You can make simple glass original using several technologies. For example, make a stained glass window, create a drawing on it, or make a mosaic. But the most interesting way to make a truly designer product is to transform it into frosted glass.

After matting, it turns into a material with a modified surface structure, becoming opaque. Several processing techniques can be used on one glass to produce original and truly individual products.

Glass products - decorative lighting fixtures, souvenirs, vases, various dishes - these items are in great demand among the population. Often, we choose these items if we need to give a gift. We are attracted by matte sconces, salad bowls and glasses; they are decorated with various designs, patterns and natural ornaments.

Undecorated products, although they cost much less, practically do not attract attention.

You can matt both completely flat surfaces and things with complex shapes. There is no thing that would be impossible to decorate using matting. And their appearance is limited solely by the richness of your imagination.

Usage

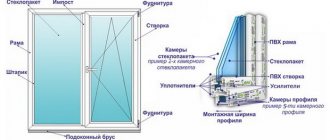

The main purpose of frosted glass is protection from prying eyes, which often appears.

For example, for organizing a protected and intimate environment in the bedroom, when organizing separate compartments in a common room, or for making partitions in sanitary rooms. When planning an office space, dividing walls with frosted glass will become indispensable.

Often, matting is used in everyday life, making parts of glazed doors, edging mirrors, dishes and lighting fixtures from it. You can purchase ready-made frosted glass from glass workshops or make it yourself.

The process is carried out in the following ways:

- Mechanically.

- Using chemicals.

- Using a sandblasting machine.

The technology of mechanical processing (with special pastes) is quite simple. Using chemicals at home is risky. And the use of sandblasting requires special equipment and makes it possible to transform mainly thick glass, and processing using this method turns out to be rough.

To install frosted glass in all-glass products, it is tempered.

Knowing how to frost glass can also help the home craftsman. Often, kitchen cabinet doors are made using frosted glass. Restoring furniture is expensive, it will be cheaper and more convenient to make it yourself.

Glass with frosted surface

An interesting design element would be the use of a matte plexiglass surface. Thanks to its ability to diffuse light, many lighting designers have successfully used it in lamps and night lights. If you are planning to create a comfortable sconce lamp for the bedroom or a night light with dim diffused light with your own hands, then you will need to watch a video on how to make the polymer matte.

How to make frosted plexiglass at home? Very simple. Take medium-grit sandpaper and start sanding the surface until it becomes matte. If you have the desire and opportunity, you can also treat the surface on the other side.

If you don’t like this option, then you can opt for chemical treatment of the surface - etching it with an acid solution, which is not very desirable for an apartment. But there will be no need to use physical force. Still, it is better to carry out processes using chemical compounds outside.

Pros and cons

Why are they good:

- Isolation of space from prying eyes.

- Variety of designs, elegance and beauty of frosted glass products.

- Variety of types of material.

- Selecting the appropriate matting technology.

- Versatility of use.

The negative qualities of this material are considered to be slight roughness; dust collects on them. This flaw can be eliminated by coating the glass with a special varnish.

Recommendations for glassmaking

Making glass with your own hands at home requires care and attention - in the absence of experience, such a process can be difficult, especially at the final stage. For the first attempt, you should not prepare large volumes of melt

To simplify working with such material, you can use the recommendations of experienced glassblowers:

- As a substitute for quartz sand, sifted white river sand is used.

- Large granules of the charge components are thoroughly crushed in a mortar before heating.

- Pieces of failed products can be added to the batch - this saves material.

The annealing temperature to complete the product ranges from 400°C to 600°C. The indicators depend on the refractoriness of the mixture used. Cooling of the finished glass depends on the size of the ingot and its thickness - large objects need gradual cooling. After completion of the work, the product is strengthened by glazing or lamination.

Manufacturing technologies

There are several ways:

- Processing using a sandblasting unit.

- Chemical treatment.

- Pasting with special film.

- Lakomat.

Changing the structure of a glass surface using sandblasting is the most common matting technology. The flow of sand removes the top surface of ordinary glass, and it loses its transparency. By changing the fraction of abrasive material and the pressure in the unit, you can change the roughness and degree of dullness.

There are several types of sandblasting glass:

- Planar.

