Drilling a window frame is not an easy task and requires a careful approach. You need to be especially careful when drilling plastic windows. The lack of certain knowledge and skills, the right tools and special screws can lead to irreparable damage to the structure. Therefore, if you need to drill holes in plastic windows for repair, decorative or any other purposes, it is best to turn to professionals or, at a minimum, study the issue of proper drilling of PVC windows with special care.

Why drill plastic windows

Window structures are drilled when it is necessary to install additional accessories - mosquito nets, blinds, child locks, handles.

It is not advisable to integrate a window sill into the window structure. It is installed and secured in a special groove.

Situations are possible when all work on the installation of the structure has been completed, but no thought has been given to the wires. To drill a hole in a plastic window for the cable, you will have to make a through hole. If you get into the camera or glass, you can seriously damage the structure. The tightness of the profile will be broken. Even if the hole is reinforced with sealant, it cannot be ruled out that the window will freeze during the cold season. It is safer to lead the cable into the apartment through a hole in the mounting foam or wall. It will take longer, but the window will definitely not be damaged.

Difficulties and mistakes, their consequences

Ignorance of the design features of windows and possible “weak” fastening points makes the drilling process dangerous. It is often difficult to cope without professional help, since even with a good result of drilling, errors may remain. To check their corrections, professional help is precisely what is needed.

Many people who have carried out such manipulations advise immediately contacting specialists, since this will cost less than the subsequent correction of unpleasant consequences.

It is also important to note that there are methods for attaching and running various wires that do not require making holes in window structures.

Consequences of unsuccessful drilling:

- Loss of rigidity of the window structure, since the frame consists of a thin sheet of metal and is completely hollow inside.

- The box is depressurized, moisture and cold enter the room, the glass becomes covered with condensation.

- Damage to the locking mechanism, which requires replacement of the entire window sash

- Violation of the aesthetic quality of the window

Safe drilling areas

Remember that you only need to drill around the perimeter of the blind sashes. It is important not to get into the fittings, double-glazed windows, or glazing beads. Make sure that the insulation is not damaged in the process, and that the attached parts will not interfere with opening and tilting the doors.

Basic Rules:

- use a metal drill;

- make an indent of approximately 2 cm from the glazing bead (so as not to touch the glass);

- we take a drill of a smaller diameter than the fastener, so as not to break the tightness;

- drill no deeper than one and a half centimeters. So, the air chambers will remain intact.

+7

Call

Order windows at a profit!

Until the end of the week, 30% discount on windows and balconies!

I want a discount

Cable entry through window

Question: what are the ways to insert cables through the frame of metal-plastic windows? I just don't really like drilling. If possible, please share your ideas. Own or observed. Just in case, I’ll ask the question not only here. If I have any interesting ideas, I’ll share them.

- Share Share this post via

- Digg

- Del.icio.us

- Technorati

- Post on VKontakte

- Post on Facebook

- Post to MySpace

- Post on Twitter

- Post to LiveJournal

- Post to Google

- Post to Yahoo

- Post to Yandex.Bookmarks

- Post to Links@Mail.Ru

- Reddit!

He did not pass through the frame, but through the corner of the window, where the window opening and the window meet. I drilled this joint using a hammer drill. In general, the operation is facilitated by the fact that this joint is usually filled with polyurethane foam. After laying the cable, seal the hole and the job is over.

- Share Share this post via

- Digg

- Del.icio.us

- Technorati

- Post on VKontakte

- Post on Facebook

- Post to MySpace

- Post on Twitter

- Post to LiveJournal

- Post to Google

- Post to Yahoo

- Post to Yandex.Bookmarks

- Post to Links@Mail.Ru

- Reddit!

Good evening everyone!

Question: what are the ways to insert cables through the frame of metal-plastic windows? I just don't really like drilling. If possible, please share your ideas. Own or observed. Just in case, I’ll ask the question not only here. If I have any interesting ideas, I’ll share them.

