Window measurement is a mandatory and responsible operation in construction practice, on which the production quality of the window unit and its accuracy in performing installation procedures largely depend.

As a result of poor-quality measurements, especially, the errors are so great that the window cannot be installed in the niche at all.

The customer must understand that each window opening is individual; even in a typical high-rise building there are no equal-sized structures, which is explained by the unevenness of the walls and other construction errors. In order to measure a window correctly, you need to follow certain rules and have experience.

Otherwise, it would be better to invite specialists. Experts say that the best principle for installing windows is: “he who measures, carries out the installation.”

What is freezing?

It is a mandatory technical procedure for establishing the actual dimensions of a technological window opening in a wall and is carried out using the method of instrumental measurements. The results obtained are processed using calculations that are used when ordering the manufacture of a window block.

The procedure for conducting and documenting window measurements is regulated by building regulations. During the measurement procedure, the following must be taken into account: the type of housing construction, wall material and the characteristics of the external finishing.

When measuring windows, a diagram of the wall opening is drawn up, on which its entire configuration is applied exactly, both from the inside and outside, indicating the vertical and horizontal dimensions, and the dimensions of the ebb, including the depth of its placement, the dimensions of the window sills and the width of the slopes are plotted .

Why is it necessary?

The need to take measurements in standard-built houses is explained by the fact that all wall openings have different thicknesses, which in many cases are complicated by construction defects.

The dimensions must be determined as accurately as possible, since a deviation of even 2-3 cm can lead to problems with the installation and operation of the defective unit.

These consequences include:

the formation of excess gaps, which lead to an increase in the cost of construction and installation work due to increased deadlines, additional costs for foam and the implementation of large slopes;- frame deformations, especially for PVC profiles;

- violation of the functionality of fittings and basic mechanisms of window construction;

- the invasion of dampness and drafts into the house;

- the appearance of ice and condensation on glass;

- reduction in the aesthetic appearance of the window and the façade of the house as a whole.

How to measure correctly?

In order to professionally carry out window measurements, you will need to adhere to the standards and recommendations of experienced craftsmen, this will help minimize the level of errors and negative consequences.

Basic concepts for measuring windows:

- When taking measurements, take into account that the frame cannot be installed tightly into the opening; standards allow minimum construction gaps from 20 to 50 mm.

- In order to determine the depth of the opening as accurately as possible, measurements are taken from the inside and outside of the wall.

- If a skew is detected, the parameters of the window block are increased by its size.

- For stone walls with an overhang that is 25% of the brick size, called a “quarter,” a special measurement method is used.

- To reduce the risk of errors, measurements are taken at least 3 times.

When establishing the dimensions of the window niche and window block, the building material of the walls is taken into account.

Features of determining dimensions in a brick house:

- The depth of the “quarter” protrusion sometimes reaches 10 cm, so when calculating the frame you need to take into account that it should be hidden behind the quarter by 3 cm.

- When determining the line of a load-bearing wall, the layer of plaster is taken into account, since it can have a significant thickness.

- Measurements are taken in three places along the width and height, outside and inside the room.

- When calculating window sizes, an installation seam of 3 cm is taken into account.

The peculiarities of a wooden house are that the window niches in it do not have protrusions, the frame is installed flush with the wall, and therefore there are no slopes.

When taking measurements of such windows, the width and height are also measured in 3 places and the smallest one is taken. If a window frame is installed in the house, measurements are taken from it, adding 5 cm to the installation seams.

Cost calculator: what parameters can be configured?

The more complex the product being sold, the more details managers have to discuss with customers when placing orders. Accordingly, the higher the chance of error, that the customer will express his wishes incorrectly or the representative will poorly understand him.

Our way is to simplify the cooperation of our employees with clients by adding a calculator to calculate the cost of plastic windows available for ordering from us. To open this utility, you just need to click on the corresponding button in the site header.

What tools are needed?

To take window measurements you need to have precise tools. To check the angle of repose, which should be 90 degrees, use a telescopic ruler with a digital designation and a spirit level to check the angle of the masonry slope at 90 degrees. Laser instruments—rangefinders—give very good measurement results .

Checking the slope angle can also be done by measuring two diagonals. If they differ from each other, then the angle is not right, so such an opening cannot be accepted for installation; it will need to be aligned.

In addition to serious measuring tools for measuring an opening, you will need simpler ones that are available to any home craftsman, such as pliers, a folding meter, a level, a tape measure, a chisel, a knife, a pen and a notepad.

Requirements for tools for measuring window openings:

Laser tape measure , the error should be no more than 3 mm, the model should have a viewfinder, a level gauge, calculator and area calculation functionality, screen backlighting, the ability to determine inclined lines and save measurements.- A telescopic ruler with a display must have at least 2 built-in levels, millimeter divisions and fixing screws securing the sliding sections, the size of the ruler must be larger than the measured values, sizes from 3 m are universal.

