Folding interior doors will help you decorate the room with taste, and at the same time preserve free space. The design received its name because of the peculiarity of the mechanism - when opened, two doors are folded in half. Paying attention to doors of this type is important if the size of the apartment is small and the openings are narrow. In the manufacturing process of the product, various materials, fittings and mechanisms are used. Having understood what kind of folding interior doors there are and how they need to be installed, it will be much easier to arrange the interior (see step-by-step instructions for installing interior doors with your own hands).

How to make canvases for a folding door with your own hands

First you need to decide on the material.

It is not practical to use heavy natural wood or large sheets of tempered glass for a folding structure. The material is quite heavy, which over time will negatively affect the performance of the suspension system. You can order ready-made MDF canvases or make them yourself.

It is best to use a panel structure for the manufacture of interior door panels. To do this you will need the following material:

- wooden blocks (25 by 25 mm);

- dowels;

- PVA glue;

- HDF panels.

HDF panels

A frame for the future canvas is assembled from the bars, depending on its size. The bars are cut into pieces of the required size and fastened together with dowels coated with glue. It is advisable to place the bars not only along the edges of the leaf, but also to form stiffening ribs from them inside the door.

HDF panels (3 or 4 mm thick) are thin sheet material with one smooth surface, made by hot pressing of sawdust. This material is cut into fragments the size of a door leaf. The panels are then attached to the brook sheathing. The rough version of the door leaf is ready. It can be painted, laminated, or veneered depending on individual preferences.

You can also make door leaves from MDF panels covered with veneer or other material. This is the simplest solution - you need to choose the material that is optimal in color and thickness and cut it into sheets of equal size. Experts recommend using MDF with a thickness of 22-25 mm.

MDF panels

Door edges can be processed in two ways: stick special paper with an iron or use ready-made plastic edges that are pressed onto the ends of the panels. The latter option is distinguished by its strength and durability, since the pasted paper can simply fall off after a while, ruining the appearance of the door.

Book door

For a folding door, two panels of equal size are made and fastened together with hinges. In order for the structure to be strong and reliable, it is recommended to attach 3 sets of hinges: at the top, bottom and in the middle of the canvas. The resulting structure folds and unfolds like a regular book.

What do you need for work?

Sheets of plywood

At home, it is difficult to process thick tempered glass for door panels or solid wood. Most often, a lightweight structure is assembled from the most accessible materials:

- bar 2.5 cm thick;

- additional elements and trim for the door frame (it is better to buy ready-made decorative parts);

- plywood 0.5 cm thick or fiberboard;

- loops (card, piano);

- fittings and decorative finishing (veneer, film, etc.).

It is very convenient to use ready-made MDF panels as a door leaf. They can be ordered from a furniture store or construction company. This material can be cut on site to the dimensions provided and a PVC or film edge glued to the cuts. Unusually openwork and beautiful doors are made from perforated HDF panels. If desired, you can combine materials, making only the upper half of the sashes openwork, and taking the lower half with ordinary fiberboard.

To work, you need to prepare the following tools:

- jigsaw or hand saw;

- hammer drill and anchor;

- chisel and hammer;

- drill with a thin drill and a screwdriver attachment;

- screws or furniture dowel;

- sandpaper;

- polyurethane foam;

- carpentry glue.

It is not recommended to drive nails into a thin block. Connections should only be made using dowels or self-tapping screws. The last type of fastener must be screwed into pre-prepared holes with a diameter slightly smaller than the thickness of the screw.

Sliding door mechanism

Regardless of the type of sliding interior doors, the operating principle of their mechanisms does not differ significantly. Rollers are mounted on the canvas, which, moving along the guides, ensure the movement of the sashes.

The guides are usually attached to the wall, but in some cases they are also fixed to the floor. In the case of framed door options, a separate running element must be installed on each section.

Schematic representation of the mechanism of sliding structures.

Sliding door devices are divided into hanging and rail. In the case of a suspended mechanism, the running gear, one or more, is installed only on top of the structure, and an additional roller is fixed below to ensure easy movement.

The rail mechanism looks the same, but the running elements are attached both above and below the door frame, that is, the lower roller does not move along the floor, but along a rail built into it. This design is more resistant to heavy loads, so it is suitable for door models with large dimensions.

