A shelf is a functional decor for any interior and an excellent way to organize space. Separate and combined products make it possible to conveniently store a wide variety of items: books, dishes, souvenirs, audio, video equipment, etc. You can make a glass shelf to accommodate any stylistic direction. This material does not burden the space at all, allows sunlight to pass through, allowing the most efficient use of natural and artificial lighting.

Glass has a number of undeniable advantages:

- Environmentally friendly, hygienic material that is easy to wash and disinfect. It can be used in the manufacture of glass shelves for the bathroom, kitchen, and on a closed loggia.

- Does not absorb foreign odors.

- It does not lose its original characteristics for a long time, retains its transparency and desired shape.

- Insensitive to moisture and sunlight.

- Thick glass, like triplex, can withstand increased loads, for example, the weight of a TV or other home appliances.

- Glass products have a beautiful appearance.

- Low cost of material.

The use of lights or special holders that attach the shelf to the wall creates the impression that objects located on a transparent surface are floating in space. This effect allows you to make a small room more spacious and adds charm and lightness to the atmosphere. A relative disadvantage of the material is its fragility, but this phenomenon can be successfully combated by using triplex or making hanging shelves from plexiglass. Experts do not recommend installing any glass structures in children's rooms.

Simple glass shelf

Glass shelves can be installed almost anywhere: on a wall, a windowsill, or they can fill a corner of a room. With the help of professionals or with your own hands using a special tool, glass is given different shapes: from rectangular or round to more complex shapes. A small simple glass shelf is always useful for placing shampoo, toothbrush, soap in the bathroom, and in the living room you can put photos of loved ones on it, souvenirs reminiscent of memorable dates, interesting places.

Important information

Experts advise that when starting to select a material, design and independently manufacture a glass shelf, you should take into account some important facts:

- When cutting glass, the result may have an error of 1 mm.

- The edges of the product must be polished.

- When choosing mounting hardware, you need to take into account the thickness of the glass used (ranging from 4 to 10 mm).

- If possible, use tempered glass. It is not dangerous, as it is almost 5 times stronger than usual.

What you need to prepare for work

To make your own glass shelves, you need to purchase materials and tools in advance:

- Glass about 7 mm thick. Depending on the interior of the room, you can choose tempered, colored, black, gray, bronze, matte (or satin), transparent glass with printing or with a sandblasted pattern.

- Fastening elements. A popular model of devices is the “pelican”. You need to buy 2 of them per 1 transverse element. This project will use a metal profile.

- Glass cutter.

- Drill.

- A grinder with a grinding wheel attachment.

- Building level.

- File.

- Duct tape.

- Polishing paste.

- Scissors.

- Roulette.

- Ruler.

- Pencil.

- Cardboard for the template.

Work order

You need to start by preparing a template for one or more shelves (if they are of different sizes and shapes). Before making a cardboard model, you need to determine the exact dimensions of the shelf and the configuration of the wall surface. This will ensure optimal fit of the product during installation.

- Draw and cut out the template to full size. Slightly round the corners of the shelf where it meets the wall.

- Clean the glass from dirt. Use regular detergents for this material. Check: the glass should be at room temperature during operation.

- Cover the flat working surface with a cloth (rag) and place the glass on top of it.

- Place the template on the glass. Using a glass cutter, cut a piece of the required size under the ruler.

- Wear cloth gloves before you begin finishing the edges. Clean the contours of the shelf using a file dipped in kerosene (turpentine).

- To sand the edges, use a grinder with a grinding wheel. Then polish the edges with a grinder and a felt wheel using polishing paste.

- Select a location on the wall where the shelf will be installed. It should be smooth. Using a building level, mark the location for the shelf on the wall with a horizontal line. Mark the locations for fasteners.

- To install the fasteners into the wall, drill holes.

- Using an aluminum profile, check the correct marks for the fasteners.

- Insert dowels into the holes.

- Insert the bracket into the drill in place of the drill.

- Install the screws into the dowels. Place washers on the protruding parts of the screws.

- Screw the brackets onto the wall screws.

- Use a level to check that the brackets are installed correctly.

- Attach duct tape to the back edge of each shelf. This will protect the glass from friction against the metal parts of the fasteners.

