Principles for selecting sealing products

Armed with the above information about the types of seals, you can safely go to a retail outlet and make a purchase, not forgetting to first measure the dimensions of the cracks and decide on the most suitable profile section.

Having picked up the product you like, the first thing you need to do is pay attention to the information provided on the packaging. No matter how competent the sales consultant is, it is better to make sure for yourself, for example, what material a particular seal is made of and, in the case of a self-adhesive product, whether it has expired by the date limiting its suitability. Then you need to make fun of the insulation a little - try it by touch, squeeze, stretch - the main thing is to evaluate the product for elasticity and softness, and if the seal has these qualities, after manipulation it returns to its original shape, then the product is of high quality - you can take it

If, in an everyday situation, the seller grumbles and swears and does not allow tests to be carried out, this may be a hint of poor quality of the product. If the choice is made and it falls on a seal without an adhesive surface, you need to take care of what to use to attach the product to its proper place. In this case, you need to additionally purchase high-quality glue, for example, silicone sealant.

Manufacturers and prices

Today, many companies are engaged in the production of insulation for wooden windows. Moreover, more than half of them provide low-quality products. To avoid buying a fake, you need to pay attention to the following manufacturers:

- Aviora – price 15-30 rubles per m.p.

- Cyclone - price 18-28 rubles per m.p.

- Deventer – price 450 rubles per queen.

- KIM TEC - price 1400 rubles per queen.

- TEKOPLAST – price 45 rubles per m.p.

- Ultima – price 25-30 rubles per m.p.

- Bison – price 475 rubles per queen.

- Lada-imide - price 35-47 rubles per meter.

Details on how to adjust plastic windows are described in this material.

Some representatives

Today on the market you can find several types of insulation for plastic windows. To determine which one is better, you should evaluate their properties:

- Rubber. Seals made from this substance are among the most common. The black color of the material indicates that soot was used here, which gives strength to the product. Light-colored rubber products are characterized by lower technical properties. The service life of such products can reach 10 years. It should be understood that this depends on the specific manufacturer and technology for obtaining the material.

- Silicone. Seals made of this substance feel great at temperatures from -40 to +100 degrees without losing their technical features. Also, the material does not age as quickly as similar products and is not subject to destruction under the influence of many aggressive substances. They are used very rarely, as they are very expensive.

- EPDM. Thermopolymers are resistant to compression, which allows them to retain their original shape. The service life of such substances can reach 20 years. Such insulation materials are among the most common and in demand on the market.

Budget-friendly methods for eliminating drafts

Some of the listed methods are familiar to everyone since childhood. Others can be called modern: they are considered more reliable, such technologies help solve the problem for several years at once. If the room is very cold, you will most likely have to combine several methods.

Newspapers and paper

This is the cheapest (and sometimes free) and elementary method of insulation. There are several variations of its use.

- Newspapers or paper are rolled into thin tubes, moistened and pushed into the cracks.

- The leaves are torn into small pieces and soaked in water to make a paste. It covers up the gaps.

- Several newspaper scraps are mixed with a glass of flour, two glasses of chalk and water until it becomes sour cream. The mixture is then used as putty.

- Paper (preferably white) is cut into strips 4-5 cm wide and glued to a soap solution in places from which it blows. Masking tape is used for the same purposes.

The method has disadvantages. Paper strips glued to wood are difficult to clean and sometimes come off along with the paint. The second problem is that you can only open the window for ventilation.

Wool and fabric

Another insulation for wooden windows, known for many years. Technical wool is pushed into the cracks with a sharp object. In principle, you can use any rags you have at home. The fabric needs to be cut into strips 4-5 cm wide, wet, soaped, lightly wrung out and sealed all the gaps. The advantage of this method is that the fabric does not turn yellow like paper and easily comes off the frame. It will be just as easy to get cotton wool when spring comes. The only, but significant, drawback is that you won’t be able to open the window or you’ll have to do it all over again.