Interior doors folding in half: installation in the opening

In order to properly assemble and install a folding door, you will need door leaves, a sliding mechanism, fittings, a drill, a screwdriver, pliers, a tape measure and a level.

Installation instructions:

First, the upper guide is attached, along which the future folding door will ride.

It is very important that this rail is installed strictly horizontally; for this you need to use a water level. Stoppers are placed along the edges of this groove; they prevent the door from hitting the wall. Runners are attached to the door leaves, which must subsequently be inserted into the upper guide. To install the door in the opening, you need to press the slider wheel on the door and squeeze it into the rail.

Before installing interior doors that fold in half, you need to prepare the tools

After the door is installed, you can begin installing the trim and remaining fittings.

If the doors are too heavy, it is recommended to install a special rail in the floor, into which the lower part of the door will also be inserted. This system should be equipped with anti-dust brushes that prevent dust from accumulating on the metal.

Book door: its structure and features

The folding door leaf looks like two leaves that are connected by hinges. The first leaf is mounted on axial hinges, and the second one rides on a roller. When opened, one leaf rotates along its axis and pulls the second one along with it.

- Their structure resembles the design of a screen - the same doors and the same hinges. The only thing added here are the guides along which the doors “ride”.

- As for hinges, they can be not only standard, but also hidden - such door models look aesthetically attractive.

- For the manufacture of these doors, chipboard, glass, solid wood, laminated sheets can be used; veneer is also successfully used, which can significantly reduce the cost of the finished product without reducing its aesthetic appeal.

- The doors open and close easily, although their movement is accompanied by slight noise.

- By equipping such doors with a lock, you will provide yourself with privacy, which is extremely necessary, for example, in the bathroom.

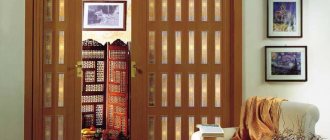

Such doors can be installed in any room where increased sound insulation is not required - a living room, a children's room, a kitchen, and even a bathroom with a bathtub. And if you choose doors with transparent inserts that are capable of transmitting light, you will thus ensure illumination of passage corridors and even neighboring rooms.

Folding door book photoIt should also be noted that this is a good option for a closet in a hallway or closet - in narrow corridors, such a sliding design will be the best of all types of doors.

You can take a closer look at the flip door in this video.

Folding design: maximum freedom and convenience

There is never too much living space. And this statement is true regardless of the number of rooms and square meters of the home as a whole.

Since most apartments have a standard layout, they often have a cramped hallway or corridor, usually connected to a toilet, bathroom and kitchen. If the door is installed as a swing type, then it blocks two-thirds of a narrow room, which causes considerable disturbance for residents.

Types of folding doors.

The radius of the hinged doors forces homeowners to take into account its size and place the furniture in the wrong place. In such a situation, it is often necessary to refuse a piece of furniture that you like. After all, the dimensions do not allow it to be installed, since they interfere with the movement of the door leaf.

Of course, there are options for replacing the door. For example, you can hang a thread curtain and a fabric curtain, or you can install a sliding structure. True, in the latter case, you will also need space for the sash to move along the wall. For this issue, there is a much more interesting solution - a folding door device. After all, there is no need to open its flap, move it along the wall surface, or hide it in a pencil case.

A folding door requires an assembly of 2 or more segments that move along a guide attached to the top of the structure. Public transport is equipped with doors of such a device: trolleybuses, buses and trams. Devices with two doors, typical of urban transport, are called book doors. These devices are very reliable, but have a significant flaw - the doors are heavy.

Related article: Laying laminate on chipboard, linoleum, parquet (video)

A folding door can have either two leaves or a whole structure of folding leaves.

When folded, the leaves of these products become 2 times narrower than classic swing doors. And the sections that make up the doors can be either symmetrical or asymmetrical in relation to each other. The last option is especially original. In accordance with the design features of the folding door, the doors move either in one direction from the doorway or on both sides of it. When folded, the sashes are either assembled along the edges of the opening, tucked inside the pencil case, or placed next to the wall.

