Currently, many city dwellers strive to have, if not suburban housing, then a garden plot or a dacha. Most often, bathhouses are built first on cottages and garden plots. But building a good Russian bathhouse is a rather complicated and troublesome process. Therefore, when constructing a bathhouse, many different conditions and safety regulations must be taken into account and observed.

A log sauna is usually made of three components. Firstly, this is the dressing room, which serves as a locker room and rest room. This room must have an area of at least 3 square meters; the optimal size is considered to be 1.8 x 2 m.

Secondly, the main parts include a small steam room and a washing room.

General characteristics of the technical side of bathhouse construction

When building a bathhouse, it is necessary to take into account many nuances, from the selection of the type of wood from which the frame will be assembled, to the size of windows and doors.

For example, during construction you need to know that it is advisable to install the entrance door to the bathhouse on the south side, since in winter it will be less covered with snow, and in the spring the snowdrifts in this part will melt first.

It is recommended to place the windows in the dressing room on the southwest side, in which case you will be able to enjoy natural sunlight for a long time in the evening.

It is also advisable to install the front door taking into account the directions of water jets from rain, which are typical in the area. If these parameters cannot be taken into account, then it is better to build a vestibule in front of the bathhouse to protect the door and porch from water and swelling. The bathhouse should be located on the site so that the entrance door to the bathhouse and the building itself are clearly visible from the window of a residential building.

Waiting room

If we consider it literally, the dressing room is a place located in front of the bathhouse, in which you can comfortably prepare for bathing ceremonies. Windows are mainly placed on the façade.

Sometimes compact windows are placed above the stove. The dressing room can be installed in different sizes and shapes. The presence of a window provides additional lighting and ventilation.

Parameters and sizes of windows in the bathhouse

Windows in a Russian bathhouse are usually made small. The experience of builders has shown that the optimal dimensions are as follows: height about 40-60 cm, and width 60-70 cm. After all, very bright light inside the bathhouse is hardly needed. The glazing area (window sizes) is usually no more than 5 percent of the shelf area. It is better to place the window in the dressing room at eye level of the person sitting on the bench, so that while relaxing from the steam room you can admire the sunset. In addition to aesthetic considerations, it is customary to place windows low above the ground, since this position allows for better heat retention in the room. Most often, windows are made square or rectangular, but this is not at all necessary.

Previously, in a smoky bath, the upper edge of the window was made no higher than one meter from the floor level. Currently, many steam lovers still prefer to install windows according to the same requirements.

Nowadays, many people glaze using double wooden windows. Double frames are placed at a distance of 10-15 cm. In order to improve the ventilation of the bathhouse, it is advisable to install windows that can be opened as wide as possible. It is not advisable to install locks and latches made of metals that are susceptible to corrosion on the internal frames of windows. Since in conditions of high humidity they will quickly become unusable.

Windows are often not installed in a steam room, but it is better to install them on the wall on the west side, just below the ceiling, usually at a distance of 60-80 cm. With this location of the window, more sunlight is used.

Combined

Such modern designs have a very high price. But their quality and basic characteristics are significantly superior to models made from only one material. Combinations of wood with metal and plastic increase all the positive properties and brighten up other disadvantages.

Methods for producing combined windows:

- The frame is made of either plastic or aluminum. The inside of the window is then covered with wood trim.

- A wooden frame is made. Then it is sewn up on the outside with aluminum or plastic panels.

- The design has two frames. The outer one is made of metal or plastic. The inner one is made of wood.

The second and third methods are suitable for windows that can be installed in a steam room. Because all problematic materials remain outside, and only natural ones are inside. Therefore, it is impossible to inhale harmful fumes or get burned on heated metal.

Combined window made of wood and aluminum Source okna-fresh.ru

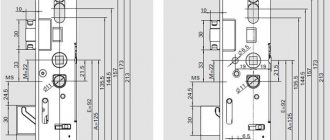

Parameters and sizes of doors in the bathhouse

The bathhouse door is also made low and relatively narrow in order to reduce heat and steam loss. The optimal doors are those with dimensions of 1.5x0.8 m. It is better to install the door so that it opens outward, and it is better to install the metal structures that help open the doors on the street side. As a rule, the entrance door is installed with a single leaf.

The door in the steam room is also made of wood, but its surface is covered with a heat-insulating layer of felt or mineral wool. This room has high humidity, so it is better to use brass hinges and install them with screws made of the same material. Latch and English locks are only installed on entrance doors; they are not installed in double rooms due to the possibility of accidental slamming. The door handles in the steam room are made of wood.