Film

A new way to seal a room, which is easy to do yourself. It will require a transparent polyester film. It serves as an additional air gap between the room and the street, transmits light well and is almost invisible. To create this heat vacuum, you will need clear double-sided tape, a knife or scissors, a long ruler, gloves, a marker and a tape measure.

How to insulate wooden windows for the winter using film:

- Wash, dry and degrease the entire structure, including the frame and glass.

- If gaps have formed in the sashes, seal them. This is important, as you will reduce heat loss to a minimum.

- Place tape around the perimeter of the frame.

- Measure its length and width.

- Place silica gel or other moisture-absorbing filler under the bottom bead. This is necessary to prevent condensation.

- Lay out the film on the table. If it is double, first divide it into layers.

- Measure the required amount and cut to a tolerance of 1.5-2 cm.

- Remove the protective strip from the tape.

- Apply the film to the top of the frame and glue it in place.

- Gently press the material against the vertical sides and secure it at the bottom.

It is better to do all the work with cotton gloves so as not to leave greasy marks. Do not pull the film too tight. But at the same time, do not allow it to bend towards the glass. Wrinkles can be smoothed out with a hairdryer without bringing it close to the surface. This method will help make the apartment warmer, but to achieve full results it must be combined with other methods.

Foam rubber, linen and sealing cords

It is not difficult to insulate windows with these fillers, and their efficiency is high. Foam tape with an adhesive backing is inexpensive and you can find it in any hardware store. With its help you can seal large cracks for 2-3 years. At the same time, you can ventilate the apartment not only through the window. The strip is glued around the perimeter of the sashes. Paper tape is glued to the top of it.

Linen cords are fixed to the surface in the same way as foam rubber, but with the help of nails or glue. The downside of this method is that when warm weather arrives, you will have to put in a lot of effort to remove such insulation.

Photo: Instagram @okno_ekb

Photo: Instagram @too_pillaris

Sealing cords are made from rubber, PVC, polyurethane and polyethylene foam. The most budget option is polyvinyl chloride and rubber seals, but in severe frosts they crack and break. There are also several forms of such a product on sale. Each of them is designed for gaps of different sizes.

- P-shaped - for medium ones.

- D-shaped - for big ones.

- E-shaped - for little ones.

The last two types of products are suitable for wooden frames. The installation principle is the same as with foam rubber. The difference is that some seals do not have an adhesive side and you need to buy glue or sealant separately. Another technical feature of the material is that it cannot be used to seal holes at temperatures below -10°.

Sealant and polyurethane foam

The last of 5 budget ways to insulate wooden windows. The sealant is ideal for sealing holes between wood and glass. At the same time, it is important to carefully select products in the store so that the dried glue remains transparent and does not turn brown.

Procedure

- Remove the glazing beads - thin parts that secure the glass. First pull out the bottom rail, then the side rails and finally the top rail. Elements may break, so stock up on new ones for replacement.

- Clean the groove from debris and grease, dry it and squeeze the sealant into it.

- Reinsert the glass and glazing beads.

You can coat the cracks on top without removing the glass. The temperature outside during work should be no lower than +5 degrees. In addition to silicone, the following are suitable for the same purposes:

- Paraffin. Heat it to a liquid state, pour it into the syringe and close the slots.

- Wood putty.

- A mixture of plaster and chalk. Mix them in a 2:1 ratio and dilute with water until the consistency of the putty becomes viscous.

Polyurethane foam is used to cover large gaps near slopes, frames, and window sills. The surface on which the foam is applied is prepared, moistened with water and the composition is applied in zigzags. Before use, the container must be shaken well and turned over for a few seconds.

A few rules:

- It is more convenient to blow with foam at positive temperatures.

- The frozen composition increases in size, so the holes are filled only ⅓.

- It is better to start sealing from the bottom.

