Modern plastic windows are not only effective enclosing structures, but also decorative elements.

The aesthetic properties of window blocks apply to both the facade and interior sides. When ordering a window of interest, the consumer can choose the color and texture of the polymer film.

Laminated plastic windows imitating wood or other valuable materials are gradually replacing simple white structures from the market.

What does the concept mean?

Lamination of a plastic window is a production process that involves covering a profile with a flexible polymer film that has a certain shade and texture.

Most often, work is carried out using specialized equipment under the influence of high temperature.

When exposed to heat, reliable adhesion of the two polymers occurs, which increases the service life of the window structure.

In addition to shrink film, press technology is also used for lamination. If the work is done at home, with your own hands, self-adhesive films are available for sale.

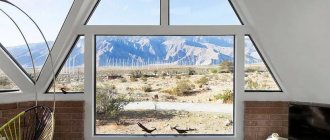

Photo

The photo shows laminated windows:

Laminated windows with layout

To make the window look more elegant and complement the interior style, along with profile lamination, the so-called decorative window layout is used. It is an imitation of a window frame. There can be two types:

- Shpros — installed inside the double-glazed window at the window manufacturing stage. Due to the tightness of the air chamber, dust and dirt do not accumulate in it, and there is no interaction with the external environment.

Windows with frames - False binding – are plastic linings that are glued to both sides of the window and provide a visual division of the glass unit into several parts. Can be of different shapes depending on the wishes of the buyer. Rectangular layouts are often used, but there are also layouts in the form of triangles, diamonds, arched and radial patterns.

Windows with decorative layout

If the interior is made in a certain design style, then it is very convenient to use a combination of laminated windows with a layout. In this case, you can choose the desired window color and a specific layout in exactly the style that will suit the overall design of the room.

Standard false frames and frames are white, but in the case of a laminated window they will also be laminated to match the color of the profile. In this form, the window will look more attractive, emphasize the originality of the interior and give it a unique modern look.

How to choose the right option?

To correctly select the desired lamination option, you need to take into account a number of important nuances:

- Color scheme for the building facade . If we are talking about an apartment building, you should choose the same shade that was present when the property was put into operation. In a private cottage, each owner has the right to choose his own texture and color scheme.

- Interior design style . With a classic finish, you need to stick to pastel colors. The best texture for such rooms would be to choose imitation wood. When creating modern interiors, every designer has the right to experiment.

- Before ordering lamination , it is necessary to pay special attention to the technical parameters and quality of the product, since the film should not fade in the sun or crack from frost.

- When purchasing textured lamination with deep veins, the owner needs to prepare for frequent washing of window structures, since dust settling on an uneven surface contributes to the formation of mold, as well as loss of aesthetic properties.

- One of the most important qualities of lamination is the method of its construction - if the film is pasted at the factory without the use of special heating equipment, you should refuse to order such a product, since over time the material will begin to peel off.

When choosing a film, you should also inquire about the country of production and the cost of the material. Cheap Chinese products will last much less than high-quality films from well-known manufacturers, for example, 3M.

Lamination film composition and color options

The film also has wood embossing.

The film for plastic windows consists of several layers, the total thickness of which is 0.2 millimeters . The acrylic base gives the material color and ensures the plastic's resistance to overheating. The transparent top layer of polymethylacrylate and polyvinylidene fluoride creates a protective function that allows you to avoid the influence of external negative factors, and also adds a glossy shine. During manufacturing, all layers are glued together, and a single whole is obtained in the form of a laminating film.

The variety of colors and shades of film is very large. There are currently more than 150 different options . The film can be made in a single-color matte, glossy, metallic version of any color scheme. In addition, the film can have a different texture, replicating wood, leather and other materials. The most widespread is film that imitates natural wood. It so closely matches the color and texture of the wood covering that it is almost impossible to distinguish it from a real wood profile. There are also many varieties of films with wood tones. For example, imitation can be carried out under oak, pine, larch.

Everyone can find a suitable option for themselves. The popularity of wood flowers is explained by the fact that real wooden windows are too expensive and are not as durable as PVC windows. In addition, natural shades are always in fashion and harmonize with almost any interior. And in country wooden houses they fit perfectly into the appearance of the facade and the general surroundings.