73! Vladimir, UR0ET

I just have the cables drilled and wired in. No problems. It is important not to doubt - drill and go. Look there are photos - and actually the answers to your question https://forum.cqham.ru/viewtopic.php?t=22040&highlight=

- Share Share this post via

- Digg

- Del.icio.us

- Technorati

- Post on VKontakte

- Post on Facebook

- Post to MySpace

- Post on Twitter

- Post to LiveJournal

- Post to Google

- Post to Yahoo

- Post to Yandex.Bookmarks

- Post to Links@Mail.Ru

- Reddit!

In fact, it’s easier and more practical to make a hole anywhere of the required diameter with a hammer drill - for concrete now this is not a problem, any drills and various good hammer drills - mock-ups, Boschs, Hilti - the question time is 2-3 minutes, and then a sealant or a drop of foam to prevent siphoning

Added after 5 minutes you need to make a loop when entering so that drops do not collect in the apartment or inside the wall

Last edited by RA3POY; 03/22/2010 at 20:18. Reason: Message added

- Share Share this post via

- Digg

- Del.icio.us

- Technorati

- Post on VKontakte

- Post on Facebook

- Post to MySpace

- Post on Twitter

- Post to LiveJournal

- Post to Google

- Post to Yahoo

- Post to Yandex.Bookmarks

- Post to Links@Mail.Ru

- Reddit!

I thought that a window frame was much more expensive than a hole in the wall. I used a hammer drill to drill a hole under the window sill (at an angle to prevent moisture from entering) and inserted a plastic tube. When the cable was installed, I sealed the ends with sealant. If you need to run another cable, I peel off the sealant.

- Share Share this post via

- Digg

- Del.icio.us

- Technorati

- Post on VKontakte

- Post on Facebook

- Post to MySpace

- Post on Twitter

- Post to LiveJournal

- Post to Google

- Post to Yahoo

- Post to Yandex.Bookmarks

- Post to Links@Mail.Ru

- Reddit!

The cheapest, simplest and most reliable way is under the window sill. The frame and window sill from the bottom are foamed with polyurethane foam; the foam from the apartment is puttied, most likely with a small layer of putty. There are approximately two centimeters between the window opening and the window sill. Outside, under the tide, there is only foam. It is attached to three or four self-tapping screws. If you have mild frosts in winter, you can insert a plastic tube, but it’s better to just foam it.

- Share Share this post via

- Digg

- Del.icio.us

- Technorati

- Post on VKontakte

- Post on Facebook

- Post to MySpace

- Post on Twitter

- Post to LiveJournal

- Post to Google

- Post to Yahoo

- Post to Yandex.Bookmarks

- Post to Links@Mail.Ru

- Reddit!

And before installing the window profile, I thought about the cable wiring in advance, and when the installers came from the organization, I simply slipped them a prepared polypropylene pipe, the size of which is slightly larger than the width of the wall. During the installation process, they successfully mounted this device under the window sill, everything turned out aesthetically pleasing.

- Share Share this post via

- Digg

- Del.icio.us

- Technorati

- Post on VKontakte

- Post on Facebook

- Post to MySpace

- Post on Twitter

- Post to LiveJournal

- Post to Google

- Post to Yahoo

- Post to Yandex.Bookmarks

- Post to Links@Mail.Ru

- Reddit!

Naturally, my family didn’t allow me to drill a plastic window, and to be honest, it wouldn’t have looked very aesthetically pleasing. Therefore, I took a hammer drill, a 16 mm drill, 700 mm long (the house is brick - the wall thickness is about 60 cm), drilled the wall in the right place with a slight slope outward (so that water did not flow from the cable), inserted a 16 mm plastic tube into the hole (such a tube used for electrical wiring), pulled the cable through the tube, sealed the gap between the cable and the tube with polyethylene foam (from old packaging). Everything turned out quite aesthetically.

Where you can't drill

There are several points in the window design where making holes is not recommended:

- Glass perimeter. It is limited by a special latch - a bead. Any damage will result in the glass having to be replaced. Step back at least 2 cm to avoid getting hit.

- Tilt and turn and swing doors. The frame contains hidden mechanisms responsible for its operation. If you hit it with a drill, the fittings will break and the sash will no longer fit tightly. This means that both the heat-saving and sound-insulating capabilities of the window will be impaired.