Structurally, the accordion is similar to the musical instrument of the same name. In Europe, for example, such products are called accordion doors, since this name is preferable for Europeans. Their doors have over 2 sections, their width is 10-12 cm. Their doors resemble strips of blinds with one difference - the slats that make up the accordion have a rather rigid hinge fastening between each other, and are wound in the upper part (sometimes at the bottom) into guide rails. The segment with the handle is responsible for movement along the guides, and the segment located close to the door jamb is attached to it using metal axles.

Instructions for making wooden doors

Necessary measurements for making a door

The door block manufacturing process consists of several sequential operations:

- measuring the size of the opening in the wall;

- drawing development;

- frame manufacturing;

- canvas assembly;

- decorative finishing;

- installation and adjustment;

- installation of fittings.

Before starting work, materials are purchased and tools are prepared.

Tools for making wooden children

To make a door from boards with your own hands you will need:

- a router for making grooves and selecting a pattern;

- hacksaw or jigsaw - for precise cutting, the teeth of the tool or files must be small;

- plane and sander;

- hammer, mallet;

- a set of chisels for selecting grooves for locks and hinges;

- screwdriver or drill;

- a workbench larger than the door leaf;

- clamps of different sizes;

- wood glue, brushes, sandpaper, stain, varnish or paint.

Depending on the desired appearance, veneer, MDF, and other finishing materials may be needed.

Frame making

Making a door frame

If you plan to coat the door with clear varnish, choose the same type of wood for the door leaf and frame.

For tying, a timber with a thickness of 4 cm or more is used so that you can select a groove for the canvas.

The external size of the box is chosen 2–3 cm less than the minimum dimensions of the opening. This will allow you to have a reserve of space during installation, which will be needed to fit the door block.

Longitudinal and transverse planks are secured with self-tapping screws, or by making half-board cuts.

Whether or not to make a bottom crossbar at the frame depends on the purpose of the door. In the entrance doors, a bottom strip is made with a recess of half the thickness of the timber to prevent drafts.

Solid wood canvas

To get the desired color, use stain

For production, blanks with a thickness of more than 25 mm are used. Purchase tongue and groove boards or make the joints yourself.

The grooves and tenons in the boards must be at least ½ the thickness of the material in height and depth.

The trim boards should be flat on one side. The grooves and tenons are removed with a plane.

Step-by-step instruction:

- Select high-quality material without cracks and large knots.

- Dry the wood indoors, avoiding direct sunlight.

- The boards are cut according to the size of the blade, taking into account the width of the upper and lower crossbars, if provided.

- The canvas is assembled on a workbench, and the joints are treated with wood glue.

- The resulting structure is compressed with clamps and left until completely dry.

- If necessary, use a router to select a pattern.

- Mark and select surfaces for mounting hinges and locks.

- Clean the surface first with coarse and then fine sandpaper.

- Treat the surface with stain or tinting impregnation. Before painting with opaque paints, treat the surface with an antiseptic.

- Cover the surface with transparent varnish or paint of the desired color.

After drying, install the door leaf into the frame, regulate the opening of the door and the operation of the locks.

Panel

Door made of wooden frame and laminated veneer lumber

A simple manufacturing option involves assembling the frame and then filling the internal space.

Algorithm for assembling a panel door with continuous filling:

- The outer frame is assembled - the frame of the canvas. To do this, the side bars are connected to jumpers - upper, lower, central. To create a rigid structure, use tongue-and-groove joints or make cuts half the thickness of the bar parts.

- On one side of the frame, sheathing made of laminated MDF 10 mm thick, fiberboard or plywood is glued.

- The cavities inside the frame are filled with bars, which are attached to the cladding with wood glue.

- Glue the second facing panel.

- They cut in hinges, locks, and handles.

- Install the door into the frame.

During the assembly process, MDF is glued end-to-end to the surface, and for stability, blocks of wood 10-15 cm long are laid between the strips. The result is a kind of fence.

Manufacturing algorithm

Whatever you end up making it from, self-installation of an accordion door is carried out according to the same principle, regardless of the material

Of course, any material has its own nuances that should be taken into account, but the installation algorithm itself does not change

Necessary materials

First of all, you need to purchase fittings; it is best to do this at a furniture store. The kit should include axles, stoppers and a carriage with runners. In addition to accessories you will need:

- sheets of material with an area equal to the width and height of the doorway, sheet thickness - 17-20 mm;

- loops;

- self-tapping screws;

- PVC edge, the color of which must match the door.