- Place the glass on the holders. To prevent it from slipping, put special rubber tires on the metal parts.

What properties does glass have?

Handmade glass shelves are an elegant and inexpensive home decoration. Transparent and light, they are able to visually unload the interior, making it spacious and light. The material suits any design - from modern to classic.

In order for the design to be functional and withstand several kilograms, the product should not be thin. Usually for this purpose it is recommended to take glass of at least 8 mm.

To add more strength to it, the material is hardened. Thus, glass prepared specifically for shelves can withstand several tens of kilograms.

We want to show you how to make a backlit glass shelf with your own hands - you will see that it is not at all difficult. Those who want to realize their vision of home comfort strive to improve interior elements with their own hands - it is for such people that we have prepared a master class with step-by-step instructions.

Glass shelves on the wall with lighting

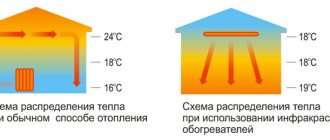

When installing a glass shelf in an aluminum profile, which is located along the wall, it is possible to decorate the product with LED lighting. The design will take on an original look, which will become the accent of a modern minimalist or high-tech interior.

- When purchasing a metal holder, be sure to ensure that the size of the groove for installing glass matches the thickness of the shelf.

- Cut the profile to the length of the glass shelf blank. Remove burrs from the cut areas so that they do not become an obstacle when attaching the LEDs.

- Attach the profile to the wall with screws. Prepare markings for wall mounts. Prepare the holes. Place dowels in them. Attach the profile with screws, installing them in the hole of the dowels.

- The profile, which is fixed to the wall, already contains a plastic spacer tape. It protects the LED from touching the aluminum profile to prevent short circuits. Place the LED strip on top of the plastic spacer. This task requires accuracy and attention.

- All that remains is to place the glass in the groove of the profile. Experts advise using a rubber hammer to facilitate this process - lightly tap the glass into the groove of the aluminum holder.

Your fantastic shelf is ready!

Rules for working with material

First of all, it should be noted that you should work with glass very carefully, thinking through every movement.

First you need to take a glass cutter. Before cutting the material, you need to practice a little so that you don’t make a mistake at the right time.

Next, you need to decide on the dimensions of the future structure and create markings. This is easy to do with a regular marker.

Next, you may need a belt sander. It is necessary for edge processing.

Advantages of plexiglass

A good material for wall and floor shelves is plexiglass. It is a transparent plastic that looks like glass. Plexiglas has a number of advantages:

- Safer (compared to glass), durable and impact-resistant.

- Has little weight. 2 times lighter than glass.

- Has high thermal insulation characteristics.

- Easy to process and polish with special paste.

- Can be cut into elements of the desired shape and size with a hand saw or jigsaw.

- Acrylic blanks can be given the desired shape by bending. To do this, heat the bend area with a hair dryer (on one side only). Gently bend and leave to cool for 5-6 hours.

That is why almost everyone is able to make plexiglass shelves with their own hands for an apartment or office.

It is best to glue plexiglass parts with dichloroethane. But since this substance is toxic, precautions should be taken. The disadvantages of acrylic products also include (compared to glass shelves) high price and ability to burn.

How to connect power to an LED strip with your own hands

The tape is usually sold in 5 m reels with lighting effects in different colors. Such a large length is usually cut off, and only then connected to the electrical wiring. In our case, you will need 60 cm of tape along the length of the product.

You can connect it using an LED connector. This is the fastest and easiest way to connect wires to the tape contact - you just connect the contacts and snap the cover. If you choose an LED with several wires, then each of them needs a separate connector.

Plexiglas shelf

Like a glass shelf, an acrylic shelf is an ideal product for the bathroom. It is not afraid of moisture, fungus, is easy to clean and looks aesthetically pleasing. Even in the smallest bathroom there is room for a three-tier corner structure. Here you can place shampoo, soap and other hygiene products.

To make such a shelf from plexiglass yourself, you need to prepare. Buy:

- Plexiglas sheet. When choosing a material, give preference to a denser one. Proceed to cutting after making a pattern from cardboard and choosing the place where the shelf will be mounted.