After the layer of polyurethane foam has dried, all excess is cut off. The result will not look very aesthetically pleasing and can be covered with something, for example, gypsum putty, the proportions of which we gave a little higher. This is also necessary because the foamed seam cracks under the sun's rays.

Stores sell professional and household foams. The second option is suitable for your purposes. It can be applied without a special gun.

Both sealant and foam are good because they block drafts for a long time and reduce heat loss in the apartment. Both materials are easy to apply. The only caveat is that it’s better to do this with construction gloves and clothes that you don’t mind. This is especially true for polyurethane foam - it is not easy to clean and wash it.

- Window

How to install wooden slopes: instructions for 2 methods of fastening

How to tell if a window seal is worn out

The minimum service life of sealing rubber is 5 years. And with proper care, it lasts for 10 years. If problems appeared earlier, it is better to pre-adjust and tighten the fittings. Only if this does not help, you need to start replacing the rubber bands on the plastic windows. There are several main signs of wear:

- During the cold season, condensation appears on the profile around the opening sashes.

- The rubber band has visible defects: dents and cracking of the surface layer. It became stiff and lost its elasticity.

- There are signs of depressurization. The room quickly gets cold, and when there is a strong wind, it blows from the vestibule.

- In frosty weather, ice forms on the windowsill or the frame itself.

- The level of sound insulation has decreased. You can clearly hear the sounds of passing cars and people talking on the street. In strong winds, an increased hum and even whistling appears.

- Due to increased humidity, pockets of fungus or mold appear near weakened porches.

If it is not possible to call a technician to carry out diagnostics and repairs, the first thing you can do yourself is to lubricate the adjusting pins and move them to the “Winter” position. If nothing changes, proceed to replacing the tire itself.

Signs of seal wear

On average, seals last up to five years. If the following symptoms appear, you should make an urgent replacement:

- the house has become noisier, extraneous sounds from the street are heard more clearly than before;

- Condensation, ice appears on the windows, traces of mold are visible;

- dust on the windowsills began to accumulate in large quantities, it has to be wiped off more often than once every three to five days;

- the room is uncomfortable, there are drafts and you can hear the wind blowing;

- upon visual inspection, cracks and deformation of the material are noticeable;

- the seal has become hard;

- the heterogeneity of the shade of the sealant is noticeable.

Seal wear

Price table for seals for wooden windows

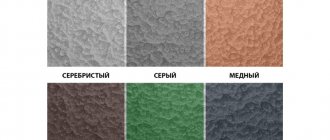

We offer a large selection of different types of seals in a wide range of colors: white, ivory, mahogany, brown, light oak, gray, black.

The cost is indicated per linear meter of sealant, taking into account the visit of the specialist and all installation work.

If you don’t find a similar seal in the table, don’t worry, call, the measuring engineer will definitely select an original or an analogue of the seal.

If a wooden window has been in use for many decades and a draft blows through its cracks, cold penetrates in the winter, and the roar of a motor can be heard from the street, then it is necessary to look for a way out of the situation. Today, this problem can be solved very simply - by installing a seal along the contour of the window structure.

Why do you need a seal and what malfunctions can occur?

A seal is an element that serves as sound insulation, thermal insulation, protection from drafts, condensation, etc. That is why it is one of the most significant elements of the system.

The most common malfunctions are:

- ice formation. This may happen because the seal has worn out;

- for the same reason, condensation may occur;

- Windows may allow drafts.

By replacing the seal, you can get rid of these problems and restore the former protective properties of your wooden window.

Carrying out compaction work

The seal has been purchased and you can begin installing it on the window structure. If the product has a self-adhesive surface, installation is performed in the following sequence:

- the working surface is thoroughly cleaned of dirt and dust, degreased and dried;

- locations on the frame or sash for gluing the seal are determined;

- the insulation is, if necessary, divided and then cut into pieces of the required length;

- the product, after the protective layer is removed from it without stretching, is attached with gentle pressure to a certain place around the perimeter;

- after 2 hours the window can be used.

