Aluminum window structures have been in demand among consumers for many years, thanks to the increased strength, reliability and durability of this lightweight non-ferrous metal from which the profiles are made.

When analyzing reviews from users on the Internet, you can see that almost no one complains about the quality of the aluminum products themselves, however, windows often leak and allow moisture to pass through.

This is due to the fact that the composite structure, which includes a double-glazed window and opening sashes, is insulated using polymer seals, which can become unusable.

That is why it is important to know which seal should be chosen for trouble-free operation of the window.

What is a rubber seal?

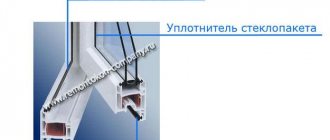

The seal for aluminum windows is an elastic polymer material that is fixed to the profile of a blind or opening sash along the perimeter of the junction of the parts to each other.

Reference. The seal has a special cross-sectional shape, which allows it to be fixed in the protrusions on the profile, forming a locking structure.

What is it for?

The sealing tape plays an important role in ensuring comfortable operation of the window structure. When a quality product is installed correctly, the following important functions are performed during its use :

Protecting the room from blowing and drafts.- Reducing the risk of indoor air pollution and dust settling on the windowsill.

- Sealing the room contour from moisture.

- Improving the thermal properties of window construction.

- Increased sound insulation characteristics.

In addition, a high-quality seal has high tensile strength and can withstand significant impact loads . This leads to the fact that the polymer element protects the profile structure from mechanical influences.

Requirements

The quality, composition and technical characteristics of the seal for aluminum windows are regulated by the requirements of regulatory documentation.

The necessary indicators are specified in GOST 21519-2003 “Window blocks made of aluminum alloys” and GOST 30778-2001 “Sealing gaskets made of elastomeric materials for window and door blocks.” According to these documents, the following requirements are imposed :

- Cross-sectional uniformity.

- Compliance of the product with samples approved for use.

- Smooth surface of the tape without bulges or bubbles.

- The coefficient of thermal expansion should ensure that the length of the tape changes with a temperature difference of no more than 3%.

- The material must have absolute water-repellent properties.

- The sealant should not lose its physical properties during prolonged contact with an aggressive environment.

- The polymers included in the product must meet environmental requirements and have an appropriate official conclusion.

- Depending on the responsibility class of the product, the material must satisfy the tensile strength conditions of at least 4.0 - 8.8 MPa, and, in the event of a breakdown in the structure, elastic connections must ensure its elongation by at least 150% - 300%.

- The sealant should not lose its performance properties at outdoor temperatures down to -50 °C.

Each sealing material that has been certified by government agencies in our country must meet the requirements listed above.

Reviews about our work

Grigory Davydov 04/02/2019

I want to thank the guys for the work done. My window on the balcony was fogged up. It didn't look very aesthetically pleasing. I decided to contact the experts. They arrived and explained everything clearly and what the problem was. It turned out that the seal was completely worn out. They changed it for me quickly, without any dirt, and most importantly, at a reasonable price.

Valentina Gavrilina 11/10/2018

How lucky I was to stumble upon Window Repair Service. It was blowing on my loggia all the time. And in our harsh winters this is quite dangerous.))) A friend advised me to contact the specialists and gave me their number. The guys are so polite: they came, told us everything, showed everything. The problem was with the old seal. They replaced it for me with a new one. And very quickly, the price was also quite satisfactory. Completely satisfied.))

Read all reviews

Kinds

Chemical production enterprises that produce products from polymer materials intended for sealing parts of aluminum windows divide their products into several categories.

Important. The types of sealing tapes depend on their functional purpose in the design, the type of raw materials used, the cross-sectional shape, dimensions and installation method.

Each of these categories of sealing tapes is described in detail below.

Classification depending on function

All sealing tapes used in aluminum window structures, depending on the functional purpose, are divided into the following types :

For glass .

It is a tape with a special cross-sectional structure, divided into 2 parts. The first part is formed in the form of a conical widening, which makes it easy to lock the tape to the profile.The second part of the product is made in the form of a flat “blade”, which, when installing the glass in the profile, is under constant tension, ensuring a tight fit of the polymer to the structure.