The doorway in a steam room is made no more than half a meter high, and the threshold is as large as possible, the height of which can be up to 20-30 cm. With this device, when opening the front door, less steam will escape from the opening, and cold, on the contrary, will not enter. The steam room door is usually made so that it opens towards the washing room. All bathhouse doors usually open towards the exit from the room.

It is very difficult to build a Russian wooden bathhouse with your own hands, taking into account all the requirements; it is much easier to order a turnkey bathhouse from a construction organization. In this case, you just need to choose the bathhouse design you like.

Why is it important to know the standards?

It is necessary to strictly follow the recommendations for the dimensions of bath windows. The products perform several important functions. Non-compliance will lead to a violation of the window's performance characteristics:

- Ventilation. If it exceeds the optimal values, heat will be lost. The design will not be able to provide the required tightness. It will only perform the function of ventilation, but when closed it will not be able to maintain the microclimate of the room.

- Illumination is the second task of glazing. The bathhouse is not intended for the penetration of other people's views. Therefore, the location and dimensions of the openings must meet the requirements. If the dimensions are smaller, the room will be dark. If it is more, heat loss will increase.

- Safety. Dimensions must allow escape from the premises in case of fire or other dangerous situations.

- Decorative. Designs that are too large or too small significantly reduce the aesthetics and harmony of the overall appearance of the bathhouse.

By maintaining ideal dimensions, you can maximize your comfortable stay in the bathhouse.

What windows are installed most often for a bath?

Each of the rooms in the bathhouse, except perhaps the utility room or storage room, should be equipped with a window. This is required by safety regulations. In addition, the presence of daylight improves comfort, and, most importantly, if necessary, any vapors and gases are removed from the bathhouse using an open flap.

You can determine the parameters of the window in the bathhouse from the following considerations:

- The corridor, locker room, and washing room are usually equipped with a small window, if possible on the sunny side of the building. The window opening directly depends on the area of the room; SNiP recommends that the window area be at least 5% of the floor area;

- The dressing room must be equipped with at least one window. The location of the window opening should be opposite the entrance to the room from the corridor. The size of the window opening without internal bulkheads is made at least 5-7% of the floor area of the dressing room and entrance door;

- In the rest room, size does not play a special role; most often these are plastic windows of the usual design. The geometry of the window opening and its location are determined by the vegetation and buildings surrounding the building;

- In a steam room in a bathhouse, they most often try to keep the window area to a minimum. A window is necessary only for reasons of safety and ease of maintenance of the room.

Overview of species

The presence of a window in a log bathhouse must be thought through during the design process; moreover, it is an integral part of such a room. Although a sauna does not require natural light, the structure is required to provide ventilation. The market offers different product options from leading manufacturers, each of them has its own features, technical and operational characteristics, as well as advantages that attract consumers. Therefore, you can consider each type of window separately to figure out which design will be the best choice for use in a bathhouse.

Wooden

The modern market often offers products made from natural wood, which have become quite popular. In addition, the material undergoes special processing, due to which the structure becomes resistant to moisture, various temperatures and other atmospheric factors.

It should be noted the main advantages of natural wood - it “breathes”, therefore a favorable microclimate is created in the room, and this is important. Frames made of alder and linden look noble and aesthetically pleasing, and also add solidity to the interior

A wooden surface can accumulate heat well, and you can’t do without it in a bathhouse. Of course, over time the structure will have to be restored, but this does not take much time, and besides, it can be restored to presentability without any problems. Scuffs or scratches do not appear on the surface of the wood so quickly.

With a little skill and time, you can independently make a window with the required dimensions and shape for a steam room, and it is also several times cheaper than ordering a factory design. Of course, you will have to take care of choosing a quality breed that will be stable and durable. Wooden windows also require special care to maintain their integrity and beauty.

The cost of such structures is an order of magnitude higher than other analogues, but many prefer this option because of its environmental friendliness. To prevent damage from mold or insects, the product will need to be carefully maintained. But these small disadvantages do not outweigh all the advantages.

The most unpretentious option is considered to be pine, which is easy to process, moreover, it has high resistance to moisture and will not be afraid of temperature changes. As for strength and durability, larch, oak and beech are in great demand for these indicators, from which bath windows are often made. But since people often go to the sauna not only to relax, but also to improve their health, you can consider such types of wood as aspen, ash, linden, which, when heated, emit a pleasant smell and have healing properties.

Plastic

This option has been in great demand for many years. The popularity of PVC structures cannot be denied due to the number of advantages that they have. Such products are great not only for residential but also commercial premises, so they are also often used in saunas. However, it should be understood that the plastic structure cannot be placed in a place where the temperature is too high, which can negatively affect the material, so other options are more suitable for the steam room.

