, then the pigtail can correct the situation by fastening them and aligning them. It also protects the house from the penetration of cold air and moisture. At the same time, warm air remains in the room - the window acts as a sealant.

The pigtail allows you to prevent shrinkage of the house, stop the processes of its destruction and deformation.

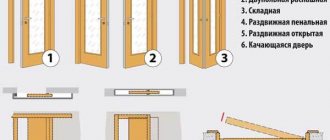

There are several types of doorway casings

- Chernovaya. High-quality casing at low cost.

- Finishing. This option does not require cleaning the slopes.

- Eurocasing. There is also no need to clean the slopes.

- Power. It is usually installed in arched openings, large windows and large doorways.

- Combined. It is inexpensive and stylish in appearance.

- Arched. Consists of solid pine.

The production time for different sieges depends on the size and quality they will be

It is important to choose high-quality materials, as well as calculate the dimensions of the casing in advance. Today, manufacturers offer a wide range of inexpensive, but quite practical and durable casings

Method N 1. Installing doors using a special casing

The procedure for carrying out work by installing a special casing is as follows:

- The first step is to cut out the opening intended for installing the door frame. It needs to be cut in such a way that half of the log or beam remains on top and bottom.

- Next, using a cutter, you need to cut a groove at the end of the opening measuring at least 50 × 50 millimeters. You can use a chisel to adjust the size of the groove.

- A beam is inserted into the resulting opening. It is necessary to take into account its length. If the log house is new, then the size of the timber should be 5 centimeters smaller. If the structure has already shrunk, then the length of the beam should be less than 2 centimeters.

In some cases, the timber needs to be strengthened. This can be done using a board with a thickness of at least 50 millimeters, and its width must be no less than the size of the wall.

Sometimes, instead of timber, metal channels of appropriate sizes are used. Additional reinforcement of the opening is important when constructing heavy buildings, for example two-story buildings.

Watch this video on YouTube

After the beams are fixed in the side parts of the opening, a threshold should be made. To achieve maximum strength, a timber with a thickness of at least 10 centimeters is used, which must be cut in a T-shape.

Method No. 2. Circular casing made of timber

Installing doors in a log house using the second method can also be done with your own hands. The principle of its implementation is not much different from the first. All you need to do is install the blank under the box, following the rules mentioned above.

In other words, it is necessary to install bars around the entire perimeter of the opening. They can be fastened to each other in several ways:

- tongue and groove method;

- self-tapping screws;

- nails.

In addition, it is possible to install the casing without the use of fasteners. To do this, you need to fit the bars as tightly as possible to each other.

It should be noted that in most cases, the construction of log houses is carried out according to this principle. The pressure created by the weight of building materials is quite sufficient for the stability of the structure. The bars must be installed by surprise.

What tools will be needed for installation?

When deciding how to make a doorway and insert a door, first of all you need to decide on the tools necessary for this work. They must be at hand at all times. This will allow installation to be completed as quickly as possible. To carry out the work you will need:

- chainsaw or electric saw with a bar;

- hammer;

- perforator;

- circular saw or manual milling machine;

- chisel;

- construction measuring instruments: level (preferably laser), tape measure and square.

As a rule, searching for tools will not take much time, because all of them, one way or another, were used during the installation of the log house. Having prepared everything you need and understood how to install the door correctly, you can begin work.

Equipping a doorway with casing

The interior opening begins to be designed when it is already formed in the walls. Further work proceeds according to the following scheme:

- using a router it is necessary to make a groove in the end part of the opening, its depth should be about 50 mm;

- tools need to be modified manually;

- You need to hammer a wooden beam with a cross section of 50x50 mm into the prepared groove. Moreover, its length is determined by the degree of freshness of the log house. If this is a fresh log house, then the length of the wooden beam should be 30 mm shorter than the groove; for a dry log house, its length should be 20 mm less.

It is important! If you don’t trust wood, then you can decorate the interior opening with a metal channel. This technique is used when installing metal entrance doors, but this method is also suitable for interior models.

- A wooden beam is sometimes extended with a board, the width of which is equal to the thickness of the end of the wall, and the extension itself is carried out using nails;

- the upper and lower boards are stuffed to the bottom of the beam, thereby forming a threshold and the upper contour of the box.

Preparing a groove for casing

The main advantages of wood as a material for the manufacture of entrance doors

Natural wood has unique properties. Thus, there are types of wood whose strength is simply incredible - the indicators can even be compared with metal. This material also has a fairly long service life - good door models can last from 40 to 50 years, but with proper care this is far from the limit.