- The spirit level must have a length corresponding to the dimensions of the window niche, the body must be made of a light but durable alloy, and the measurement accuracy must be high. When choosing this tool, you can check it by placing a sheet of paper under it; a professional spirit level should determine it by changing the position of the bubble.

How to determine with your own hands for installation?

In order to eliminate errors when measuring a window, you need to separately measure the niche with and without a “quarter”, and also measure the double-glazed window separately.

When measuring a wall opening, window craftsmen use the following definitions and rules :

- The height of the window is the distance from the lower base of the niche to the outer upper slope minus the gap for the mounting foam up to 2 cm and adding 3 cm to the window entrance in the upper “quarter”.

- When installing the stand profile, the contractor must additionally reduce the height of the frame by approximately 3 cm.

- The correctness of measurements is checked according to the following indicators: without a substitution profile, the height of the frame must be less than the distance from the window sill to the internal upper slope, and with a substitution profile it cannot exceed the distance from the lower edge of the window sill to the internal upper slope.

Window hole

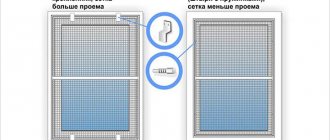

Depending on the type and architectural features of the building, measurements are carried out according to different schemes: with a “quarter” and without a “quarter”. Calculating the size of a window with “quarters” is a rather complicated process, especially when measuring old windows.

You will first need:

- set the thickness and height of the window sills;

- take measurements of external “quarters” and slopes;

- installed indoors, while the width of the frame should not exceed the size of the outer “quarters” by 6 cm.

If the excess is more than 6 cm, rough wooden extensions or PVC expanders are used.

With a quarter

“Quarter” is a specially made protrusion on top and sides of a wall niche that protects the window structure from falling out and prevents drafts and moisture from penetrating into the room. These dimensions differ in width for different houses: brick - 65 mm, and panel - 50 mm.

Window measurement is performed in 4 stages :

- measuring and calculating the characteristics of openings and windows;

- determining the size of the ebb;

- window sill measurement;

- determination of values for slopes.

The measurement of the wall opening begins from the outside.

For this purpose, the window sash is opened and the width between the “quarters” is determined at three points. To the smaller result add from 3 to 5 cm in a panel building, and from 4 to 6 in a brick building. This indicator is the width of the window structure. If during measurements it is determined that the opening has an external protrusion, then most likely the opening is skewed. In this case , you will need to follow these rules :

- The size of the frame must be calculated so that it extends beyond the side protrusion by 2-4 cm, and beyond the top by 2 cm.

- The stand profile should be installed 2 cm higher than the wall.

- The height of the frame cannot be greater than the distance from the high slope to the lower contour of the window sill.

Quarter to

In this version, the measurements are simpler, but, nevertheless, to obtain the true values, measurements are performed three times. The top line, center, and bottom line are measured in width, and the right, middle, and left in height; the smallest result is selected.

Next we move on to calculating the frame dimensions.:

- Width. The width of the niche is reduced by 2 - 5 cm per installation seam.

- Height: subtract from 5 to 6 cm from the height of the opening, including 3 cm for the stand profile.

In order to determine the length of the ebb, add 5 cm to the gap between the quarters, and for its width add 2 - 3 cm to the size from the cut of the wall to the window.

When determining the size of the window sill, you need to take into account that the new frame, especially PVC, can be much thinner than the old wooden one, so to determine the width of the window sill, take the distance from the outer part of the frame of the old frame to the edge of the window sill and add 5 cm.

In this case, you need to ensure that the window sill does not block the heating device. The length of the window sill is determined by the distance between two opposite parts of the wall opening.

Double glazing and glass

Of course, before ordering a new double-glazed window (SP), it is still better to have the measurements taken by a specialist, since errors can be disastrous. An incorrectly manufactured glass unit in the frame may crack and you will need to purchase a new one.

The most accurate method for measuring the characteristics of a double-glazed window is to measure it in its natural form; for this you will need to remove it from the frame. Despite the fact that the joint dimensions taken without dismantling are less accurate, they can be used to order a new double-glazed window.

Options for measuring glass without removing the glass unit:

- To measure the width of the joint, measure the width between the glazing beads along the glazing groove with a tape measure, with an accuracy of 1 mm, and subtract 10 mm from the resulting value by the value of the deformation temperature gap between the frame and the glass.

- In many cases, you can only measure the height and width along the glazing groove; during manufacturing, window craftsmen will independently subtract the required value for deformation.

- Study the data printed on the information bar. Dimensions, GOST and the formula of the double-glazed window must be marked on it.

- Refer to the order contract for the manufacture of windows; it also indicates the main dimensions of the double-glazed window.

