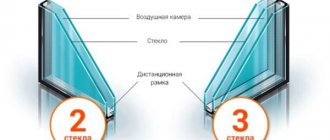

The largest heat losses per 1 m2 of area occur through windows, or more precisely, double-glazed windows. So, near the walls the heat transfer coefficient is approximately 0.3 W/(m2*K). A similar indicator for double-glazed windows is 1.1-1.3 W/(m2*K). Therefore, window manufacturers are looking for ways to reduce heat loss through the window opening. In action are:

- a large number of cameras in a double-glazed window;

- use of low-emissivity glass;

- replacing air with inert gas.

The measures taken are producing results. Multi-chamber double-glazed windows with inert gas krypton and k-glass increase the energy efficiency of the window - the heat transfer coefficient is reduced to approximately 0.7 W/(m2*K). In principle, this is enough. But another problem arises: the window design becomes more complicated, which leads to a strong increase in its cost (only wealthy cottage owners can buy it) and an increase in the weight of the double-glazed windows and sashes, which in turn requires an increase in the thickness of the reinforcing metal. It turns out to be a vicious circle.

Technologists and scientists are trying to solve the problem by pumping air from the chambers of double-glazed windows. Japan has advanced the furthest in this direction. China also has its own developments. Russia and Germany are not far behind them.

The editors of the StroyGuru website decided to introduce their visitors to the innovative type of windows and tell them what vacuum double-glazed windows are, their advantages and disadvantages, and development prospects.

What is it and what is its feature?

Heat loss through a double-glazed window is caused by:

- thermal conductivity of solid materials;

- convection of air atoms;

- electromagnetic radiation.

Thermal conductivity. The main form of heat transfer is thermal conductivity of solid materials. Heat losses can be reduced in this way through thermal insulation materials or the use of hollow structures.

Convection. The second way of heat transfer is the movement of gas atoms (convection). The lighter they are, the faster they move, and therefore transfer more heat. It turns out that the air from the heated glass quickly transfers heat to the cold glass.

Heat loss can be reduced in two ways: pump heavy gas atoms into the chambers, such as argon or krypton (moving slowly), or remove air altogether: in a vacuum, heat is not transferred by convection. It is calculated that heat loss decreases linearly with pressure drop.

Radiation. Heat rays travel through vacuum and air, as the sun clearly demonstrates. Radiation can be delayed by a special glass coating that transmits light (short waves) and delays, or rather reflects, like a mirror, infrared radiation.

The researchers decided to reduce glass loss in two ways at once: pump out the air from the chambers of the glass unit, creating a vacuum there, and apply low-emissivity spraying.

When pumping out air, the problem of glass sticking immediately arises. It is clearly demonstrated by ordinary double-glazed windows. In summer, at high temperatures, glass, due to increased pressure, takes on a curved appearance. In winter, concave. If glass deforms with a slight change in pressure, what will happen to it in a full vacuum.

a – high blood pressure; b – low atmospheric pressure.

Calculations have shown that glass with an area of 1 m2 has a load of 10 tons. Therefore, when the air is pumped out of the chamber, the glass unit, if it does not burst, will stick together. The effect disappears, since the main path of heat transfer begins to operate - thermal conductivity. Spacers, which are evenly placed in the glass unit chamber, help to avoid glass collapse.

The idea of such window designs was in the air for a long time, but could not find a concrete implementation - the glass was too fragile and could not withstand wind pressure.

Everything changed in 2016, when she produced a vacuum glass unit “LandVac” with increased strength - the surface tension exceeded 90 MPa. This meant that the window was able to withstand wind loads and small impacts.

In addition, a flexible edge seal has been proposed that successfully resists linear expansion due to changes in temperature and pressure.

The peculiarity of this window: many breakthrough advantages and no less weaknesses. Research centers continued to work to combat the shortcomings. Builders hope that in a short period of time they will have long-lasting, energy-efficient vacuum-glazed windows to install.

Why choose double-glazed windows with i-glass?

When choosing energy-saving windows, special attention should be paid to the characteristics of the glass itself, since they make up up to 80% of the entire structure. Not only the heat transfer coefficient is important, but also the transmission properties of light and thermal energy from solar radiation.

- Glass with low-emissivity coatings reduces the loss of long-wave thermal radiation emitted by radiators and lighting fixtures, and at the same time transmits the heat of solar radiation inside.

- Energy-saving glass is aesthetically neutral, allowing it to accurately reflect colors and shapes. This ensures comfortable conditions in the interior and a beautiful view from the outside.

- Double-glazed windows with smart glass can transmit up to 65% of the thermal energy of sunlight, which gently heats rooms due to passive heat transfer. Thanks to this, you can save twice as much – on artificial lighting and on heating the premises.

Vacuum window design

A vacuum window consists of a conventional window block made of plastic or wood and an innovative double-glazed window. The glazing is made using two tempered impact-resistant “LandVac” glasses with a thickness of 4-6 mm, located at a distance of approximately 0.7 mm. To prevent the glass from “collapsing” under atmospheric pressure, quartz spacers or “spacers” are placed between them scientifically. The diameter of the gaskets is always equal to the width of the chamber.

