The glass industry is well developed in Russia. There is a wide range of different types of glass products on the market. The products are partially left for domestic consumers, and the rest is exported. However, this industry has some features and problems that affect the prospects for further development.

Role in the Russian economy

The glass industry is an area that strengthens the economy of the Russian Federation. At the same time, it plays an important role not only in the domestic market, but also in the global one.

This type of light industry is becoming an integral part of the production of other products, for example, products from the field of architecture and construction, optics, lighting engineering, fiberglass, etc.

Consumers are not only individuals, but also organizations engaged in the following activities:

- construction;

- Agriculture;

- food industry;

- furniture manufacture;

- automotive industry;

- pharmaceuticals;

- cosmetology;

- medicine.

Glass products for household consumption are no less important.

Russian products can fully cover the needs of the construction industry. In addition, according to experts, it is able to satisfy demand in the future.

Properties of glass

Glass has the following properties:

- the bending strength of ordinary (annealed) glass is at least 450 kg/cm2,

- semi-hardened - not less than 1000 kgcm2,

- tempered glass “Stalinite”—2500 kg/cm2;

- hardness (on the hardness scale) - 5 and above;

- volumetric weight - 2500 kg/m3;

- When heated, the glass softens.

Hydrofluoric acid (hydrofluoric) acid corrodes glass, so it is used for etching designs on glass and for giving it a matte surface. Sulfuric acid acts much weaker, other acids act very weakly. Alkali solutions and even water, especially warm water, although very slowly, spoil glass. Water extracts some of the alkalis from it, and the released silica is released to the surface in the form of scales, and the glass first begins to cast all the colors of the rainbow, then becomes cloudy and rough.

Market formation

The Russian glass market is based on several factors, the main one of which is the demand for manufactured goods. He sets all the trends in both the foreign and domestic markets.

The list of other points includes:

- an increase in enterprises using glass containers for storing and moving products;

- improvement of the construction sector, including an increase in the number of civil and residential construction projects;

- economic growth and expansion of the furniture industry, creating a need for large volumes of glass products.

There are areas for which the glass industry plays a particularly significant role (for example, the production of furniture and transport).

Another important indicator is market structure. In Russia, it consists of several entities, including manufacturers, suppliers, trading companies, processing enterprises, and end consumers.

Industry enterprises

Among the representatives of the glass industry in Russia, the following companies stand out most:

- Guardian Glass;

- "Expo Glass";

- JSC "Caspian Sheet Glass Plant";

- JSC "Salavatsteklo";

- JSC Saratovstroysteklo;

- RPK Etalon LLC;

- Euroglass-Techno LLC;

- Bor glass;

- JSC "Vasilievsky Glass Factory".

Other companies operating in this industry are presented in the Glass factories section.

Glass making methods

Glass materials used in construction include: sheet window and other glass, structural products, architectural and decorative products, thermal insulation materials and pipes. The high technical and architectural advantages of glass (especially polished and colored) and glass products provide great prospects for the use of glass in our construction.

Glass is a supercooled melt of complex composition, consisting of a mixture of silicates and other substances, with a gradually increasing viscosity, which solidifies upon cooling. It is amorphous, homogeneous and isotropic. The process of transition from a liquid to a glassy state is reversible.

The chemical composition of the most common window glass is as follows:

- Si02 - 71-72%;

- CaO - 7.5-8.5%;

- MgO - 3-3.5%;

- Na2O - 15-15.5%;

- А12О3 - 1.5-1.6%;

- Fe2O3 up to 0.2%.

The main raw materials for glass production are: pure low-iron quartz sand, limestone and soda or sodium sulfate.

Glass melting is carried out mainly in bath furnaces at temperatures up to 1500°. During the glass melting process, silicates are formed, the glass melt is clarified, it is given homogeneity, and it is partially cooled to acquire the viscosity necessary for molding products.

Molded glass products undergo a special heat treatment - stress-relieving annealing or tempering (see below, tempered glass). The production of window and other types of glass is mechanized.

The usual method of making window glass on vertical drawing machines is to lower a fire-resistant float (boat), which looks like a long rectangular beam with a through longitudinal cutout that turns into a narrow slit at the top, into the molten glass mass, cooled to approximately 1000°. The glass mass is squeezed through a slot, formed into a ribbon of a certain thickness and cooled as the ribbon passes between refrigerators. The tape passes between several pairs of transport rollers and is then cut into sheets.