Assembling the door leaf

A do-it-yourself accordion door cannot be installed without assembling the door leaf, which is carried out in the following order:

- It is necessary to mark a rectangular sheet of material. Two panels will be cut from this sheet to form the accordion door leaf. The width of the panels can be kept constant, or one can be made much wider than the other - it all depends on desire.

- If the door is made of wood, fiberboard or MDF, then the edges at the end of the cut panels should be wiped with sandpaper, and then the remaining dust should be removed with a regular rag.

- Grease the end of the panel with glue. We glue the plastic edge to the end, firmly pressing the parts together. In this case, a roller will help. The edges must dry thoroughly, so they should be left for 12 hours.

- The next step will be marking the places where you plan to install the hinges, carriage, fittings for the axle and handle with lock.

- You need to place two metal axes on the top and bottom of the sash. Drill holes in the areas designated for the axles so that the depth of the hole does not exceed the length of the axle.

- Next, you need to symmetrically fix the axes on the panel, that is, so that the position of both axes completely coincides in all directions.

- Drill a hole where the roller runner should be attached (at the upper end).

- The panels forming the door leaf must be laid horizontally, maintaining the position of the panels in which they will be connected by hinges. You need to place 3 hinges between the doors closest to each other. The hinges on one sash must be positioned strictly at the same level and at the same distance from each other, otherwise the panels will be slanted.

- Panels that are next to each other must be connected in such a way that a distance of 3 mm is maintained between them in the open position of the sash.

- On the panel that is located on the edge, you need to install a groove in which the door handle will then be placed. Unlike standard doors, the handle on an accordion-type door is mounted on the outer panel, and not on the end of the sash. The grooves for the lock need to be drilled between the panels in the middle. The finished sash can be hung on pre-installed fasteners in the door opening.

Installation Features

When starting installation, you must strictly follow the instructions and take into account important points:

before installation it is necessary to prepare the doorway; during work, it is important to clearly monitor the spatial position of the elements, otherwise the canvas may get stuck and the rollers may wear out; the dimensions of the opening must be geometrically accurate.

The doors are installed according to the following step-by-step scheme:

- A guide element is attached to the top of the box in a horizontal position.

- The leading part of the leaf is placed as close as possible to the door jamb and the top guide.

- Using rollers, the driven part is fixed in the guide.

- Stoppers are installed to prevent the doors from touching the walls.

- Fittings are being installed.

- The parts are lubricated with an oil composition.

Preparing the doorway

After purchasing the kit, you need to start work by preparing the doorway. To do this, the old door is dismantled. It is necessary to remove the old drywall or mortar to the surface of the wall so that there are no difficulties in installing a new box. After dismantling is completed, measurements of the opening are taken. This is necessary to determine whether it is necessary to reduce or increase the opening for the purchased structure.

Attention!!! The doorway prepared for installation must be smooth around its entire perimeter. An error in the upper overlap is allowed, but not more than 5 mm. This is determined by the level. The sides must be strictly parallel to each other and of the same thickness throughout the entire height - without narrowing or widening.

The frame of the new door is assembled from purchased accessories. You can buy them in the official stores of the manufacturer that produces canvases and components. The upper crossbar is fixed in the upper corner with self-tapping screws. The assembled box is inserted into the opening. The extensions are secured with anchors. The box in the shape of the letter “P” is installed in the opening, fixed with anchor bolts and polyurethane foam. When working, you should use a level to avoid distortions of the box. After the foam has completely dried, they move on to the next stage of work.

Some useful tips for installing a folding door

The door leaves are folded into an accordion and passed through the rail

The difference in installing a folding door is only in the number of guides, as well as the method of fixing the panels. When two guides are used, additional difficulties arise in the installation of this structure. However, the book will be much more reliable and much stronger.

The upper guide is attached to the ceiling. For beauty, it is decorated with decorative details. This is necessary to ensure it matches the interior of the room.