- For profile . The seal is designed to seal the aluminum profile around the perimeter of its abutment to the window opening. It is made in the form of a wide tape coated with an adhesive composition to ensure better adhesion to the rough surface of the opening.

- For the porch . Designed to seal the joint between moving window elements. When the sash is closed, the elastic material compresses, eliminating the formation of gaps and the penetration of moisture or air into the room. The composition and shape are similar to the glass seal, but may have a different configuration.

Although all seals perform a similar function, their cross-sectional shape may vary depending on the manufacturer.

From material

Depending on the required quality of the product, as well as strength characteristics and the maximum permissible retail price, seals are made from several types of materials :

- Rubber .

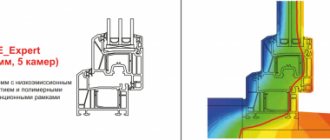

A classic material made using synthetic rubber. It features increased tensile strength and reliable sealing of the structure. Among the disadvantages, the risk of cracking of the element in the cold should be highlighted, since polymers have insufficient elasticity. In addition, this material is most often found in black, which reduces the visual characteristics of the window structure. - Silicone . The most promising, but more expensive material for sealing. It has a high relative elongation and increased tensile strength. Unlike rubber, it does not lose its elastic properties when subjected to strong cooling and can be completely transparent and invisible.

- Polyethylene with filler .

They are considered the best materials for sealing sashes in vestibules. The product has a porous but homogeneous structure and can undergo significant elastic deformations without losing shape when the load is removed. They are produced in single- or double-chamber form with different dimensions, which allows you to select the desired seal, depending on the size of the profile.

Important. All elastomers used for sealing and sealing aluminum windows do not contain toxic substances and do not emit foreign odors when heated, which allows their use in residential premises without restrictions.

Type

In the production of seals, different types of products are used, which have international markings, making it easier to select and purchase if there is a need to replace them :

TPE .

The Russian abbreviation is TEP, or thermoplastic elastomer. The product is an elastic tape that has all the properties inherent in rubber.However, when heated, the elastic properties, relative elongation and tensile strength of the element increase significantly. Universal sealant, can be used for sealing profiles, glazing beads and sashes.

- VMQ . Sealing rubber products are made on the basis of silicone rubbers. Withstand extreme temperature changes, maintaining all performance properties. The maximum water absorption does not exceed 0.5% - 1.0%, which allows for maximum sealing of the sash structure in the vestibules.

- EPDM . It stands for ethylene-propylene rubber, manufactured on the basis of heat treatment followed by polymerization of a special material. The product is resistant to precipitation, including acidic and alkaline environments. It is distinguished by its affordable price and durability.

Among the listed types of seals, VMQ and TPE are most often used. Products of the EPDM type are used less frequently, since some properties do not meet the requirements for comfortable operation and sealing of joints.

By configuration

Polymer profiles installed as seals on aluminum windows can have different cross-sectional shapes. This is explained by the configuration of the profile itself, as well as the installation location of the product. In practice, the following types of seals are distinguished according to this criterion:

- Solid sealing tapes are used to seal the window unit in the opening around the perimeter of the contact surface during installation.

- Volumetric elastomeric products are used to increase the sealing of the recesses during the closing of the sashes. They are supplied with an adhesive coating with a protective film, which ensures uniform fixation of the material on the profile.

- Polymer products of a special profile are equipped with locking thickenings to allow mechanical fixation in the metal protrusions of the window profile. They are selected based on the shape, size and depth of the locking connection. They have their own internal markings.

As a rule, manufacturers of window structures use only the 3rd type of products at the factory, and flat and volumetric elastic tapes are installed during installation or operation of the structure.

By installation method

Depending on the method of fixing the sealing tapes for sealing window structures, all polymer products in this category are divided into the following types:

The most common installation method is mechanical fastening of a rubber product.

Such seals are made entirely of homogeneous material, and fixation occurs due to the creation of internal tension by thickening the polymer in the grooves of the metal profile.- Two-component seals consist of an elastic polymer and an adhesive part. This type of product is installed by removing the protective film from the adhesive side and uniformly pressing the material against the profile surface.

