When installing plastic windows, specialized fasteners are used.

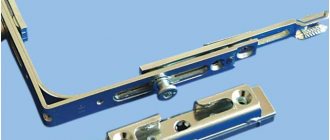

As a rule, the window is mounted on anchor plates, which, in turn, are fixed to the plastic frame using self-tapping screws.

When choosing hardware, it is necessary to take into account the material, profile thickness, and requirements for ensuring the strength of the finished structure during operation.

Self-tapping screws for plastic windows ensure long-term operation of the translucent structure, without the need for repair or dismantling.

What does the concept mean?

A self-tapping screw for a plastic window is a type of fastener that is fixed in the body of a PVC profile by twisting the rod metal element with force, clockwise.

Hardware has the following distinctive features :

- A pointed tip on the surface of contact between metal and plastic.

- A threaded surface with a pointed profile, which allows you to cut channels in the body of the PVC profile, preventing the hardware from being pulled out when a tearing force is applied during operation.

- A head with a machined edge for gripping a screwdriver bit or a screwdriver tip when tightening a part in the profile body.

All self-tapping screws for PVC windows are made of high-quality high-strength steel and vary in length, diameter, head shape, which determines the choice of tightening tool profile.

When to use?

Self-tapping screws for PVC windows are required when installing and assembling the structure before starting its operation:

For fixing anchor plates to the surface of a plastic profile.- When installing hinges and other fittings to allow the window to open.

- For installing handles for the subsequent transfer of lever force to the fittings.

- When performing repair and restoration work, in the event of failure of individual elements of the translucent structure.

The self-tapping screws used in assembling a plastic window are usually selected by the manufacturer at the factory. During installation, the diameter and length of the elements are determined by the dimensions of the profile, the width of the hole in the mounting plate, as well as the requirements for ensuring the strength of the window structure under the influence of external loads during operation.

Installing a window using plates

To carry out the work you will need the following tools:

Tools for window installation.

- electric hammer drill (or drill with impact function);

- screwdriver;

- hacksaw (it’s wiser to use a jigsaw);

- hex key for adjusting fittings;

- anchor plates (5 pcs.);

- bolts (self-tapping screws);

- polyurethane foam in cylinders;

- silicone in cylinders (and a gun for working with it).

Don't forget to have your measuring tools ready. You will need a measuring tape, a building level and a square. All necessary marks can be placed with a simple pencil. As a rule, traces of it can be removed from plastic with ordinary dishwashing detergent. When everything you need is prepared, you can begin installing the windows.

Kinds

Depending on the place of use and operating mode of the window opening filling element, different types of self-tapping screws are used, which differ in :

- form;

- sizes;

- maximum tightening force and other parameters.

Below is a detailed description of each type of self-tapping screws for PVC windows.

Fittings

Designed for installing fittings in window profiles. These products are distinguished by the following features and technical characteristics :

- A multi-layer protective coating that prevents corrosion, as well as expansion/contraction of the element when temperature changes.

- A relatively small diameter and, accordingly, an increased pitch between adjacent turns of thread on the hardware, which helps speed up installation.

- When installing fittings, it is important to ensure that the hardware is completely embedded to its full depth in the element being connected. The head of such self-tapping screws is made in the shape of a cone, which ensures that the hardware is immersed in the metal of the fittings when tightened.

- Self-tapping screws in this category are standard hardware that can be purchased at any hardware store.

When purchasing such products, it is necessary to measure the dimensions of the profile, since the market offers self-tapping screws with a length of 15 to 60 mm or more with a single diameter.

Fittings and repairs

Repair self-tapping screws are used in cases where the old fastener has damaged the threads in the plastic when the permissible pulling force is exceeded. Self-tapping screws differ from fittings in the presence of the following features :

Reinforced metal structure for the ability to transmit increased force when tightening.- Larger diameter of the rod and thread, compared to standard hardware screws, to allow the fastener to be fixed into the same hole where the thread was stripped.

- A smaller thread cutting pitch ensures more reliable adhesion of the self-tapping screw to the inner edge of the hole.

When choosing such products, it is necessary to measure the diameter of the old self-tapping screw and select repair hardware with dimensions that differ by no more than 1 - 2 orders of magnitude. In such cases, additional drilling of the hole is not required.

With countersunk head and drill bit

A self-tapping screw with a drill tip is designed for cutting through metal when tightened under pressure. It is used when it is necessary to install fittings in plastic profiles reinforced with steel brackets for through cutting of the product and ensuring reliable fixation.

They have a number of advantages compared to conventional fittings:

- Locking hinges on the head, signaling the maximum tightening of the product in the body of the structure.