- Factory welded areas in the corners of the frame. A very vulnerable place. Any damage can destroy the entire structure. It is simply impossible to repair such a seam at home.

A special feature of metal-plastic windows is a reinforced contour inside. It gives rigidity to the structure. If you hit it with a drill, the window will begin to deform. In such a situation, one cannot count on a long service life.

When starting work, carefully study the design so as not to damage important elements, and do not rush.

Window preparation

The plastic window must be disassembled before installation:

- remove the sash,

- remove the glass unit from the blind part.

Next, we will consider the most common type of window, in which the frame is divided by a vertical impost into two sections: blind (does not open) and open (with a sash). This is the popular “kopeck piece” shown in the figure.

A standard size window (approximately 1300 x 1400 mm) can have other configurations: with two sashes (without capercaillie), with two capcaillie (without sashes), with one sash for the entire window, or with one capercaillie for the entire window window. There is no point in considering each option separately, because there are no fundamental differences in installation between them, and individual nuances will be mentioned additionally.

Removing the sash

So, first of all, we remove the sash. To open and remove the sash, you must first install the handle. In addition to the handle itself, the window handle also has a base that is attached to the sash. Holding the base with one hand, try to twist the handle with the other - you will feel that you need to apply some force to do this, since there is a mechanism in the base that locks the handle every 45°. Turn the handle so that it is parallel to the base. Remove the protective film from the sash in the place where three holes are made for the handle (two for the mounting screws, and one between them for the tetrahedron of the handle) and firmly insert the handle into the sash with the handle facing down (see picture). Pull the edges lightly with your fingers and rotate the cap 90° on the base of the handle. Insert and tighten the mounting screw into the top hole, just do not tighten too much so as not to break the base of the handle. Turn the handle to the horizontal position (the sash will open) and screw the second screw into the bottom hole of the base. Close the lid. That's it - the handle is installed, the sash is open.

Now you need to disconnect the sash from the frame at the top hinge assembly. To do this, pull down the top hinge pin (shown in the photo). To do this without difficulty, the sash must be closed, but not locked (the handle is horizontal). The pin should first be pressed from above with something, such as a screwdriver, to move it away from the internal spring latch. After this, you can carefully pick it up with pliers at the lower end and pull it down, but not necessarily completely - just so that the upper hinge mechanism is disconnected (make sure that the pin is not lost during work!). Now the sash can be easily removed from the window: tilt it towards you to disengage it from the upper hinge, and lift it slightly - the sash will be removed from the lower hinge. There is no need to do anything else with the sash and it is better to put it away from the installation site, covering it with something on top so as not to cover the fitting mechanism with debris and dust.

If the pin is completely disconnected from the loop, then:

- remember where it is top and bottom, so that you can orient it correctly during installation;

- Please note that the cross-section of the pin is not perfectly round. MACO fittings it has one flat edge, so when installing the pin back into the hinge, this face must be aligned with a similar face in the loop hole to prevent the pin from jamming;

- the pin can only be inserted into the loop in the direction from bottom to top;

- the pin must be inserted into the loop until it clicks, i.e. until it is secured with a spring latch inside the loop.

Removing a glass unit

To remove a double-glazed window from the blind part, it is necessary to remove the beads holding it on the inside of the window. This is done using a regular kitchen knife. It is better to start with a long bead, as it is easier to bend. The standard “kopeck piece” has longer glazing beads - vertical (side), so start with one of them. The PVC window glazing bead is held on the frame using a latch. In the photo, number 1 indicates a special protrusion on the glazing bead, which snaps tightly into the corresponding groove on the window frame. Number 2 shows the sealing rubber, which is pressed tightly against the glass and, in addition to its main function of heat and waterproofing, additionally tightens the glazing bead, preventing it from playing in the groove of the frame. To pull the bead out of the groove, carefully drive the blade of a knife between the frame and the bead approximately in the middle of the bead. Do not be afraid to damage the glass: the blade will enter the gap literally 3 - 4 mm and rest against the base of the protrusion (indicated by the number 3 ).