- A special type of sealing tapes installed in industrial production conditions are thermoplastic products. Installation is carried out at elevated temperatures, when the polymer medium begins to melt, which promotes molecular bonding with the metal surface and reliable conjugation during reverse polymerization.

Important. When choosing a sealing tape, remember that these products belong to the category of consumables that must be periodically replaced. Thus, mechanical fasteners are considered more versatile, despite some difficulties during their installation.

By labeling and manufacturer

There are several chemical enterprises operating in our country that produce seals for aluminum windows. Each manufacturer uses its own product labeling , which is reflected in the list of specifications issued to them by government agencies:

- VSMPO:

- 16.001, 770.16.004, TPU-004 – products for sealing glass and profile elements;

- 16.007A, 770.16.008 – seals for vestibules.

- "Tatprof":

- TPU-6001, TPU-8901, TPU-004MM – glass and profile sealing;

- TPU-006-01MM – seal for sashes.

- "Realit":

- REG 001, REG 013 – sealing of double-glazed windows and profiles;

- REG 012 – sealing of the rebates when closing the sashes.

Despite different markings and differences in some properties of products, in accordance with the technical specifications, all materials meet the requirements of GOST and have almost identical performance characteristics.

By size

The cross-sectional dimensions of seals for aluminum windows are regulated by GOST 30778-2001, depending on the profile dimensions and the presence of additional requirements for ensuring sealing, as well as improving thermal and sound insulation properties:

- Up to 4 mm – for double-glazed windows and glazing beads.

- 4 – 10 mm – for double-glazed windows, glazing beads and profiles.

- 10 – 40 mm – for profiles and sashes.

- Over 40 mm - for large-sized sashes, or in the presence of special operating conditions.

In practice, aluminum window manufacturers use sealing tapes with an average size range of 10 to 20 mm.

Prices for seals for aluminum windows

We have a large selection of seals for window systems: Tatprof, VSMPO, NewTec, Agrisovgaz, Sial, Realit, Alutech, Alumark.

Show price table

*The price is indicated per linear meter of seal, taking into account the work required to install it.

| Parameters and material | Purpose |

Sealant for TATPROF window systems, from RUB 270,250/l.m. | |

| TPU-6001 (M=0.066kg/m) | External glass seal |

| TPU-004MM (M=0.055kg/m) | Inner bead seal |

| TPU-006-01MM (M=0.031kg/m) | Narthex (internal) |

| TPU-8901 (M=0.113kg/m) | Internal seal (middle contour) frame |

For VSMPO window systems, from 250 rub/rm. | |

| 770.16.001 | Glass and profile seal |

| 770.16.004 | Sealing of glass and glazing bead |

| 770.16.007A | Internal frame and sash seal (revere) |

| 770.16.008 | External frame and sash seal |

| TPU-004 | Sealing bead and glass |

For NewTec systems, from RUB 270,250/rm. | |

| 695001 (G001P) | Narthex and glazing bead |

| 695003 (G001D) | Internal seal for glazing bead (3 mm) |

| 695012 (G012D) | Compaction medium |

| 695017 (G017D) | Ceiling seal |

| 695045 (G045D (G007D)) | External seal (3 mm) |

For Agrisovgaz windows, from 250 rubles/rm. | |

| G 003 D | Assorted glass seals |

| G010D | Middle circuit seal |

| G 012 D | Compactor medium AGS |

| G 017 D | Recessed seal for sash, frame |

For Sial window systems, from 250 rub/rm. | |

| TPU-004mm | Assorted filler seal (glass unit) |

| TPU-006mm | Entrance door seal |

| KPU-17-1 | Main seal, middle circuit |

| R-5 | Casement window seal, recessed |

For Realit systems, from RUB 270,250/rm. | |

| REG 001 | Fixed glazing seal |

| REG 012 | False seal |

| REG 013 | Transom seal |

For Alutech brand windows, from 250 RUR/rm. | |

| FRK98 | Window sash seal |

| FRK07 | Door seal, door leaf, frame |

| FRK36 | Assorted glass seals |

For Alumark, from RUB 270,250/rm. | |

| ALM750072 | Medium seal for swing doors |

| ALM770001 | Sash window seal for hinged sashes |

| ALM770020 | Door seal |

If you know the brand name of your aluminum windows and it is not in this table, do not worry, contact us and we will definitely solve your problem.