Temperature changes are also not so dangerous for this material. A huge advantage of double-glazed windows is that they are sealed and easy to care for. Such products are offered not only in white, but also in other shades, some of which can imitate natural materials, such as mahogany or pine.

Combined

During the production of such structures, metal, wood and plastic can be used in different proportions. For example, on the market you can find wood-aluminum windows, wood-plastic, aluminum-plastic and others

Thanks to the combination of several materials, the durability of the product increases significantly, as well as its energy-saving properties, which is no less important. Wood-aluminum and wood-plastic combinations are in great demand.

Such windows can also be used in a steam room without any problems, since the metal or plastic part of the structure is located on the street side, and all connections will be sealed, and the risk of burns is minimized.

Features of choosing window size and material

Most recommendations for choosing a window design and its size are based on practical experience of use and recommendations for providing lighting in non-residential premises.

Window in rooms reserved for recreation

There are no special requirements for the windows of the corridor and dressing room of the bath; most often these are small transoms measuring 20x40 cm, intended mainly for ventilation and ventilation of the room after sanitary treatment. In most cases, these are plastic transoms that are not suitable for full opening throughout the entire opening. Blind window structures are not used in such rooms.

In the rest room, windows are made according to the same scheme as for ordinary living rooms of a private house. Double-glazed windows made from PVC profiles or metal-plastic structures are considered a good option. Depending on the location of the bathhouse and the presence of trees, outbuildings, and pedestrian paths in the area adjacent to the building, the size of the opening can be made in full size, for example, 70x100cm, or in the form of two small horizontal window transoms measuring 40x100cm on the sunny side of the building .

In this case, the lower edge of the window opening is most often raised to the level of human height. This allows you to ensure normal lighting of the room, while protecting those in the room from prying eyes. If the building is built from wooden beams or rounded logs, the most organic would be to make windows in a wooden frame. Small windows without a window are most often made with your own hands. For a new bathhouse made of timber, installing a frame even of a small size always involves the need to take into account the vertical shrinkage of the walls, which can cause the frames to become deformed and cracks to form in the glass.

Therefore, in such cases, frames can be installed on a layer of silicone sealant instead of traditional blowing with polyurethane foam. The high thermal conductivity of rubber will require additional thermal insulation around the perimeter of the frame. If the bathhouse does not have a heating system that allows you to maintain normal thermal conditions, in this case it is recommended to limit yourself to one window and make it two or even three-chambered.

Regardless of the time of year and the air temperature outside, this design and size of the window opening will lead to the appearance of a strong draft. In a number of cases, thanks to such ventilation, smoke and fumes from the chimney entered the room.

If the bathhouse is located in a holiday village, large window openings will require the installation of protective grilles or roller shutters, which can protect the bathhouse from penetration, but will increase the cost of construction.

Window sizes for shower, dressing room and steam room

In the waiting room, the presence of natural light is due to safety requirements. Most often, a small window 40x40, 40x50cm is installed in such a way that daylight illuminates the entrance to the room from the rest room or locker room as much as possible. In some cases, a small window frame is made directly above the stove firebox and ash pan.

The frame design must provide two modes: full opening and ventilation mode. This allows you to quickly and effectively ventilate the dressing room or open the door in ventilation mode if necessary to get rid of the smell of burning or combustion products that have gotten inside the dressing room. The size of window openings should be such as to avoid large heat losses through the glass. The best option would be plastic windows.

In a washing or shower room, effective ventilation is necessary to ensure that condensation is removed from the surface of the walls and floor. For effective ventilation of a shower room measuring 1.5 m2, a transom measuring 20x40 cm is sufficient.

The most controversial issue is installing a window in the steam room. Firstly, even small-sized glass increases heat loss by 5-7 times. Secondly, the air temperature in the steam room is so high that it leads to cracks in the glass. In addition, constant temperature fluctuations can lead to the appearance of cracks and deformation of the frame. In such conditions, PVC frames are unsuitable for a steam room, so the only option would be to use a sauna window frame made of linden or alder. Despite all the shortcomings, a window opening in a steam room, even of a small size, allows you to quickly and effectively ventilate the room in case of smoke or the formation of a large amount of carbon monoxide.

In some cases, the window opening in the steam room is closed with a special plug or shield assembled from lining and heat-insulating materials. And although this method can significantly reduce heat loss, it must be used extremely carefully, since a sharp change in air temperature in the steam room and cold street air can lead to deformation of the frame and the appearance of cracks in the glass.

Most often, a window for a steam room is ordered from craftsmen or specialized workshops. In this case, heat-treated wood and tempered glass are used. Even a small window opening can effectively reduce the temperature in the steam room, ventilate and dry the room after sanitization. In this case, it is used in conjunction with a small hole with a wooden valve installed at a height of 10-15 cm above the floor level.