- Colored.

- Tinted.

- Three-dimensional.

Glass etching to form an opaque glass surface is done using hydrofluoric acid. The matting paste covers the unprotected parts of the product through a stencil, and after a certain time it is removed and the glass surface is washed.

Areas treated with paste become matte. Compared to sandblasting, sandblasting makes the surface less rough and does not require a protective coating after treatment.

In production, the glass surface is completely treated with matting substances, which makes it possible to create an ideal matte surface, which is called satinato.

Frosted films for glass

Finishing with film is the most economical method. The glass is covered with a film with shading, patterns or designs.

The disadvantage of this method of matting is the need to use the finished glass under special conditions - friction or heavy wetting of the surface should not be allowed.

Lakomat is a special matting method. The surface is covered with a layer of matting varnish; it can be either translucent or white.

When coating glass with varnish, the following tools are needed:

- rubber trims;

- rollers;

- brushes;

This method requires special care and accuracy.

Original products with an unusual effect are obtained by changing the glass surface using laser radiation. There is a method of processing glass using surface detonation and using metal spraying using a plasma installation; with this processing, small drops of molten metal heat the glass to a high temperature.

As a result, microchips and very small cracks form on the surface of the glass. They create matte areas. But such matting technologies are practically not used due to the high price of equipment and the complexity of the manufacturing process.

Types of glass that are used in the manufacture of frosted products:

- mirror;

- tinted;

- painted;

- hardened;

- triplex;

- polished;

Classification of frosted plexiglass

There are several types of frosted plexiglass:

- Colored. The composition contains a coloring component, and the surface can be either smooth or rough.

- Satin. The matte effect is achieved due to the roughness of one or both sides, while there may be no dye in the material itself. Minor damage is almost invisible.

- Glossy. Both sides are smooth. The material itself is milky in color, its saturation can vary from slightly transparent to opaque. It looks attractive, but chips and scratches are clearly visible on the surface, as well as grease and dirty handprints.

- Grooved. There is a distinct raised pattern on one side. Can be white or colored.

Preparation of matting paste

Attention!

Since making your own paste requires working with chemicals, everything must be done with protective gloves and a gown. There are several “recipes” for matting paste. Made using hydrofluoric acid or liquid glass.

For hydrofluoric acid paste you need:

- Sodium fluoride.

- Gelatin.

- Distilled water.

Add the components in a ratio of 2:1:25 and mix well. The finished mixture is applied to the glass surface with a roller; after treatment, they are washed off with clean water.

After this, the glass is dried and kept in 6% hydrochloric acid for 60 seconds. Frosting of glass using this method is done using hydrofluoric acid. It cannot be used to form a pattern - the mixture will penetrate under the stencil.

Liquid glass must be mixed with distilled water, after which a small amount of tooth powder is added to it, and the composition is mixed well. Pigments are sometimes added to the paste, for example, ultramarine or red lead. The washed glass surface is coated with paste using a roller, and after drying, washed with water.

Special types of glass

In addition to the standard one, glass in the game, thanks to various mods, can take on any shape and properties.

- Colored glass. The method for obtaining it is quite simple: all you need is ordinary glass and dye.

- Liquid glass. Appeared in the game thanks to the Forestry mod. In it you can craft various electronics and obtain glass in liquid form.

- X-ray glass. It is the most interesting option for amateur miners, as it allows you to see everything that is underneath it, dozens of blocks below. It is a very expensive luxury, as eight diamonds are needed to produce X-ray glass.

- Additionally, thanks to the Fancy Glass mod, glass can be turned into a purely decorative block, like a brick. Thus, ordinary glass has turned into a building material, and a house consisting entirely of this material can now be built with one’s own hands.

Care

More intensely than on regular glass, any dirt is more noticeable on frosted glass, even fingerprints are clearly visible. It is easier to remove them immediately after they appear - you need to wipe the contaminated area of the surface with a slightly moistened microfiber cloth.

Serious stains, such as those caused by grease, can be removed. Such glass must be occasionally wiped with a piece of natural suede and washed with heated water and a small amount of vinegar. After this treatment, the cleaned surface is dried using microfiber.