Now press the knife blade from the side in the direction from the glass unit to the frame, turning the glazing bead out of the groove (picture on the left). If after this the glazing bead tends to snap back, insert some plate into the gap that appears, and with a knife continue to turn the glazing bead a little further from this place. As a result, it will be possible to hook your fingers into the middle of the bead and pull it out of the groove completely. Next, the upper and lower (short) glazing beads are pulled out, and they must be turned out not from the middle, but from the free ends - also with the help of a knife. And lastly, the remaining side bead is removed using the same method. Now the glass unit can be removed from the frame. But this must be done carefully, since now it is most likely spread out on all sides by compensating spacers, which may interfere with the removal of the package. Therefore, some or all of them, except the bottom ones, will have to be pulled out before removing the glass unit. For this purpose, a special plastic mounting spatula in the form of a wedge with a handle is used, but at home, an ordinary kitchen wooden spatula will do. Insert the tip of the spatula into the gap between the bag and the frame next to the clamped gasket and, slightly bending it, bend the profile a little so that you can pull out the gasket. Having freed the package from the “spacers”, first squeeze its upper part towards you, and then, firmly grasping it from the sides (be careful: the double-glazed window is heavy, it can slip and cut your hands!), pull it out of the frame and set it away from the installation site, placing underneath it are wooden blocks or rubber, a thick piece of cloth, etc., to protect against chips on the glass due to random pebbles or a protruding nail head.

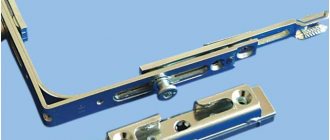

Self-tapping screws for plastic windows

The wrong fastener is no less dangerous than the wrong place for drilling. Most often, screws that are too large are chosen, which damage the fittings or air chambers. We must remember that it is almost impossible to carefully disguise the site of unsuccessful drilling. This looks ugly and will not add strength to the window.

There are no special screws for PVC structures. Therefore, experts advise choosing fasteners from 9.5 to 17 mm in length. Kinds:

- hardware screw with a countersunk head. Suitable for attaching mosquito nets and blinds;

- repair screw - will help secure it if the thread of the first one is broken;

- wide pitch screw with a sharp end - for heavy fittings and curtains.

How to clean drain holes?

Clogged ventilation openings are a common occurrence that leads to a decrease in the life of the window and a decrease in its functionality. Because the plugs are almost invisible, many residents forget about them and that they need to be cleaned at least once a year. You can do this while washing windows (1-2 times a year will be enough).

The ventilation ducts must be opened and all dirt removed from there. This can be done in different ways, the most effective way is with a vacuum cleaner. You can also use a stick, wire or a small stiff brush.

installation of blinds It is recommended to fasten horizontal structures with six self-tapping screws, which will hold them at the top of the window and serve as fastening for the control chain. The holding lines can be secured to the glazing bead with special clamps.

Screwing in screws is possible to a depth of half a centimeter. This will ensure that the structure remains intact.

Some experts argue that when attached to a metal-plastic structure, screws provoke the formation of “cold bridges” that disturb the microclimate in the room.

You can “ennoble” a window structure with your own hands if you have the skills and knowledge of the process. But ideally, you need to trust competent specialists. If you indicate your desire to install blinds or roller shutters at the stage of installing plastic structures, then the installers will equip them with special plates. In the future, with their help and without drilling, it will be possible to install “curtains”.

How to screw self-tapping screws into PVC frames

Determine the locations in advance and apply markings. Make sure safe points are selected.

Screws for plastic have a thin base, so use a metal drill to make a hole of a smaller diameter and carefully screw in the screw. Thus, if the screw has a drill, you can screw it in right away. If without, then with preliminary preparation.

If the fasteners are of the appropriate size, the holes made will not affect the properties of the window in any way, it will still be warm and airtight.

Features of a double-glazed window with a hole

Such design solutions have a number of features:

- They, just like standard models, have heat-saving functions. The hole is not cut out in a finished window, but is made according to industrial standards, taking into account a hole of suitable diameter. In this way, the vacuum condition is not violated, because the requirements for the density of the space between the glasses are one hundred percent met.

- A glass unit with a hole does not lose its strength. You will not be afraid that the window is fragile and requires special care during operation.

- The edges of the hole are not sharpened. There are no drainage holes in the window; this can be done even on. There is no risk of cutting your hand. To process the edges of the cut, special devices and seals are used.

