Continuing the topic of thermal insulation of window and door structures using installation, we have determined that the most convenient, effective “protector” is polyurethane foam. At the same time, its “protection” will work if the foam is covered with additional special materials that will perform the functions of protecting moisture permeability, vapor permeability and insulating the foam from ultraviolet radiation.

Also, when installing structures, it is necessary to maintain installation gaps, otherwise the “dew point” will shift and no matter how good the materials are, they will not work to their full potential.

But everything is in order.

Let's look at GOST and see that all materials used during installation must meet certain standards.

Let's read the Technical Requirements section and pay attention to Table 2 - Recommended mounting clearance dimensions.

Installation gaps must be maintained depending on the material of the structure being installed. They are different for different types of structures - this is due to the properties of the materials of the manufactured product. In particular, with such a property as compression-expansion under the influence of heat and cold.

The gap between the wall and the window, the so-called installation seam, after fixing the window in the opening during installation, is filled with polyurethane foam.

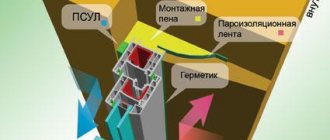

Let's move on to protecting the foam from external influences (heat, cold, rain, wind, sun). We have two layers of protection. One from the outside of the building (outer layer), the second from the side of the room (inner layer):

- external – waterproofing (diffusion tape), vapor-permeable (PSUL tape);

- internal – vapor barrier (duplicated and metallized tapes).

Let's look at how protection works using the outer layer.

The mounting foam on the outside must be protected from the sun (it is destroyed by ultraviolet rays) and rain, i.e. water (which impairs the durability and thermal insulation of the polyurethane foam, and destroys it when it freezes), but at the same time, the external protection of the mounting seam must be vapor-permeable, that is, water condensate that forms in the pores of the polyurethane foam, during the transition from cold to heat, must be discharged outside to prevent the foam from getting wet and breaking down. To solve these problems, PSUL tape is used.

PSUL tape

PSUL is a pre-compressed self-expanding sealing tape

used for sealing seams. When installing products in an opening, PSUL fills the gap between the window frame and the wall opening. It is designed to fill any gaps, within the limits of standards, in construction and is a strip of porous elastic material resembling foam rubber with special impregnations. The tape is made from modified acrylic and polyurethane. Acrylic impregnation slows down aging and extends the service life of the seal. For ease of use, PSUL tape has an adhesive mounting layer on one side.

Color black or grey. It is produced in a compressed state in rolls with protective tape attached. PSUL expands under the influence of moisture in the air. The purpose of PSUL is good waterproofing with guaranteed vapor permeability, protection from ultraviolet rays and high durability in conditions of various deformations of the window profile relative to the wall opening.

Polyurethane foam is weather-resistant, but PSUL is not.

From the inside, the foam of the assembly seam is closed completely hermetically, providing complete vapor barrier to the seam and completely eliminating the penetration of moisture into the seam from the room. For this purpose, special vapor barrier membrane tapes are used. We'll look at this below.

But not everything is so easy and simple.

The main disadvantage of installation using PSUL is that the width of the external gap between the front surface of the frame and the opening must be maintained in the range from 3 to 15 mm. This is due to the fact that when the PSUL tape expands beyond the specified normalized values, its waterproofing ability decreases. The tape itself expands to 40-45 mm (a fivefold increase in thickness is possible). But this is a completely non-working tape and it will not perform its functionality. Therefore, you should not believe what installation organizations sometimes say about the operation of the tape no matter how wide it is.

When removing the protective packaging and sticking the PSUL onto the working surface, the tape expands to operational working dimensions (discussed above). Then, it is desirable that the PSUL fully expands before the installation seam foams. Penetration of foam behind the PSUL tape is unacceptable. The time for complete expansion of the PSUL directly depends on the ambient temperature; for example, at 10 °C, expansion can take 15 hours or more. You can use the option of gluing an already expanded PSUL tape, but then it is necessary to press the frame to the quarter with clamps, which also complicates installation and, thus, can reduce its quality (this option is not recommended when changing products).

PSUL tapes come in different sizes, both in width and in the size of the “working” extension.

It is necessary to select the correct size for each specific installation of a translucent structure.