- Use a laser tape measure.

- After removing the beads, a straightened paper clip is inserted into the gap between it and the frame until it stops; the depth of the entry will show the desired value.

In the case where it was not possible to take measurements from a double-glazed window using any of the above methods, proceed to its dismantling :

- To do this, insert a spatula or knife into the gap between the frame and the bead.

- Loosen the glazing bead with a knife so that it comes out of the grooves.

- Remove the glazing beads crosswise: vertical right-left, then horizontal top-bottom. This dismantling scheme will not allow the glass to fall out and break.

- Take out the straightening plates and remember their location so that they can be installed correctly later.

- Carefully, tilt the glass unit, remove it from the frame and measure the dimensions: thickness, width and height.

- Insert the glass unit into the frame in the reverse order.

When dismantling a double-glazed window, all work must be carried out in compliance with safety regulations, wearing protective clothing, gloves and goggles.

How is the size of a plastic window calculated?

The first thing to do when updating windows is to determine the size of the opening where the new structure is planned to be installed. The success of all further installation steps depends on how correctly the measurements are taken. Measurements are taken not only from the inside - it is necessary to take measurements from the outside. Double measurements of the opening will allow you to determine the parameters of the required product correctly, avoiding possible distortion of the opening and complications of installation.

Precise measurement of the opening and taking into account the obtained indicators during further production will allow you to eliminate end-to-end distortion. If errors in measurements are identified at this moment, it is important to correct them immediately, because later installation will become possible only after reworking the current opening.

Already at the measurement stage, you can make a preliminary calculation of the amount of mortar for plastering work that will be required when sealing cracks and gaps. Correct measurements and taking into account the obtained dimensions will minimize the volume of material, and, consequently, installation costs.

When taking measurements, it is recommended to adhere to the following sequence:

- Measure the opening as accurately as possible. To avoid problems with incorrect calculations, it is recommended to contact specialists who have experience in such work.

- Determination of the exact dimensions of the future structure, made to order.

- The selection of additional elements that give increased functionality to the window (mosquito net, window sill) is determined by the size of the ebb.

- The quality of the binding, the style of the product, the shape and color of the structure, the special characteristics of the fittings, the type of glass unit and their quantity are agreed upon.

- Bringing window sizes to uniform values.

- Preparation of documents for installation, production of products, specifications and other accompanying papers.

How to calculate it yourself?

After the window niche has been measured, taking into account its configuration, we begin to calculate the external dimensions of the window block.

An example of window calculation for different wall opening options:

- Measured without a quarter . With the opening width Wpr = 1360 mm, the window width will be equal to Wо = Wpr - 2*Wm = 1360 - 2x30 = 1300 mm, where Wm is the installation seam, it is taken into account on each side. With the opening height Npr = 1470 mm, the height of the window structure is equal to: But = Npr - Nmv - Nmn = 1470-30-40 = 1400 mm, where Nmv is the gap for the upper assembly seam and Nmn is the gap for the lower assembly seam taking into account installation window sill.

- Opening with a “quarter”. The width is measured both from the street side (Wul) and indoors (Wkv). With Wul = 1360mm, the window width Wo = Wul - 50= 1360 +50=1410 mm, and with Wkv = 1450 mm, the window width Wo = Wkv - 40= 1450 - 40=1410 mm. If there is a “quarter” in the window at the top and bottom, then the height of such a frame according to the height of the opening measured from the street Nul = 1470, with a deduction of 30 mm, the frame will have a height Ho = 1470 + 30 - 15 mm = 1425 mm. If the height is only at the top - in this case, at Zero = 1455 mm, But = 1455 + 30-60 = 1425 mm.

For window sill and ebb

The length of the ebb is set in accordance with the street width of the window niche. To this indicator add allowances of 40 mm on all sides. Its width is determined from the frame to the outer cut with the addition of allowances: 20 mm for going under the frame and 40 mm for the protrusion of the ebb onto the street.

The length of the window sill should be measured according to the width of the wall opening indoors and add 100mm to the allowances on each side. Its width is equal to the depth along the inner wall from the cut to the frame, with an allowance of 20 mm for going under the frame and an allowance for the window sill to go beyond the cut of the wall.

At the same time, it should not block the heating device by more than 1/3, so as not to disrupt the convective heat exchange in the room and not to create conditions for condensation on the windows and walls inside the room.

If the PVC window frame is smaller than the old wooden frame, the ebb and window sill must be made with a larger width.

Bugs and difficulties

As a rule, most of the measurements' errors are discovered during installation. And it’s good if the old window has not yet been dismantled, since correcting such errors will take time.

There are two most common mistakes made by window measurers - smaller and larger than the required size, with the worst option being the latter. If the gap in size is small, then the installation of the window does not stop, but becomes more labor-intensive; in addition, it causes greater consumption of installation materials and increases installation time.