Installation of canvases

Installing windows is a rather labor-intensive process. If you have never installed canvases before, entrust the work to specialists.

Installation of a wooden window (stone baths)

The process consists of several stages.

- Measuring openings. The work is performed using a tape measure, plumb lines or level. The area is cleared of any kind of contamination.

- Installation of windows. The canvases are usually attached in three ways - using anchors, dowels and blocks. The most commonly used are dowels. Holes are drilled in the frame, then the structure is inserted into the opening, after which it is leveled, and then the places for the dowel sleeves are marked. The frame is set aside and holes are drilled in the walls using a hammer drill. At this stage, the dowels are driven into the holes, the frame is inserted, nails are driven into the sleeves and all gaps are filled.

Installation of a wooden window (wooden baths)

The work will not cause difficulties if you do it step by step.

- Measurement. The work area is cleared. The height and width are measured.

- Casing (casing). The box protects the canvas from the harmful effects of negative factors. It is made from bars. A small gap is left between it and the wall. The casing is fixed using a tenon or embedded beam. The first method is most often used: a tenon is cut on the side walls of the opening, and a groove is cut on the casing, then the elements are tightly connected.

- Installation of canvas. The frame is inserted, leveled, connected to the frame and secured with fasteners.

In principle, the work is not difficult, but it requires a responsible and painstaking approach.

Installation of plastic sheets (wooden baths)

The work consists of two stages.

Manufacturing of casing. The process looks like this:

- a groove is cut out;

- the work area is cleared;

- a block is cut out;

- insulation is placed in the hole made in the opening;

- the block is fixed;

- attached to the frame of the box post;

- lower and upper jumpers are installed;

- holes near the jumpers are insulated;

- a window structure is inserted into the frame;

- platbands are fixed.

Window installation after shrinkage. The following work is performed:

- the casing is removed;

- cracks are sealed;

- wood is treated with antiseptic compounds;

- foil tape is fixed;

- the window block is attached;

- a window is installed;

- the position of the canvas is checked;

- the frame box is fixed;

- the gaps are filled with foam;

- the hardened polyurethane foam is cut off;

- platbands are tightly fixed;

- the ebb is installed at an angle from the opening and the gap is foamed.

Yes, it’s still a lot of work!

Are there technical standards?

This is what Finns do in a public sauna, by the way.

We studied SNiP II-L.13-62 “Baths. Design Standards (with Changes)” in search of an answer to this question. However, it does not say anything about the size of the window in the bathhouse, only that yes, windows are needed, and they must be made with glazing suitable for winter frosts. If you are suddenly interested, then double glazing up to -40 degrees according to SNiP , and if in winter the temperature drops below -40, then triple glazing.

A couple more tips from the same document:

- It is recommended to install transoms and vents in windows for ventilation (which is why we have a sneaking suspicion that the windows themselves are meant to be blind, that is, without the ability to open).

- It is better not to make wooden window sills in wet rooms at all. Make them out of something else and cover them with glazed tiles.

However, this SNiP talks about the construction of public baths, so its applicability in a private bath is rather conditional.

Nuances

When choosing sizes for windows in a bathhouse, one should not forget that structures larger than 50 by 50 cm require a window, which adds to their cost. Also, when choosing dimensional characteristics, it is necessary to take into account that it will be difficult to install a mosquito net on windows that are too small, which is simply necessary in many regions. In addition, large window structures must be placed at eye level in order to see what is happening on the other side, which means that when choosing a size you must also take into account the height of the room.

The window should fit into the overall appearance of the bathhouse and in size too

When deciding what size the window openings in the bathhouse will be, do not forget about drafts. In order not to create a direct flow of air through the rooms, it is necessary to place windows not on opposite walls. In addition, there should be only one large structure, and in other rooms it is necessary to install more compact windows. This approach will make it possible to effectively ventilate the bathhouse and not create unnecessary discomfort. Only one conclusion can be drawn from the information provided - one must approach the determination of sizes very carefully and consider this issue from different aspects.

Heat loss and good sides

Since there are no technical standards, we have to rely on common sense: that’s why, traditionally, small windows are installed in the bathhouse ? Correct answer: to reduce heat loss. But the question is, is the situation with glass still the same as one of the main sources of heat loss? After all, double-glazed windows that cope quite well with retaining heat indoors.

In addition, if desired, you can also make a coating on the glass, which reflects heat into the room . Although this will increase the cost of installing such windows.

By the way, we found a completely scientific description of the heat loss inherent in double-glazed windows. It says they occur either by infiltration or transmission. In the first case, we are talking about the penetration of air into the chambers of the glass unit under the influence of wind and heat pressure. In the second, we are talking about the thermal conductivity of the window materials themselves.