As a result, we received positive qualities of PSUL:

- easy to use during installation

- it is very plastic and thanks to this it can fill any cracks and gaps.

- allows water vapor to pass from the house to the outside

- UV and aging resistant

- resistance to heavy rains up to 600 Pa

- takes any shape

- and most importantly, the PSUL tape is not covered with anything, either plaster or any other material. This is simply not required.

PSUL tape is used for sound insulation of steel castings

tape layout diagram

Diffusion tape

Go ahead. On the street side, to cover the foam, another vapor-permeable tape is used, which protects the mounting foam under low tide and it is installed under low tide. Its name is diffusion tape.

Diffusion moisture-proof vapor-permeable tape NL is made of membrane-type synthetic non-woven material and is intended for waterproofing the lower assembly seam (under the ebb) from external moisture, as well as any other joints and construction seams when installing structures.

The tape has two adhesive butyl rubber strips on one side:

- one strip is intended for gluing the diffusion tape to the product,

- the other is for gluing the tape to a wall opening or slope.

There are enough standard sizes of tapes to choose it for almost any size.

Treatment of the installation seam with diffusion tape provides reliable protection of the installation foam from the penetration of moisture from the outside into the room and, at the same time, ventilation and removal of moisture from the insulation (foam) of the installation seam.

Diffusion vapor-permeable tape is adhesive to different surfaces.

- Resistant to direct sunlight for up to 8 months

- withstands pressure up to 600 Pa

- vapor permeability coefficient not less than 0.15 mg/(m h Pa)

- operating temperature from -50° to +100° C

- chemically neutral

You can read how diffusion tape is used in the article Installation of ebb tide.

How to choose PSUL tape

First of all, you can pay attention to 2 key parameters:

Firstly, you need to give preference to trusted companies. Typically, their products are a little more expensive than analogue manufacturers, but they guarantee their quality, full compliance with international or state standards, as well as durability.

Secondly, before purchasing, you need to carefully study the packaging. If it is broken or there are defects, then you should choose another option. It is impossible to say for sure whether only the packaging is damaged, or whether the tape itself is now also sold with defects. Therefore, it is better not to take risks, even if the seller offers a discount.

Other characteristics to pay attention to:

- Length of the product. They are selected depending on the amount of work that needs to be done.

- Product width. Many people mistakenly believe that it is better to take a wide tape. However, such a PSUL will not fit into relatively small holes. Accordingly, you will have to cut it out and waste your time. Also, cut pieces of tape cannot be used; they are thrown away. As a result, buying a tape whose width is incorrectly selected will result in more money being spent than necessary and also increasing the time spent on repairs.

- Expansion coefficients. The choice is shaped by how large the holes and voids are present. You should not overpay for a high ratio if there is no real need for it.

Mikhail Voronov

Ask a Question

Experts recommend considering water resistance parameters. Since the main task of PSUL is to protect seams from moisture penetration, it is the moisture-proof properties that should come to the fore. And if the product is manufactured according to GOST, then there will be no problems with this characteristic.

Dubbed tape

What is a dubbed tape?

This is an elastic vapor barrier tape, which is made of butyl rubber and backed with non-woven fabric (spunbond) with a self-adhesive mounting strip for attaching to products, which has a high degree of adhesiveness. The tape isolates the installation joint from the penetration of moisture from the air from inside the room, and also prevents condensation from escaping from the joint into the room and onto slopes, preventing the formation of mold and mildew on the inner surface of the joint.

It is used for noise and heat insulation of junction points during the installation of structures. Available in rolls with widths from 75 mm to 200 mm. Self-adhesive butyl rubber layer, with the help of which the tape is glued to the structure and wall opening (slope), protected with anti-adhesive film or paper.

How is duplicated tape used?

The tape does not require additional preparation or special tools and is immediately ready for use. The surfaces of seams and joints must be cleaned of dirt. Weak and absorbent surfaces must be primed first. The duplicated tape must be glued tightly along its entire length.