A seal without a self-adhesive surface is installed according to the same principle, with the only difference being that you have to figure out the method of fastening yourself. You can fix the insulation with your choice of silicone sealant, rubber glue or using a stapler.

Another method of fastening the seal is called groove, and it is performed using Swedish technology.

- The sashes are removed from the window frame, and a channel of the required size is cut along their contour at an angle of 45º towards the flashing.

- A detour is made at the location of the loops, leaving up to 15 mm at each edge.

- Chips and sawdust are removed from the groove made.

- The tubular insulation is installed with a fold into the channel, after which it is pressed in with a roller, using back and forth movements to avoid tension on the product.

- The sashes are returned, and the functionality of the window is checked.

The insulation is installed - now there will be no blowing from the wooden window, it will be warm in winter, and the noise of vehicles passing nearby will not be heard.

Installation using Swedish technology

In modern windows, installation of the seal in the groove, known as the Swedish method, has become widely used. During manufacturing, a recess is made in the frames, into which insulation is subsequently placed. If there is no such groove, you can make it yourself:

- the sashes are removed;

- a groove is cut in the frame to the size of the seal mounting leg;

- and the width is made 2-3 mm narrower, the depth is greater than the leg by approximately the same value.

To ensure that the sealing material does not wear out due to abrasion, it is installed in such a way that it is compressed when the valves are closed. On the frame, this can be achieved by securing it from the front side, and where the hinges are located - from the end. For ease of threading the tape, a mounting roller is used. When working with it, in order not to stretch the material, the wheel is rolled in two directions.

Using the roller

Types of seals for wooden windows

Before purchasing a seal and installing it, you first need to study the range of these gasket products, and it has recently been quite rich and varied. The consumer needs to know that insulation materials differ in material, profile and installation method.

Depending on the installation method, seals are divided into:

- insulation with an adhesive installation surface;

- insulation materials that are attached using glue;

- insulation installed through a groove.

The tightness of pressing the sash to the frame largely depends on the cross-sectional size and configuration of the sealing product. A profile that is too thin will not provide the necessary pressure between the structural elements, and a profile that is too thick will interfere with closing the window. The configuration of the seal for wooden windows also affects the performance of the structure, therefore, for each specific case, one of the following profiles, which is similar to Latin letters, is selected:

- D - section for large gaps (size no more than 11 mm);

- P - section for medium gaps (size ranging from 3 to 7 mm);

- E, V - section for small gaps (size no more than 3 mm);

- C, I - section for small gaps (size no more than 1 mm).

The material of manufacture is of great importance for the quality of the seal, the characteristics of which determine the tightness of the fit of the sash to the frame and the service life of the product itself.

- Foam rubber seals are used primarily to prevent heat loss in rooms. Since this material strongly absorbs moisture and is fragile, its effective service life does not exceed 12 months. The above insulation materials are produced in thicknesses from 10 mm to several cm, with or without an adhesive surface.

- Polyethylene seals have an identical purpose; in addition, they are moisture resistant, restore their shape well, last a relatively long time, and can be produced as self-adhesive.

- Polyvinyl chloride seals, the basis of which is plastic, do not stand out in anything special - in warm seasons they soften greatly, and on frosty days they become brittle.

- Rubber insulation is the most in demand and popular today. They are heat-resistant and durable, elastic and flexible, and are made in different colors and sections.

Reviews about our work

Polina Nefedova 03/29/2019

My house has wooden windows. And at first I thought that this was a common phenomenon for them - drafts. But I saw on the Internet that the problem was with the seal. I came across . They quickly installed a new seal for me. And everything turned out very cheap. Very pleased.

Denis Bogdanov 04/10/2019

This is not the first time I have contacted you and I have never regretted it. The first time I ordered their services for adjusting aluminum windows in my office. And the last time their services were needed was at my home, when my wooden windows began to become covered with ice in winter. Then I needed to replace the seal. Everything was done quickly, cleanly and inexpensively. I was satisfied

Read all reviews

Why do you need a seal for wooden windows?