Coverage Requirements

Film for PVC windows is subject to a number of strict technological and design requirements , the fulfillment of which ensures high quality products:

Increased resistance to environmental influences - the film should not fade in the sun or be destroyed by temperature changes.- Wear resistance of materials - over time, the material is exposed to gusts of wind with solid impurities in the air, which negatively affects its structure.

- Mechanical strength of the product - the lamination should not be damaged by accidental scratches or impacts with hard objects.

- Adhesive resistance - the adhesive composition must ensure a tight fit of the material throughout its entire service life.

- Environmentally friendly - when heated, the material should not release toxins, the effects of which negatively affect human health.

- The material should be easy to clean from dirt and have increased resistance to exposure to weak chemicals contained in detergents.

According to the listed requirements, each material must have appropriate certificates issued by government agencies after a series of tests, which guarantees reliability, durability and safety during operation.

Advantages of laminated windows

Laminated windows have a number of advantages over traditional plastic products:

- Increasing the service life to 25-27 years;

- Increased resistance to precipitation;

- Consistency of gloss or color of the film. During service it does not fade or fade;

- Protection of the plastic surface from mechanical damage;

It also simplifies the maintenance of windows, since a dark product does not show slight dirt and dust.

A significant disadvantage of laminated windows is their high cost.

Rice. 4. Lamination on windows is great for balconies

Materials

If it is not possible to install lamination in the factory, or with the involvement of professionals, this work can be done with your own hands. To achieve the desired result, you will need the following materials :

- Laminated film for plastic profiles of the selected shade and texture.

- Special adhesive composition to ensure reliable adhesion. If the film has a self-adhesive surface, you can do without this material.

- Cleaning agent for PVC profiles, necessary when preparing the surface.

- A degreaser that removes all foreign substances after cleaning the structure.

- Antistatic – a liquid composition that prevents dust particles from settling during operation.

All materials must be of high quality, certified for use in aggressive environments. Experts recommend refusing to purchase cheap compounds from dubious manufacturers.

Other consumables and tools

To independently stick PVC film onto a window profile, you will also need a set of simple tools :

Ruler, tape measure, corner and pencil for measuring and marking the material.- Construction knife or scissors for cutting film.

- When using self-adhesive material, you should stock up on a pin to separate the protective layer of the adhesive composition and to smooth out bubbles on the surface of the laminated product.

- A rag for cleaning and degreasing the profile surface.

- Spatulas with silicone or plastic working body.

- A cylindrical steel or wooden roller, or a special pressure roller for rolling out and reliable adhesion of the material to the profile surface over the entire area.

When choosing shrink film, you may also need a hair dryer to heat the surface of the polymer product.

Renolit laminating film

One of the most reliable manufacturers who have proven themselves only from the best side in the market of decorative laminating films is the German company Renolit . For several decades now, it has been producing high-quality materials for lamination of plastic windows. During all this time, not a single case of defects, violation of external characteristics or integrity of the film coating was found. Renolit provides a 20-year guarantee on the color preservation of its materials when applied to profile window structures.

Why choose Renolit products:

- All types of Renolit films have German certificates confirming the declared properties of the products;

- The quality of Renolit films is constantly monitored in the company’s own laboratories to maintain product characteristics at the highest level;

- The proprietary acrylic-based coating of Renolit decorative films ensures brightness and color saturation for many years of use of materials in various temperature conditions. The film will maintain its impeccable appearance in Siberian frosts, tropical heat, and in highlands under the scorching sun;

- The Renolit company offers a large selection of colors; it has more than forty branded colors, a huge range of wood shades;

- Renolit films can be used in precise quantities with minimal waste, and their thickness is the same across the entire roll area. This ensures their efficiency and ease of use.

- Renolit film is highly durable and has excellent ductility, which is why it is in great demand among Russian buyers.

Instructions for lamination after DIY installation

To successfully stick PVC film onto the surface of a plastic window profile, you must adhere to the following flow chart :

- The profile must be freed from double-glazed windows and fittings.