Installation of a folding door must be carried out carefully and accurately. It should fit tightly into the door frame. If you do not follow the installation rules, the structure will creak very quickly and the door will not close completely.

The most important operation is considered to be preliminary preparation of attachment points and leveling of the floor. The door mechanism must be checked when purchasing

It should work quietly and smoothly.

Long-term operation of the door is guaranteed if you treat it very carefully and always close it very smoothly. Only in this case will it work properly for many years.

The negative side of a flip door includes poor sound insulation, play when the door opens, and high odor permeability. However, thanks to the use of modern fittings, such disadvantages are minimal.

A serious drawback of this design is the lack of a protective function for the door-book. Since its canvases do not have high strength and are not installed rigidly, it will not become a reliable barrier.

The best posts

- How to make a plasterboard ceiling in the kitchen with your own hands

- How to paint drywall: little tricks

- Socket boxes for drywall: correct selection and installation

- Grouting drywall joints: materials and techniques for performing the work

- Epoxy resin, application

- How to cover a radiator with plasterboard without losing heat in the room

- Repair of plasterboard ceilings: we fix the problem ourselves

- Machine for the production of profiles for plasterboard: production of frame elements

Advantages and disadvantages

The popularity of accordion doors is due to the following advantages:

- Economical free space. Such designs are relevant among owners of small apartments. When opened, the accordion folds, so it saves space compared to swing systems.

- Ease of installation. If you have basic skills, you can install the doors yourself in a few hours. Accordions are sold assembled, so to install them you only need to attach the block (without the use of foam or other building materials).

- Multifunctionality and versatility. You can purchase several doors and connect them. The structures can be mounted in radial and straight openings. The guides can be bent and hung on the ceiling, turning the doors into transformable partitions. The width of the canvases is almost unlimited, so the structures can be used as a transforming partition.

- Wide range of solutions and forms.

There are few disadvantages to folding doors. Essentially, it all comes down to the material used to make a particular model. For example, plastic structures will be fragile and not resistant to temperature changes, and wooden options are demanding to maintain. A common drawback of folding doors is breakage of the rollers, but this problem can be corrected with high-quality assembly and installation.

Peculiarities

Books are placed in almost any room (kitchen, bathroom, bedroom, pantry, cellar, etc.), as they are not inferior to ordinary doors in terms of variety of colors and materials.

Types of materials

Most known materials, including fabric, are used in the manufacture of book doors. Designs with soft fabrics are useful for separating a small part of the room. The most common materials are:

- Tree. This is a classic, environmentally friendly option. The exquisite appearance of wooden products will decorate every room. But their price directly depends on the quality of the wood. And due to the heaviness, a stronger fastening mechanism will be needed.

- MDF. MDF book models are placed in any room, but most often in the bathroom and kitchen, due to their resistance to moisture and temperature changes.

- Chipboard. Characterized by high strength. They are usually covered with a decorative film that replicates the structure of natural materials.

- Glass. The key advantage of glass structures is their original appearance. But they are not very popular. This is explained by the fact that with them the sense of privacy is lost. And heavy weight negatively affects the service life of fasteners. In the manufacture of the canvas, glass is used: tempered, laminated glass of the triplex modification or double-glazed window.

- Plastic. Plastic doors are the most affordable. They are resistant to moisture and do not require additional care. They are mainly used to cover a dressing room, or as a partition in a room.

- Aluminum. Aluminum structures are strong and lightweight. Negative points include: high price, poor insulating qualities.

Folding door sizes

According to the dimensional characteristics, folding doors are standard and non-standard. The former predominate in the catalogs of companies selling similar products. Standard for most factories: width from 400 to 1800 mm, height up to 3000 mm.

Designs with non-standard dimensions are manufactured only upon individual order. For example, you can order a very small partition to cover some niche. A large model is suitable for separating zones in a room.

Color options

The choice of canvas color deserves great attention. A universal option - doors in light colors

They fit into any design and do not distract attention from its other elements. Designers see no less advantages in models of dark tones

The cappuccino color looks attractive; it will suit both dark and light rooms.

An interesting idea is to match the door design with the flooring, especially if they are the same color. This helps complete the look of the room. It's good when the tone of the floor matches the color of the doors.