Consequences

The most negative consequence that results from incorrectly measuring a window is its re-manufacturing. The guilty party, the measurer, pays for such an error.

If a window with the wrong dimensions is installed, then its owner should expect the following consequences :

- Wide mounting slots, creating cold bridges in the window structure.

- Condensation on windows and walls due to a violation of the energy efficiency of the connection between the window unit and the wall.

- Violation of the aesthetic appearance of the window.

- Deformation of the frame, which leads to freezing of the glass unit, loss of structural density, as a result of which moisture and dust will enter the room from the street. This will lead to the appearance of mold, mildew and deterioration in the health of others, especially those suffering from asthma.

Nuances of the sizing procedure

When taking measurements, it is recommended to take into account the requirements stated in SNiP and GOST . This will be the key to high-quality execution of the order.

Plastic products of standard dimensions must meet light transmission requirements. The design must provide sufficient access of light to the room without compromising the quality of the functions performed.

Despite the fact that design options are selected for a standard high-rise building, sometimes there is a serious difference in the size of the openings.

Expert commentary

Vladislav Dobronravov

Leading technical specialist at Okna-Media company

Even within the same building, designs can vary. That’s why it’s so important to measure the opening for each of the products being installed.

The dimensions of the structure affect its functionality and the access of natural light inside. The product should also look harmonious, taking into account the area of the room in which it is planned to be installed.

Not only the size of the room, but also the side of the location, the intensity of natural light, and the installation location will affect the size of the structure. The dimensions of the smallest PVC window depend on the dimensions of the opening and its location.

Expert commentary

Vladislav Dobronravov

Leading technical specialist at Okna-Media company

Important! The dimensions of a regular plastic window with two sashes are 130 cm in height and 140 cm in width. If the window is three-leaf, the standard dimensions will be 206 cm wide and 140 cm high

In practice, it is difficult to select a product model that exactly matches the individual dimensions of the customer. Most often, it is necessary to manufacture plastic structures according to specific measurements . Installation of a custom-made product is much simpler, while reducing the cost of producing a standard design is always associated with the difficulties of installation in an existing opening.

As a rule, work on taking the dimensions of a future product is carried out as part of a set of services paid for by the customer. Some manufacturers provide measurements completely free of charge for customers.

links to materials that complement this article: Round plastic windows - an elegant solution for the home + photo

Corner windows – beautiful large windows from floor to ceiling

Triangle-shaped windows - stylish and beautiful

Casement windows - more light in the apartment

Average cost of service

Many serious window companies do not charge customers for window measurements; this is a bonus for them and a guarantee that the work will be entrusted to the given one from measurement to post-installation service.

For those customers who decide to order window measurement as a separate operation, you need to know that the cost of such a service depends on the location of its implementation, for example, in Moscow and St. Petersburg they are 10-15% higher than in other regions. In addition, it will be affected by the number of floors where the window is located, the type of house, the characteristics of the window opening, the design of the window, the material from which it is made, as well as the state of the transport interchange to the facility.

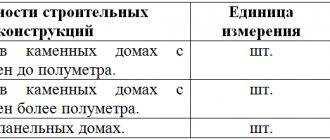

Average prices for measuring window wall openings:

PVC window, standard, panel house - 200 rubles;- PVC window, standard, brick house - 300 rubles;

- PVC window, non-standard, wooden house - 300 rubles;

- PVC window with balcony, panel house - 300 rubles;

- PVC window with balcony, brick house - 400 rubles;

- PVC window, non-standard with a balcony, wooden house - 450 rubles;

- aluminum window, standard, panel house - 250 rubles;

- aluminum window, standard, brick house - 350 rubles;

- aluminum window, non-standard, wooden house - 300 rubles.

Online calculator "Windows of the Century" - a reliable customer assistant

PVC plastic windows are very popular in the consumer market due to the high quality of materials, reliability, durability and functionality. Today you can purchase ready-made designs or make them to order. Those who want to find out the cost of upcoming expenses study search engines by entering the queries “Plastic windows price calculator”.

When planning to replace old window structures with new ones, many homeowners prefer to install plastic windows. Calculating sizes and prices using an online calculator allows the customer to assess their financial capabilities.

For those who decide to install high-quality plastic windows at home, the price (the calculator allows you to calculate it as accurately as possible) is a very important factor.

In order to find out exactly what costs await you, our website has a convenient tool that estimates how much plastic windows will cost. The calculator allows you to calculate costs as accurately as possible. This feature is available to all site visitors.

Perhaps the most important criterion by which you can evaluate the costs of plastic windows is sizes and prices. The calculator allows the buyer to calculate the total cost of the order with various parameters in order to choose the most rational option for themselves.