Laboratory glassware, depending on the application, must have certain physical and chemical properties. Laboratory glassware is expected to have the following consumer qualities: • durability; • chemical inertness; • resistance to heat and temperature changes; • transparency; • resistance to shock loads.

Measurable indicators of these properties of laboratory glass, and how they are tested, are set out in GOST 21400-75. “Chemical laboratory glass. Technical requirements. Test methods".

TS group. Characteristics

Laboratory glass of the TS group is most in demand for serious work - it is thermally resistant. Its chemical resistance is at the level of other groups - XC1, XC2 or higher, and thermal resistance and coefficient of thermal expansion have better performance.

| Aspirator bottle with tap and ground-in stopper, 1000 ml (Wulff bottle) | 3-neck flask 1000 ml | Allina refrigerator with two sections 29/32, 400 mm |

Heat resistance tests according to the standard imply that the sample is placed in an oven and heated to the temperature specified in the regulatory technical document as the limit, then placed in cold water.

Undamaged samples are reheated and cooled again. Thermal resistance is calculated using the formula given in the standard.

GOST 21400 states that the thermal resistance of laboratory glass of the TS group is at least 250 °C, while glass of other groups is only 120 and 190 °C.

Flat glass brands

M1 glass is used in double glazing for PVC windows

The highest quality glass is M1. It produces the least optical distortion and has few structural defects. GOST 111-90 specifies the following characteristics of M1 glass:

- the number of air bubbles in the thickness of the glass with a diameter of up to 1 mm per square meter. m – no more than one;

- with a diameter of up to 2 mm - no more than 1,

- length of hairline scratches – no more than 100 mm;

- the total number of defects (“glass defects”) is no more than 4 per square meter. m;

- deviations in sheet thickness - no more than 0.2 mm in each direction;

- the coefficient of directional light transmission with a glass thickness of 4 mm is 0.88.

Glass M4

M1 glass is used for the manufacture of car windshields, high-quality mirrors, as well as double-glazed windows (complies with the European standard EN 572-2.).

For the production of particularly precise glass parts, glass grade M0 . It should not have bubble inclusions and have more than 3 defects per square meter. m of surface. It is clear that such glass is not used for domestic purposes - only in industry and scientific institutions. For example, for the manufacture of measuring instruments, optics.

The higher the digital index in the designation of the glass brand, the lower its quality. M4 glass can have up to 12 defects per square meter. m of surface. Its directional light transmission coefficient is 0.85 (glass thickness is 4 mm).

Review of popular glass manufacturers in Russia - see the link:

Scope of application

Glass laboratory glassware made from TS glass is, in particular: • measuring vessels - flasks, beakers, burettes; • vessels heated over an open fire – Erlenmeyer flasks, round-bottomed and others; • refrigerators and other elements of reactor plants.

Heat-resistant glass vessels can be autoclaved because the steam temperature is significantly lower than the maximum heating temperature. Glassware from the TS group is used in many industries: • chemical and petrochemical; • medical and pharmaceutical; • biochemical and biological.

Selecting a double-glazed window

When choosing a double-glazed window, as well as when choosing glass for it, several factors should be taken into account. It must be remembered that the number of cameras in a double-glazed window is one of its main characteristics.

The layer of air located between two adjacent glasses is called a chamber. Typically, in products for residential or office premises there are from one to three. It is important to understand here that the thermal insulation properties directly depend not so much on the number of chambers, but on their thickness. That is, the thicker the layer of air or inert gas between the glasses in the bag, the higher its heat-saving properties.

At the same time, the weight of the double-glazed window is important, which is determined by the number and area of glass in it. Glass is a very heavy material, and neglecting this indicator, especially if the windows are large enough, will lead over time to sagging of the opening sash and premature failure of window fittings.

Few people know, but with a two-chamber package you can achieve higher sound insulation rates than even with a three-chamber package. To do this, you just need to make a double-glazed window with chambers of different thicknesses.

A double-glazed window is an important element in the design of a house or apartment. The main loss of heat occurs through the windows in the room; they are, as it were, “cold spots.” Therefore, it is categorically not recommended to save on the quality of glass and double-glazed windows themselves, because their subsequent replacement with more optimal ones can entail not only large expenses, but also the possible need to replace the entire window.

Discussion: there is 1 comment

- Anastasia:

10.22.2019 at 14:56I didn’t find your contact information, how can I contact you?

Answer

What products does the store offer?

PrimeChemicalsGroup offers a wide range of TC glass. These are mainly products of the Simax company, there is also Russian, as well as laboratory glass produced in other countries. You can purchase almost all glass products needed for a laboratory. These include: • connecting elements; • measuring utensils; • jars and flasks for storing reagents; • flasks of different sizes and shapes.

The characteristics of Simax borosilicate products correspond to the heat-resistant glass group according to GOST 21400. Most products have certificates of conformity, in which the generally recognized quality of TS borosilicate glass is confirmed by Russian official documents.

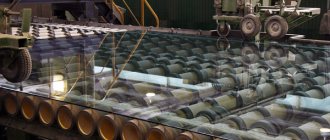

Buying glass

You can purchase any brands directly from the manufacturer or from official dealers. There is always a wide range of products in warehouses, so choosing the right amount of material is not difficult. For transportation, you need to hire special equipment so that the glass does not break on the road. It is best to cut them on site using modern high-precision equipment, which will make it impossible to damage the entire sheet.

The price of sheet glass per square meter will depend on the brand. Bulk purchases will save you an impressive amount of money.