Mechanism design

The design of folding interior door-books is more complex than that of swing or sliding doors. It consists of one or two sashes, divided into sections, moving on special rollers, a fixation and braking system.

The mechanism is mounted in a box on hinges or supports that are attached to the upper beam. The strength of the structure is affected by the quality of its installation to the vertical beams. Placing the mechanism at the same time above and below will also have a positive effect on strength.

Sliding interior structures

It happens that, due to the small size of an apartment, equipping it with swing door models does not have the best effect on the functionality of already small rooms: opening swing structures requires additional free space, which may not exist. In this case, the most optimal way out of this situation may be to install sliding-type interior doors.

Like the previous, swing version of doors, sliding systems can be made from the above materials, or a combination of them. In this case, sliding doors can be as follows:

- Recoil. Models that operate using this type of opening have roller wheels and a guide along which the door leaf moves. Sliding doors fit most naturally into openings of standard width (up to 900 mm). For openings whose width exceeds this value, the difficulty in selecting a door lies in the need to use a special roller mechanism designed for additional load.

- Sliding double doors. From the name itself it is clear that in this version of sliding doors, two doors are used at once, opening in different directions. Interior sliding doors can allow their doors to be opened either simultaneously or separately - it all depends on the roller mechanism used.

- Sliding cassette type. Using cassette sliding doors in an apartment, especially a small one, can significantly save space that would be required for their operation. The essence of the functioning of this design is that when a cassette door is opened, its leaf seems to “go” inside the wall, and does not move parallel to it, as is the case with a sliding door. We can say that the operation of the cassette design does not require additional space, which is so necessary for the functioning of other door systems.

- Sliding doors. They may contain more than one or even two valves. This fact significantly expands their functionality. Now, with the help of compartment doors, organizing a transforming partition instead of part of the wall has become easier than ever. As you know, a wide passage into a room has always been an attribute of a spacious home.

How to make it yourself

Different designs vary in complexity of manufacture. The simplest is a smooth solid wood door. It is also not difficult to make a panel room. More complex ones are paneled and keyed.

Required tools and materials

When the wooden boards have been prepared and the drawing has been completed, tools and materials can be prepared.

Their list:

- roulette;

- level;

- plane;

- chisel;

- drill;

- milling cutter;

- hammer;

- mallet;

- sandpaper;

- dry tongue and groove boards;

- self-tapping screws;

- loops;

- wood glue.

For an interior door, a board thickness of 25 mm is sufficient, for an entrance door - 50 mm.

Manufacturing from solid wood

The easiest door to make is a flat door, that is, without panels or keys.

Manufacturing a door leaf from solid wood consists of the following steps:

- Mark the prepared boards and cut them into pieces of the required length.

- Place the sawn boards on the table so that the pattern of the annual rings is directed in one direction.

- Assemble the boards into a single sheet, fastening them together with a tongue-and-groove connection.

- Cut off the tenon from the end board of the canvas and process the end.

- Compress the assembled canvas with clamps and leave to dry.

- If necessary, add a second or third layer of wood so that each layer is perpendicular to the previous one.

- Fasten the canvas with crossbars. The segments for them should have a length equal to the width of the door leaf, and the shape of the crossbar should be trapezoidal. The depth of the groove should be half or a third of the width of the board. Coat the grooves with glue and insert the crossbars into them using a mallet.

To make the structure last longer, it must be treated with antiseptics.

Paneled doors

The basis of a paneled door is a frame made of timber. Horizontal crossbars, vertical jumpers and mullions are inserted into it. Panels are inserted into the resulting cells, which can be made of either wood or laminated chipboard.

How to make paneled doors with your own hands:

- For the frame, cut two posts from the beam, as well as the upper, lower and key cross members, the upper and lower mullions.

- Process the edges of the timber with a router and cut grooves for inserting the panel.

- Cut connecting tenons at the ends of the crossbars, grooves for inserting mullions and panels at the ends, and grooves for connecting the crossbars with the tenons at the bottom and top of the vertical posts.

- Connect the frame parts together using a tongue-and-groove method.

- Using a mallet, fasten all joints until they are tightly connected.

The play when inserting a panel into a cell can be up to 2 mm.