- The drill tip cuts through any material, protecting the metal of the thread on the side surface from destruction and abrasion.

- The product is completely embedded in the material until a smooth surface is formed.

- The jaws on the head, designed to engage with the tip of the screwdriver bit, are highly durable and do not wear off when transmitting torque.

These self-tapping screws are used not only for reinforced PVC profiles, but also when installing sills, steel flashings and other metal window parts.

With semicircular heads

The products differ from the fastening options described above in the presence of a visible head, the reverse side of which has a smooth surface. This form of hardware ensures the following functions :

- Tight pressure of the joined surfaces when tightening.

- Elimination of local deformations of metal or plastic elements due to concentration of forces.

- Possibility of using flat washers to distribute pressure on the surfaces to be joined.

This type of fastener is used when joining mutually orthogonal profiles of a window structure, when fixing vertical imposts separating different window sashes, which requires the use of washers to avoid pushing through the soft material.

With press washer

They are universal self-tapping screws that can be used on the farm to ensure reliable mechanical fastening of the parts being connected. There are several types of such hardware :

- Self-tapping screws with a press washer and a sharp tip for automatic thread cutting in plastic.

- Fastening elements with drill tips for cutting through steel elements of window fittings.

- With standard heads, for Phillips or flat head screwdrivers.

- With universal heads that fit any type of bit tip.

- With hex heads for greater torque capability.

The minimum diameter of such products starts from 4 mm, length – from 10 mm. Each consumer has the opportunity to choose a product that meets the functional requirements of the surfaces to be joined.

For window frames

Reinforced self-tapping screws for through fixation of the profile to any materials of wall structures. They can be screwed either into the wooden surface of the end of the opening or into a pre-arranged plastic dowel in a stone wall.

They are a more gentle analogue of wedge expansion anchors , which can cause excessive stress in a weak structure, which will cause it to chip.

They differ in increased length - from 100 mm or more, diameter - from 5 - 6 mm, and the head is machined into a multi-faceted star to ensure reliable fixation of the bit in the body of the screw. They can be tightened with a screwdriver bit or an L-shaped wrench with a long arm, which enhances the muscular strength of the master.

Features of tides for wooden windows

A groove must also be made in the frame of a wooden window for installation. In this case, there are no problems and installing window sills is no different. To be on the safe side, you can also lay a strip of waterproofing under the tide, tucking it into the same groove. When using a sealant, you need to look for one that has good adhesion (adhesion) to wood and metal or plastic - depends on the type of casting chosen.

External tides on wooden windows

If there is no ebb groove in a wooden window, you can make one yourself. The groove is not made too deep and wide. This may be a narrow cut into which only thin metal can be inserted. To prevent wood destruction, treat the cut with protective agents before installation. As a last resort, you can apply paint.

How to determine which ones are needed?

The choice of high-quality self-tapping screws largely determines the safe, long-term and comfortable operation of the window opening filling element.

Before purchasing self-tapping screws, you need to pay special attention to the following nuances :

Preliminary measurements of the parts to be connected to select hardware of the optimal length and diameter.- Selecting a self-tapping screw head. For moving elements of the sash, fastening elements with hidden heads are required, which form a single plane with the metal surface of the fittings.

- When attaching vertical and horizontal profile elements to each other, self-tapping screws with press washers or round heads are required to prevent pressing through the soft structure of the PVC product.

- All hardware must be made of high-strength steel; the jaws on the head must not wear off when tightened.

- The best solution would be to buy self-tapping screws with a galvanized coating, which prevents corrosion and destruction over time.

- The thread on the surface of the product must be uniform, without scoring, the tip of each self-tapping screw must be sharp, without bends.

If a consumer has doubts about the quality of a self-tapping screw at a retail outlet, it is recommended to purchase a small quantity to check its strength, and then order the bulk.

It should be noted that a self-tapping screw cannot cost less than the steel itself from which it is made. If the price for 1 kg of products is too low, such hardware is most likely made of low-quality material.

Self-tapping screws for attaching the starting profile to the window frame

To attach the starting profile to the window profile, 3.5*11 screws (bugs) are usually used. They can be either with or without a drill. It would seem like a small thing. But it is the choice of the self-tapping screw tip that will ultimately determine not only the ease of installation, but also the quality of work. When tightened, a self-tapping screw without a drill pushes all the plastic of the starting profile outward from the drilling area, due to which a rather high and hard tubercle “grows” on the reverse side. It will inevitably interfere with the tight fit of the starter to the window profile. To remove the tubercles, you will need to spend time unscrewing the screws, cutting off all the protrusions and re-attaching the starting one. And if you leave everything as it is, there will be a gap. Using a self-tapping screw with a drill allows you to solve this problem. Although the plastic squeezed out with a self-tapping screw will still end up on the back side of the starting one, but in much smaller quantities. There will be no more accumulation of plastic around the hole, because most of it will come out in thin shavings to the top and will be pressed by the head of the self-tapping screw to the inside of the starting profile.