How to hang blinds on a plastic window without drilling

Since drilling is a rather unsafe method of fastening, more gentle methods can be used to install blinds.

- Double-sided tape

Many people consider this method unreliable. This is wrong. Choose construction double-sided tape. Then wash the frames thoroughly with soapy water. Dry and degrease the areas where the fastener will be glued. If the weather outside is cold, warm the frame with a hair dryer. After gluing the tape, press the element firmly for a few seconds. After some time, you can install the curtain cassette. If everything is done correctly, the fastening will be reliable and will not damage the frame. But at the same time it is quite easy to dismantle if necessary. - Brackets

These are plastic or aluminum hooks. They are hung on the sash and secured with a seal on the spring. Next, a cover and a shaft with a curtain are installed on the bracket. For lightweight vertical models, plastic mounts are suitable. And for heavy metal blinds - aluminum ones with a presser foot. The disadvantage of this method is that they are attached only to opening doors. In addition, carefully monitor the condition of the sealing contour. When using such a fastener, it becomes pinched in the places where the brackets are installed and may crack.

Thus, the simple operation of drilling a hole in the frame can lead to damage to the window and costly repairs. If the situation allows, choose a gentle method for installing additional accessories. And when drilling cannot be avoided, carefully study the theoretical part or call a specialist.

Types of blinds and mounting features

At the moment, window manufacturing companies provide a wide selection of blinds of various configurations and the ability to customize them to specific window sizes. Among the possible variations, there are several main types of blinds:

- vertical;

- horizontal;

- roller shutters (fabric, internal roller shutters).

The option of installing vertical blinds in a residential apartment or your own house is quite questionable. Still, they are too strongly associated with office space. However, they are also suitable for some interior design solutions. They are mounted above the window, actually instead of curtains, which further limits their usefulness.

A more extensive number of mounting options is provided by the use of horizontal blinds. They can be installed on top of the window opening and along the outer edge on the upper slope of the window and directly on the window structure, with separate blinds installed on each sash. The last two options will go perfectly with any curtains and curtains, and choosing the last type of installation on the window itself will not take up any space on the windowsill. Roller shutters are also mounted directly on each glass.

We also recommend:

Everyone must choose the appropriate option independently, based on their preferences and requirements.

Reasons and necessity for making holes

Modern plastic windows installed recently when closed do not allow air into the room, unlike wooden ones. This fact requires measures to equip rooms with ventilation, which is carried out by installing window air conditioners or fans.

In addition, floor-standing air conditioners, which require an air duct to be installed outside, are becoming very popular. In this case, the device itself is installed near the window in a convenient place.

Often, when purchasing such household appliances, to simplify their use, it is advised to only lead the air duct to the street through an open window. However, this method minimizes the use of air conditioning, since hot air will enter from the street through the remaining gaps.

To work effectively, you need to make special holes. It should be taken into account that there should be no gaps between the air duct and the hole for it, for which it is protected with sealant and rubber seals.

If this is not done, hot air will enter the room, significantly reducing the efficiency of the air conditioner.

In the case of using a floor-standing air conditioner, only the cost of cutting a hole for the air duct is added, which is much cheaper and easier than installing a split system. But also in such cases, a function that is not available with split systems is implemented. This is heating a room at an air temperature well below 10 degrees below zero.

To install air conditioners or fans, you need to make square (for an air conditioner) or round (for an air duct, hood or fan) holes in the glass being installed or already installed.

When choosing a particular fan, you must take into account that not all manufactured models are suitable for installation in holes. This must be clarified before purchasing them and cutting holes for them. It is especially necessary to clarify the thickness of the fan fit and compare it with the thickness of the window in which it is planned to be mounted. Otherwise, the fan will not fit in thickness and will not fit, even if the passage is of the required size.

But you should also be careful when choosing air conditioners. In particular, glass cannot withstand heavy loads, so in most cases it is impossible to plan to install a household window air conditioner into the hole.

Currently, not all enterprises produce products with holes of the required sizes.