Another option for cleaning a frosted glass surface can be treatment with a composition of several spoons of powdered chalk and 200 grams. clean water. The mixture is applied with a piece of rag to the glass surface, and when it dries, it is wiped off with newsprint.

Heavy contamination must be removed using ammonia, but it smells strong and unpleasant, for this reason, during such treatment it is necessary to intensively ventilate the room.

Self-made frosted glass can become a true work of art, and with the help of timely care, the beauty of the product will last for a long time.

How to make a window opaque?

I live on the 1st floor, the window faces the courtyard, next to the entrance door. I want to make the glass opaque so that I can't be seen from the outside. I thought about sticking a regular matte film, but I read on the Internet that there are some sprays for frosting glass. I don't know which is better. How do you think?

Woman.ru experts

Find out the opinion of an expert on your topic

Zinovieva Natalya Yurievna

Psychologist. Specialist from the site b17.ru

Dyachenko Elena Vladimirovna

Psychologist, Gestalt therapist in training. Specialist from the site b17.ru

Slobodyanik Marina Valerievna

Psychologist. Specialist from the site b17.ru

Nikulina Marina

Psychologist. Specialist from the site b17.ru

Sheludyakov Sergey

Psychologist, Clinical psychologist. Specialist from the site b17.ru

Trifonova Maria Anatolyevna

Psychologist. Specialist from the site b17.ru

Gundertailo Yulia Danilovna

Psychologist. Specialist from the site b17.ru

Vyacheslav Potapov

Psychologist, consultant. Specialist from the site b17.ru

Wrzecinska Eva

Psychologist. Specialist from the site b17.ru

Natalya Maratovna Rozhnova

Psychologist. Specialist from the site b17.ru

I took the film and peeled it off. and you will be scrubbing off the spray for 3 months

There is tinting, I don’t know the technology. But I ordered windows so that from the outside they would reflect almost like a mirror, but from the inside you could see everything as usual. Maybe some company can tint the existing windows.

Definitely film. It can be removed at once and leaves no traces (tested on myself), and besides, you can choose not just matte, but some kind of stained glass (with a pattern) - it will be even better!

Paint over it with oil paint, as they used to do in hospitals.

Stained glass. You can paint it yourself. There are colors. You can buy stained glass film. No problem. The Germans and Austrians do a lot.

Related topics

The film does not stick. It just sticks and comes off easily. No glue.

Mirrored windows are good during daylight hours; in the evening, when the lights are on, everything in the room is visible. Maybe hang fabric roller blinds on the glass? The choice of fabrics is huge, as are the designs. Choose something light but thick so that the room is not dark. You can order ready-made frosted white glass. They are made by plastic window companies. I did this on the loggia, the light passes through, but the “image” does not!

Are the curtains or curtains available?

Lay with glass bricks

Sandblasting method

This matting method is most often practiced in production. However, there are also household units on sale that are designed for this procedure. With this machine you can perform matting of varying densities and depths, and it also makes it easier to work with large surfaces. But you need to learn how to work with this device; you shouldn’t start working on the surface right away, you should practice first.

The disadvantages of this method include the fact that after processing the glass thickness decreases by about 3 mm.

Therefore, you can only work with glass with a thickness of 5 mm or more. If you already have a sandblasting machine, then before processing the glass you need to ensure that you have a respirator and clean sand.

With this method of frosting glass, the work flow is as follows:

- Clean the work surface.

- If there is a drawing, then glue the stencil to the desired place. It is important to note that you must glue carefully, because grains of sand under pressure can get under the stencil. It is not recommended to cut lines thinner than 5 mm or other small details. Seal the open space of glass or close it in another way.

- Protect the room, hands, face and eyes, because a small sandstorm will be created.

- Check the pressure and quality of the jet on a test piece of glass.

- Press the pump onto the glass with the stencil and use circular movements to evenly process the desired surface. Do this several times (the longer the time passes, the deeper the layer will break out in the glass).

- When finished, peel off the stencil and wash the glass product.