- The surface is measured with a ruler, the results obtained are recorded on paper, and then recorded on film.

- The material is carefully cut, taking into account the formation of an overlap of at least 2 mm, if necessary, joining along the length or width.

- The surface of the profile is cleaned and degreased, coated with an antistatic agent, and dried with a hairdryer.

- The profile and film are heated with a hair dryer.

- The sticker starts from the main surface, in one go.

- The material is smoothed from the middle to the edges of the profile.

- To fix the film onto the folds, it is necessary to preheat all edges to at least 60 °C, and then tuck the material into the grooves with spatulas.

- After installing the film, it is necessary to check the formation of bubbles. If air accumulates in certain areas, it is recommended to carefully pierce it with a needle and smooth the film with a roller.

It should be noted that at home, in the absence of special equipment - pressure rollers or a conductor, it is almost impossible to achieve ideal quality.

Manufacturing technology of laminated windows

The production of laminated windows has several main stages:

1. A special primer is applied to the PVC blank, which will ensure the strength of the top layer.

2. The film is applied to the profile, which is located on the machine. In this case, acrylic-based glue is used and a certain temperature is maintained.

3. The workpiece is processed with rollers to ensure uniform coating.

4. The profile is left to allow the film to smooth out.

5. Quality control is a mandatory requirement, due to which unevenness during film application can be avoided.

6. The profile is cut and welded, after which a finished window is obtained. In this case, modern equipment is used, so this window meets the necessary standards.

Difficulties and mistakes

When laminating window structures on their own, many home craftsmen often encounter a number of difficulties and make many mistakes :

- Incorrect measurements of the structure - if tolerances are not taken into account, the joining seam may diverge over time by up to 1-2 mm, which will affect the appearance of the product.

- Incorrect cutting of the material - cutting should be done along a ruler, with a well-sharpened tool that eliminates the appearance of burrs. Each unevenness in the joining seam will lead to delamination of the material during operation.

- Poor surface preparation before gluing the film - any solid particle remaining on the plastic will be visible after lamination.

- Formation of bubbles and unevenness after gluing - the material should be smoothed evenly, gradually, from the center to the edges of the structure. When a film is applied simultaneously over the entire surface, there is a risk of warping of the material.

The main mistake that home craftsmen make is choosing low-quality film. It should be noted that the material must have a thickness of at least 100 microns and not stretch when force is applied.

Differences between internal and external lamination

Technically, laminating plastic windows inside and outside is no different. The only difference is the result:

1. Internal lamination influences the interior design of the room;

2. External lamination makes the window opening attractive from the outside.

The Windows Prestige company laminates installed windows indoors and outdoors. As a result, you will get windows that match the interior design and façade of the building. Many clients who have ordered installation of PVC window structures from us prefer lamination.

Pros and cons of working independently

Lamination at home provides the owner of the premises with a number of undeniable advantages :

Saving money on materials and work.- Acquiring an additional skill.

- Possibility of providing control at all stages.

- Independent selection of environmentally friendly and harmless material, as well as auxiliary chemical compounds.

- Possibility of installing different lamination in each room, according to the style of interior design, without additional costs.

At the same time, in addition to the advantages, this procedure entails a number of obvious disadvantages that affect the quality of the finished product:

- The lack of specialized equipment does not allow achieving high quality.

- If the heat gun is handled incorrectly, there is a risk of the PVC profile or film melting.

- Only a limited number of options for colors, textures and other technical characteristics of the laminating film are available in retail sales.

The main disadvantage of this solution for self-installation of lamination on plastic windows is the impossibility of filing a claim in case of an error. If the profile is damaged during the work, it will have to be replaced at your own expense.

What is plastic window lamination?

A “living” tree looks much nicer. It’s not for nothing that craftsmen used to clad the façade of a house with polished and processed slats. Then they were covered with stain and varnish, and after that the house looked impressive, acquiring a decorative appearance.

Now everything is returning to the old traditions. First of all, many window manufacturers have now begun to laminate window blocks. In other words, lamination is an imitation of a wooden cut.