Care of double-glazed windows and plastic surfaces

Glass should be cleaned inside and out as it becomes dirty; a layer of dust reduces the light transmittance of the glass unit and does not add to its aesthetic appeal. A soft viscose or cotton cloth and household glass and mirror cleaner are suitable for cleaning. It is also permissible to use a soap solution, but then it will not be easy to bring the glass to a perfect shine without streaks. You can also use a rubber scraper for cleaning.

Plastic frames can be cleaned with a sponge using any detergent without acids, abrasives or strong solvents. It is not recommended to use hard brushes and compositions in the form of powders - micro-scratches may remain on the surface into which dust will clog. You also need to wash the space between the sash and the frame, this is where the most dirt accumulates.

For areas that cannot be cleaned normally, apply a special reagent from the care kit or a plastic cleaner, according to the instructions on the package.

Basic rules for laying cables

The television cord is placed at a distance from the main electrical wiring so that the emitted electromagnetic field does not spoil the signal transmission.

The fewer branches, breaks, and kinks are made, the longer the conductor will last. It is best if the product is laid directly from one point to another.

It is not recommended to make a daisy-chain connection through splitters, so as not to reduce the throughput characteristics.

This device belongs to the low-current category, that is, it does not require a large discharge of energy for constant operation. This makes it possible to install it in a single channel with other low-current transporters, for example, telephone or from an Internet provider.

When laying wires, you cannot make loops or twists in order to maintain the free flow of information.

Restoration and painting of old wooden windows

- How to paint a wooden frame correctly

- Step-by-step window painting scheme

- How to choose paint for painting windows

- Coating the old layer

- Painting with the help of professionals

Despite the fact that nowadays most houses are equipped with more modern structures made of plastic and aluminum, which have won universal love, many apartments have wooden windows. Painting windows is a procedure that owners of wooden windows sometimes have to carry out. This is done to ensure that the frames retain their attractive appearance and serve their purpose for as long as possible.

How to paint a wooden frame correctly

Take note of a few rules that will help you and tell you how to paint a wooden window correctly. This applies to the preparation stage for work and will greatly facilitate the application of the coating.

- Wooden windows are painted only at the right time of year. It is better to do this at the end of spring, when warm and dry weather sets in and precipitation is almost impossible. The right time is the end of summer, when the intense heat subsides, but the autumn rains have not yet begun.

- Before painting the window, it is necessary to eliminate all defects and damage.

- All painted surfaces must be cleaned, previous paint removed, and sanded.

- Be sure to apply the paint in several layers, at least twice with an application interval, this will increase its service life.

- Before painting the frame, it is recommended to coat the putty areas with a primer. It is recommended to seal glass and window fittings with masking tape or paper strips to prevent paint from getting in.

- Do not forget to dilute the paint from the can with a solvent, since the composition in the container is too thick.

- When working with paints and solvents, be sure to wear gloves and a respirator - take care of your health.

Read consumer reviews about wooden windows on our website at https://oknanagoda.com/okna/derevo/derevyannye-okna-so-steklopaketami-2.html.

Read what are the advantages of larch windows and why you can give them preference.

Step-by-step window painting scheme

So, how to paint wooden windows yourself? Do not forget that painting window frames depends not only on the quality of the paint and tools, but on the correctness of the preparatory stage.

- Prepare the necessary tools. It is better to cover the surfaces around the window with newspapers and seal the glass and fittings.

- The window must be cleaned of old paint - remove it with a spatula and sandpaper or use a special liquid sold in stores.

- Remove all dirt and dust.

- Degrease the frames or rinse with water.

- Fill any cracks and chips on the frame. Then prime the window. Do not forget that before applying putty and primer it is necessary to thoroughly clean the surfaces. We recommend that you first go over the putty areas with primer or paint so that the paint is absorbed and dried, this will ensure uniformity in painting.

- Let the frames dry thoroughly. Now you can start painting. The frames are painted first from the inside, then from the outside. Apply paint from top to bottom, covering the horizontal surfaces first, then the vertical ones.

- Apply one coat of paint and let it dry! Then apply the second and third layers, the strokes should lie on top of each other. Walk over the surface with a roller to smooth out any unevenness.

- Paint with a wide brush, paint corners and hard-to-reach places with a thin brush.

