A family's provision of living space is one of the most important indicators of living standards. However, it does not reflect the quality of living conditions, which many want to improve. Trying to correct the problem, some owners carry out major renovations in their home, during which issues are raised about moving walls and dividing a single space in a large room into several functional zones. At the same time, it is necessary to solve a number of problems related to both the coordination of documentation and the choice of material for installing new fences. They can be built from brick, foam block, plasterboard, or use glass blocks for partitions. Let's look at the last of the listed building materials in more detail.

Features of glass blocks

Glass blocks appeared on the construction market not so long ago. The first prototypes were produced by the American company Luxfer Prism Company, founded in 1886 by James Pennicuik. However, the invention, patented in 1885, differs significantly from the brick blocks that have been used in construction since the 30s of the 20th century. The product was a metal lattice filled with square glass tiles.

The building material was used in different countries, and the peak of its popularity occurred in the 60s - 70s of the twentieth century. Initially, the blocks were used to illuminate basements, but over time they began to be installed in many institutions. Those who lived through the Soviet era remember the finishing of schools and kindergartens, swimming pools, staircases, made using this raw material.

Glass block is a building material that is obtained by joining two pressed glass plates. Thanks to the qualitative and aesthetic improvements of this product, a significant increase in the range, architects and designers began to use it not only for the exterior decoration of buildings, but also for interior design. Partitions are erected from them, and inserts are made into walls.

The main feature of the building material is not its decorative qualities, but its ability to save energy. Another important feature inherent in the product is the light transmittance. Products can transmit light, diffuse it, direct it, while completely hiding everything that is behind them. Some brands are comparable in strength to brick, and even stone.

The structure, built from glass blocks, is characterized by tightness; it creates good thermal insulation, sound insulation, light transmission, and provides protection from the cold. This allows you to make living conditions more comfortable, which is important both for large cities and for cottage villages.

SOLARIS, Germany

SOLARIS glass blocks are not as widely represented as the products of previous manufacturers, but are also available to domestic buyers. The material is distinguished by the highest German quality and ideal geometry, which allows installation using modern seamless technology.

The blocks are produced in different colors and textures, painted in mass. A unique offer from, which occupies a worthy place in the company’s collection. Glass blocks are presented in different formats; for user convenience, “halves” of blocks are produced, which can significantly simplify installation. The range includes round and corner glass blocks, as well as glass blocks for floor finishing.

Advantages and disadvantages

A glass block can be called a kind of hollow brick, which, unlike the original, is made not from clay, quartz sand or limestone screenings, but from glass. The material is widely used in construction, due to a number of useful properties inherent in the finished product. Among the main advantages of the products under consideration are the following aspects:

- Strength. The building material is almost impossible to break. It withstands mechanical loads, including impact and compression.

- Durability. The service life is at least 15 years. At the same time, the products are not afraid of direct sunlight; even painted versions will not lose their original appearance under the influence of ultraviolet radiation.

- Range. Manufacturers produce a wide variety of blocks that differ in shape, size, surface texture, and have a wide range of colors. This allows you to bring to life any design ideas, both when creating the exterior and when organizing the interior.

- Scope of application. Glass blocks are used in the chemical and food industries, in medical institutions, in laboratories, in the construction of private houses, public buildings, and in other areas.

- Easy care. Ready-made structures are easy to maintain. Glass does not absorb dirt and is inert to chemicals. Dirt is easily removed from the surface. Dust cannot enter the internal cavity.

- Light transmission. Glass elements allow light into the room well.

- Easy installation and dismantling. You can erect a partition from glass blocks with minimal construction skills, and to replace a damaged element you do not need to completely dismantle the masonry.

- Noise insulation. Glass blocks have good sound insulation characteristics, which allows them to be used in load-bearing walls.

- Moisture resistance. Glass is not afraid of moisture, it does not absorb water, it is not afraid of condensation, which is why the material is used in the construction of partitions for bathrooms.

- Fire resistance. The products are classified as non-flammable substances. Able to withstand exposure to open flame for an hour.

- Heat resistance and frost resistance. The blocks can withstand differences of up to 40 °C, and a temperature range from – 40 to + 500 °C.