Wood is very reliable and has high heat and sound insulation characteristics. Door leaves made of wood perfectly absorb various noise, and also do not let cold and drafts from the entrance or street into the premises.

In addition to all this, wooden doors have a very aesthetic appearance. Even the most expensive finish for metal door systems cannot compete with a solid wood door leaf. It is for this unique appearance that such products are chosen by people who have good taste. And what is the smell of natural wood worth? Wood constantly “breathes” and thereby harmonizes the atmosphere of any room - this material has high bioenergetic capabilities.

Professional installation – guarantee of reliability and durability

Please note that the installation of doors and windows in a house made of rounded logs should be carried out after installing the casing. Only professionals will do the wiring correctly, which guarantees long-term operation of the structures and eliminates the appearance of cracks and gaps.

Improper installation of a door or window frame will lead to serious problems. These include frequent drafts and creaks, jammed doors and locks, skewed openings and walls. To avoid such troubles, entrust the work to the masters of the MariSrub company!

Specialists will manufacture and install blocks, insulate openings around the perimeter using thermal insulation materials and vapor barrier film. This will protect against the penetration of wind, cold and excess moisture into the room.

Sources:

- https://dveridoma.net/ustanovka-derevyannyx-dverej-svoimi-rukami/

- https://marisrub.ru/uslugi/ustanovka-okon-i-dverey

- https://dveri.nebo.by/articles/megkomnatnye-dveri-derevyannye

- https://marketer-stroi.com/dveri-v-derevyannom-dome/

Features of installing a door in a wooden frame

Installing doors in a log bathhouse has a number of features, and we will now outline the key ones:

A wooden frame is prone to shrinkage, so the opening must provide compensation gaps, which are filled with easily crumpled heat-insulating material and, upon completion of the work, are covered with decorative elements - platbands. When deciding how to install a door to a log bathhouse, you can go in two ways. The first involves the construction of a solid structure, and then the cutting of openings, according to the markings applied, in accordance with the developed project. In the second, the filling of openings is carried out directly at the construction stage, which implies a set of measures to strengthen the walls in which there is an opening. However, it is necessary to strengthen the wall against longitudinal and transverse displacement of elements in the first case, immediately after the opening is made. The door block of a bathhouse is somewhat smaller in size compared to doors, say, in a house. This is due to the desire to reduce heat loss and minimize the risk of deformation, which manifest themselves more clearly on larger canvases. Thus, generally accepted practice implies that the bath door block has geometric dimensions not exceeding 1820 mm in height and 800 mm in width. During installation, you cannot use polyurethane foam, which is widely used in this type of work. Firstly, in the conditions of a bathhouse this is unsafe for human health, and secondly, the microclimate of the bathhouse contributes to the rapid destruction of the foamed mass. The overall dimensions of the door leaf should be 5 - 7 mm smaller than the dimensions of the opening. This circumstance will prevent the door from jamming as a result of swelling under the influence of moisture in the interior space of the bathhouse. As insulation and gap compensator, you can use tow padding based on flax fibers or jute strips or strands.

Selection of the necessary tools

The advantages of an iron entrance block over wooden analogues are obvious. Basically, manufacturers or trading platforms, when selling a metal door, undertake the work of measuring and installing their own products. Most often, payment for installing a door block is included in the price of the product, sometimes an additional amount is charged for the work. However, installing the entrance structure with your own hands is not so difficult for a skillful owner, especially if it saves the family budget:

| Type of services offered | Standard size of door blocks (mm) | Average cost |

| Removing the old front door | 860/2050 | from $3 to $20/hour |

| Installation of a new metal door | 860/2050 | from $20 to $52/depending on complexity |

The installation of a metal door at the entrance should be approached with the utmost responsibility. It’s worth assessing your own strengths, stocking up on patience and some tools. Even if the installation is not done with your own hands, it is still worth knowing a lot about the process itself in order to control the installers.

The installation of a steel door structure is expected at the entrance to the apartment, so it is important to know that the door leaf must open outward in accordance with fire safety standards. There are, of course, exceptions regarding the method of opening the door, which were discussed earlier.