Cost of matting liquid

The price includes packaging. The larger the volume of matting liquid you buy, the better the purchase! Delivery at Russian Post rates is 5-7 days (250-350 rubles). Fast delivery by SDEK courier service 1-4 days (RUB 155-450). You can buy any volume of matting liquid indicated in the table below!

| Name | Net weight) | price | note: consumption |

| Nevidal matting liquid | 200 gr. | 800 rub. | for 2 sq. m. + reuse up to 3 times! |

| Nevidal matting liquid | 500 gr. | 1800 rub. | for 5 sq. m. + reuse up to 3 times! |

| Nevidal matting liquid | 1000 gr. | 2900 rub. | per 10 sq. m. + reuse up to 3 times! |

| Nevidal matting liquid | 2000 gr. | 4800 rub. | for 20 sq. m. + reuse up to 3 times! |

| Nevidal matting liquid | 3000 gr. | 7200 rub. | for 30 sq. m. + reuse up to 3 times! |

| Nevidal matting liquid | 5000 gr. | 9800 rub. | for 50 sq. m. + reuse up to 3 times! |

The matting liquid is produced for a specific order, and the moment of shipment actually coincides with the date of its manufacture. You get the freshest and highest quality product, which has no analogues in Russia and EU countries! Shipment is possible in any volume from 200 grams!

For entrepreneurs: Selling our high-quality matting liquid at a favorable purchase price is another profitable solution for your business! Nevidal matting liquid can be shipped up to 150 kg every week! Do business with us!

Delivery by any transport companies is possible upon agreement!

Production of matting liquid - (Omsk). There are truly no analogues in the whole world! The quality that we have been developing since 2011 has reached its perfection. Thanks to our wholesalers for recognition!

Our matting liquid mattifies not only glass surfaces, but also porcelain, porcelain, and ceramic tiles! The matte surface is not afraid of greasy fingerprints (they will not be visible on the glass), unlike sandblasted glass. The matte surface is pleasant and silky to the touch. Matting can be done even at home. Matting occurs in seconds; it makes no sense to keep the product in the matting liquid for more than 10 minutes. Glass frosts very quickly! Our matting liquid is odorless and does not pollute the room! After matting, the glossy surface cannot be returned! Matting liquid provides a very low cost of glass matting! It can be reused up to 2-3 times! Even if the matting liquid is frozen, after returning the temperature to room temperature, its properties will not change! The liquid can be stored from +5 to 40 °C

Shelf life - 1 year! Our matting liquid has better properties than liquid produced in Europe, and, very importantly, lower cost! When you order, you receive a liquid produced specifically for you, and thus you get the freshest possible product!

Vintage style

This solution will give the interior door a special appeal and make it the main exclusive element in any interior. Even the ceiling and walls can be decorated in vintage style, creating a unified design. So, we will need:

We combine painting the door surface with the decoupage technique. Decorative elements will serve as an addition. Of course, you can offer your own design option for the door surface, for example, supplement it with acrylic panels or mirror inserts. Before starting work, you will need to remove the door from its hinges and place it in a horizontal position. During dismantling, be careful not to crack the glass.

First stage. The surface of the door should be painted with acrylic paint. To apply it, it is recommended to use a brush with stiff bristles. Paint should be a thin layer in one direction.

Second phase. Once the acrylic paint on the surface of the door is completely dry, it will need to be sanded. To do this we use sandpaper, this way we will create the effect of antiquity.

Third stage. We decorate the main (central) part of the door surface. We tear the sheets of the music book together with the prepared newspapers into small pieces. Next, draw a square or rectangle of the required size on the surface of the door with a pencil and grease the resulting field with PVA glue. Immediately we begin to place the torn paper in a random manner on the glue and immediately straighten it out. Varnish is applied over the paper in several layers.

Fourth stage. We attach a baguette along the perimeter of all areas that were covered with torn paper. To do this, we use prepared mounting adhesive.

Decoration in vintage style

That's all, now you know how you can seal the glass in the door. There are many other options that allow you to create real masterpieces of art, watch the video. Perhaps there you will find the best door decoration solution for yourself.

Source

Glass inscription

Glass lettering can be easily achieved using layer effects, without resorting to filters that are used to create most text effects. Let's look at two examples. In one of them we will create an inscription from scratch, to create the other we will need a background image.