Calculations carried out by engineers say the following (the wooden window taken for comparison means an old-style window):

Below you can see a graph that shows the relationship between the window area and the associated heat loss:

In other words, the more you take care of the protective properties of the window structures you choose, the less reason there is to follow tradition and make small windows in the bathhouse .

However, small windows will cost less and will not require investment in infrared reflective film.

Well, here everyone will choose for himself what he likes and can afford. We are only clarifying that in our time the old restrictions are no longer relevant.

As for the good sides, everything is simple and obvious:

- firstly, with windows, the bathhouse is ventilated and dried faster, although for drying, the stove will still be even more important.

- secondly, sunlight enters through the windows, which is always better than artificial light.

- thirdly, windows in the bathhouse guarantee that visitors will not experience discomfort from the enclosed space. And if the view outside the window is beautiful, then they will also admire it during the procedures.

Well, in fact, there are not so many options for windows for a bathhouse, but with sizes there is complete freedom. You can choose from finished products to suit almost any taste or for any design project.

So, you can install either plastic or wooden structures. If you want to get acquainted with the nuances of the construction of both, read our articles on plastic and wood in the bathhouse.

Here we will touch only on the most basic points related to the material from which the frame is made.

Plastic

The wave of popularity of plastic has made it conditionally suitable for installation in bathhouses.

One conclusion follows from the above:

small plastic shower window

there are also those who put quite large windows in the steam room

The sizes of plastic windows can vary widely: from a tiny window of 20x30 or 30x30 cm, which is only enough to stick your head out of, to the standard size of a plastic window in an ordinary residential building. Of course, they will make a window of any size you require, but usually the largest is standard for residential premises. And by the way, it is usually placed in the rest room or dressing room.

Wooden

There are old (Soviet) wooden window structures and new ones. The latter are distinguished by the fact that they have the same double-glazed windows as in plastic, but the frame is made entirely of wood. The old ones suffered from the following disadvantages: they were not airtight and released up to 70% of the heat from the room.

A modern wooden frame with double-glazed windows can be used as a window for a bathhouse; The dimensions are also determined primarily by the project approved by the customer. Because such a frame (like a plastic one) is manufactured based on the results of measurements of the client’s window opening.

In principle, the profile of a wooden window frame can be viewed when choosing from most major manufacturers. It looks like plastic, but it doesn't have internal voids like that one.

If we talk about the advantages and disadvantages, then wood, of course, is preferable due to the fact that it does not emit volatile organic and inorganic compounds like plastic, but this is only if it has not been treated with various impregnations or varnishes that protect it from high humidity and temperature . And if the wood is not treated, then it should not last in the bathhouse - it will rot, develop mold, etc.

Regarding the size of the window in the steam room, there are no agreements between bathhouse lovers, there have not been, and it is unlikely that they will ever be reached.

The trends are as follows: some say that windows are needed for rapid ventilation , so the size needs to be appropriate (not too small).

Others believe that a window is needed to stick your head out through it when your body is steaming with might and main.

Still others care about emergency exits , therefore they believe that the dimensions of the window should be such that in the event of a fire it is possible to leave the bathhouse through it. (Their opponents believe that such a window is also convenient for getting inside.)

For the fourth, a blind window is generally enough, as long as sunlight penetrates through it.

In general, there are no better or worse options here. The minimum size, as mentioned above, is 20x30 or 30x30 cm.

Windows are often placed in the steam room in the following size range: height from 40 to 60 cm, width from 60 to 80 cm. As you can see, there is freedom to vary the degree of elongation of the rectangle.

A window with a length of a meter or more on one side is a rarity in a steam room.

Steam room design

It is best to design an option with an area of 3 by 4 meters. Its height should be 2.10 - 2.15 meters

As a result of the design, the functionality of the steam room in the bathhouse is optimized. Correct developments at this stage contribute to the organization of effective recreation, saving money on construction, arrangement and finishing. The design of a private steam room at the dacha takes into account the number of visitors, and the dimensions of the building depend on this. Sometimes a bathhouse is attached to a house, but this arrangement has its drawbacks.

The project and documentation for construction includes sections:

- plan for the construction of the foundation, walls, roof;

- layout of internal rooms, their convenient location;

- water supply and sewerage design system;

- electrical wiring, connection diagram to the main source;

- ventilation system plan;

- procedure for installing heating equipment, water heating boiler.

Premises requirements

In the steam room of the bathhouse, effective ventilation or a circuit with air recovery and purification must be installed. The system is cleaned regularly, once a year, and disinfected.