When installing metal entrance doors, it is important to take into account the technological features of the building material from which the structure is constructed. To dismantle first and then install the door block, you will need the following tool:

- Construction level;

- Medium sized crowbar;

- Nail puller;

- Hammer or electric impact drill;

- The owner of a wooden house will need a hacksaw and a chainsaw instead of a hammer drill;

- A chisel is needed in order to install a block in a structure made of timber;

- Depending on the method of fastening: anchor plates, self-tapping screws, steel rods;

- Construction foam for filling technological gaps.

Article on the topic: Do-it-yourself cradle, hanging type and on a frame

It is worth noting that if the unit’s configuration does not include anchor bolts, then it is permissible to purchase them yourself. These are simple hardware products, the length of which is up to 15 cm. The diameter of the bolts purchased will depend on the holes for installation in the box (usually d = 12-15mm). The pieces of steel rod that are mentioned in the list of tools may also work.

The difference between a metal and wooden door

Which is better, wood or metal? No material has an absolute advantage. Both metal and wooden front doors have positive and negative sides. Before choosing, you need to have a good understanding of the general characteristics

It is important to compare the advantages and determine where there are more of them. It doesn’t hurt to find an alternative to certain disadvantages

Wooden door

Many people adhere to the version that wood is the best material that can protect not only from bad weather, but also from strangers. Undoubtedly, this type of door has a large number of positive properties, but at the same time it also has negative qualities.

To give a sober assessment and make a choice, it is important to carefully consider the “pros and cons”

A wooden door looks organic and beautifulSource de.decorexpro.com

Pros:

- An ideal combination with the overall interior. The doorway merges with the overall appearance and creates the impression of a monolithic texture.

- Wood is an excellent heat insulator, which will save on heating bills.

- It is not necessary to buy a new part, as you can assemble it from scraps, thereby cutting the construction budget.

- This is an environmentally friendly material that will not cause an allergic reaction or illness (with the exception of pine needles).

Minuses:

- The design is not reliable and can be easily hacked. If this is a country house, then installing a tree as protection is highly not recommended.

- Such a door is highly susceptible to changes in weather conditions. Due to moisture and cold, it can change its size and thereby cause inconvenience.

- The surface is highly susceptible to mechanical damage and requires frequent maintenance.

- Poor sound insulation.

Advantages of a metal door

As is the case with a wooden door, a metal structure also has weaknesses. But still, installing a metal door in a wooden house is the best solution today. The main advantage is that every minus can be removed with a little modification. As a result, you can get an almost ideal input design.

A metal door can also look interestingSource moipros.ru

Pros:

- A strong structure that is difficult to damage without special equipment. Everything is complemented by internal hinges and locks with a built-in complex mechanism.

- With a special coating, a high degree of protection against moisture ingress is provided.

- With seals, there is good sound insulation and protection from drafts and dust.

- The metal is not flammable, which means it does not support combustion.

Minuses:

- The iron sheet freezes strongly and releases all the heat from the house to the street.

- Such a door stands out strongly against the background of a wooden structure and can greatly spoil the appearance.

- Installation and purchase require more time, money and effort.

Wooden interior doors

Doors are an integral element of the interior. And today we also have a wide selection of doors made of plastic, glass or metal. But most owners still choose wooden ones. They are much more reliable and practical than all the others.

The first includes panel boards. They are made from various species of trees. The base, namely the shield, is filled with chipboard, slats, and it can also be small-hollow. Of the latter, interior doors are most often produced. Full panels are used for doors that have high requirements for thermal insulation, sound insulation and safety. And for those that perform a decorative function, a small-hollow shield is best suited. These doors have a low price and attractive appearance.

There are also interior doors made of solid wood - they are a method of continuous filling with natural wood. These are expensive doors and most of them are made of birch, oak, alder and other species.

The main advantage is that only natural materials are used in their production, without veneer, glue, sawdust or artificial materials. Solid wood interior doors are of very high quality and also neutralize sound well.

There are also paneled doors, which are made exclusively from hardwood, which includes oak, walnut and species that grow in the tropics. This type is divided into 2 subtypes: The first subtype is doors, the parts of which are fastened with special spikes. The second subtype includes doors that are assembled using glue. All their parts are glued to each other with glue, without the use of screws or other connecting means.

Paneled doors are an expensive pleasure, as they are made of expensive material

Paneled doors are an expensive pleasure, as they are made of expensive material. But still, if you want to install a paneled door at home, then to save money you can buy the second option, since its price is reduced due to a less expensive production technology.