Installation of the tape should be carried out using the “from the frame” technology, having previously glued it to the frame of the product. The tape must be overlapped. It is recommended to seal the assembly seam “on the wet foam”. This is necessary so that the polyurethane foam, when expanding, sticks the tape to itself and stretches it a little for more convenient work during subsequent plastering of the slopes. The use of duplicated vapor barrier tape in the installation seam is a guarantee of its reliable and long-term operation. This insulating layer protects the insulation (foam) of the assembly joint from premature destruction and aging, since it has high vapor permeability. To finish the diffusion tape, you can use various materials, both dry and wet plastering.

The conditional service life of duplicated tapes is more than 20 years.

Let's move on to the last insulating tape used to protect the polyurethane foam - this is a metallized tape that is glued under the window sill.

Advantages of PSUL

- The tape is highly elastic and retains it over a wide temperature range – from −40 to +85 °C.

- Thanks to its plasticity, it can be easily laid in joints of different configurations. It takes the appropriate shape and leaves no air gaps.

- The material is not damaged by ultraviolet radiation and precipitation, mold and mildew.

- It is characterized by high moisture resistance and mechanical strength, and can withstand high wind loads.

- It has a long service life (more than 20 years) and does not deform.

- Suitable for sealing joints with uneven surfaces.

- It is chemically neutral, does not react with other substances, does not emit harmful fumes, and therefore can be used in residential construction.

- It is highly fire resistant and not prone to ignition.

- It has good noise and dust insulation properties.

- It is easy and quick to install, does not require special skills, bends and cuts effortlessly.

PSUL is compatible with various building materials - plastic, metal, concrete, natural and artificial stone.

The service life of PSUL, according to manufacturers, is from 20 to 50 years

Metallized tape

Insulating vapor-proof metallized tape is made on the basis of non-woven fabric coated with aluminum foil or metallized film reinforced with high-strength synthetic thread. The tape has two butyl rubber strips on one side. One strip is intended for gluing the tape to the product, the other is for gluing the tape to the slope of the wall opening. On the side of the strip intended for fastening to the structure, the tape is duplicated with non-woven material to create adhesion of the tape with the plaster mortar. The presence of non-woven fabric allows you to create adhesion of the tape with plaster mortar or polyurethane foam

The tape is intended for internal hydro- and vapor barrier of assembly joints, followed by possible plastering and installation of the window sill.

Metallized tape is produced in rolls with a width of 75 mm to 200 mm and is used depending on the width of the gap between the window opening and the frame. Self-adhesive butyl rubber layer, with the help of which the tape is glued to the structure and wall opening (slope), protected with anti-adhesive paper or film. The tape is sold in rolls.

The use of metallized tapes provides high protection of the foam from moisture from the side of the building and prevents moisture from escaping from the seam on the surface of the internal slopes.

Algorithm of actions

Sealing window openings is a painstaking process on which the comfort of your home depends. During the work, the seams of the structure from the street and from the side of the room are sealed. We recommend that owners of apartments on the upper floors seek help from high-rise specialists.

Surface preparation

This stage occurs after the windows are installed. After polymerization of the polyurethane foam, the remains are carefully cut off with a construction knife. If the excess mass is not removed, the surface will look sloppy. Irregularities are smoothed out with sandpaper. The outside of the seam is treated with cement mortar and the drying period is waited for.

Ribbons

Sealing plastic windows with tapes takes place in 3 stages. First, the frames are carefully measured and the raw materials are cut into pieces. Then a vapor barrier element is glued to the opening from the side of the room. Diffuse material is fixed to the lower structure from the outside, positioned exactly under the casting profile.

Sealant

Waterproofing plastic windows with sealant is the same for all types of mixtures. The surface is cleaned of construction dust using a stiff brush. The PVC structure is degreased with alcohol. To avoid contamination, masking tape is glued along the contour of the glass block.

The tube with sealant is installed in a construction gun. Slowly squeeze out the composition, moving the tool along the seam line or gap. Professionals do not recommend applying a lot of mass, otherwise it will be difficult to clean when grouting.

Insulating cracks after installing windows Source okna-dom.net

The material is removed with a special spatula for sealants. If there is no element, then you can use improvised means. Put a latex glove on your hand, moisten your index finger in clean water and rub it over the substance. Drops and stains are removed with a wet cloth.

Sealing the seams of double-glazed windows next to the window sill is a little different. If the width of the gap between the frame and the canvas is up to 2 mm, then sealant is sufficient for sealing. A material of a suitable color will not stand out against the background of PVC. For large gaps (from 3 mm), professionals recommend using sealing tapes.