- Thermal insulation and energy saving. They retain heat well inside the room, which allows you to save on heating costs. In hot weather, hot air is not allowed in, keeping the room cool.

- Environmental friendliness. Natural ingredients are used in production, which ensure the environmental purity of the product.

The disadvantages of glass blocks include:

- Complex processing. The block is difficult to cut into pieces. It is almost impossible to make a hole in it; under pressure it can burst.

- Heavy weight. Partitions assembled from these bricks significantly increase the weight of the entire building structure as a whole.

- Breathability. The material does not allow air to pass through. This must be taken into account when arranging a window opening, and consider the method of ventilation.

- Price policy. Finished products are expensive compared to other building materials used for construction and finishing.

CIECH Vitrosilicon, Poland

The company is a recognized leader in the Polish chemical and glass products market. It was founded in 1988 on the basis of the Zagan glass factory, which has been operating since the end of World War II. Among other things, glass blocks are produced here today, which are in high demand both in the local market and in Europe and Russia. The highest quality of products is due to the solid experience accumulated over the years, the use of modern equipment and the implementation of the production management system ISO 9001:2008 and ISO 14001.

Today the company includes three production sites, one of which produces glass blocks under the Claroglass brand. The company produces industrial glass blocks that have excellent fire-resistant characteristics and burglary protection. Decorative glass blocks, presented in 6 collections, differ in color, shape and size, and can be glossy, matte, or colorless. There is also an assortment of exclusive glass blocks that will highlight the room and give it a zest.

Material characteristics

Glass blocks can be classified according to several parameters. First of all, attention should be paid to the country in which the product was manufactured. On the construction market you can find German, Italian, Czech, Polish, Russian, and Chinese products. They all have the same design, their dimensions are the same. The only difference is quality and price. In addition, all blocks differ from each other in the following ways:

- shape and dimensions;

- glass thickness;

- texture, color and filling;

- strength and resistance to stress;

- optical characteristics;

- scope of application.

Basic dimensions, shapes and structure of the block

To understand the structure of a glass block, just look at its definition. It follows from it that a block is a product obtained by connecting two pressed glass plates, between which a hermetically sealed cavity is formed. According to GOST 9272-81 clause 2.4, the thickness of the front walls should be more than 8 mm. Here in clause 1.1 in Table 1 the standard dimensions and weight of the finished product are indicated.

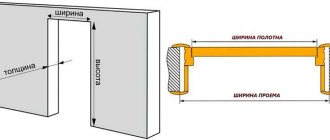

According to the GOST discussed above, glass blocks can have a square or rectangular shape. The size of the first should be (length, width, thickness, in mm) 194x194x98, 244x244x75 and 244x244x98 with a mass of 2.8, 3.8 and 4.3 kg, respectively. The second - 294x194x98 mm weighing 4.2 kg. Upon agreement with the consumer, it is allowed to reduce the length and width by 10 mm downwards.

Manufacturers offer a wide range of finished products, which may have non-standard dimensions. It all depends on the form. The smallest products are 115x115x80 and 60x146x80 mm, and the largest are 300x300x100 mm. Triangular models are available in only one size: 172x172x236x80 mm. But the most important thing is that all countries that produce designs adhere to the same standards.

The standard type of products is square and rectangle. There are also more sophisticated models in the form of a triangle, rectangle, circle, hexagon, L-shaped, with rounded side edges. There are also exclusive options that are made according to individual sketches to order; special matrices provided by the manufacturer of figured glass blocks are used for their installation.

Color variety and matting

All glass blocks can be divided into transparent and colored. Referring to GOST 9272-81, you can understand that products can be painted or unpainted. The first of those listed according to clause 2.1 may have a yellowish, bluish, greenish tint, which do not reduce the light transmittance. Clause 2.3 states that the color and relief pattern must correspond to the reference samples.

Based on the color palette, you can distinguish between colorless and colored models. In addition to the standard colors of green, yellow, red, blue, you can find bricks on sale in a huge range of shades. Coloring is done in two ways. The highest quality products that are not afraid of temperature changes and sunlight are obtained by adding coloring substances to the glass mass before molding begins.