Glass lettering from scratch

Create a new document with a transparent or white background, select a font (here - Alexandra Zeferino Two) and enter pale blue text.

Apply the Bevel and Emboss style to the text layer, setting it up like this:

- in the Style list, select Emboss;

- reduce the size to 10 pixels;

- select the gloss contour as follows: ;

- Reduce the shadow opacity to 60%.

The effect is ready (Fig. 1).

Rice. 1. An example of a glass lettering created from scratch

Glass lettering based on an image

Let's look at another example of a glass inscription (Fig. 2).

Take the original image and enter text of any color (in the example we used the DS Yermak_D font). The effect will be more expressive if the text is written not on a uniform background, but directly on the image of a blade of grass and a drop.

Rice. 2. An example of a glass inscription created based on an image

Let's highlight all the letters in a word or phrase. To quickly select, click on the text layer thumbnail while pressing the Ctrl key (Mac OS Command).

Now let's go to the background layer in the Layers palette, select any selection tool, right-click inside the selected area and select the Copy to new layer command from the context menu. As a result, on one layer we received the inscription from the background image, and on the other the background layer remained unchanged.

Let's delete the text layer, it is no longer needed. Apply three styles to the top layer with letters:

- Drop Shadow without changing settings;

- Inner Glow, replacing the outline pattern with this: ;

- Inner Shadow without changing settings.

Let's move the inscription to the bottom of the canvas (Fig. 3).

Rice. 3. Final inscription and Layers palette

Colored glass

This type of glass is most often used in apartment design, and for a minimalist style, where the surface is almost entirely made of plastic and glass, this choice will be a godsend. Shelves, a coffee table, frames, and lamps made of colored plexiglass will look great. Of course, today such glass can be ordered ready-made, painted, but doing it yourself is more interesting. Therefore, you need to think about what to paint glass with? In any case, only a small element can be painted at home.

For painting, a special alcohol-based paint with the addition of dyes is suitable. Dilute alcohol and dye in a ratio of 100 to 0.14. You can use stain, you can mix different colors. Standard painting procedure includes:

- Preparation of the solution;

- Surface painting;

- Polishing.

Liquid plexiglass

Thanks to the low melting point (about 170 degrees), you can easily organize the smelting of the polymer plastic parts you need. It is enough to follow simple rules:

- Everything you are going to work with will need to be dried to avoid bubbles.

- If your material does not exceed 5mm in thickness, then you only need to heat it on one side; if it is thicker, you will have to heat it on both sides, turning it over.

- It is not necessary to melt the glass to a liquid state; you can work wonders with a soft product.

- Transfer the softened material into the mold and wait for it to cool, do not try to speed up the process by cooling the product with water

With the help of such simple manipulations, you can revive any product in your home, come up with a lamp or shelf, or create your own unique decorative item. Plexiglas will always be in fashion, changing slightly; it has been taking part in our design for decades, helping in the construction of buildings, and winking with illumination from billboards.

Important! Under no circumstances should you try to set up a smelting workshop in your home or apartment; remember that polymer vapors are toxic. Plastic can only be melted in a specialized room with forced supply and exhaust ventilation.

Don’t forget about personal protective equipment – gloves, overalls and a respirator.

Classic wallpaper

Before starting work, you will need to prepare the surface of the door: remove the old paint from it, use putty to remove all the unevenness and finally sand it well. As soon as the surface is ready, you need to cut out a suitable piece of wallpaper and apply special glue to it. Wait two or three minutes and then carefully apply it to the door leaf, while carefully ensuring that even the slightest distortions and wrinkles do not appear.

Next, take a soft cloth and carefully smooth it out; you can also use a plastic spatula for this purpose. If there is excess, it can be removed with a blade or utility knife. You may want to give your creation more attractiveness, but you don’t know how to further decorate the door; in this case, you can make a thin frame from a regular foam plinth on top of the wallpaper around the edges; this solution will look very beautiful. Polystyrene foam is also placed on glue. While everything is drying, it is better to close the windows so that there is no draft in the room.