There is another type of paneled doors that are made from soft wood. This door is perfect for houses where the interior is made in a rustic style. That is, it is a good option for a country house. You can also find paneled doors made from combined materials in stores. Soft wood, in this case, is taken only as a base, veneered with valuable species of various trees that grow not only in the CIS countries, but also far abroad.

In conditions of prices and shortages of high-quality wood, we returned to the production of veneer doors that we had long known. The basis of such doors consists of laminated wood of less valuable, but high-quality wood species, onto which a lining is applied, and then veneer of valuable wood species is applied to it.

With properly maintained technology, such doors will last a long time, and after losing their presentation, they can be restored without any consequences. When purchasing such doors, it is very important to find a reputable manufacturer. In any case, when purchasing interior wooden doors, you need to find out what material the selected door is made of, and you should also not forget about your own material capabilities.

Window as an important power unit at home

Deformation of logs in a log house

A log house, despite its external solidity, is a rather unstable structure. The reason for this is the round shape of the logs and the change in their geometric dimensions during shrinkage and shrinkage.

If you cut openings for windows and doors in such a wall without installing casing frames, it will simply collapse. Therefore, the entire structure of the window openings is not only a place for installing double-glazed windows, but also a power unit that gives the frame additional rigidity.

Note that this feature is inherent in all wooden buildings, including houses made of profiled timber.

Differences in casing for windows and doors

Differences:

- board thickness;

- view;

- box design.

Window openings, if they have sashes, are small in size in relation to the opening

Opening and closing the doors is done carefully. The load on the casing is not large

It's different with doorways. The opening part is almost 100%. If it is an entrance door, make it massive for strength. This leads to weight gain. When slamming, force is used. The load on the door structure exceeds the window structure.

Doorway without threshold, window completely finished

For the box to work reliably, it must be made of a thick board. The locking connection must have increased strength. To increase the strength in the casing, a quarter is not selected, which automatically transfers it to the category of roughing or power. Often doors are made with a threshold mounted to the frame; the casing is deprived of the lower horizontal part.

The fastening is located in the middle part of the opening

Equipping a doorway using casing

The casing structure is implemented in several stages:

- A tenon is cut out at the end of the opening, the width of which is equal to the height of the ridge. As a rule, this width is 35-38 mm.

- The prepared tenon must be finished manually with tools.

- A wooden beam with a section of 100x100 will replace the casing structure. A groove is cut out in it, the width of which will be equal to the width of the groove. Its depth should be about 40 mm.

- To attach the casing, it is necessary to prepare grooves in the lower part of the opening; their depth should not exceed 5 mm.

To attach the top casing strip, two methods are used:

- In the first option, it is necessary to prepare a board, which is driven between the installed beams and secured.

- In the second case, one wooden beam is installed, a board is placed behind it and the wooden beam is installed again. With this installation, the board does not require additional fastening.

The difference between a metal and wooden door

During finishing work, many homeowners are faced with the question of choosing a metal door. Deciding between a metal and a wooden door is not easy. Before choosing one option or another, you should familiarize yourself with their features:

- The entrance door made of wood will harmoniously fit into the log house due to the combination of the appearance of the materials. However, the modern market offers a huge variety of trims and trims for metal doorways that imitate wood. Of course, such elements cannot be compared with natural solid wood, but if the main task of the door is strength, then you can sacrifice the aesthetics of the facade.

- Thanks to various antiseptic impregnations and fire retardants, wooden doors have high resistance to precipitation and other adverse conditions. In addition, in winter the wooden massif will not freeze.

- Ordinary wood has greater thermal insulation properties than metal. Modern companies offer multilayer metal doors, with various polymer materials that increase thermal insulation properties. One of the warmest options for a street opening is insulated (wooden) entrance doors.

Advice! Metal doors will easily fit into the overall style of the building if there are similar decorative metal elements on the site or facade.

In general, steel products have high strength and safety indicators. In modern construction, 9 out of 10 doors are metal. They are installed both in log houses and in concrete buildings. Three-layer doors made of alloy steel are considered the best option for a log house.

Professionals who choose steel doors are guided by their significant advantages:

- High degree of safety and comfort. Most modern metal doors have unique fittings and locks. Among other things, the products are equipped with durable functional fasteners that do not weaken the door panel itself during operation and installation.

- Possibility of installing automation. Metal doors have special grooves or already built-in automatic control systems. In addition, they are easy to install fasteners for installing cameras and other surveillance and security devices.