In a frame, wooden cottage

Installation and waterproofing of PVC windows in wooden buildings is carried out after complete shrinkage. We recommend gluing PSUL outdoors into the opening before installing glass blocks. After expansion, the material will completely fill the gaps, preventing moisture from entering the room. A vapor barrier tape based on foil is glued to the surface of the slopes from the side of the room.

Procedure in a wooden building Source okna-dom.net

Rules for slope insulation

Important! Before gluing the tapes, the working surface of the assembly joint must be cleaned of dust (with a brush), dried from moisture, leveled where there are large holes and depressions (trowel), in winter - a must! – from frost, snow and ice. If the surfaces of the window opening are damaged, they must be restored. It is recommended to carry out installation work down to –20°С, and it is necessary to pre-condition the tapes and foam in a room (+20°С). When installed in an opening, mounting tapes do not require special tools.

- The polyurethane foam will be reliably protected if high-quality materials from trusted manufacturers are used during installation

- the openings of the room will be prepared, i.e. cleaned of dust, dirt and leveled (restored) so that there are no holes or bulges

- mounting tapes will work if the mounting clearances are observed

- Mounting tapes must be glued tightly along their entire length. The tapes must be joined end-to-end (PSUL) and overlapped (diffusion, duplicated, metallized)

- mounting tapes must be glued in a certain sequence (outer tapes are glued to the frame before installing the product in the window opening, internal ones - after foaming the gaps)

PSUL tape for windows - what kind of material is it? PVC window installers know that this is a pre-compressed sealing strip. It is an integral element of high-quality installation of plastic and wooden windows.

This material cannot be classified as innovative, since it has been used for more than two decades. But new modifications of PSULs appear regularly, claiming to be the most reliable and high-quality ones.

Purchase and installation of PSUL

You can buy PSUL wholesale and retail by placing an order online, by phone or by visiting a store in person. As for installation, everything is extremely simple. The surface on which the tape will be applied must be dry, cleaned of dust and degreased. The last operation is optional, but provides higher adhesion of the tape to the surface. After preparing the surface, everything must be done quickly so that the tape does not have time to expand. Using a tape measure or other tool, measure the dimensions of a window, door or roofing sheet, quickly unwind, cut and glue the appropriate piece of tape. Ready. Now your home is insulated and reliably protected from climatic influences.

Why do you need PSUL tape?

The purpose of sealing tapes is to eliminate gaps and protect assembly seams. At the dawn of the appearance of plastic windows, when installing them they used (and still use) self-expanding foam. The practice of using this sealant has shown that it can be destroyed under the influence of temperature changes, moisture and ultraviolet radiation.

An active search for a new means of eliminating gaps and protecting polyurethane foam led to the invention of a simple and reliable material - PSUL tape for plastic windows. Its characteristics significantly exceeded the capabilities of polyurethane foam. Since then, window installation technology has involved the use of PSUL. What is it good for?

- Has the ability to self-restore its shape.

- Retains a high degree of elasticity throughout its service life.

- It is a reliable barrier to the development of fungus and mold.

- Has excellent vapor permeability.

- It is an effective heat insulator.

- Capable of removing moisture beyond the assembly seam.

Despite the wide range of manufacturers of these tapes, they all have the same properties and are made from almost the same materials, with minor changes in the basic composition.

The basis of the seals is polyurethane foam elastomer, saturated with a composition based on acrylic resins. The density of polyurethane foam largely determines the technical characteristics of the finished product. The manufacturer can give his product any color, but this will not affect the quality. Therefore, when choosing a product, its color should not be the determining parameter.

The first manufacturer of PSUL is the German company Illbruck Bau-Technik GmbH. In Russia and the Commonwealth countries, the products of the following brands are mainly used:

- Profband (GiT LLC, St. Petersburg);

- "PSUL-EUROBAND" (Belarus);

- "Liplent" (Ryazan region);

- "Robiband" (Robitex, Moscow).

Price PSUL. Manufacturers

The main pricing factors for sealing tapes are:

- Overall dimensions, mm;

- roll length, m;

- composition and functional features;

- country of origin and level of delivery complexity;

- number of resellers.