- Level. Allows you to attach the plexiglass shelf to the wall as smoothly as possible.

- Electric drill. Needed to attach the shelf to the wall.

- Accessories. You will need screws, dowels, and shelf holders.

- Electric jigsaw for cutting material.

- Screws for fastening the shelf parts. Choose fittings with a special coating that can protect the metal from high humidity.

- Screws with dowels for mounting the shelf.

- Thick cardboard for making patterns for shelf parts.

- Building level.

- Ruler.

- Pencil.

Advantages and disadvantages of products

An ordinary bathroom is small in size, so towels, detergents, and various small items are difficult to place at hand. In this case, glass corner shelves create a comfortable area for the necessary little things without taking up much space. On a small strip of glass above the sink, it’s good to lay out toothbrushes, a piece of soap, a bottle of elixir, and dental floss. These products have pros and cons.

Negative nuances:

- glass is a fragile substance and not the most durable, so there is a high probability that an awkward movement or a falling shampoo bottle can break it;

- limited dimensions of the planes of the shelves.

Positive points:

- Convenient placement of small items, jars, bottles, bags, tubes. There can be as many planes as desired;

- the internal space of the room is freed up, jars no longer fall off the edge of the bathroom, but “hang” on the walls;

- safety increases, the likelihood of slipping on a fallen piece of soap decreases;

- the bathroom becomes beautiful with shelves made of frosted, colored, illuminated glass; stylish products add charm to the interior;

- the material is easy to clean and chemically neutral;

- tempered glass with a thickness of 1 cm can support a flat-panel TV and become a shelf for household appliances.

On a small strip of glass above the sink, it’s good to lay out toothbrushes, a piece of soap, a bottle of elixir, and dental floss.

How to secure the product

Important! If you plan to place several structures, then for convenience you need to stick vertical strips.

You will need a simple pencil and a level. With their help, you can determine the best place for fastening. It should be remembered that the product must be fixed exactly horizontally. Otherwise, objects placed on it may fall.

After the location of future fasteners has been planned, you need to drill holes using a drill.

Next, you need to insert dowels into the holes, and then a screw is screwed into it. It should protrude 2 cm from the surface.

A washer should be put on it, and then a bracket is attached to the protruding part of the screw.

And the shelf itself is already installed on it.

Types of glass shelves

There are many types of glass shelves. Shelves are divided by style, design and purpose. Some shelves are part of a furniture structure (a furniture wall or a student's corner), and some act as an independent element in the interior.

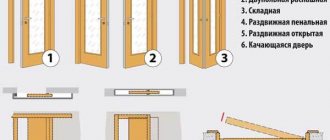

There are 3 types of glass shelf designs:

- Frame shelves. These shelves have doors and a back wall.

- Prefabricated shelves without frame or cast shelves. Basically these are shelves of unusual shapes: cubes, ladders, etc.

- Classic glass wall shelves without frame.

Shelves can also be divided into types according to purpose:

- for equipment (TVs, computers, household appliances);

- for photographs, small souvenirs;

- for books and magazines;

- for cosmetics (shelves in the bathroom or shelves near the dressing table).

Glass processing methods

Numerous types of processing of this material allow us to significantly expand the scope of glass applications. First of all, it's cutting.

The main key to the success of such an operation as cutting glass is the glazier's table, which should not have any deflections or bumps. Otherwise, the glass may simply burst or crack. Glass cutting can be done with a roller or diamond glass cutter, the main thing is that the tool used is not worn out.

The main sign of correct cutting is the characteristic hissing-crunching sound. The glass cutter in operation should not creak, squeak, or bounce on the glass. The cutting line must be drawn in one motion, without stopping or going back. If you run a glass cutter twice along the same line, the resulting edge will crumble and chip.

Glass cutter

After making the cut line, the glass is tapped on the back side with a special hammer or the handle of the glass cutter itself, and then broken off with light pressure. To remove small fragments of glass remaining on the fault line, use the slots located on the handle of the glass cutter. After the element required in size is cut, its edges should be processed. This will give the edge a rounded and secure appearance. At home, this can be done with an emery block, periodically wetting the glass with water. The direction of movement of the block should go along the edge of the glass. In this case there will be no chips.