Glass blocks, which were made of transparent glass, painted in the vacuum part (from the inside), are used exclusively inside heated rooms. Under the influence of ultraviolet radiation or as a result of a sharp change in temperature, the paint begins to crack, fade, and fade. When choosing a specific model, it is worth considering the fact that multi-colored blocks transmit light worse.

Matte structures have a light transmittance of 30-50%. Thanks to the diffusing effect, they create a greater degree of protection, so they are used in rooms with unwanted access to light from the outside. Semi-matte options are blocks in which one side is matte and the other is normal. A partition made of such bricks visually appears to be illuminated from the inside.

Special purpose

Depending on the scope of application, all glass blocks can be divided into industrial, interior and decorative models. The former are characterized by increased strength, water resistance, and fire resistance. This is the cheapest type of glass brick. They are used in production workshops, public institutions and institutions, when organizing staircases, and for other purposes.

Interior blocks are used for finishing residential and office premises, although they can also be used in the exterior. This is the most popular material that maintains a balance between price and quality. Glass blocks are characterized by a wide variety of shapes, sizes, colors and textures. They are used to construct partitions, windows, floors, make inserts into walls, and even furniture, for example, lay out a bar counter.

Decorative models contain various patterns and designs. The objects placed inside can be shells, pebbles, toys, replicas of fruits, ship models, etc. This is the most expensive type. Most often they are used as an addition to conventional glass blocks. To decorate a space and emphasize a certain design, a few bricks are enough.

Marking

Marking on Russian glass blocks is regulated by GOST 9272-2017 . Let's give an example:

PSU Blue 240×110×80

Here BP is a rectangular block, if it is square, then BC . Blue is the color, and 240 × 110 × 80 is the length, width and thickness in millimeters.

We talked about the sizes and types of glass blocks. Gave information on markings and types of installation. A universal installation method is using glue with reinforcement. For QuickTech and Vetroclick you will need special profiles that are not so easy to find on the domestic market.

In what styles is it appropriate to use

The excellent properties of glass blocks, a huge variety of colors, make it possible to bring to life the most daring design ideas. Using the material, you can create interesting compositions that complement the interior, decorated in a modern style, such as high-tech, urbanism, pop art, constructivism, loft, modern. For the Art Nouveau direction, stained glass models are ideal, which will also be appropriate in oriental stylizations.

In classical directions, it is better to avoid glass bricks. Classicism does not tolerate such a combination, this applies to Baroque, Renaissance, Empire, and others. Also, the material will look inappropriate in interiors decorated in a rustic and natural style, for example, eco, country, Provence, chalet, rustic. If you don’t have professional knowledge, it’s better not to take risks and turn to experienced designers.

Creation of furniture items

Glass blocks, due to their strength and at the same time small thickness, are an excellent material for creating stationary furniture. Original dining and coffee tables, various designs of bedside tables and bar counters, separating, for example, the kitchen area from the living area in a studio apartment.

Such furniture looks even more impressive in combination with various lighting options.

Using glass blocks in the interior of rooms

Excellent soundproofing material is often used as decoration and decoration of premises. With their help, you can play up any corner of the room, disguise the disadvantages of the layout and highlight the advantages. Glass blocks of any type and design have excellent heat-saving properties and are resistant to moisture. Translucent cubes are suitable for creating partitions, original counters, and window openings. When choosing suitable elements, you should take into account the purpose of the room, its design and size.

In the kitchen

More often, glass blocks are used in the kitchen to separate space. A beautiful matte partition in the color of the finish will be a good solution for separating the dining room and food preparation area. The practical design of identical squares is easy to clean, does not absorb odors and retains its attractive appearance for a long time.

When choosing such partitions in the kitchen, you should understand that they can serve only a decorative function. It will not be possible to load them with decor, pieces of furniture, or install heavy structures on them.

In the living room

Using practical modern material, you can create excellent decor that will become a real work of art. Glass squares are installed along one of the walls of the living room, along the perimeter of the windows, next to the interior partition. Multi-colored blocks laid out according to the planned pattern will become the highlight of the interior.