Original door design

Mirror

If you don't know how to decorate the interior design of your home so that it looks modern and beautiful, then why not try covering the glass of the door with a mirror? It must be said that this option can not only become the main highlight in the interior, but also visually make the room space wider and brighter. But cutting a glass mirror is very difficult, even if you use a special glass cutter (glass cutter) for this purpose. It is best to cover the glass on the door with special acrylic panels. Thanks to the amalgam coating, they provide good reflectivity, so they are almost as good as a mirror.

Acrylic panels can have different colors, you can choose one or several at once, this will help create an original mirror panel on the surface of the door. It should also be noted that such material is easy to process, has a low weight, is convenient to attach, and most importantly, unlike glass, acrylic panels do not break. To attach them to the door surface, you will need to apply a primer to the back of the acrylic panel, the main thing is that it penetrates deeply. Once it is completely dry, you can attach the acrylic mirror to the surface of the door using double-sided tape. For greater convenience, you can use mounting suction cups; they will greatly facilitate the work of attaching the acrylic mirror to the surface.

Mirror panels for decoration

Textile

Decorating the door surface with fabric looks beautiful and somewhat unusual. In this case, it is necessary not only to prepare the surface, but also to determine the degree of shrinkage of the selected fabric. First you need to cut a small piece from it, measure its size, soak it well in water and wait until it dries completely. After this, we begin to measure again, comparing all the readings and determining the shrinkage. If the value is large, then we wet the entire section and hang it to dry.

Fabric preparation

Advice! To decorate a door, you can take either a single piece of material or cut fragments of various textures and any color scheme.

This technique is very popular today, it is called “patchwork”, and it is this technique that designers often resort to when decorating original interiors. To attach the material to the door leaf, it is recommended to use casein glue or special mastics, such as Gumilax and Bustilat. You can paste over not only a large piece of fabric, but also small fragments, however, here you will need to pay great attention to their tightness, otherwise such decor will look very sloppy.

Decorated door

How to make frosted glass yourself?

Working with a stencil

Before you start doing anything, it’s worth considering popular glass frosting techniques, as well as methods for applying drawings and inscriptions. In the field of professional matting, engraving is occasionally used. This method requires additional tools and skills, and this is not suitable for everyone. At home, stencils will come to the rescue.

Choosing a stencil

There are three options here:

- Buy a reusable and suitable stencil (you will need aerosol glue for it).

- Buy a stencil for one-time use on self-adhesive film.

- Download the stencil on the Internet, transfer it to the desired scale, redraw it on film like an “oracle” and cut it out with scissors or a utility knife.

Glue and remove the stencil

If we talk about the first case, then you should apply glue to the stencil, wait a couple of minutes, and then stick it in the desired place and press the stencil to the glass with a dry, clean cloth using blotting movements. In the last two cases, we remove the backing from the film, glue the stencil onto the glass (which first had to be degreased and wiped dry), smooth it out with a rubber spatula, and if bubbles have formed, we pierce them and let out the air.

If the self-adhesive film stays on the glass for more than a day, it will be difficult to remove. For this reason, we advise you to remove the stencil from the glass as soon as possible after washing off the matting paste or drying the paint. We will talk about how to make a drawing with your own hands in other ways later.

We imitate dullness

How to make frosted glass at home in the easiest and safest way? We will talk about it further. I would like to note that this method will make it possible to obtain not a dull finish (in which the surface structure changes), but to create an opaque layer.

Pasting with film

This method will be a real salvation for those who want to frost glass cheaply and cheerfully. It is suitable only for flat products, or those that have a small rounding angle and will be used in dry rooms.

After you buy the film of the size you need at the hardware store, follow these instructions:

- Preparing glass - clean the surface with detergents and wipe dry.

- Try on the film, after which you need to cut it, if necessary, cut out decorative elements from it.

- Carefully remove the coating, moisten the film and surface with soapy water (this is easiest to do with a spray bottle).

- Apply the film to the glass, “drive out” excess moisture and air bubbles with a soft cloth or napkin.

If you use this method, remember that matte surfaces do not have the same properties as glass - when exposed to abrasive substances and sharp objects, the film can easily tear. Such a defect cannot be corrected.

Matting with paint

Today you can find on sale waterproof acrylic paint for matting, which is produced in aerosol cans; it is also called aerosol frost (by analogy with the effect obtained). The method is quite convenient in that the opacity effect can be removed at any time using acetone, and a smooth surface will be available.