Window systems made of wood, although they are distinguished by high quality and environmental friendliness, are unstable in terms of operation. Under the influence of temperature changes, high humidity, ultraviolet rays and other aggressive environmental factors, they dry out, become cracked or swell with moisture. All these processes lead to the formation of gaps between the sash and the frame, through which cold, dust and street noise enter the room.

Thanks to the seal for wooden windows, you can hide the gaps that are forming and reliably protect your home from blowing out. The sealing layers are an elastic profile made of elastic materials (silicone, PVC, rubber, polyethylene), with a complex cross-section in the form of the letters P, C, D, E, V. Its main purpose is to tightly press the sash to the frame structure and eliminate drafts behind by closing the windows tightly.

Using a sealant for wooden windows gives homeowners many significant advantages:

- creating an ideal indoor microclimate;

- reduction in heating costs;

- ensuring high sound insulation of the house;

- reducing the level of humidity and dampness in rooms;

- Extending the service life of a wooden window by eliminating condensation and reducing wear on the sashes.

A high-quality seal for wooden windows will become an insurmountable barrier to weather influences and precipitation, and will also ensure more comfortable use of double-glazed windows and their better opening/closing without squeaking or popping.

Purpose of seals

The main function of seals is sound insulation. It is especially important to monitor the condition of window frames for those who have a kindergarten, a busy highway or other noisy place outside their window.

The next, no less important function is protection from dust penetrating through cracks. High-quality seals trap dirt particles, as a result, both the window sills and the entire room remain clean much longer.

The window sill stays clean longer if the seals are in excellent condition.

High-quality seals help maintain a constant air temperature in the house. If the material wears out or becomes deformed, air from the street enters the room through the cracks. In winter, your home becomes colder, and in summer, less comfortable. Instead of turning on the heater or air conditioner, it is better to take care of the condition of the window frames.

Seals are also necessary to maintain an optimal level of humidity in the house. The need to replace seals becomes especially noticeable in rainy weather, when tiny droplets of water seep into the house. Moisture-resistant materials such as rubber and silicone trap steam and droplets from the street.

It is worth taking care of the condition of the seals so that the house is dry and warm

On a note!

Tightness depends not only on the seal itself and the material from which it is made, but also on the type of installation (gluing, etc.). In addition, even the highest quality product can be ineffective if the installation is done poorly. To avoid this, we recommend that you carefully read the step-by-step instructions described in detail below.

Soft and elastic seals increase comfort when using windows. Frames do not slam, close quietly, the risk of deformation of double-glazed windows is reduced and their service life is increased.

Windows will not slam loudly when closing if the seals are soft and elastic enough

Replacing seals on plastic, aluminum windows and doors

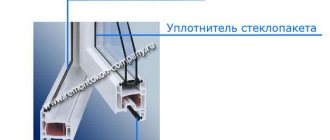

Window seal

- This is a rubber seal that is placed in a groove along the entire perimeter of the window sash and frame. The seal creates a tight connection between the sash and the window frame, thereby protecting the room from cold, moisture and noise.

If your windows are no longer new and they have ceased to fulfill the main task of keeping the house warm, and they have also begun to let in dust and noise, then the problem may be a worn-out sash seal. Our specialists will select the required type of seal and replace it. You can buy a seal at retail starting from 1 meter in our office and replace it yourself

It is not enough to simply replace the rubber with a new one; after installing the new seal, it is important to adjust the windows to fit it. Therefore, after installing a new seal, the craftsmen will adjust the windows to the new seal and also lubricate the fittings

Below are the prices for seal replacement per linear meter of seal. The price includes labor + materials. An average of 8 meters of sealant is spent on a single-leaf window (sealant on the sash and frame).

| № | Service | Price, rub.) | Units |

| 1. | Replacing the seal in plastic windows | 130 | p.m. |

| 2. | Replacing the seal with the German Schlegel Q-Lon seal in plastic windows | 250 220 (until October 1) | p.m. |

| 3. | Replacing seals in aluminum windows | 190 | p.m. |

| 4. | Replacing seals in wooden windows | 200 | p.m. |

| 5. | Replacing the seal with the German Shlegel Q-Lon seal in wooden windows | 270 | p.m. |

| A technician's visit to St. Petersburg costs 500 rubles. |

Call us on phone; and we will quickly come to your aid.