To drill holes in glass you will need a cylindrical glass crown with diamond coating, drills and a plastic bottle of water. To avoid overheating of the glass during drilling, it is watered. If the glass is thick, drill it only halfway, then turn it over and drill through the part.

The surface of glass or mirror can be either glossy or matte. To frost glass, use a special paste (for example, “GlassMat”). By the way, by applying it through a stencil, you can get a design or ornament on the workpiece. Glass processed in this way has a lower surface roughness than mechanically processed glass and a peculiar “silky” surface.

If necessary, ordinary glass can be covered with film for tinting car windows. This way you will get tinted glass, which will cost you much less than buying ready-made glass with a factory coating.

Step by step guide

You can make your own illuminated glass shelves using LEDs, which are sold in large quantities in lamp stores.

To make a glass shelf with your own hands with lighting, we will need:

glass base, the desired size and shape of which can be ordered in our store;

fastening system element – bracket with 60 cm aluminum profile;

For the master class, a panel 8 mm thick was taken. The aluminum profile used for the product should have the same height. Only if these parameters match will the shelf be strong and reliable. Instead of a profile, you can use holders - this type of shelf is also interesting, it is universal for any size, and is not fixed.

The advantage of the profile in this case is that you can place an LED strip in it. This design allows you to achieve the effect of light scattering.

- we will need screws and plastic plugs;

- Using a building level, you need to calculate the correct horizon, mark it with a pencil, and also mark on the wall with a pencil where the profile holes are located;

- Using an electric drill, drill holes for self-tapping screws (we have 4 of them);

- fix the bracket, screw in the screws with a screwdriver, after placing plastic plugs in the holes in the wall;

- Next, we insert the diode strip around the perimeter of the bracket, tucking it as tightly as possible to the inner plate.

- The last step in DIY installation is to install the glass itself.

Now all that remains is to connect the power supply.

Safe work measures are the key to success in any business

Unfortunately, not everyone sharpens their attention at this point in the preparatory operations, which sometimes leads to dire consequences. If such significant efforts are being made to realize creative plans, then why not slow down so that these creative dreams do not turn into a tragic reality? In addition, it is elementary and practically inexpensive

PPE is an indispensable assistant in work

When it comes to power tools, it is worth accepting the fact that 220 Volts is not just an unpleasant shaking, but possible death. Therefore, work should be carried out in dielectric shoes, after first inspecting cords and extension cords for the presence of bare areas. It will not be difficult for anyone to use electrical tape and eliminate the danger.

When working with an angle grinder, it is wise to stock up on construction glasses with yellow filters. The cost of purchasing them will be small, but it will serve as a guarantee of clean eyes from chips. Don't ignore hand protection - gloves will not only protect your skin from cuts, but will also help avoid unwanted stains when painting.

When installing the structure, if necessary, you should use the services of an assistant. This is especially true if you need to fasten the product at a height; there is no need to buy a construction helmet.

How to make flower pots with your own hands: outdoor, for home, hanging | Step-by-step schemes (120+ Original Photo Ideas & Videos)

Corner wooden shelves

Often, to save space, shelves are made corner, and they can be mounted both in the inner and outer corners.

Corner shelf

Corner wooden shelves

The blanks are made according to the scheme described above, only the upper and lower boards consist of two elements, with the ends cut at an angle. The process of making such a shelf is quite simple:

- the halves of the top board are coated at the ends with glue and clamped with clamps;

- repeat the same actions with the bottom board;

- when the glue dries, all workpieces are covered with stain or primed;

- Attachment lines are marked on the upper and lower workpieces and holes are drilled;

- insert the side walls and secure them with self-tapping screws.

Next, screw the brackets and secure the shelf to adjacent walls.

Corner shelf made of wood

| Wall shelf materials | Advantages and disadvantages |

| Wood: plywood, chipboard, MDF and others | This material is relatively easy to work with, it looks beautiful, natural and impressive, its service life is quite long, especially if pre-processed |

| Plastic | This material is the most versatile; it can imitate both wood and stone, while eliminating their shortcomings |

| Metal | Such wall shelves will be very strong, reliable and durable, but they will hardly fit into a classic interior. In addition, corrosion can also be a problem, so metal products will require special processing and conditions |

| Glass | Transparent wall shelves will create an atmosphere of lightness and comfort in your home. Of course, it will be quite difficult to make a glass structure with your own hands, but if you nevertheless decide to do all the work yourself, then you will have to work with glass for quite a long time and very carefully, especially if various cutouts are planned in the shelf design |

Buy or make it yourself?

