Glass can be good or worse (see the article “What you need to know about sheet glass before buying it”). Glass grades according to GOST 111-90 are ranked by quality into 7 categories - from “1” to “7”. There are also designations for special-purpose glass brands.

Further in the article on our website we will tell you how different brands of glass differ from each other, and for what purposes each of these brands is suitable, as well as about special brands of glass - chemically resistant, thermally resistant (in particular, used in laboratories, quartz and liquid glass

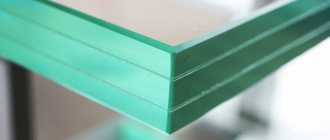

What types of glass are there?

Glass can be good or worse (see the article “What you need to know about sheet glass before buying it”). Glass grades according to GOST 111-90 are ranked by quality into 7 categories - from “1” to “7”. There are also designations for special-purpose glass brands.

Further in the article on our website we will tell you how different brands of glass differ from each other, and for what purposes each of these brands is suitable, as well as about special brands of glass - chemically resistant, thermally resistant (in particular, used in laboratories, quartz and liquid glass

Flat glass brands

M1 glass is used in double glazing for PVC windows

The highest quality glass is M1. It produces the least optical distortion and has few structural defects. GOST 111-90 specifies the following characteristics of M1 glass:

- the number of air bubbles in the thickness of the glass with a diameter of up to 1 mm per square meter. m – no more than one;

- with a diameter of up to 2 mm - no more than 1,

- length of hairline scratches – no more than 100 mm;

- the total number of defects (“glass defects”) is no more than 4 per square meter. m;

- deviations in sheet thickness - no more than 0.2 mm in each direction;

- the coefficient of directional light transmission with a glass thickness of 4 mm is 0.88.

M1 glass is used for the manufacture of car windshields, high-quality mirrors, as well as double-glazed windows (complies with the European standard EN 572-2.).

For the production of particularly precise glass parts, glass grade M0 . It should not have bubble inclusions and have more than 3 defects per square meter. m of surface. It is clear that such glass is not used for domestic purposes - only in industry and scientific institutions. For example, for the manufacture of measuring instruments, optics.

The higher the digital index in the designation of the glass brand, the lower its quality. M4 glass can have up to 12 defects per square meter. m of surface. Its directional light transmission coefficient is 0.85 (glass thickness is 4 mm).

Review of popular glass manufacturers in Russia - see the link: https://oknanagoda.com/steklo/osteklenie-steklo/steklopaketi/kakie-stekla-populyarny-v-rossii-obz.html

How, where and why coated glass is used - read here.

Glass grade M5

This glass is used in the manufacture of wooden windows, furniture, architectural translucent structures, and car side windows.

M4 is a suitable brand of glass for an aquarium: it is polished, has good optical properties, and at the same time is not as expensive as brands M1 - M3.

M5 glass should also not have more than 12 non-destructive defects per square meter. m of surface, but it is unpolished; maximum deviations of its thickness (with a nominal value of this size of 4-6 mm) should not exceed 0.4 mm in the direction of decreasing and 0.2 mm in the direction of increasing the nominal value.

Aquarium made of M4 glass in the interior of the room

M5 sheet glass is used for the manufacture of glass for tractors and other low-speed vehicles, in the production of furniture, and translucent structures.

M6 glass is unpolished window glass, now used only to create translucent structures.

M7 is thick polished glass for display cases.

It is important not to confuse the brands of glass listed above with the brands of car windshields. For example, the designation “glass for Mark 2 Toyota” does not mean at all that M2 glass is used on a prestigious foreign car. In this case, “Mark 2” is a brand of car for which a windshield of a certain configuration is used, of course, of very high quality.

You may also be interested in the article - What is I-glass and K-glass?

You will also find an overview of online stores where you can purchase molecular sieve for double-glazed windows on our website.

Advantages.

Double-glazed windows with polished M1 glass have the following advantages:

- Let in additional sunlight. This feature was made possible due to the presence of one of the highest light transmittance abilities in glass.

- There are no distortions on them. This property of M1 glass is especially noticeable when viewing the opening landscape through it. Without the distortion inherent in ordinary glass, a window equipped with a polished transparent component M1 is able to accurately convey the full beauty of nature that extends beyond the window.

- Easy to care for. Any housewife will appreciate this feature of M1 polished glass. Thanks to the smoothly polished surface, dirt and dust practically do not linger on it. This means that caring for windows containing smooth M1 glass will now not take much time and will not require significant physical effort.