In addition to this conventional method of producing sheet glass, another method of glass drawing, boatless, is used, which produces glass of higher quality.

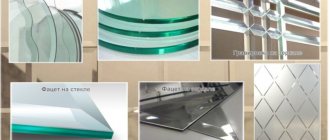

Types of glass products

Products made from glass are presented in a wide range. It is used not only for private purposes, but also for further raw materials or components for other products. That is why the Russian glass industry occupies one of the leading positions in the ranking, which determines the degree of need.

In this case, all manufactured glass can be divided into several groups, including:

- Tempered. It is created using special technologies that increase the strength of the product.

- Window. Completely transparent, despite existing coatings. Depending on the manufacturer, windows may vary. So, some models have a spray coating that helps protect the room and the people and objects in it from ultraviolet rays.

- Laminated. This type of glass has improved optical characteristics. This is achieved using a polymer material that is applied to the glass with a film.

- Reinforced. It is considered as safe as possible, as it has increased fire resistance, tolerates temperature changes well, and practically does not form defects. However, it is difficult to break due to its unusual design. The base is made of steel wire mesh. Its shape resembles a honeycomb. Despite this, glass transmits light well.

- Sun protection. It is created in order not to transmit, but to reflect or absorb the sun's rays. At the same time, the pass rate is in the range of 65-70%.

Glass classification

Glasses are classified depending on their composition. Their name depends on the content of certain oxides. The following oxide glasses are distinguished:

silicate – SiO2;

aluminosilicate - Al2O3, SiO2;

borosilicate - B2O3, SiO2;

boroaluminosilicate - B2O3, Al2O3, SiO2 and others.

Each type of glass has certain properties.

Silicate glasses are divided into ordinary, crystal, and heat-resistant. Common types include lime-sodium, lime-potassium, and lime-sodium-potassium glasses.

Crystal glasses are characterized by increased brilliance and strong refraction. There are lead and lead-free crystals. Lead crystal has increased mass and is well decorated. Depending on the amount of lead oxide, lead crystal is divided into

1. Crystal glass containing lead, boron or zinc oxide in an amount of at least 10%.

2. Low-lead crystal containing 18-24% lead oxide.

3. Lead crystal containing 24-30% lead oxide.

4. High lead crystal containing 30% or more lead oxide.

Lead-free crystal contains mainly barium oxide (at least 18%), which improves refraction, increases the hardness and shine of the glass, but reduces transparency.

Heat-resistant glass can withstand sudden temperature changes. They contain boron compounds (12-13%). The thermal resistance of such glass increases after tempering. Chemical properties of glass.

The chemical resistance of glass determines the purpose and reliability of products. It is very high, especially in relation to water, organic and mineral acids (except hydrofluoric acid). Alkalis and alkali carbonates are more aggressive. Hydrofluoric acid dissolves glass and is therefore used for applying patterns to glass, matting and chemical polishing of products.

The formation of consumer properties of glass goods occurs in the process of their production.

The production of glass goods consists of a number of stages: preparation of raw materials, composition of the batch, melting of glass melt, production of glass products, processing and decoration of products, sorting, labeling and packaging of products.

1. Preparation of raw materials comes down to cleaning quartz sand and other components from unwanted impurities, fine grinding and sifting of materials.

2. Preparation of the charge, i.e., a dry mixture of materials, consists of weighing out the components according to the recipe and mixing them thoroughly until completely homogeneous. A more progressive method is to produce briquettes and granules from the mixture; At the same time, the homogeneity of the charge is maintained and cooking is accelerated. In addition, to speed up glass melting, 25-30% broken glass is added to the charge. The cullet is washed, crushed and passed through a magnet.

3. Melting of glass melt from the charge is carried out in baths and pot furnaces at a maximum temperature of 1450-1550°C. During the cooking process, complex physical and chemical transformations and interactions of raw materials occur. Using clarifiers, the glass melt is freed from gas inclusions and thoroughly mixed until homogeneity in composition and viscosity is achieved. If the raw material processing, batch preparation and cooking regimes are violated, glass melt defects are formed (we will discuss this later).