Why you should order a replacement seal from us:

- We work strictly according to the price list that each master has with him

- We employ craftsmen who specialize in window repair, not installation.

- We provide a guarantee for the work, as well as documents for the work performed

- the technicians arrive at the exact time you set

- high-quality materials, as well as low prices for services

Seal care

All products must be maintained to prolong their service life. The care procedure is simple and not particularly labor-intensive.

It is advisable to clean not only window frames, but also seals twice a year (before the winter season and, accordingly, before the summer season), without using aggressive chemicals. After cleaning, the seals should be wiped dry and then applied with a protective agent that contains silicone. You can also use glycerin or petroleum jelly (except EPDM). This is necessary to maintain the elasticity of the material.

Silicone grease for rubber seals

Seal lubrication

Advice! If dirty renovation work is being carried out in a room, it is better not to open the windows wide so that dust and particles of construction mixtures do not settle on the seals.

Prices for various types of silicone lubricants for rubber seals

Silicone grease for rubber seals

Other types of products

Window insulation can also be obtained from the following substances:

- PVC. The materials are distinguished by a relatively simple manufacturing algorithm and low price, which has led to their fairly wide distribution. Disadvantages include poor elasticity and thermal stability, as well as loss of plasticity after exposure to low temperatures.

- Thermoplastic rubber. The material has excellent springiness, which gives it unique properties. This substance also lends itself very well to heat welding. Disadvantages include decreased elasticity at low temperatures. Modern modifications of TPE V and PP/EPDM seals are distinguished by their high-quality heat resistance and ability to retain their shape.

When choosing a seal for plastic windows, first of all you need to consider what problems it should solve and only then make a final decision.

Foam rubber

If complete blocking of windows for the winter is not considered, insulation with foam tape is a suitable option. It is sold in rolls of various sizes and has an adhesive side, due to which it is attached to window sashes.

Before sealing, for a tighter adhesion, the frame must be washed, cleaned of flaking paint and dried well. Having removed the protective layer from the adhesive side, the foam tape is attached around the perimeter of the window, closing all the cracks. In case of severe distortion of the frame and the appearance of wide cracks, the sealant is glued in several layers.

As the weather warms up, you don’t have to remove the foam rubber. If the adhesive base is of sufficient quality, the seal will last at least 2 seasons.

Polyester film

Transparent metal-coated film was initially used to increase the thermal insulation properties and strength of glass, but over time it began to be used to insulate the entire window leaf. The polyester base makes it visually invisible. The film completely transmits sunlight, but at the same time acts as a barrier to heat leaving the room.

Before applying the film, the glass and frame are washed, dried and degreased. Large cracks are sealed with window putty. Double-sided tape is glued around the perimeter of the window, onto which a film pre-cut to the size of the window is attached. To avoid leaving fingerprints, work is performed with gloves.

When the temperature changes, condensation may form in the space between the film and the glass. To prevent its appearance, you can pour a little silica gel or salt into the corners and along the bottom joint, which will collect excess moisture.

Often internal insulation is not enough. Along with thermal insulation of the frame, it is important to periodically inspect external slopes and ebbs for cracks. The cracks are sealed with foam or polystyrene foam, primed, and painted. Install a bar to drain rainwater. If you approach the issue comprehensively, then the heat from a wooden frame will be no less than from a plastic double-glazed window.