- Cover the outside of the window in the same way.

- Remove the masking tape and paper before the paint dries, otherwise they will stick and come off along with the new paint.

How to choose paint for painting windows

How to paint wooden windows is a question that must be approached carefully and responsibly. Choosing the right material is not the last thing in the entire process of updating frames, because good paint will not only change the appearance of the window, but will also increase its service life.

When choosing which paint is best to paint a wooden window, look at moisture-resistant materials - this will protect the frames from the penetration of unnecessary water and protect the wood from cracking. The paint must be elastic in order to protect the frames from deformation and shrinkage.

The best option is alkyd paint or acrylic. As a rule, these paints are good because they do not turn yellow and have no odor. Do not be alarmed that the paint is water-based (diluted with water), after drying it is very durable and will last for many years. When answering the question of how to paint the outside of window frames, choose light colors, which are able to reflect the sun's rays and thereby extend the life of the frames.

When starting to repair and paint windows, some choose varnish as a coating. How to paint old windows with varnish? Applying varnish is no different from applying paint. It is better to choose acrylic varnish, which is moisture-repellent and environmentally friendly (wave-based), in addition, it can beneficially change the appearance of the windows.

Coating the old layer

If you are thinking about how to paint wooden windows using old paint, then better give up this idea. It is not for nothing that one of the main conditions for proper window painting is the removal of the old coating. If you apply a new layer to an old one that has already cracked from time to time, you risk getting a result that is not at all what you expected. The new paint will begin to bubble on top of the old layer, unevenness and roughness will appear - it will not look aesthetically pleasing and will negate all efforts.

Read our article on the website which wooden double-glazed windows are preferred by Russian buyers.

Do you want beautiful wooden windows? Read our article “Arched wooden windows – beauty, and that’s all!”

Painting with the help of professionals

If you don’t want to think about how to paint old wooden windows with your own hands, are unsure of your abilities, or simply don’t have free time, entrust the process to professionals. Our specialists will do the work quickly and efficiently, using the best materials that will increase the service life of your window for a long time. The average cost of work in Moscow, for example, starts from 3,000 thousand rubles, which will not be an unaffordable amount. Painting wooden windows yourself will take a lot of your time and require concentration and attention. Sometimes it's easier to order new inexpensive windows at reduced prices.

If you are still thinking about how to paint old wooden frames, stop doubting your abilities, because this process is available to everyone. And if you don’t want to do the restoration yourself, call a specialized company.

Nuances and tips

You can delay the procedure when the windows are completely new. For example, there are special flexible adapters that allow you to bring the pulse source outside, and it is held in a clamp between the doors. Essentially, the device is a flexible coupling for fastening cables.

This is not the most reliable option and is not suitable for permanent use, but serves as an excellent temporary grip.

If the conductor is broken during the pulling process, it is possible to restore the connection using couplings.

Inside the room, skirting board wires with a built-in cable channel can be perfectly hidden. First, remove the top plug, attach the plastic plinth with glue, for better fixation you need to tighten the screws or screw in a self-tapping screw. Next, insert the TV cable and close the decorative plug.

Clearly useful tips are presented in the following video:

You can install the TV cable yourself, the main thing is not to rush, to follow all the features of the procedure so that connecting TV channels becomes a pleasant pastime and not a source of problems.

What kind of cable is there?

There are several types of TV cables, all products are divided by thickness, length, and bandwidth.

In total, there are three main groups of brands that are in high demand:

- RK 75-4-11, RK 50-7-11 – when connecting to cable television;

- R0K 75-4, 8-318, RK 75-4, 8-312 - an excellent option for laying digital TV;

- RK 75-2-13 is a flexible short cord connecting the set-top box to the TV.

Many provider companies provide the cord and also install it themselves. However, there is no guarantee of installation of high-quality TV cable, which should last for several years.

Most often, the elements are hidden with finishing or decorative channels, and everything will have to be disassembled and reassembled, which requires additional expenses.

Among other things, the properties of the product directly affect the constancy of the signal, which is directly related to the quality of transmitted pictures and sounds.

It is important that the wire is flexible enough to fit through corners and has good insulation.