A partition in the form of translucent bricks of different textures will look beautiful in a hall or hallway. Iridescent details will create an atmosphere of comfort and provide good sound insulation. Even colored elements can be installed near the window, since glass blocks transmit 90% of the sun's rays and will not darken the space.

In the bedroom

Translucent partitions in the rest room will create an atmosphere of relaxation and relaxation. You can achieve the best effect by using warm shades, regular geometric shapes, and special lighting when decorating. In large rooms, glass blocks can be an excellent zoning solution. They are used to separate the sleeping and reading areas, and to fence off a stylish dressing room.

By installing a partition of colored squares near the window in the bedroom, you can get soft diffused lighting and suppress unnecessary noise from the street. It will be pleasant to be in such a room at any time of the day.

In the nursery

A wide range of textures allows you to use glass blocks in a child’s room. To decorate the room, choose multi-colored squares and rectangles. You can choose products with unusual effects, creating the feeling of a fairy tale.

A multi-colored panel with sealed cartoon characters inside each element will look original in a child’s room. Low structures made of blocks are used to divide the space, separating the recreation area from the play area, and install lamps nearby.

In the bathroom and toilet

When decorating a bathroom or cubicle with glass blocks, they can be used in several ways. Design methods can be combined or a specific one can be used. For dark walls, the current solution would be to decorate surfaces with squares with transparency. This way you can reduce energy costs and effectively divide the bathroom.

If you replace one of the walls or part of it with glass block decor, you can visually expand the space. Due to the penetration of light from neighboring rooms, lighting will significantly improve. In small rooms it is better to use details of the same texture and color.

Installing partitions made of glass blocks in an apartment is an ideal solution for a bathroom, toilet, or shower. Translucent details do not narrow the space and do their functional job well. They can be used in both adjacent and separate bathrooms. The blocks are assembled in continuous rows or combined with plasterboard, brick, or wood.

In the bathhouse and sauna

Decorating such rooms with glass block partitions will make them original and unique. In this case, all the defining functions of a bath or sauna will be observed in accordance with generally accepted standards. The main useful characteristics of block finishing include water resistance, resistance to temperature changes, and excellent thermal insulation.

Glass blocks are often used as partitions, delimiting shower and sauna areas. Decorating the walls with such elements will also be an excellent solution, since they take up much less space than other options made from other materials.

Application options

Glass blocks are used to solve a variety of problems: from zoning to decorating space.

Partitions

The construction of walls can be useful in offices, for example, to highlight a sleeping area in an open space or to clearly separate the space for cooking and relaxation. Glass block partitions in the bathroom are often equipped with shower stalls.

The design of partitions made of glass blocks looks advantageous both alone and in combination with other materials - they are sewn into drywall, creating original light windows or rows.

When it is necessary to build a large wall, glass is combined with brick and concrete blocks, as it itself looks too cold, like ice chips.

Window

Glass blocks are used to decorate interior windows of residential premises or exterior windows in private homes, in bathrooms, to hide from the prying eyes of neighbors.

For example, by installing glass blocks instead of a transom between the bathroom and kitchen, you will get decorations and additional lighting at the same time. And by cutting an opening in the white wall between the living room and the bedroom without windows, you will make the relaxation area more comfortable due to the penetration of natural light.

Furniture

The material is so versatile that glass block furniture is often made inside kitchens! They serve as a stand under a table or bar counter. Add lighting to the glass and get a modern and original decoration for your kitchen space.

Apron

A glass apron over the tabletop is not only practical, but also aesthetically pleasing. The surface is easy to clean, is not afraid of water, grease, high temperatures, and transmits light: in general, in all respects, it is suitable as a substitute for tiles or leather.

Decorative inserts in the wall

Glass bricks are used in wall decoration when there is a need to use this unusual material to a limited extent. Squares, like pixels, can be assembled into any shape - from abstract to completely recognizable. If desired, you can build in a backlight that acts as a dim evening light or a night light.

Do-it-yourself technology and methods of installation

There are several ways to install glass blocks. Choose the appropriate option based on the size of the partition itself. It should be understood that elements cannot be trimmed, so before purchasing materials you need to study the products of several manufacturers. For decorative blocks with a pattern, you will first need to make a diagram according to which you will subsequently lay out all the elements on the floor.