The first three items on the list practically do not change over time and do not have a significant impact on price changes. The last two points affect the cost of the product to a much greater extent for the end consumer. Therefore, it is more advisable to buy PSUL from a regional representative of the manufacturer. This will definitely allow you to save on insulating your home. The next thing to pay attention to is the brand name. You should not give preference to companies that you have not heard of. Reviews from real buyers of the products you are interested in, which can be found on the Internet and in print publications, will help you avoid getting into trouble. You can also seek advice from relatives, friends and acquaintances.

Among the sealing materials from domestic and foreign manufacturers on the market, it would not be out of place to mention such an eminent domestic manufacturer of sealing tapes as the Robiband company. Today, thanks to the use of advanced technological solutions, flexible pricing policy and successful management, Robiband is the leader in the segment of polymer sealing tapes, producing products of the highest quality in accordance with European and world standards. The company's products are in demand both in Russia and abroad.

Technical characteristics of PSUL tapes

If you compare the technical characteristics of seals from different manufacturers, you will find that all of these products, despite the difference in brands, meet the requirements set for them.

All enterprises strive to produce competitive products, so you can buy any sealing tape to install windows yourself. She is guaranteed to complete her task. Any Psul tape, the technical characteristics of which correspond to those given below, will serve faithfully for at least 20 years.

- Expandability from 10 to 70 mm.

- Presence of an adhesive layer.

- Resistance to temperature changes (operating range from -50°C to +70°C).

- Deformation under mechanical influence is no more than 15%.

- UV resistance.

- Vapor permeability in a compressed state is no more than 0.25 m2∙h∙Pa/mg.

- Neutral to chemicals.

- Resistant to moisture, therefore painting with vapor-permeable water-based paints and varnishes is allowed.

Characteristics according to GOST

To ensure that various products on the construction or any other market are of high quality, special state standards are being developed. And any manufacturer is obliged to work exactly in accordance with them. If we consider PSUL, then its GOST is as follows:

- 3 kg/cm2 – adhesive strength;

- 0.15 (m2*h*Pa)/mg – maximum permeability;

- 600 Pa – minimum water resistance;

- -70 – +36 degrees – operating temperature range;

- 20 years – minimum performance characteristics.

It should be noted that manufacturers must adhere to the specified values. But they can make better quality products. The specified characteristics are minimum.

Application area

PSULs are sold in rolls (reels), which ensures ease of transportation and use. These seals are produced in widths from 10 mm to 40 mm to protect seams of different sizes. At the request of the customer, manufacturers are ready to make tapes of any standard sizes.

The scope of application of seals is wide. They are used to protect assembly seams when installing metal, plastic, wood, and glass structures into concrete, wood and brick openings. Required for the following types of work:

- when installing windows and balcony blocks as a sealant and heat insulator;

- when installing thresholds and window sills;

- when installing roofing structures as damper joints;

- when installing ventilation and air conditioning systems to eliminate gaps, noise and vibration;

- during the construction of building structures to seal joints and as a sound and heat insulator.

The pre-compressed self-expanding sealing tape can have two adhesive sides. One is for fixing the translucent structure to the plane, the second is for attaching to the slope.

Installation technology

The PSUL, placed in the seam, gradually increases in volume, filling all the gaps. But this does not happen instantly. It takes time to expand. The speed of filling the seam directly depends on the ambient temperature. For better installation quality, it is not recommended to use PSUL at temperatures below -5°C.

For the installation of plastic windows, the self-expanding sealing tape PSUL “Robiband” is recommended. Products of this brand have long established themselves as high-quality and reliable.

According to GOST 30971-2002, when installing windows, it is required to provide a protected installation seam. This can be done using PSUL. To install the tape, perform the following steps:

- measure the width of the seam formed between the window opening and the window block;

- determine the location of the seal on the window frame;

- check the deviations of the opening walls vertically and horizontally (in this way they obtain information about the expected width of the gaps);

- using a pencil and a ruler, mark the location of the seal on the window frame;

- remove the packaging film from the roll and cut off 3-5 cm from the end of the tape;

- remove the protective paper from the adhesive side and glue the tape along the previously made markings on the window frame;

- gradually move along the box, gluing the seal around the perimeter;

- A larger sealant is glued to the wider seams;

- at the corner joints of the box, each strip of tape should hang down by 1-2 cm;

- the joined sections are bent and pressed against each other;

- install a frame with a seal in the window opening;

- strengthen the frame with self-tapping screws.