So, if you are concerned about choosing a good modern window for your apartment, no matter what kind - plastic, aluminum, or wood, and you want it to let in more light, not distort the view, and not be difficult to maintain, we advise you to take a closer look at the windows, the double-glazed windows are equipped with polished M1 glass.

Special purpose glass brands

XC glass funnel

“What about XC brand glass, TS brand glass?” – our memorable reader will ask, who in his youthful years saw flasks with such designations in the school laboratory.

HS (chemically resistant) and TC (thermal resistant) are brands of laboratory glass. The special properties of these types of glass are determined by their manufacturing technology, which provides for the first - increased resistance to aggressive environments, and for the second - the ability to withstand temperatures up to 260°C.

Double-glazed window formula

We produce all types of double-glazed windows with installation throughout Moscow, New Moscow and the entire region. Quality is confirmed by manufacturing in accordance with GOST 24866-2014.

The design is encrypted in alphabetic and digital notations. The formula of a double-glazed window reflects the main properties and characteristics of the materials used during assembly.

What is the thickness of double-glazed windows for plastic windows?

How to correctly decipher the formula, the characteristics of a double-glazed window, find out the meaning of the abbreviations used, and consider an example:

The value in brackets is the total thickness of the glass unit. The formula always starts with the street (exterior) glass.

The first number is the thickness of the glass used, then a dash indicates the width of the spacer frame, then the thickness of the inner glass, a hyphen indicates the width of the frame spacer again, and the last value again indicates the thickness of the glass.

Call us or leave a request on the website. All our clients are provided with a 1 year warranty on their work!

Selection of cutting parameters depending on glass thickness

Influence of roller sharpening angle

The critical load for microcrack development depends on its depth. During fracture, in the case of large bending loads applied to the cut, it is necessary to ensure a large difference in size between the median and other cracks. However, the depth of the cracks is not very important here, since at high bending loads, the applied load exceeds the critical one for most middle cracks. As a result, for example, to cut thick glass, it is necessary to select cutting parameters in such a way as to reduce the number of surface and lateral cracks, even at the expense of a general reduction in the size of all cracks, including the “useful” middle ones. For this reason, for cutting thick glass, equipment manufacturers recommend rollers with a larger sharpening angle. Depending on the thickness of the glass and the equipment used, rollers with a sharpening angle from 110° (for thin glass) to 165° (for thick glass) are used. For example, the Bottero company recommends using the following rollers for its cutting tables depending on the thickness of the glass: 4-6 mm - 145°, 8-19 mm - 155°, 25 mm - 160°. As the glass thickness increases, it is also recommended to increase the cutting pressure and reduce the cutting speed.

Effect of cutting speed

Cutting speed has less effect on cut quality than pressure. In practice, as a rule, when pressure increases (for example, when glass thickness increases), it is necessary to reduce the cutting speed. In addition, the cutting speed must be reduced when cutting glass with an uneven surface, such as patterned or wired glass.

By type of glass unit:

- SPO

– single-chamber double-glazed windows, contains 1 chamber (SPO 4-16-4); - SPD

– double-glazed window, two chambers are used (SPD 4-10-4-10-4).

Glass brand:

4M1 – The highest quality glass is considered to be M1, a brand of colorless sheet glass, 4mm. and more. The use of glass of smaller thickness for double-glazed windows is not recommended.

Glass comes in high standard and medium standard. According to GOST 111-90, quality is divided into 7 categories - from 1 to 7. The higher the digital index in the designation, the lower its quality. Complies with European standard EN 572-2

Characteristics of the M1 brand:

Glass has the least optical distortion and few structural defects;

- the number of glass air bubbles with a diameter of up to 1 mm per m2 is no more than one;

- with a diameter of up to 2 mm - no more than 1,

- length of hairline scratches – no more than 100 mm;

- the total number of defects (“glass defects”) is no more than 4 per m2;

- deviations in sheet thickness - no more than 0.2 mm;

- the coefficient of directional light transmittance of 4 mm glass is 0.88.

- 1 year warranty on all types of work and materials.

- Affordable prices and flexible discount system.

- 100% fulfillment of warranty and post-warranty obligations.

Product indexing

Digital indexing signifies the quality of the glass. The higher the number, the lower the quality of the products. For example, M1 glass, which has the highest characteristics, can have up to 4 flaws per 1 square meter. m, glasses with different markings have significantly more defects. For example, for M4 it is permissible to have up to 12 defects per 1 square meter. m. The light transmittance coefficient is also different: it is 0.85 with a product thickness of 4 mm.