GOST 32.670 – 2014 contains general requirements for steam rooms:

- if the sewerage system is not connected to a common collector, provide a local drainage and liquid collection scheme;

- the water supply system must regularly supply water of appropriate quality;

- Lighting must be installed in the steam room, the number of points is calculated according to the norm

- before visiting the steam room, a person should have the opportunity to leave things in the dressing room or dressing room;

- hair drying units, scales, foot baths, washbasins are placed in a room that is located separately from the steam room;

- Organize rapid removal of water from the floor so that it is not slippery.

The steam room uses materials that can withstand high heat and high humidity, without releasing components harmful to health into the atmosphere. The room is equipped with single-tier benches, two-tier shelving made of timber and hewn logs with wooden shelves to make it comfortable to rest.

Optimal sizes

To save space, multi-tiered shelves are installed in the steam room to accommodate more people.

The installation of a bathhouse with a steam room requires compliance with height standards. The parameter does not go beyond 2.1 - 2.4 meters to ensure high-quality heating of the interior space. The width is planned depending on the number of shelves and their location. There may be a stove in the steam room, or it can be taken out to the dressing room. If the heater is located in a steam room, this is taken into account when drawing up the room plan.

To save space, multi-tiered shelves are installed in the steam room to accommodate more people. Stepped shelves are made of such a height that a person sitting on the upper bench can rest his feet on the lower bench, and a person can also climb the steps to the upper tier. A separate bench is made for the bathhouse attendant, the height of which is planned to be 70–90 cm.

The first level of shelves is placed 40 - 50 cm from the floor. Benches for sitting are made 60 cm wide, and a width of 91 cm provides comfortable lying. The length of the shelves is 1.5 meters or more, so that you can stretch your legs. The sauna seats are 50 cm wide.

Location of the stove, windows, doors

Most often, doors and windows for bathhouses are made of wood.

The stove is placed in the dressing room to ensure continuous heating if the steam room is working. No trash and fuel will be brought into the room; you can organize drying of firewood next to the fireplace. The sauna has clean air because there is no carbon monoxide, and space is saved in the steam room. The stove takes air from the dressing room, so forced ventilation is installed there.

Windows in a steam room are not always made, but the opening can increase comfort if it has a panoramic viewing function. They use special designs of double-glazed windows with tempered glass, and put a rubber or wood lining on the handle so as not to get burned on the hot metal.

In the rest room

But in a bathhouse, in a relaxation room, window sizes of more than a meter on one side are quite normal. This room is perceived as a living room, like an ordinary room in an ordinary house, so there is often a full-size window there (but not for everyone, of course), and sometimes upholstered furniture is placed there.

Bathhouse with a large relaxation room

Some people opt for two windows at once in the rest room. Moreover, they can be located either on one wall or on adjacent or opposite ones.

Of course, if there are two windows, then their sizes may be smaller. As for the location, it is especially not recommended to place their friend opposite each other on opposite walls. You will not only get a strong draft, but, under certain circumstances, smoke from the stove may also fly inside.

Insulation of the room

Attach the foil material with the reflective side facing towards the room

It is better to insulate the steam room inside than to install an insulator outside. The peculiarities of the room are such that steam and high temperature must be kept in the room, and with external cladding, part of the energy is spent on heating the wall. Condensation that appears on vertical fences will lead to their deterioration and gradual destruction from rot.

Insulation used:

- mineral, stone wool, slag wool;

- foil foam, penoizol;

- extruded polystyrene foam.

Mineral wool quickly becomes saturated with moisture from condensation and steam, so its operation requires a counter-lattice to create ventilation. This design makes an already small room smaller. Foil material, which is not moisturized and has a small thickness, works more effectively.

Burnt limestone or quicklime

Chalk, or carbonated lime for walls, has extensive use in the preparation of adhesive paints, being part of their composition alone or for whitewash, as well as for the preparation of putties and putties. The best varieties of chalk are called fused chalk, which is obtained by grinding nuggets.

In Russia, chalk is found in a fairly pure form that does not require processing, in the Kursk province and is known in trade under the name Belgorod chalk, especially putty chalk, sold in sacks. The so-called Swedish fused chalk is widely used in painting. In recent years, excellent quality Vyshgorod chalk has appeared on sale - melted and putty.

Lime for whitewashing walls is obtained from limestone or calcareous stone, which is found in different areas. Limestone often contains clay or ferruginous components. In the latter case, it has a bluish color and has great density and hardness.

Lime can be obtained by burning limestone in special kilns for several days in a row. At the beginning of firing, thick black suffocating smoke with a peculiar odor will be released from the furnace, which then gives way to white, which is one of the signs of the transformation of limestone into lime.