To achieve this, films with different wood cut patterns and specific shades are used, as well as laminated color films. Currently, different films are used, and they differ from each other in color and characteristic properties.

The first option suggests:

- Color film with a matte tint;

- Glossy color film;

- Wood imitation;

A plastic window block coated with such a film does not differ in appearance from a wooden window frame.

On a note! In some cases, manufacturers also laminate glass to provide greater surface protection.

When ordering laminated windows, you need to keep in mind that you will have to pay more for it. And also when installing windows, the color of the handles and fittings will differ from the decor of the frame, since the manufacturer does not laminate such small parts.

In the second option, film is used:

- With sun protection properties – allows you to protect the room from the penetration of sunlight into the room. This film is glued to the glass and after that, the main part of the ultraviolet rays will be delayed. Recommended for use on windows on the south side of the house;

- With energy saving effect. Such laminated film has the property of not giving off heat in winter, and not allowing sultry heat into the room in summer. Moreover, air ventilation devices even lose in this case, since they dry the air;

- With shockproof effect. In this case, protection is provided against mechanical damage that can be caused by thieves and hooligans. And the film, which has an additional layer of triplex, protects the window even from a blast wave.

Rice. 2. Facade design of the house

General advantages and disadvantages

Laminated windows, which are widely sold or made to order, have many advantages :

- Attractive appearance.

- Additional protection of the profile from damage due to impacts or scratches.

- Resistance to ultraviolet irradiation.

- Emphasizing the good taste of the owner of the property.

- The possibility of installing window structures in apartment buildings with the original shade, which does not require special coordination with the CAG and operating services.

Among the disadvantages of such a solution, only a few subjective disadvantages :

- The complexity of the lamination device, which affects the retail price of the product.

- If the window is mechanically damaged and replaced, additional difficulties arise in finding the same material.

- When choosing a cheap film, the visual appeal of the window will be compromised over time.

Despite some disadvantages, most owners of residential and public buildings are increasingly deciding to order window structures in laminated film with different textures and shades.

Types of window lamination

- Double-sided lamination - performed on both sides of the window. Thanks to the correct color scheme, the appearance of the room will be aesthetic and original. You can choose different shades from the inside and outside.

- Single-sided lamination includes:

- Internal film covering – the plastic covering of the window is covered with colored material on the inside. It is used to complement the interior and integrate windows into the overall style of the room.

- Applying film coating on the outside of the window. This type of lamination is in demand in country houses to fit into the overall concept of the building, or in apartments where the facades of houses must match the style of the entire building, as a rule, this applies to historical parts of the city.

- Bulk lamination is the use of laminated film not only on the outside or inside of the window, but also in the section. It gives the greatest effect, since in this case there is no white plastic in the section, which makes the window presentable. However, this type is the most expensive among other types of lamination of PVC profiles, since its implementation requires the use of expensive equipment.

Average prices in the Russian Federation

Lamination for PVC windows is presented in a wide range on the consumer market. Considering the large number of competing enterprises, prices for these materials and finished products are approximately the same.

To profile

When ordering windows from a production and installation company, a separate price is generated for lamination of the white profile. As a rule, the final cost is calculated by marking up the original product, depending on its length and thickness :

With one-sided internal lamination - 25-75%, relative to the cost of a white profile.- With one-sided facade lamination - 35-85%, relative to the cost of a white profile.

- With double-sided lamination - 55-110%, relative to the cost of a white profile.

Thus, if a finished structure with fittings and double-glazed windows costs 10 thousand rubles. per 1 m2 including installation, the price of a white profile is about 2-2.5 thousand rubles, and lamination adds from 500 to 2.5 thousand per 1 m2, in addition to the base price.

On film

Materials for laminating window profiles can be purchased at every major hardware store at the following prices :

- Self-adhesive film, plain, glossy or matte - from 300 rubles. for 1 linear meter (roll width 600-900 mm).

- Textured material for laminating windows – from 450 rubles. for 1 p.m. (roll width is the same).

- Shrink film – from 400 rub. for 1 p.m.