Keyed door

A do-it-yourself wooden front door can be made from boards with dowels. Such doors are installed in residential buildings in rural areas and in utility rooms. Thanks to them, heat is retained well in the room.

Manufacturing a blade with dowels consists of the following steps:

- Cut the boards to the length of the door leaf.

- Lay them in a row, compress them into a shield and mark the grooves for the dowels. The grooves must be made to their full depth; width: bottom - 50 mm, top - 35 mm.

- Cut grooves for the strut with dowels using a router or plane.

- Cut a strut and dowels from a beam with a cross-section of 40 × 40 mm.

- Insert them into the grooves of the canvas and screw them with self-tapping screws.

- Remove temporary bridges.

In this case, the keys on internal doors can be fixed with glue, but more often they are assembled as entrance doors.

Panel door

The popularity of panel doors is due to the low cost of their manufacture. Such a door consists of a frame, filler and linings.

Panel door manufacturing process:

- Cut blanks for the frame and fiberboard sheets from the boards according to the size of the sash.

- Place all the parts, except for the top fiberboard panel, on the table and connect them together with wood glue and self-tapping screws.

- Fill the insides of the structure with filler: sawdust, mineral wool, polystyrene foam, polyurethane foam.

- Apply glue to the top of the frame and lay the top fiberboard panel.

- Compress the entire structure with a press.

The panel door can be covered with veneer, and it is also possible to stick various decorative elements on it, including relief ones.

The use of folding doors in the interior

Folding doors are widely used in any design. They have a rich palette of shades. Such designs will allow you to make a bright accent or do everything in one scale. To visually expand the space, you can use glass systems or models with mirror elements. There are many unique combinations and combinations available, including stained glass inserts.

The use of book and accordion-type structures is a relevant, practical solution for home and apartment, which fulfills a decorative and functional purpose.

Where can you install an accordion door?

Such interior doors are installed almost everywhere. They are suitable for:

Such accordion doors are very popular when creating a studio apartment. By installing a lightweight plastic door, you can divide the room into certain zones.

Since such doors have a wide variety of colors, you can create a separate dressing room or women's boudoir. An installed “accordion” that fences off the dressing room will look like a luxurious screen. The interior will look more elegant and original.

Many designs of interior “accordions” are made without a door frame. Therefore, they can be installed to the entire height of the room.

The sliding design becomes indispensable when it is necessary to combine the living room with the kitchen. Such a distinction always looks beautiful and impressive.

It must be said that a door with an accordion mechanism is installed not only in small apartments. It is suitable for installation in country houses. Here the problem of building an additional exit leading to the garden very often arises.

Installing large swing structures is sometimes very inconvenient. “Accordion” makes it possible to create a new entrance very quickly, while saving significant money.

It is very difficult to expand a bathroom using adjacent rooms. An accordion door solves this problem, but it must be made of plastic panels that are resistant to high humidity.

In addition to plastic, you can also use wood treated with moisture-resistant varnish.

Such structures are also widely used for closing auxiliary rooms. For example, space in the pantry will be saved, and the decorated canvas will complement the interior of the room.

The “accordion” can be installed on the door of a wardrobe. At the same time, it should be very light. If this design is decorated with beautiful decor, for example, bright drawings, then the cabinet will take on an original and luxurious look.

Execution options

Folding structures may vary in the material used for their manufacture.

Such sliding door systems can be made of the following materials:

- plastic;

- wood;

- skin;

- chipboard;

- fabrics;

- glass;

- MDF, etc.

Most often, pine is used to make door system panels. The advantage of this material is difficult to overestimate: it is cheap, and the pattern of this type of wood is quite interesting (light wood with dark spots). However, pine is too soft a material: a small blow will leave a dent on the canvas, which means it will ruin its original appearance.

More expensive models are made of oak, maple or beech. These folding structures look impressive and are also durable. In addition, there are also cheap folding doors on the modern market: they are made of MDF or chipboard. But, unfortunately, such swing blocks have a short service life.

Door systems made of glass look amazing. For their manufacture, transparent, frosted or colored glass can be used, fixed in metal or wooden slats. Such folding structures are expensive products.