Burnt limestone provides quicklime, or caustic, lime in pieces, often called limestone, which exhibits caustic properties that quickly destroy organic tissue. When left in the air for a long time, this lime absorbs carbon dioxide from it and becomes weaker and weaker and less suitable for use.

A little about the disadvantages of PVC double-glazed windows

All manufacturers are silent about the shortcomings of plastic double-glazed windows in bathhouses. But just open the forum and read the reviews. Among the most popular negative reviews, I would like to highlight a few:

- At high temperatures, low-quality plastic can become deformed. Therefore, you should not install PVC windows in the steam room.

- Condensation accumulates on the glass, flows onto the wooden trim, the lining under the window sill has turned black and has begun to rot.

- When heated, the plastic began to smell unpleasant.

- The glass unit burst while heating in the steam room.

Considering the disadvantages that users write about, it becomes clear that when choosing windows for a bathhouse, you need to buy high-quality ones and install them anywhere, but not in a steam room.

Indeed, inexpensive Chinese plastic can melt at high temperatures and at the same time release toxic fumes. In such a bath you can even get toxic poisoning. High-quality German or Russian plastic windows are manufactured using the latest technologies and are able to withstand temperatures from +90 to -80 degrees. Another thing is that a non-professional cannot determine quality by eye.

General installation questions

So, first you need to measure the window and the opening area.

For this purpose you will need 2-4 cm bars and a building level. The bars should be placed first from below, and then from above. And it is important to ensure that the openings are completely identical along the entire perimeter - which is why you took a level with you

In any case, when choosing a window for a bathhouse, it is important to be guided by the following criteria:

- How reliable is the design?

- What is the size of the windows in the bathhouse and are there exactly those available, and not “approximately”?

- Is it suitable for the climatic conditions of the area where the bathhouse is located?

- Is the window designed for large temperature changes and high humidity?

- How tight is everything?

- Is it safe to use this window in a sauna environment?

- Will it be possible to install the window myself, or will I have to call a special team?

As for installation, plastic windows and doors for the bathhouse are secured using aluminum corners, after which they are filled with polyurethane foam

And after exactly one day, you can begin to carefully remove its remnants.

And you can decorate your bath window with a chic stained glass window made by yourself from film material - on any theme and any style.

There is also an interesting fact: you can insert double or triple glazing into almost any frame of a regular window - and the result will be no worse than a regular plastic window. It just needs to be milled to the depth of this package, that’s all. And decorative film, lintels and other fashionable fittings are not a problem at all. And what is the advantage of such a window? The fact is that in the bathhouse with him it will be both warmer and quieter. And if you do all this on the basis of a regular aluminum profile, then it will be even better: such a window will not “lead”, it will not dry out, will not heat up, and you can even put handles on it. In addition, if the installation of windows in a bathhouse is ordered for someone, it will not be cheaper than the window itself. That’s why many people today do it on their own. And it's not difficult.

Let's summarize: beautiful windows for a bathhouse that fit perfectly into the interior are not only decor or an important part of the original interior. This is also a guarantee of heat preservation. Therefore, choosing a window and placing it in the steam room only needs to be done thoughtfully and competently.

Do-it-yourself high-quality drying oil from sunflower oil

Caustic quicklime for whitewashing walls is converted into slaked lime before use, which is achieved by slaking it with water. Caustic lime is placed in the box designated for slaking and a sufficient amount of water is poured onto it, and slaking occurs, that is, strong absorption of water. At the same time, the lime becomes very hot, boils and emits a lot of thick steam;

If a lot of water is taken during slaking, then the lime will weaken its strength, and if not enough, then unslaked and, therefore, unusable pieces will remain in the lime. These are the main aspects of how to properly dilute lime for whitewashing walls; if you follow them, then preparing a working solution will not seem difficult.

As for the amount of water required to slak the lime, it is not always the same and depends on the composition and quality of the lime taken. That is why water is not poured into the lime immediately, but gradually until all the lime is quenched.

Lime produces a very common strong white paint on water for cheap brick and plaster work.

Lime destroys organic colors, but with earthy ones it gives durable tones.

Spar, light and heavy, serves as an admixture in paints to reduce their cost; it does not affect the color, but weakens the roofing ability. The surrogate, although commonly used, is dishonest.

Most paints are diluted in oil, which can be of mineral, vegetable or animal origin. Mineral oils include petroleum, rock wax, etc.

In painting, oil and drying oil for wood are used exclusively of plant origin, extracted from the seeds of various plants and mainly flaxseed. You can find out which ones are suitable further in the article.

Vegetable oils are very diverse in their composition and are commercially available in solid (Japanese wax), thick (coconut oil) and liquid (linseed oil).