The tightness is ensured by glass solder - a special glass paste that softens at a temperature of 350oC. To increase the thermal insulation properties, a low-emissivity coating is applied to one of the glasses. Its location is always on the inner glass on the camera side.

Vacuum double-glazed window from the end.

The vacuum in the double-glazed window was previously created by pumps pumping air through a plastic capsule placed in a layer of sealant. This solution turned out to be not entirely successful: the tightness was broken within a short time. I solved the problem of pumping air through the glass - after disconnecting the pump, the capsule is sucked into the chamber, rests against the opposite glass and tightly blocks the access of air inside the glass unit.

A capsule through which air is pumped out.

Glass

The glass used does not fully satisfy the manufacturers. Currently, work is underway in several countries around the world to improve LandVac glass. Researchers are trying to increase its strength while imparting the properties of i-glass.

Sealing

Existing sealing methods do not allow maintaining a vacuum in the glass unit chamber for the entire service life. However, not all types of sealing material have a low thermal conductivity coefficient. Therefore, the search for new means for sealing ends is being carried out in several directions at once:

- increase the service life of the sealant to 25-30 years at an operating temperature from -40oC to +60oC;

- reduce thermal conductivity to acceptable levels (0.7-1.1 W/(m2*K);

- increase elasticity - helps prevent the occurrence of cracks when the load on the edges of the glass increases.

Spacers

The spacers in the chambers can be metal or quartz. Metal ones are visible from a distance of 1 m, quartz ones are difficult to notice at close range. The spacers are located in a checkerboard pattern at a distance of 30-40 mm from each other. According to experts, they occupy less than 0.1% of the area. Therefore, they do not have a significant effect on thermal conductivity and visibility.

Sound insulation: VIG vs triplex

Another important property of vacuum glass is its soundproofing characteristics. The sound insulation of such glass, as shown in the report by Peter Schober (Holzforschung Austria, Wien Ulrich Pont, TU Wien), is comparable to triplex

with glass of similar thickness. That is, the use of VIG as part of a double-glazed window leads to improved sound insulation characteristics in the same cases where triplex was used for this.

The sound insulation of vacuum glass, according to a report by Peter Schober (Holzforschung Austria, Wien Ulrich Pont, TU Wien), is comparable to triplex with glass of the same thickness Photo: IFT Rosenheim

Pros and cons of vacuum double-glazed windows

New technology is just making its way into the window market. Therefore, she has many weaknesses. But the existing advantages give hope for excellent prospects for vacuum windows in the future.

- record low thermal conductivity coefficient – 0.5 W/(m2*K);

- excellent noise insulation - sound waves of medium and low frequencies are effectively blocked (produced by construction and road transport equipment). As a result, the noise level is reduced by 39 dB, which is 10 dB more compared to a conventional double-glazed window;

- the light transmittance of the window opening increases due to the smaller number of glasses in the double-glazed window;

- the weight of the window structure is reduced - the reinforcing metal can be thinner;

- There is no spacer bar, which makes the design lighter. In addition, the cold bridge disappears, and with it the fogging of the glass;

- the sash becomes lighter (fewer chambers), which increases the service life of the fittings.

- fragility of the structure. Even LandVac tempered glass, specially designed for vacuum insulating glass units, does not have the strength of conventional glazing. Technologists continue to work in this direction;

- problems with sealing. The slightest microcrack is enough for the vacuum to disappear;

- actual service life is about 8 years. Then replacing the glass unit or resealing it;

- thin glazing does not harmonize in size with the frame. Therefore, the window looks unusual;

- the highest price due to complex manufacturing technology - while such windows can only be afforded by wealthy people.

Features of application

Vacuum double glazing

is not yet widely used due to several factors. The first of them is too high a cost (since no cheap production technology has yet been created). The second reason is the aesthetic component. Double-glazed windows with a thickness of about 8 mm do not harmonize very well with a standard PVC profile, and profiles corresponding in thickness with reliable thermal insulation properties are not yet produced.

Most often, such glass blocks are installed in hybrid translucent structures instead of one of the glasses, and even then only in justified cases (due to the high cost). Installation of such a structure can only be justified by good thermal insulation.

Prospects

The obtained characteristics of energy-saving vacuum windows give reason to assert that the task assigned to scientists has been successfully solved. Now all efforts of researchers will be aimed at solving specific issues: increasing the strength of glass and searching for new methods of sealing.

If the research results make it possible to increase the service life of such windows to 25-30 years, then the technology has a bright future ahead. An increase in production volumes will certainly have a positive impact on the cost - it will steadily decline. Indeed, now the price of vacuum double-glazed windows includes not only the cost of production, but also the cost of research and development. And they are significant.

One more important point should be noted: manufacturers of window profiles are actively developing frames for innovative glazing. If this problem is solved, then in the near future new types of windows will begin to displace traditional plastic and wooden window blocks.

Glass coating

Glass - manufacturer of high-quality mirror glass of various sizes, up to 2500x1600mm. Our products are produced by applying metal thin-film coatings. In this case, vacuum deposition of wear-resistant materials is used - titanium and its oxide and oxy-nitride compounds. This technology makes it possible to apply durable tinted low-emissivity coatings to glass with a given efficiency. Coatings made of metals and their oxides have great strength and resistance to chemical and mechanical influences.