This paint is most often used not to make glass matte, but to apply matte designs on it. This is where the stencils we talked about earlier come in handy. Once they are applied, we recommend using masking tape to prevent accidental painting of other areas and surfaces. After preparation, spraying is done, and the manufacturer’s recommendations should be followed. Once the paint has dried (usually within 30 minutes), the stencil can be removed.

Aquarium

To make it yourself, you will need:

- Premium grade silicate glass.

- Glue containing silicone. Look carefully at the information on the packaging: it should indicate that it is suitable for aquariums (it does not contain antibacterial substances that harm fish and plants).

- About 8 pieces of small corners, suitable for pre-designed sizes.

When gluing parts, you need to remember certain requirements:

- the seams must be thick, at least 2-3 mm;

- The outer edges must be sanded, and those under the glue must not be touched.

The build process itself looks like this:

- We take one block and make a hole in it with a thread for a bolt of a suitable size. In the other we make several holes for the self-tapping screws on which the bars will be attached.

- A total of 4 bars of equal length will be used, with corners attached to both sides. The length of the bar determines the internal width of the aquarium.

- Prepare 8 plywood and rubber spacers of suitable size.

- The glass that will be located on the sides must be clamped with a special device. The bars ensure the same length and parallel arrangement of the glass relative to each other. But keep in mind that you will have to work hard before you get right angles between the edges of the glass. You will need to take a square and measure the diagonals.

- The resulting structure must be laid on its side and glass attached to it. If everything is smooth, then the side windows are positioned perfectly.

- We apply sealant and carefully lay the front glass, pressing down a little so that the substance fills the seam completely.

- After a couple of hours, you can turn the structure over again and glue the rear window in the same way.

- Wait two hours for the material to dry.

- Next, you need to remove the bars from the bottom of the glass, then turn the structure upside down and glue the very base (bottom) of the aquarium here.

- Again, leave the product for two hours, turn it over and glue strips of glass along the top edge. In this design they play the role of stiffening ribs.

- We leave the product for exactly one day. This time should be enough for everything to dry. Now the aquarium is ready.

Do not rush to immediately “transport” fish and other marine life here. Conduct a 3-5 hour hydrotest - fill it with water and check whether the structure is leaking liquid, whether the seams are leaking, etc.

Now you have an idea of how to make an aquarium yourself at home.

Additional qualities of matting liquid

- the liquid is not a dye and does not change the structure of the glass

- when matting, the liquid does not react with acrylic films (Oracal film and others), as well as with polymers, plastic and wax, which allows the use of these materials as protective and limiting coatings when matting

- The matting liquid has virtually no odor

- the liquid has a completely transparent structure

- Shelf life of matting paste is 1 year, if stored in a hermetically sealed container

Windows aero doesn't work.

What to do if windows aero does not work. First, install all operating system updates.

Second, go to the website of the manufacturer of the video adapter you have installed, download and install the latest version of the driver.

If, after these steps, Windows aero still does not work, download the free troubleshooting program “Mats_Run.aero.exe” and run it.

It will check your operating system, change settings or tell you what you need to do to get Windows Aero to start working.

You can use another method. Go to the control panel, find “troubleshooting” and in the “design and personalization” column, click: display desktop aero effects and until the process is completed, click “next” at the bottom on the right side.

Piskostrumene matuvannya warehouse

Now let's look at the power tool and the power tool. The sandblasting method makes it possible to treat large surfaces, provides deeper etching, and allows you to produce matting of varying thickness and depth on one piece. If you need a compressor, you will drink it! So on the balcony of your ninth upstairs, you won’t be able to practice for a long time in the name of mysticism. Your neighbors learned the MNS number a long time ago, and this time they will definitely use it.

And if you live in a private cabin, or would like a garage, then be kind! The range of actions is much wider. The hour is not far off, when a stream of zamovniks flows to you, and your gut has another stream, a crunchy one. And you will forget how much you paid for the compressor.