- Degreaser – from 250 rub. for 400 ml.

- Detergents – from 100-150 rubles. for 250-350 ml.

Prices may vary slightly depending on the internal policy of the outlet.

The lamination process consists of several stages

- Chemical treatment of materials to completely clean and remove foreign particles from plastic. When washing, washing solutions based on alkaline substances are used, which are preheated to 30-35 degrees .

- Drying materials until moisture is completely removed.

- Priming the coating with a special solution called a primer. It consists of glue and solvent in a ratio of 1:10 . This procedure is carried out so that the film fits better on the profile. After applying the solution, at least a day must pass before the next work.

- The film is glued to the profile in a special chamber at a certain temperature. (+130 degrees) and pressure and humidity standards. Glue is applied to the film using a squeegee to ensure its even distribution over the surface of the film.

- Next, the film passes through the drying zone at the required temperature. The temperature of the film itself should not exceed 45 degrees , otherwise air may form under it due to evaporation of the solvent. At the same time, the rollers are turned on, they press the film against the profile and remove excess air between them.

- Separation of excess material from the profile. If the film dimensions are larger than required, the remaining part is cut off with a wedge-shaped disc cutter. If necessary, starting knives with sliding blades are used to clean or reduce the chamfer radius. Under no circumstances should you sand the laminated surface, as friction heats it up and the film may melt.

- Exposure of a new product for complete shrinkage of the film. There must be at least two weeks to prevent deformation of the surface of the glued profile.

- The last step is to ensure the protection of the new surface of the window frame during its transportation and installation, for which a protective self-adhesive film is glued on top.

Brown window and room style

Imitation wood will always be popular when decorating a room and if you want to save money. Therefore, all the different shades of brown are always in demand among designers. Let's consider which styles this palette is close to.

Brown windows in the interior are suitable:

- Any oriental style. Including Japanese, Chinese and Indian.

- Classic. But the imitation plastic window under wood must be covered with curtains.

- Country. Because a hut without a wooden window does not live up to its name.

- Mediterranean. Because brown goes well with azure and red.

- Minimalism.

- Eco style. But you will need high-quality imitation wood.

How to laminate a window profile

The convenience of almost all types of coating is that the window manufacturer does not have to keep stocks of colored profiles in stock. You just need to purchase the necessary film. It is glued on a special machine onto a white plastic profile. In this case, the base is first primed and then heated very much. The film is pressed tightly and rolled using special rubber rollers.

After several rolling, the laminated profile must rest for some time for the film to shrink. After which it will be ready for window production. The peculiarity of plastic profile lamination is that the film not only sticks to the surface of the profile, but also literally penetrates into its upper layers. However, bulk lamination is carried out only at the profile manufacturer.

No. 5. Profile color and interior

This is where you can give free rein to your imagination! At home, everyone is free to do whatever they want, and we have a wide selection of colors and shades at our disposal. Here, just like with the facade, you can use a color that fits into the color scheme of the interior, or you can play with contrast.

There are several win-win solutions:

- selection of window frames to match the color of interior doors . Windows and doors change quite rarely, they should be in harmony with each other, so this solution will create a stylish interior;

- choosing a window profile match the color of the walls - also a good solution to create a harmonious interior space. Let's say the walls are painted blue, but the profile can be light blue. This is an excellent basis for arranging a children's room for a boy;

- choosing a window profile to match the color of the furniture - a more complex and often reckless decision, since many people change furniture much more often than they do repairs. If we are talking about high-quality wooden furniture, then the decision will be justified - windows with wood lamination will look as advantageous as possible;

- a lot depends on the style of the interior . Windows laminated to resemble wood in brown shades will ideally fit into the classic style, and windows laminated under wood in light shades will fit perfectly into the Provence style. For country style, you can choose lamination to match dark types of wood, or choose plain brown frames. If we are talking about modern interior styles (minimalism and hi-tech), then preference is given to plain profiles. If white doesn't suit you, opt for gray or metallic ones. For the Art Nouveau, kitsch, boho style, you can take a profile of a bright unusual color: yellow, red, green, purple, pink - whatever your heart tells you;