How to properly attach PVC structures to hardware?

When installing plastic windows with self-tapping screws, you must contact a professional team from a specialized company. If the owner of the premises does not have such an opportunity, and the work has to be done with his own hands, experts recommend following the requirements of the technological map :

- To install the profile to the end of the opening, you should choose self-tapping screws exclusively for fastening window frames.

- For fixation, spacer polymer washers will be required, which are placed between the profile and the end of the wall opening to create an installation gap.

- If the window is delivered to the site assembled, it must be disassembled - remove the opening sashes, unpack the blind filling elements of the translucent structures.

- In the corners of the frame made of plastic profiles, through holes are drilled with a diameter 2–4 mm smaller than the dimensions of the screws on which the window will be installed.

- The frame is fitted into the opening strictly in the installation position, after setting the gaps and observing the geometry.

- At the end of the opening, places are marked for making holes for dowels.

- The frame is dismantled from the opening.

- Holes are drilled at the designated points, into which dowels are subsequently hammered.

- The frame is installed in the opening, wedged with plastic clamps of variable cross-section around the entire perimeter.

- The technician checks the position of the frame, the alignment of the holes for the screws, and the size of the installation gaps.

- Each self-tapping screw is sequentially fixed to the profile and the wall. A polymer spacer is placed between the elements, which also prevents the orthogonal window structure from bending when tightly tightened.

Upon completion of the procedure and tightening of each screw, the master inspects the unchanged position of the structure and compliance with orthogonality. If necessary, the element is weakened for minor straightening.

Advantages and disadvantages

Self-tapping screws for attaching window frames to enclosing wall structures with openings are often used by both professional installers and beginners. Advantages of using self-tapping screws:

Reliable fixation of the frame in a given position.- Elimination of structural movement during operation.

- Formation of a permanent installation gap for filling with foam.

- There is no shoulder between the contact surfaces - forces are transferred directly to the stone or wooden wall structure.

- There is no need to use additional fixing elements in the form of anchor plates, which increase the cost of installation.

In addition to the advantages, the use of self-tapping screws also has a number of disadvantages , which is why professionals do not always resort to this method of fastening:

- Loss of room energy efficiency due to the inability to install the window frame exactly above the insulation.

- Formation of additional cold bridges.

- The inability to move the window, which can lead to excessive stress and cracks in the glass, during sudden temperature changes or gusty winds.

- The installation of self-tapping screws requires increased labor costs associated with the mandatory disassembly of the finished window structure, removal of sashes and double-glazed windows.

Most installers tend to use high-tech anchor plates, as this method is considered more effective. At the same time, self-tapping screws provide increased strength, reliability and durability of the window structure installed in the main walls of the building.

Installation of a balcony block according to GOST. Fastening plastic windows

Our contacts

When installing plates, the following rules must be observed:

- For fixation, use only mechanical fasteners (screws). Never use glue or foam.

- When forming holes for fastenings, use the impact mechanism only if the slope is made of concrete.

- The drill must be long enough. Make sure that the drill chuck does not damage the window frame. The edge can be protected by placing a piece of PVC next to the socket being drilled.

- If the wall is made of brick with vertical voids, then the hole must be formed in the seam between the blocks. The solution will “hold” the fastening quite securely.

- To install self-tapping screws, it is better to use a screwdriver with a torque limiter. This will allow you to control how the fastener fits into the frame and how deep it goes.

Following these simple principles will help you install the window without errors that will be difficult to correct.

Average prices in the Russian Federation

Self-tapping screws for PVC windows are sold in every construction market in the country in a wide range from different manufacturers. Average price for 1 kg of metal hardware , as of August 2022:

- Fittings – 300-350 rubles.

- Fittings and repairs – 280-350 rubles.

- With a countersunk head and a drill tip - 500-550 rubles.

- With semicircular heads - 450-500 rubles.

- With a press washer – 500-700 rubles.

- For window frames – 800-1200 rubles.

When purchasing products from 100 kg or more, the wholesale price offered by the manufacturer applies. Thus, for installation organizations, the hardware used in the manufacture and installation of PVC windows is much cheaper than for retail buyers.