Well, we need a sandblasting device. The photo shows a yoga diagram. There are plenty of folk craftsmen who construct it themselves from practically available materials. Golovne, understand the principle: the sand is forced to flow from the nozzle under the required pressure in the required direction. Please note that when independently assembling such a folding thing, masters buy spare parts in medical equipment stores for dentists, for example, ceramic nozzles! If you need a compressor, you can take the one you bought if you wanted to dedicate your entire life to airbrushing. It remains to be screwed behind the circuit. Alternatively, you can immediately buy the entire device for free.

How much money will you have to spend on a respirator? Because the wind during the process itself will be like a blowing storm. Axle, in power, and everything is necessary. Ale we forgot about the sand! Craftsmen sift river or quarry through a sieve. And it’s not even the people who buy ready-packed sand.

Once all the technical components are ready, let’s proceed with all the preparation steps, as when working with pasta. It is only necessary to glue the spitting as tightly as possible, so that the pressure under a strong pressure will support the weakly adhered sections, and the pieces will be smeared. For this reason, it is not necessary to stencil lines thinner than five millimeters, and small details, they are simply created. For filigree robots, use vicor paste.

Seize the place, seize the hands, denunciation, and especially the eyes. Please, before sanding, you don’t need to wash the sand, it’s fine. Press the release button, turn the pressure level and the power of the sand jet onto a test piece of the error. Press the gum pump firmly against the stencil and use circular hands to evenly go over the entire surface. You will instantly become rude, so you won’t be able to do anything. Just walk over the skin area several times with smooth hands. Mastery, as always, will come with evidence. The more an hour, the deeper the ball to knock out the pinches in the glass.

Over the years, you will work with yard little ones - after the first sanding, the edge is cut, another stencil is glued, and the sanding is repeated again. In this manner, in places where the wedding is held, the selection will be deeper. This way you can create amazing pictures. Well, once we have completed the process, we rip the stencil out of the glass, lift it, rub it, and follow the notes. Before speaking, the slope looks really good with a vibrator, which is illuminated from the end. The independent picture is ready.

After practicing on small pictures from behind the glass, you can move on to the mirror. This is a more powerful material, which visually increases the appearance of skin defects. Having mastered the mirror, you can create anything at once: mirrors with a small wardrobe for a wardrobe, glass tables and little tables with a small wardrobe, countertops, partitions, cracks in doors, windows and everything that the amiable assistants will ask for. And the light on the mirror is either changing or saving, and will enliven the interior, every day in a new way. Therefore, this type of dressing is never out of fashion.

Matte stains on the glass

This article will look at a very important topic: how to create matte patterns on glass and mirrors yourself, without resorting to the expensive services of companies like “Cetif”. Everything that is hidden behind secret doors with the sign “no outsiders should enter”, I have been wary of for a long time. I want to say that there is nothing there that cannot be repeated by people whose hands grow correctly, and whose creativity is overflowing.

Maybe we can’t immediately clean the doors for the wardrobe, but build a mirror in the hallway, clean the doors in the kitchen cabinet - completely! And also - matte patterns on dances with champagne, for example, on kelikhs, navit on kahl... Oh, go away, hand, itchy, shoulder! Matte looks very good both on large and miniature surfaces.

LiveInternetLiveInternet

—Categories

- We knit with pleasure. (564)

- We sew with pleasure. (415)

- All sorts of goodies (190)

- Programs. (155)

- Cakes (118)

- All sorts of useful things. (95)

- Knitted hats (94)

- With my own hands. (90)

- Bags (84)

- Salads (68)

- Textile doll (62)

- Cold porcelain (60)

- Painting (57)

- Decoupage. (46)

- Meat (31)

- Cookies cookies. (28)

- Fish. (25)

- Interesting. (22)

- All kinds of boxes. (21)

- Sweets (18)

- For the New Year. (15)

- Cleaning tricks. (15)

- Pillows (14)

- Drawings (13)

- Bread (12)

- Slippers. (eleven)

- cats (11)

- Poetry. (eleven)

- Bas-relief. (eleven)

- Music. (eleven)

- Whether in the garden or in the vegetable garden. (eleven)

- Crackle. (10)

- Cheers! (10)

- Ice cream (9)

- Cheese (7)

- For the diary. (6)

- Macrame. (4)

- Molds. (4)

- Glass bottle. (3)