- game of contrast is a risk that can lead to complete success or, conversely, cause complete disappointment. As in the case of the facade, you need to choose a shade so that it is contrasting, but at the same time harmonizes with the interior. Focus on the combination of colors on the color wheel;

- it is also important to consider room features. For example, for small rooms it is better to take a profile of light shades: beige, cream, light gray, etc. If the windows face south, cool shades of green, blue, and purple will help bring coolness into the house. If there is not enough light and warmth, then you can choose a profile of cheerful yellow, orange or red colors. Remember also about the specific effects of color on the nervous system. The red tint, for example, has a stimulating effect, so it is clearly not appropriate in the bedroom, but in the kitchen - please. Calmer tones are suitable for rest rooms: green, blue, beige, wood, brown;

- When installing panoramic windows, it is better to choose a calm shade of the profile, since the windows will already attract a lot of attention. The ideal solution in this case would be a gray, brown, black or metallic profile.

Please note that the color in the catalog and in reality may vary slightly - this is normal, you just need to make allowances for this fact. It’s better to come to the company’s office and get acquainted with samples of the desired color. Many manufacturers have special programs in which you can visualize the interior of the room and the color of the profile in order to evaluate your own decision and, if necessary, make changes in time.

What makes them special?

Plastic windows are in great demand due to the large number of advantages - they can provide good sound insulation of the room, and at the same time they look elegant and neat. And thanks to them, there will be no drafts in the room - plastic windows retain heat perfectly. That is why most apartment and house owners are happy to get rid of old “wood” and install plastic.

Unfortunately, if a wooden frame can be repainted in absolutely any shade, then this number will not work with plastic ones. They are traditionally available in white or brown in various shades. And given the modern creative needs of people, these are extremely boring variations. Previously, it was completely possible to change the design of a plastic window only with the help of unusual curtains.

Plastic windows

But, starting in 1982, so-called laminated windows began to appear on the market - about 35 years ago, the Rehau company first carried out the procedure of plastic lamination, that is, using a special film, it turned an ordinary white window into a colored one. Since then, window frames made of plastic began to be produced in color, and the shade can be chosen to suit absolutely any interior - be it a strict dark one for an office, or a colorful one for a child’s room.

Colored plastic windows

On a note! For a long time, only residents of houses located in the private sector could purchase and install laminated windows. The fact is that most apartment buildings have special requirements for a certain style of facade, which is why all windows must have the same color. However, now new lamination technologies have appeared, and now everyone can buy and install colored windows. It’s just that the window will only be painted on the inside, and on the outside it will be normal.

Laminated windows - several popular colors

What about the cost

Agree, all of the above suggests that these options will cost much more than regular white ones. However, due to the fact that such windows have begun to enjoy great popularity, manufacturers have pleasantly reduced the price, and literally everyone can afford them.

Note! Single-sided profile lamination will make the final amount more expensive by 15-20%, while double-sided lamination will increase this figure to 30-40%. If you use films with a pattern not from the general catalog, but turn to specialists for an individual design, then the cost of the window, of course, can rise to 80-90%. The cost will also be affected by the size and thickness of the profile and glass unit.

The cost will also be affected by the size and thickness of the profile and glass unit.

Advantages of PVC film

PVC film itself has a lot of useful properties and imparts them to the window during the lamination process. It is very durable, not afraid of mechanical stress, and is not even afraid of sudden temperature changes (it will continue to function properly even in the temperature range from –80 to +130 degrees). Accordingly, laminated windows last a very, very long time, do not fade under the influence of the sun, are easy to maintain and are not afraid of the effects of aggressive cleaning agents. In addition, they will be able to add zest to the interior or completely change it beyond recognition, which is especially important in the modern creative world.

Blue laminated windows

Advantages of laminated windows:

- a wide variety of colors, which allows you to match them to any interior;

- durability, coating strength (does not scratch), practicality;

- environmental Safety;

- the window is easy to clean and does not require painting;

- The film protects the window surface from exposure to the sun, water and temperatures.