M5 glass is also available in sheets. Most often it is used for wooden windows, car side windows, inserts in door structures, and various architectural solutions that are transparent to light. You can use this glass to create an aquarium. Polished glass of the M4 brand is suitable for the same purpose; higher quality markings are several times more expensive.

For marking M5, the technical requirements are similar to M4: there should be no visible defects per 1 square meter. m more than 12. The main difference is that these sheets are not polished; deviations in thickness are allowed up to 0.4 mm with a sheet thickness of 4 to 6 mm. To the side, the denomination may deviate by 0.2 mm. Glass marked M5 is used for furniture inserts, for example, interior doors, as doors of sideboards, cabinets; it is suitable for creating glass for tractors and other equipment that is not capable of high speed.

M6 marking is used mainly to create architectural structures that are transparent to light. The product may have many defects and is not polished. Thick M7 glass is used for shop windows.

M7 glass

How to order?

- Call or leave a request on the website.

- In a few hours, meet the technician who will perform diagnostics and measurements.

- Production at the factory will take 1-7 days.

- The technician’s return visit and work will take up to 1 hour.

| We also use other special glasses during assembly. | |||

| AND | Low emission glass is low emission and energy saving glass, hard coated with silver oxide particles. (Pilkington Optitherm S1 and S3, ClimaGard N, CLGuN, Top-N, Top-N+, I-glass, i-glass) | ||

| M.F. | multifunctional glass with heat-saving properties and protection from solar radiation, as well as a mirror effect. (SunCool, SC70/40, GuSolar ClimaGard Solar, StopReyNeo, StRNeo) | ||

| 3.3.1 / 4.4.1 | triplex, created from several layers 3 (4) mm thick, using one-millimeter polyvinyl butyral film, provides impact resistance. (Stratobel Clear and Optilam Clear) | ||

| Zach (D) | glass tempering is used for high-security structures. If such glass breaks, it is impossible to cut yourself on the fragments | ||

| A (Active Clear) | have a self-cleaning option, which allows you to wash windows less frequently | ||

| Satin, SatMat | frosted glass, produced by chemical etching or sandblasting | ||

| Krizet | patterned glass, classified as decorative, contains a relief pattern on the surface | ||

| Planibel | colored tinted in mass, painted in a certain color | ||

| Stopsol Classic | reflective glass, has a mirror effect Stopsol Classic Bronze (where Bronze means the color of the glass) | ||

| Colored glass comes in a varied palette. The name of the color is written into the formula after the name of the glass itself. | |||

Types of filling the chambers of double-glazed windows:

The chambers between the glasses can be filled with different gases; the absence of markings (blank) means that the chamber is filled with dry air:

- A (Ar) - reflects the presence of argon;

- Kr – krypton filling;

- Xe – xenon gas is used;

- Sf – filling with sulfur hexafluoride.

Distance frames:

If the frame is not further indicated in the formula, then it is standard aluminum. Its width varies from 6 mm to 30 mm.

- TR, S (PVC frame) or PV – warm spacer frames based on a plastic profile, used in the production of thermal packages;

| Examples and explanation of double-glazed window formulas: | |||

| (22) 4MF – 14TP – 4M1 | It stands for a transparent single-chamber double-glazed window with a thickness of 22 mm. with multifunctional glass (4 mm), with warm spacer (14 mm wide) | ||

| SPO (32) 4M1-24-4M1 | Single-chamber package 32 mm wide using a conventional 24 mm aluminum spacer frame, with conventional 4 mm glass. brand M1. Characteristics: general construction | ||

| SPO 4M1-10Kr-4M1 | This formula means a single chamber of 2 M1 glasses of 4 mm each, with a 10 mm frame, filled with krypton gas | ||

| SPD 4M1-14-4M1-14-4M1 | In this case, we are talking about a 2-chamber double-glazed window made of 3 M1 glasses, with 2 frames of 14 mm each, the space between the glasses is filled with rarefied air | ||

| SPD (36) 4MF-12TR-4M1-12TR-4M1 | Double-glazed window 36 mm using one multifunctional glass 4 mm thick, two transparent glasses 4 mm each, M1 grade, plastic frame 12 mm wide. Characteristics: multifunctional heat package | ||

| SPO (30) 4MF-22TP+Ar-4M1 | Single-chamber thermal package using one multifunctional glass, a 22 mm warm frame, a chamber with argon gas and one M1 4 mm. New generation class of increased heat saving, sun protection and energy efficiency | ||

| We can produce packages for any purpose. | |||

E-mail: This email address is being protected from spambots. You must have JavaScript enabled to view it.