- Highest degree of fire resistance. Unlike wood, metal is absolutely not flammable.

- Moisture resistance. Doors with protective coatings can be used without problems in areas with high humidity. Even with active use and lack of maintenance, the products retain their moisture-proof properties.

When choosing a steel door, you should pay attention to the quality of the coating and the multi-layer nature of the material. This ensures housing safety and heat preservation

Installation of doors in aerated concrete and in a wooden house

Stages of installing doors in aerated concrete

To carry out such work, it is necessary to prepare welding and buy a metal corner with a shelf width of 3.5 to 5 centimeters (the choice depends on the weight of the door and the expected loads).

Next, it is necessary to trim the metal corner so that when welding the joints of individual parts, it can cover the doorway along the entire perimeter on both sides. To strengthen the two frames together, it is necessary to weld the embedded parts, and the shank must have a thickness of at least 3 millimeters and a width of 5 centimeters. These elements are placed at the places where the door frame is attached. The door frame is fixed using screws on previously installed lintels.

For reliable fastening, you should use 12-centimeter self-tapping screws, which are screwed into each of the tires. It should be noted that the door will also be attached in these places, so the screws should under no circumstances overlap each other. At the next stage of installing doors in aerated concrete, use a building level to align the door frame, and then fix its position using wooden wedges.

The final fixation of the door leaf is carried out using screws up to 15 centimeters long or dowels.

After this, it is necessary to coat all the cracks with sealant or blow out with foam.

Installation of an iron door in a wooden house

You can install a new front door with your own hands in just three steps:

- dismantling the old structure;

- doorway preparation;

- installation of an iron door.

The old entrance doors to the apartment are dismantled like this (mostly wooden):

- Provided that the door leaf worked on collapsible hinges, we pry it open with a crowbar or other lever. This way the panel will rise and jump off the loop. Provided that the hinges are not dismountable: you need to unscrew the screws that hold the door in the frame using a screwdriver or screwdriver.

- It is not difficult to dismantle an empty box with your own hands if it is made of wood. To do this, fasteners (visible) are unscrewed: screws, anchors, nails are pulled out. If the box is firmly held in the opening and cannot be removed, its side posts are sawed off and torn off with a crowbar. After which the lower and upper parts can be removed without any problems.

- If a metal box is being dismantled or a wooden box is attached to the opening with anchors, then it is easier to saw them off with a grinder, just like metal posts.

- Next, the opening is cleaned of old insulation, remnants of plaster, protruding fasteners and other things. Provided that the doorway for the new door has been previously correctly measured, its size should exceed the perimeter of the frame by a couple of centimeters. This is necessary so that there is enough space to align it in the opening. If you made a mistake in measurements earlier, you will have to work hard to widen the passage with a grinder with a circle on the stone. If the opening is too wide, it can be narrowed by additionally applying cement mortar.

A metal frame can be attached to a doorway in two ways:

through technological holes in the box profile;

using special mounting plates.

We put the input structure:

A door frame without a leaf is installed in the opening. Wood wedges are placed under it, which are necessary for fixing, adjusting its position and to ensure technological clearances.

- Having adjusted the position of the box, they begin to drill holes in the wall through the previously made holes in the profile: 15-20 cm deep. Anchors are inserted into the drilled sockets, and the position of the racks is checked again. When positioned correctly, the anchors are twisted and covered with decorative elements matching the color of the box.

- Next, the door leaf is hung on pre-lubricated hinges and all the fittings are attached. The canvas is covered, and the gaps around the perimeter of the rack are checked, which should not exceed 4 mm.

- The functioning of all latches and locks is checked. Inaccuracies are eliminated with wedges. Holes are drilled for the second pillar, which we also secure and check for smooth movement of the door leaf and locks.

- The technological gaps between the box and the wall opening are filled with foam, which must dry for at least 24 hours. After which the remaining foam is cut off, and the surface of the wall is puttied. Installation completed.

Mounting the door block on plates is one of the most common methods and is somewhat simplified for doing the work yourself. Often, metal structures are equipped with mounting plates with prepared holes for fasteners, which are welded directly to the frame.

Box installation

The box is installed in the interior opening and secured with two wedges. Adjust it vertically and horizontally and secure it to the frame bars with self-tapping screws. Here you need to make sure that the screws do not go through the beam, otherwise the door will warp during shrinkage.

The gaps formed during installation of the box must be foamed.

Installation of the box in the doorway