If a plastic structure is installed, the surfaces are pre-degreased. You can use White Spirit. If the expected gap width is 4-5 mm, use tape with a 20 mm extension. If the gap is more than 6 mm, a PSUL with a 30 mm extension will be required.

Have you decided to install ready-made plastic or wooden windows with double-glazed windows yourself? Let us warn you right away: self-installation has its own tricks that humanity has developed to insulate and seal wooden windows in wooden houses.

Inexpensive plastic windows for a summer residence have their own installation specifics! And dear ones too! Let's consider advanced solutions for sealing the junction of a wall and a window using PSUL tape

Innovative solution with PSUL tape

What is PSUL tape - it stands for pre-compressed self-expanding sealing tape.

PSUL is a self-expanding tape made of polyurethane elastic foam, which is impregnated with a mixture of modified acrylic. It significantly improves the properties of polyurethane seals, increasing their resistance to aging. The tape comes to the market in a compressed state, rolled into rollers. The sizes of the sealant come in different sizes, so it can be matched to any seam. PSUL tape for windows has a layer of adhesive on the surface, which simplifies its use. In addition, this prevents it from moving. Heavily compressed film expands only after the packaging is removed. A fivefold increase in thickness is possible.

PSUL for windows has many positive qualities - it is very elastic, can take almost any shape, is resistant to ultraviolet rays and heavy rain, and perfectly ensures the release of water condensate from the product into the atmosphere. Thanks to its plasticity, it can fill any gaps. PSUL tape can be used with almost any building materials: concrete, brick, steel, wood, plastic and other materials.

At the same time, PSUL has good moisture permeability: it will not prevent steam from leaving the house outside. GOST 30971-2002 prescribes the use of PSUL in residential construction. But when constructing or restoring a dacha, GOST recommendations are usually forgotten. The purpose of this article is to remind them. And if you have custom-made wooden windows installed at your dacha, help ensure that the contractors also do not forget about GOST.

PSUL tapes have the following characteristics:

PSUL tape in packaging and after expansion

- resistance to precipitation;

- resistance to ultraviolet rays (sun);

- resistance to moisture and wind under pressure (up to 600 Pa);

- has high adhesion and flexibility.

- PSUL also protects the foam (installation seam) on the street side from environmental influences.

PSUL is a self-adhesive polyurethane foam tape impregnated with a special neoprene compound. The tape is supplied compressed and rolled into rolls. A wide range of standard sizes of tape sealant allows you to choose the material to protect seams of the size. There are two types of PSUL tape: gray and black. The tapes differ slightly in characteristics and type of impregnation. Gray tape has better performance. The tape placed in the seam expands independently, completely filling all irregularities and voids, providing reliable protection of the seam from all adverse climate influences.

The use of PSUL tape complies with GOST 30971-2002 “Installation seams of joints connecting window blocks to wall openings.”

PSUL size 15x40-6m Explanation: width of the adhesive layer - 15 mm, maximum expansion 40 mm, length of the tape in the roller - 6 meters.

PSUL tape on windows: a double-glazed window for a summer house increases its service life!

The main difference between new window technologies and old ones is the widespread use of polyurethane foam. It is with its help that PVC windows for dachas are installed in our time: it secures it, keeps heat out of the house, and is a jack of all trades. There is only one problem: when wet, polyurethane foam loses its beneficial properties. And no amount of old-fashioned platbands, canopies and moss pads will save you here: if the foam is not soaked by rain from outside, it will be saturated with steam from inside the room.

Places for installing PSUL tape to the box

Bottom line: after two years of operation of windows, 2-3 times more heat is lost through the wet mounting foam between the frame and the wall than through the double-glazed window, sashes and frame combined!

Where to buy and how much does it cost?