Glass m1 characteristics

NATIONAL STANDARD OF THE RUSSIAN FEDERATION

COLORLESS SHEET GLASS

Clear flat glass. Specifications

OKS 81.040.20 OKP 59 1100

Date of introduction 2012-07-01

The goals and principles of standardization in the Russian Federation are established by Federal Law of December 27, 2002 N 184-FZ “On Technical Regulation”, and the rules for applying national standards of the Russian Federation are GOST R 1.0-2004 “Standardization in the Russian Federation. Basic provisions"

Standard information

1 DEVELOPED by the Open Joint Stock Company "Institute of Glass"

2 INTRODUCED by the Technical Committee for Standardization TC 41 “Glass”

4 This standard has been developed taking into account the main regulatory provisions of the European standard EN 572-8:2004 * "Glass in construction - Basic products of soda-lime glass - Part 8: Delivery and final dimensions" (EN 572-8:2004 "Glass in building - Basic soda lime silicate glass products - Part 8: Supplied and final cut sizes", NEQ) ________________ * Access to international and foreign documents can be obtained by clicking on the link. — Note from the database manufacturer.

5 INTRODUCED FOR THE FIRST TIME

Information about changes to this standard is published in the annually published information index “National Standards”, and the text of changes and amendments is published in the monthly published information index “National Standards”. In case of revision (replacement) or cancellation of this standard, the corresponding notice will be published in the monthly published information index “National Standards”. Relevant information, notifications and texts are also posted in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet

GOST 21400-75 S. 5

APPENDIX 2* Recommended

FLASK, GLASS AND SAMPLE BASKET

| 455 | |

| 1 - flask; 2 - glass; 3 - basket for samples | |

APPENDICES 1, 3. (Excluded, Amendment No. 2).

89

APPENDIX 4 Information

INFORMATION DATA ABOUT COMPLIANCE WITH GOST 21400-75 ST SEV 1569-79

Clause 3.1 of GOST 21400-75 corresponds to ST SEV 1569-79. APPENDIX 4. (Introduced additionally, Amendment No. 2).

CHEMICAL LABORATORY GLASS

Technical requirements. Test methods Chemical and laboratory glass. Technical specifications. Test methods

21400-75

MKS 71.040.20 81.040

Date of introduction 07/01/77

This standard applies to chemical laboratory glass (hereinafter referred to as glass) intended for the manufacture of laboratory glassware, instruments and apparatus.

The standard corresponds to ST SEV 1569-79, ST SEV 825-77 regarding glass of the TS group (Appendix 4) and recommendations for standardization of SEV PC 1885-69.

The standard takes into account the requirements of ISO 695-84 and ISO 719-85.

(Changed edition, Amendment No. 2).

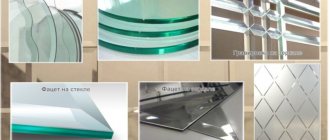

Advantages.

Double-glazed windows with polished M1 glass have the following advantages:

- Let in additional sunlight . This feature was made possible due to the presence of one of the highest light transmittance abilities in glass.

- There are no distortions on them . This property of M1 glass is especially noticeable when viewing the opening landscape through it. Without the distortion inherent in ordinary glass, a window equipped with a polished transparent component M1 is able to accurately convey the full beauty of nature that extends beyond the window.

- Easy to care for . Any housewife will appreciate this feature of M1 polished glass. Thanks to the smoothly polished surface, dirt and dust practically do not linger on it. This means that caring for windows containing smooth M1 glass will now not take much time and will not require significant physical effort.

So, if you are concerned about choosing a good modern window for your apartment, no matter what kind - plastic, aluminum, or wood, and you want it to let in more light, not distort the view, and not be difficult to maintain, we advise you to take a closer look at the windows, the double-glazed windows are equipped with polished M1 glass.

Method of production and characteristics of M1 glass.

The technology for producing this type of glass is quite complex. For this, the so-called float method is used. The essence of this method, developed 50 years ago, is to combine glass melted under high temperatures and tin, brought to a liquid state by heating. Upon completion of the interaction of two substances heated to a liquid state, a film is formed on their surface, due to which the surface of the hardened glass becomes polished.

What is M1 glass? It is no secret that when producing on an industrial scale, it is difficult to predict exactly what characteristics the glass will have at the end. Therefore, glass polished using the float method is usually divided into several categories. All of them are divided according to gradation of quality characteristics. For example, M1 means glass has the highest parameters. There are also glasses designated M2, M3, etc.

The M1 brand is characterized by:

- the presence of the ability to increase the transmission of light flux;

- maximum possible surface polishing;

- glass thickness is the same over the entire surface;

- no optical distortion.

Choosing the right brand of glass

Transparent sheet glass is widely used in the construction of residential, industrial and civil buildings. The process of manufacturing the material consists of pouring a layer of molten glass, consisting of a mineral base (calcium, sodium and silicate), onto a sheet of molten tin located in special baths. The lower density of the glass mass and surface tension forces lead to the formation of a thin surface layer on the metal with an absolutely flat surface.

After the glass layer has hardened, it is cut into sheets of standard sizes. The rectangular sheets give rise to the name – sheet glass. Used, along with the described technology, the method of vertical drawing with the help of special equipment of glass melt coming from melting furnaces in molten form, which after active cooling was a continuous ribbon, is practically no longer used. The main reason is unsatisfactory product quality and optical distortion.

Glass in double glazed units

A double-glazed window is a translucent structure of several glasses (at least two), fastened along the contour with spacer frames with careful sealing. The brand of double-glazed glass is mainly M1 or M2. Double-glazed windows are widely used for glazing windows of residential buildings, public and civil buildings, and for constructing various light-transparent structures and facades. Glass thickness from 4 to 6 mm. can be transparent, mirror, tinted, fire-resistant, impact-resistant, heat-resistant and laminated.