7 Control methods

7.1 Control of dimensions, dimensional and shape deviations

Thickness, length, width, deviations in thickness, length, width, variations in thickness, difference in lengths of diagonals, deviations from flatness, straightness of edges, squareness of corners are controlled according to GOST 32557.

7.2 Optical distortion control

Optical distortions in transmitted light are controlled according to GOST 33003 (section 6).

Optical distortions in reflected light are controlled according to GOST 33003 (section 7, method A).

7.3 Control of defects

Defects are controlled according to GOST 32557.

7.4 Determination of directional transmittance of light

The coefficient of directional light transmittance is determined according to GOST EN 410.

It is allowed to determine the directional transmittance of light according to GOST 26302.

The test is carried out on a finished product (sheet of glass) or a sample cut from it.

7.5 Determination of residual internal stresses

Residual internal stresses, characterized by the difference in the path of the rays during birefringence, are determined according to GOST 3519. When testing, the glass sample is installed so that the light beam passes through the transparent ends of the sample parallel to the edges.

7.6 Determination of water resistance

The water resistance of glass is determined according to GOST 10134.1.

7.7 Presentation of results

The results of control (tests) of glass are documented in a protocol.

If the manufacturer or consumer of a product conducts tests for internal purposes (during production and incoming inspection, acceptance, periodic, type, qualification and other categories of tests), it is allowed to document the results of control (tests) in the manner adopted by the manufacturer or consumer, without registration protocol.

Glass m1 characteristics

NATIONAL STANDARD OF THE RUSSIAN FEDERATION

COLORLESS SHEET GLASS

Clear flat glass. Specifications

OKS 81.040.20 OKP 59 1100

Date of introduction 2012-07-01

The goals and principles of standardization in the Russian Federation are established by Federal Law of December 27, 2002 N 184-FZ “On Technical Regulation”, and the rules for applying national standards of the Russian Federation are GOST R 1.0-2004 “Standardization in the Russian Federation. Basic provisions"

Standard information

1 DEVELOPED by the Open Joint Stock Company “Institute of Glass”

2 INTRODUCED by the Technical Committee for Standardization TC 41 “Glass”

4 This standard has been developed taking into account the main regulatory provisions of the European standard EN 572-8:2004 * “Glass in construction - Basic products of soda-lime glass - Part 8: Delivery and final dimensions” (EN 572-8:2004 “Glass” in building – Basic soda lime silicate glass products – Part 8: Supplied and final cut sizes”, NEQ) ________________ * Access to international and foreign documents mentioned in the text can be obtained by contacting the User Support Service. – Note from the database manufacturer.

2 Normative references

This standard uses references to the following interstate standards:

GOST EN 410-2014 Glass and products made from it. Methods for determining optical characteristics. Determination of light and solar characteristics

GOST 3519-91 Optical materials. Methods for determining birefringence

GOST 10134.1-2017 Glass and products made from it. Methods for determining chemical resistance. Determination of water resistance at 98°C

GOST 26302-93 Glass. Methods for determining the coefficients of directional transmittance and reflection of light

GOST 32361-2013 Glass and products made from it. Vices. Terms and Definitions

GOST 32529-2013 Glass and products made from it. Acceptance rules

GOST 32530-2013 Glass and products made from it. Labeling, packaging, transportation, storage

GOST 32539-2013 Glass and products made from it. Terms and Definitions

GOST 32557-2013 Glass and products made from it. Methods for monitoring geometric parameters and appearance indicators

GOST 33003-2014 Glass and products made from it. Methods for determining optical distortion

GOST 33004-2014 Glass and products made from it. Characteristics. Terms and Definitions

GOST 33560-2015 Glass and products made from it. Safety requirements when handling glass

GOST 33561-2015 Glass and products made from it. Operating instructions

GOST 34279-2017 Glass and products made from it. Production technology. Terms and Definitions

GOST ISO 9385-2013 Glass and glass products. Hardness determination method

Note - When using this standard, it is advisable to check the validity of the reference standards in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet or using the annual information index "National Standards", which was published as of January 1 of the current year, and on issues of the monthly information index for the current year. If the reference standard is replaced (changed), then when using this standard you should be guided by the replacing (changed) standard. If the reference standard is canceled without replacement, then the provision in which a reference is made to it is applied in the part that does not affect this reference.

(Changed edition, Amendment No. 1).