PSUL tape framed by frame

Whether you install ready-made plastic windows for your dacha yourself, or a contracting organization installs custom-made windows for your dacha, you will most likely have to buy PSUL tape yourself. There is no need to be afraid of this: compared to the current price for dacha windows, the cost of PSUL will pleasantly surprise you. For example cost:

- a tape with dimensions 10x20x15 (the first number is the width in mm, the second is the thickness after swelling in mm, the third is the length in m) made in Estonia costs 186 rubles;

- 15x40x8 – 200 rub.;

- 20x40x8 – 230 rub.;

Types and prices of PSUL tape

Prices are given according to the price list of the online store imperstroy.ru, not for any advertising reasons, but for reasons of practicality: ordering only sealing tape via the Internet is expensive - delivery will be more expensive than purchase, and on this site you can buy many more useful things in summer cottage construction : shutters for windows in the country house, bars for windows in the country house, curtains for windows in the country house, etc.

Read about how to insulate a plastic window with your own hands here: https://oknanagoda.com/okna/plastik/uteplenie/uteplit-plastikovoe-okno.html

Where to order a plastic window? The answer to this question will be told to you by the rating of Moscow window companies

The article “Flats for plastic windows - description, prices” will tell you about another way to protect the polyurethane foam around the window from adverse weather conditions

Advantages and disadvantages

There are many positive properties if you protect the seams with tape:

- Prevents the penetration of moisture and cold air masses from the street. If we talk about summer, then PSUL does not allow heated air masses to pass inside, which provides the opportunity to create a comfortable and favorable microclimate with minimal energy consumption;

- Guarantees moisture-proof properties throughout the entire perimeter of use. If drops of water get in, they will simply flow down;

- Can be used inside and outside the house. The tape is safe, it adapts to the surface, therefore, there are no restrictions on use;

- Prevents the formation of condensation, since all chambers will maintain approximately the same temperature. This increases the service life of not only the seams, but also the plastic profile itself;

- Retains its original physical, mechanical and protective properties, even if operation is carried out in harsh climatic conditions;

- Durable, if you choose and glue the tape correctly, it will last for decades;

- Combines and interacts with other materials upon contact.

Recently, experts have been using PSUL and abandoning polyurethane foam. In contrast, the tape has several characteristic advantages:

- Absolute surface elasticity. Because of this, the material can take virtually any shape; its use does not require leveling the surface, etc.;

- Does not react to high temperatures. Polyurethane foam quickly deteriorates if the sun shines on it, heating the surface. It dries and collapses, which creates voids inside (between the profile and the opening). Subsequently, cold air will pass through them, which will lead to disruption of the created microclimate. PSUL does not react to temperatures, so no problems will arise when used on the sunny side or in a hot region of the country;

- Not sealed. The air will continue to circulate, it will remove microscopic drops of moisture out. Thanks to this, in comparison with polyurethane foam, condensation does not form when temperature changes inside and outside the apartment become noticeable.

If we talk about the disadvantages, then:

- The PSUL must stand still for some time in order to expand. Therefore, you cannot use other materials on the site for ~15 hours. After expansion, the surface can be worked on.

- Some use already expanded tape. However, it must be pressed firmly against the gap between the frame and the opening, pushed inward, and this does not guarantee complete filling of the voids.

How to choose?

Installation diagram of pre-compressed sealing tape

When selecting a PSUL, two things should be remembered:

1. The tape is sold already compressed. When swelling, its thickness will increase approximately 5 times. That is, the tape, which was 4 mm when purchased, will expand to 20 mm after installation.

Measure the gaps that you need to cover and select

A special feature of PSUL is the presence of a self-adhesive surface

a tape that will really seal the contour and not flutter in the gap between the window block and the wall.

2. When installing the PSUL, it is not recommended to bend it. It is better to cut it into pieces equal to the sides of the opening to be sealed, and stick the tape so that its sections meet each other.

Please also note that the rate of increase in the volume of PSUL depends on the ambient temperature. At 30°C, complete expansion of the tape will occur in 30 minutes, at zero temperature - in several hours. Therefore, when installing windows in the cold season, the PSUL should be warmed up after installation. For example, a hair dryer.

Buy with reserve. Don't be afraid of what will remain. With the help of PSUL, tiled roofing and non-pressure pipes (for example, storm drains) are also sealed.

How it is made

Consists of polyurethane foam impregnated with a special solution of a mixture of modified acrylic.