A few more examples of laminated windows

It is also worth mentioning the lamination of window glass. Such glass does not transmit harmful ultraviolet radiation, blocking about 98% of the total radiation volume. Mirror PVC film can also hide what is happening inside the apartment by the type of tinting. At the same time, it will be transparent to a person indoors. Laminating glass will protect the room from overheating in the sun, and in winter it will not release excess heat outside. There is also an anti-vandal film that will protect windows from hooligans.

Tinted plastic windows

The main disadvantage of any plastic windows, including laminated ones, is the complexity of installation. And such windows, like ordinary white plastic ones, “breathe” poorly.

Panoramic windows

In various articles, this term refers to frameless glazing, French windows, and metal-plastic glazing. This variety of names is explained by two reasons: misunderstanding of the term and an advertising ploy. What designs can be called panoramic windows in the correct understanding of the word?

Window glass lamination

When they talk about laminating windows with their own hands, they mean not only profiles, but also glass improvement:

- By gluing a sun protection film onto the glass, they protect the room from ultraviolet radiation. If you take a mirror film, then through the window from the street it is impossible not to see anything in the room, but from the room everything is perfectly visible;

- By laminating the glass with energy-saving film, we will prevent heat loss in winter, and in summer hot air from the street will not penetrate into the room;

- By gluing an anti-vandal film, we will make the glass resistant to impacts, which means we will protect ourselves from thieves.

As you can see, the process of window lamination is not simple, and in order for the quality to be at a high level, you also need good equipment, as in this video:

No. 4. Profile color and house facade

The largest selection of possible solutions opens up to the owners of their own houses, cottages and summer cottages. Here you don’t need to take into account the general appearance of the house and set a profile like everyone else’s so as not to stand out. Owners of private houses, with all the variety of available shades, essentially choose one of two possible paths - either the window is in harmony with the facade and its details, or it contrasts strikingly with it.

Designers advise paying attention to the following options for selecting a suitable shade:

- choosing a shade that harmonizes with the color of the facade. For example, for a house decorated with terracotta-colored brick, you can choose a profile of the same shade or a similar one, for example, brown. If the facade is made in gray, then why not choose frames in the same gray color, just a couple of shades darker. It is also possible to use black or metallic colors;

- We must not forget about the architectural style of the house . If we are talking about houses in a classic style, then you can’t think of anything better than a wood profile, but there is freedom of choice here too, because wood comes in different shades: from almost white to rich brown. Such windows will look especially good in wooden houses and houses covered with wood. For the classic style, calm shades of the profile, such as chocolate, brown, cream and black, are also suitable. For modern architecture, frames in grey, graphite, anthricite and the same black shade are suitable. If the house or office space is made in an extravagant kitsch style, then all restrictions are lifted - choose either blue or crimson frames;

- Can focus on the color of the roof and doors. For example, brown siding will look great with brown frames. Doors and windows of the same color are the golden rule for a harmonious façade;

- there is a tendency to base the choice of color for the outer part of the profile on the color of the garage door . The garage is often part of a common building; it is clearly visible from the street, and the gates have a fairly large area, so the garage should be treated not as a technical and auxiliary element, but as a full-fledged part of the house. If there is a garage on the property and it is attached to the house, it makes sense to make the windows and garage doors the same color. This does not cancel all other rules. Let the windows, gates, doors, and fence with roof be of the same shade, which will blend perfectly with the facade of the house. For example, dark chocolate and creamy color;

- the most daring and, at the same time, difficult decision is Contrasting profile color. In this case, the task is to highlight the windows, but to do it in such a way that they remain part of the overall harmonious facade and are not alien. If everything is done correctly and tastefully, the façade of the house will become memorable. Most often, this solution is used for the arrangement of commercial buildings. Clients will definitely not forget the company’s office with unusual blue or purple windows. You can choose a corporate color for painting. When decorating residential buildings, contrasting shades are rarely used, but if you want to make your home stand out from the rest, then why not.

Let us note once again that you should not immediately reject the option with a white profile - it really fits perfectly into most facades due to its neutrality. Moreover, white has a mass of shades, from snow-white to cream - you can find a suitable solution in any case.