All vegetable oils when left in air for a long time oxidize, thicken and turn bitter.

Liquid and lubricating oils have the property of being viscous, harden and are able to form a beautiful elastic, rubber-like mass.

The second: wood, olive, almond, rapeseed, rapeseed, mustard, beech, castor, etc.

Flaxseed oil is extracted by pressing flaxseeds. Cold pressing produces the best type of oil with a pleasant smell and light yellow color, which makes it possible to eat it.

In oil mills, however, cold pressing is considered unprofitable due to the relatively low yield of oil and is replaced by hot pressing, and the resulting product will be darker in color with a strong odor. This unrefined oil is used almost exclusively for the preparation of drying oil (boiled oil).

As for the quality of the oil, it depends on the method of preparation and the quality of the seed from which it is prepared.

Since linseed oil is a rather valuable product, it is often mixed with various impurities that spoil its quality. The most common contaminant found in flaxseed oil is mineral oil. Such drying oil usually dries poorly and becomes tacky. If you look at it through the light, you will get a bluish tint, which, however, is not always noticeable, because recently they have begun to use well-refined mineral oil (colorless) as a mixture.

Of all vegetable oils, linseed oil is the most widely used in painting, representing the best product for preparing linseed oil.

Poppy oil is obtained from poppy seeds by pressing at ordinary temperatures, or by heating. In the first case, the oil will have a light color, a pleasant taste, and therefore such oil is usually used as food. In the second, the dark color and bitter taste due to the abundance of impurities make such oil suitable only for technical use, such as, for example, in the preparation of expensive dyes. This oil is rarely used for ordinary painting work.

Sunflower oil is extracted from sunflower seeds, which grow almost everywhere in Russia and are especially sown in Little Russia, the southern provinces and the Caucasus. The color of the oil is golden yellow, when fresh it has a pleasant taste and smell and is readily consumed. Sunflower oil is mainly used for preparing light drying oils and for diluting white and light paints. It dries much slower than linen. If prepared improperly, such drying oil becomes sticky and acquires a red tint.

The drying of vegetable oils is based on the ability of these oils to absorb oxygen from the air, which in raw oils, however, occurs very slowly. To speed up this process, the oil is subjected to high temperature along with oxygen-rich substances, which partly dissolve themselves and partly give up their oxygen to the oil. For this purpose, red lead, silberglet, manganese peroxide and others are used.

When cooking to prepare drying oil from sunflower oil at home, one must not forget that excess oxides, or so-called drying, have a detrimental effect on the strength of drying oil and paints prepared with it.

Cooking butter in small quantities at home is quite difficult and requires a lot of skill, because the slightest oversight can ruin the whole job. If the oil is overcooked, it will dry poorly and become sticky, while undercooked oil will have its own, no less significant drawbacks.

Any clean, quick-drying vegetable oil without foreign impurities can be suitable for preparing drying oil. The best oil in this regard should be considered old linseed oil, precisely the kind in which, due to time and long standing, impurities and mucous substances have managed to settle and water has separated.

High-quality oil is poured at least 4.5-9 cm below the top edge of the boiler so that during boiling it cannot overflow and flare up.

Light a not particularly strong fire under the boiler and, without covering the boiler with a lid, allow the oil to boil for at least 2 hours, after which add a little red lead and zilberglet, counting 400 g of zilberglet and 100 g of red lead for 16 kg of oil, with constant stirring with a wooden paddle The oil is allowed to boil for 1-1.5 hours, and then the fire from under the boiler must be extinguished and the oil allowed to gradually cool.

How long it takes to cook drying oil from sunflower oil cannot be determined with accuracy, since here you have to take into account the quality of the oil. The following practical method is usually followed in order to find out whether the butter is cooked enough or not: dip the end of a goose feather into boiling oil, and if at the same time the feather curls into a tube, this can serve as a sign that the butter is cooked enough, otherwise the feather will not bend .

During cooking of drying oil, cases of ignition of the oil are very possible. Then the boiler must be immediately covered with a metal lid, but do not pour water into the burning oil, which can cause a dangerous explosion. Before making drying oil from sunflower oil, you need to study all the technologies and safety rules.

In general, it should be noted that cooking drying oil at home should be avoided; the quality of the resulting product is not always satisfactory. That is why there is no reason to cook it at home, but it is better to buy ready-made drying oil. By purchasing oil from reputable companies that are specially engaged in large-scale cooking, in devices and devices specially prepared for this purpose, you can be completely guaranteed to obtain a homogeneous product of good quality, which is especially necessary when performing painting work.

In some cases, you can make drying oil from oil using a cold process by adding 3 to 5% paint dryer to the raw oil.