Buying ready-made shelves for walls is not a problem. Nowadays you can find all kinds of products in stores, among which you can almost always choose the one that will fit perfectly into the interior and will be in perfect harmony with the environment, but at the same time remain comfortable and functional.

Wall shelves for kitchen

But often shelves are made with your own hands. Why? It's simple. The fact is that not all cities have such a variety of furniture stores that will allow you to find exactly that dream shelf. Also, some variations of furniture products can cost incredible amounts of money, especially when it comes to designer products. In addition, making a shelf yourself is quite simple - sometimes it turns out to be even easier than finding an option that is ideal for the room. So the creation and further use of a homemade product is completely justified. Plus, it saves money. And with due desire and effort, a handmade shelf can practically become a work of art.

Corner shelf on the wall

Original shelves for books

Shelves of non-standard shape are in increasing demand, so if you wish, you can try to assemble something original. For example, a bookshelf in the form of a simplified labyrinth is used.

To make it you will need:

- edged board 20 mm thick;

- wood glue;

- clamps;

- roulette;

- level;

- hacksaw;

- miter box;

- Sander;

- stain;

- furniture screws, self-tapping screws;

- decorative shelf holders.

If you have everything you need, you can start making the shelf.

Step 1. Marking

On the prepared boards, mark the cut lines with a pencil under a ruler. Measurements should be taken very carefully, since all horizontal parts have different lengths.

Step 2. Trimming the blanks

The ends of each workpiece are cut at an angle of 45 or 90 degrees. The diagram shows the first option, so you will need a miter box for sawing. It is very important to correctly install the miter box on the board so that the cuts are symmetrical. If the ends are cut off incorrectly, you will not be able to fold the shelf.

Step 3. Assembling the structure

The ends of the parts are smeared with glue, pressed tightly and additionally secured with slotted furniture screws. Ordinary self-tapping screws are not suitable here. Each joint will require at least 2 screws. Both parts of the shelf are applied to the wall, leveled and the attachment points are marked with a pencil. After this, holes are drilled for the dowels, brackets are screwed to the shelf with self-tapping screws and the structure is hung on the wall. Instead of brackets, decorative pelican shelf holders are often used.

Shelves of non-standard shape

Wall shelf size chart

Shelf

Hanging

Not very numerous, but an original type. The most important thing is that it can be done easily: a few planks, four ropes or two belts and you can get to work.

Old leather straps can also become the basis for a suspension system

This is a complex system of blocks...and the shelves can be located at any level

Two planks, four ropes and half an hour of time are all that is needed to make this shelf

How to make a hanging shelf - graphic step-by-step instructions

Backlight

Properly selected lighting makes shelves unusual. It visually expands the room and makes it more alive. If you turn off the main light and light a couple of candles, the room will create an atmosphere of pleasant twilight. LEDs can work in color changing mode, so you will always have the opportunity to add color to the room, which is important at a house party.

Advice! If you want to put an expensive vase or antique on a shelf, then lighting will make the item look more advantageous. This technique is used by the owners of boutiques and jewelry stores.

Glass shelves are illuminated using LEDs or LED strips. They are connected to a power source with a voltage of 12-24 volts. LED strip allows you to create a pleasant and soft light. Also, its big advantage is that it does not heat up during operation. You can safely put flowers on the shelf.

For small shelves it is better to use single LEDs, and for complex structures LED modules are suitable.

Special controllers that allow you to add effects: changing color, flickering or backlight intensity will help you create a unique shelf design.

How to make glass shelves for the bathroom

A stylishly decorated interior requires extraordinary solutions. But if you take all these extraordinary solutions from the store, you can go broke. After all, a truly designer item is very expensive. And I really want, for example, in such intimate places as the bathroom, to be beautiful and cozy. However, you can always take matters into your own hands and build something yourself, for example, elegant glass shelves.