In addition, sliding book systems, the sections of which are made of leather or fabric, have a magnificent appearance. These products are recommended for installation in doorways of non-standard shape.

Folding systems also differ in the type of coating.

As a rule, folding doors have the following type of coating:

- lamination;

- veneering;

- toning;

- coloring.

The simplest methods of surface treatment are painting and tinting. Usually, before tinting, the canvas is coated with a transparent or translucent varnish. Lamination of door systems involves covering their surface with a special film (it can be either paper or plastic based). When veneering, a special film is applied to folding doors (its thickness must be at least 1 mm).

Disadvantages of the model

When installing folding interior doors, you will have to face the following disadvantages of the model:

- Poor sound and heat insulation. The presence of folds, a seal in the upper part, as well as a guide with rollers leaves a small distance through which noise and cold penetrate.

- When installing the product, you cannot do without specialized fittings.

- The folding mechanism is not as durable as a door made from a single piece.

- If the door is too heavy, then you will need to additionally install not only the fastening on top, but also rollers on the bottom, and this is an extra expense.

- When the door leaf is decorated with glass inserts, you need to open the product carefully or equip the mechanism with a closer so as not to break the decoration.

Installation of an accordion door

In order for the installed structure to last long enough, it must be installed correctly. We suggest you understand the sequence of assembling the structure and performing installation work so that you can do everything yourself.

You can do the installation yourself

How to assemble an accordion door: instructions are provided by the manufacturer

To figure out how to assemble an accordion door, you should carefully study the instructions included with the manufacturer. It describes the process in detail. Most often, assembly is performed in the following sequence:

- insert an axle into every second panel. If the manufacturer has not provided mounting holes, we form them ourselves;

- Place the panels in the required sequence. If a pattern will be formed on the sash, the previous point should be performed taking into account this feature;

- We mark the places for installing hinges. The fittings should be fastened in three places at equal distances;

- we connect the panels into a single system, providing a gap of 3 mm between adjacent elements;

- install a door handle of a suitable type.

The sequence of the panels must be observed

Installation of an interior accordion door: sequence of actions

Installation work is carried out in the following sequence:

- the old door system is dismantled;

- dimensions are taken;

- the doorway is being prepared;

- a box is assembled without a lower threshold. Attaches to the doorway;

- guides are installed. To fasten them, either self-tapping screws or clips are used;

- installation of accordion interior doors with the side on which the rollers are attached into the guide profile. After the sash takes its assigned place, side profiles are installed.

Rollers are inserted into guides

Installation locations

Installation of folding book doors can be carried out at the entrance to various rooms. Often consumers install in the bathroom. In this case, it is preferable to use plastic, metal or glass options. This is due to the fact that temperature changes and high humidity may occur in the bathroom. These doors are also suitable for use in the kitchen.

Wooden doors can be installed at the entrance to living rooms - such as the living room and bedroom. A wooden book door can also belong to the economy class segment, but the choice should be approached with particular scrupulousness.

From different materials

Folding accordion doors, like book doors, can be made from different materials. Let's look at them in the photo galleries below.

Accordion door made of natural wood

Natural wood. Durable material provided it is properly processed: the wood is impregnated with an antiseptic, covered with stain and varnish. Over time, the coating is updated. A door made of this material is not resistant to changes in humidity.

MDF accordion door

MDF. The most resistant material, not susceptible to the destructive effects of fungus and mold. Compared to chipboard, the material is more suitable for the manufacture of doors of complex design. Chipboard is quite durable, lightweight, environmentally friendly, moisture-resistant and fire-resistant.

Accordion door made of chipboard

Chipboard. Cheap because it is a sheet of sawdust glued together. A door made of such material will be flimsy. Since it consists of sawdust compressed and glued together, the screws do not hold very tightly in it. The advantage of the material is good heat and sound insulation, but the design of the accordion door does not allow the material to fully demonstrate these qualities. Chipboard also has high moisture resistance and bio-stability, but still this is far from the best option for folding doors.

Accordion door made of plastic

Plastic. Cheap, wear-resistant and water-resistant material. Ideal for a shower stall. Easy to process, does not chip, scratch or crack, and does not dry out. For interior doors, plastic with a pattern is usually used: wood, the color of the walls, etc.