How to install and replace the seal?

To replace or install a seal in a profile or on an aluminum window sash, no special skills or tools are required. The whole procedure takes a few minutes and can be done with your own hands. When performing this work, you must follow step-by-step instructions and take into account some nuances :

- To replace the seal on the beads at the junction of the glass unit, it is necessary to remove the old rubber product. To do this, you need to pull the product by the free edge, and then carefully remove it from the groove.

- When the installation cavity is free of old material, it should be thoroughly cleaned, blown out and foreign debris removed. If necessary, you can rinse the element and dry it with a hairdryer.

- A soap solution is diluted in a separate container and applied to the cleaned groove with a brush.

- The new sealing element is also treated with soapy water to reduce friction during installation.

- A contact surface with a locking connection in the form of a conical or harpoon thickening is selected on the sealing tape.

- Installation starts from the corner of the frame or the end of the bead. The product is forcefully pushed into the groove until there is a barely audible click.

- When one edge of the polymer is fixed, it is enough to push the tape along the entire length of the landing groove.

- If the seal is performed on the sash using self-adhesive tape, the surface must be degreased with an alcohol solution.

- The tape is fixed at both ends of the profile, after which it is evenly smoothed from the middle to the edges.

Important. Upon completion of installation work, it is necessary to check the tightness of the connection of the product along the entire length of the contact plane, as well as the uniform fixation of the lock in the aluminum profile.

More details about replacing the rubber seal in the video:

Lubrication rules

For long-term operation of seals installed in the rebates or on the outside of the profile, it is necessary to ensure proper care of rubber products. This will require the use of a special lubricant, which provides the following advantages :

- Protects the polymer surface from drying out and cracking.

- Increases the elasticity of the element.

- In winter, it eliminates the risk of polymer freezing to the aluminum profile.

To properly apply lubricant to the seal, you must follow these steps :

- Make sure that the seal has no defects or cracks.

- Wipe the polymer with a damp cloth, removing traces of dirt.

- Dry the surface.

- Degrease the contact surface with an alcohol-containing material.

- Apply lubricant evenly along the entire length of the seal.

- If necessary, remove smudges and distribute the composition along the plane of the polymer.

It is better to apply lubricant at above-zero outside temperatures, since this ensures the maximum duration of effective operation of the substance.

Possible problems and malfunctions

During installation and operation of the seal, some problems may arise that are associated with the following factors :

Low quality of the product leads to early aging, the formation of cracks with a subsequent decrease in performance properties.- An incorrectly selected size can lead to poor fixation of the element in the grooves of the profile, which is why it will constantly fall out and will not provide proper sealing of the window.

- Lack of lubrication can lead to rupture of the polymer tape installed in the sash when opening the sash in severe frost.

- Prolonged exposure to ultraviolet rays can adversely affect the quality of the polymer and lead to its destruction.

- Incorrect installation with an error in selecting the required mounting side will not guarantee normal operation of the product.

Important. If malfunctions are detected, they should be corrected as soon as possible. Otherwise, the performance characteristics of the window structure will be significantly reduced, which can lead to drafts, freezing or leaks into the room.

Examples of work on sealing aluminum windows

Our specialists often carry out work to eliminate leaks and blowing of translucent aluminum structures. Below you can see how one of the trips took place.

- Departures: 1

- Time: 6 hours

- Cost: 15,500 rub.

- Quantity: 1 piece

An order was received for servicing the aluminum entrance group of an office building.

During the initial diagnostics, specialists found that the frames allow moisture to pass through, in some places there is condensation on the glass and visually visible gaps both between the double-glazed window and the frame, and between the window structures and the walls of the building. The scope of work has been determined: it is necessary to clean and seal all seams, partially replace the seals and dismantle the worn ones.

The total cost of the work, including the cost of a new seal, was 15,500 rubles.

Call a specialist