4. Molding of products from viscous glass melt is carried out by various methods. The molding method largely determines the configuration of products, wall thickness, decoration techniques, coloring and is therefore an important assortment feature and pricing factor.

Household products are made by blowing, pressing, press blowing, bending (bending), casting, etc.

Blowing -

the oldest method of molding glass products. Blowing can be mechanized, vacuum blowing, manual in molds and Guten (free).

Manual blowing is carried out using a glass blowing tube. Such blowing can be done in molds or without molds. By blowing in molds, products of any configuration and wall thickness with a smooth and shiny surface are obtained. They produce colorless, dyed and applied products (two- and multi-layer).

Blowing without a mold or free blowing (in trade - Huten molding) is also carried out using a glass blowing tube, but the products are shaped and finally finished mainly in air. The products are characterized by the complexity of their shapes, smooth transitions of parts, and thickened walls.

Mechanized blowing on automatic machines produces colorless products of simple outlines, mainly glasses.

Blow molded products have the smoothest walls, high shine, great transparency, and the most varied shapes and wall thicknesses. They are decorated in almost every possible way and are considered to be of the highest quality.

Pressing is the most widespread and economical way to produce glass products. Products are molded on automatic and semi-automatic presses in special molds, where a design is immediately applied to them. They are characterized by large wall thickness (more than 3 mm), large mass, lower transparency and heat resistance, significant bottom thickness, and traces of the mold are visible. Dishes made by pressing have simple shapes with a wide top.

They try to overcome some monotony of pressed products by creating a light relief pattern on the surface (textured press), pressing without an upper ring, which makes it possible to obtain a freely formed edge that is different for each product, and a combination of pressing and bending (press bending).

Press blowing is characterized by the fact that the molding of products takes place in two stages - first they are molded in a mold, and then hot with air. The products have a narrow neck, thick uneven walls and mold marks. Press blowing produces jars, bottles, decanters, and vials; Products obtained by this method differ from pressed ones in a more complex shape, and from blown ones in thick walls, mold marks and a rougher pattern.

Industry problems

The glass industry has certain difficulties that slow down, and in some situations completely eliminate, the possibility of development. Thus, one of the most popular is the lack of demand for high-quality glass products. This factor is due to the fact that production is very expensive, and this significantly increases the cost. If we take the example of consumers such as construction organizations, then most often they prefer to make a choice in favor of more outdated products, since this can save money.

However, there are other problems, including:

- rapid decline in demand in the domestic market;

- rising cost of raw materials;

- instability of the foreign exchange market, affecting the increase in prices of equipment and other elements necessary in production;

- inability to take out loans or borrowings due to the risks of insolvency.

The state is trying to minimize difficulties in this industry. From time to time, new projects and laws are submitted for consideration that contribute to the development and solution of problems.

History of glass

Glass first appeared in Ancient Egypt 3…4 millennia BC. However, the glass of that era was even different in appearance from the current one. They were, as a rule, poorly transparent and contained a large number of bubbles. Mostly decorations were made from this glass.

At the end of the 7th century. glass production originates in Venice, where by the 9th century. it reaches a high level. Famous Venetian glass stained glass windows and mosaics decorated churches of that period, and various artistic products made of colored glass, mosaic and filigree glass, and mirrors were a monopoly of Venetian glassmaking. This art then spread to other countries in Western Europe and the Middle East.

At the end of the 17th century. In the Czech Republic, glass was invented, characterized by purity, transparency and hardness and known as “Bohemian crystal”.

Glassmaking in Russia arose in the 9th - 10th centuries, i.e. much earlier than in America (17th century) and earlier than in many other countries of Western Europe.

The first glass factory in Russia was founded in 1638 near Moscow. This factory produced window glass and other glass products. Glassmaking received great development under Peter I. During this period, glass factories were created near Moscow, in Kyiv and other cities. By 1760, there were already more than 25 glass factories in Russia, located in various provinces. These factories produced mainly window glass, bottles and household utensils.

The founder of the scientific foundations of glassmaking in Russia is M.V. Lomonosov, who in 1752 built a factory near St. Petersburg and organized the production of colored glass there. M.V. Lomonosov developed a method of hot pressing of glass.