Each manufacturer has an individual manufacturing technology, but among them there are also similar stages:

- The base of the strip is polyurethane foam made from gas-filled plastic.

- Impregnation of the manufactured product from the previous stage with acrylic solution or other substances.

- Connections of layers in the drying chamber.

- Treatment with adhesive composition.

- Application of binding material: reinforced mesh and paper layer on the outside.

The final stage is twisting and compression. After removing the packaging, it expands 5 times.

Procedure for working with sealing tape

Gluing PSUL to the window frame

Installation of pre-compressed sealing tape occurs as follows:

The PVC window and window opening are prepared for installation. To do this, dirt and loose plaster are removed, the surface is cleaned of dust using a vacuum cleaner, and wiped with a damp cloth. It is recommended to treat the surface of joints and seams with a special dust-removing compound.

The surface of the quarter is coated with an acrylic primer for exterior use. Markings are made and fasteners are installed. A few centimeters (3–5) from the beginning and end of the roller are cut off and not used. A piece of sealant is cut to the required length and the paper layer is removed. The tape is installed on the outside of the frame facing the street, with a distance of 3–5 mm from the outer edge of the quarter. The product is pressed to the surface. PSUL tape: technical characteristics, GOST

The PSUL is glued end-to-end, there should be no overlap. Vertical seams are filled without interrupting the tape at cross joints. Do not bend the seal at the corners.

After filling all the gaps between the window and the wall, you must wait until the tape expands to its free state. The rate of increase in the thickness of self-expanding material to working condition:

- at a temperature of 0°C the tape expands to the optimal size in 48 hours;

- at an outside air temperature of +18–20°C, the expansion process lasts 2–3 hours;

- at +30°C expansion occurs in 0.5 hours.

Blitz tips

- Tip 1. When purchasing a self-expanding sealant, be sure to ask the seller for a certificate of conformity or a product passport - this will once again confirm the quality of the product being sold.

- Tip 2. If this is your first time encountering this product, it is advisable to consult with knowledgeable people about its properties and installation method.

- Tip 3. Do not unwind the entire roll at once - it is not possible to return the tape to its original compressed state on your own, and installing expanded sealant will cause additional difficulties and errors may be made during installation.

- Tip 4. When working in conditions of low temperatures or lack of time, it is allowed to warm up the self-expanding sealant with a construction hairdryer; the increase in the rate of increase in size will be 50–100%.

Features of the work

Firstly: the inner surface of the quarter, as a rule, has shell gouges and other damage. Secondly: the width of the external gap A between the front surface of the quarter frame, closed by the PSUL, is strictly defined for a given standard size of tapes. As a rule, inexpensive PSULs with a gap A of 3-5 mm, 6-10 mm are used. When the PSUL expands beyond the standardized values, their waterproofing ability decreases. It follows from this that it is necessary to putty and bring the inner surface of the quarter as parallel as possible to the window frame. Flaws. Unfortunately, our builders, both in the past and now, rarely indulge us with smooth openings. In brick houses, this is also supplemented by the need to seal the joints between the bricks. All this requires plastering and removing the inner surface of the quarter. This is labor-intensive and low-tech, especially in winter. Installation of a special vapor-permeable waterproofing tape under low tide

Features The tape is glued under low tide with one side to the window sill profile and the other to the bottom of the opening. It is necessary to very carefully waterproof the installation seam in the lower corners of the window opening. It is these places, as logic dictates, that are most critical for waterproofing. Rainwater flowing down the vertical surfaces of the assembly seam exerts maximum pressure at the junction of the ebb and the quarter.

Flaws . The importance of additional sealing at the junction of the flashing (waterproofing tape under the flashing) and the vertical PSUL is not emphasized.

The need to install a waterproofing tape under low tide is generally questionable, because low tide was invented for waterproofing. It does not prevent steam from escaping from under it. The junction of the waterproofing tape with the vertical PSUL is also leaky, like that of the ebb. Probably the most technologically advanced method of waterproofing in this area is the use of special sealants. They must have good adhesion to the joint materials, not destroy them and, most importantly, be durable when exposed to ultraviolet radiation. From all of the above, it follows that window installation using PSUL sealing technology works 100% only in ideal or specially prepared plastered openings. For greater clarity, we recommend watching the video.