Frame

The method is suitable for creating light, small-sized structures. More often these are semi-partitions for zoning. The strength indicators and soundproofing qualities of the structure in this case will be much lower than when assembled using other technologies.

The main advantage of frame assembly of glass blocks is aesthetics. Also a plus is the ability to replace elements and the cleanliness of the work. A wooden frame is used as a base. The design with cells to match the size of the glass parts resembles a lattice or shelving.

First of all, fix the frame to the base. It is screwed to the floor or wall with dowels or anchors. Special rubber gaskets are put on the glass blocks and inserted into the cells of the frame or ladder. To add strength to large structures, sealant is used.

If a wooden structure needs to be given a certain color, it must be painted in advance.

For solution

Cement is used as an adhesive mixture. It should be uniform without large grains of sand that could leave scratches on the glass. You will also need to purchase crosses to install between the blocks at a fixed distance and provide rigidity. Strengthen the glass block wall with metal rods.

After a series of glass elements have been laid, a new layer of cement is applied and a metal rod is laid horizontally. If the structure area is large, additional metal supports are installed vertically. It is recommended to lay no more than three rows of glass blocks at a time. To prevent the structure from falling apart, the cement mixture must be allowed to dry for at least a day.

On glue

A wooden frame is used as a base. It is cleaned of debris, dust and basic markings are applied. To determine the required distance on the panel, lay out blocks and plastic dividers. Then the length and height of the future structure are measured and the dimensions of the frame are calculated. If in the future it will be attached to a wall structure, holes must be drilled in certain places.

To lay transparent elements, use white tile adhesive. This way the seams will be more aesthetically pleasing, and the likelihood of staining the part will be minimal. First, they check the integrity of the glass blocks, since manufacturers guarantee the quality of the elements only until they are installed. Then they are laid in rows, laying reinforcement for structural strength.

It is not recommended to remove the protective film from glass blocks during installation. This will help protect them from damage. If it is not provided, polyethylene should be used, secured with paper tape.

Partitions

GOST 379-2015 bricks, stones, blocks and silicate partition slabs.

general technical conditions The design of modern homes dictates the construction of partitions of unusual shapes.

They may be:

- trapezoid;

- pyramids;

- steps;

- arches;

- ziggurats;

- ovals;

- circles with holes.

Glass blocks in the bathroom interior are used for bathroom partitions and wall cladding inside the shower stall. Glass has good moisture resistance, diffuses light, and is not afraid of temperature changes.

For an additional aesthetic effect, small objects can be placed inside the blocks. For this purpose, the bathroom is decorated with shells and pebbles. “Edible” elements are suitable for kitchens: voids are filled with artificial berries or coffee beans.

The main thing here is not to overdo it. If you are not sure that it will turn out stylish and tasteful, it is better to refrain and not use fillers.

Which glass block manufacturers are best to choose?

The correct choice of glass blocks is an important point when assembling a decorative structure. The range of such elements is varied. You can purchase products from domestic, Czech, and Italian manufacturers. Each glass block option will have special characteristics:

- Domestic. Affordable price and high quality make such parts the most popular on the market.

- Italian. They stand out for their special difference in color tones from other manufacturers. All blocks have perfectly precise lines.

- Czech. They occupy a leading position in production. They are distinguished by a wide variety of designs and unique colors.

External surface

Modern glass blocks can have a flat and smooth surface, this will increase the light flux passing through it. On sunny days, your room will be illuminated by pleasant sunshine.

There are also options with decorative motifs or matte surfaces. Thanks to this, you can create an interesting interior from glass blocks in an apartment or private house.

Main types of surfaces:

- Smooth transparent;

- Mirror shine;

- Opaque;

- Simulated.

Formation of window openings

Often, interior windows in apartments and houses are formed using spectacular glass blocks. They give lightness and airiness to the walls and allow better dispersion of the sun's rays.

Particularly noteworthy are the illuminated designs, which look great in the design of living rooms, bedrooms and hallways.

Installation of glass blocks using masonry mixture

Laying blocks on a frame, despite its simplicity, significantly increases the cost of the structure. In addition, the installation of vertical load-bearing posts requires high marking accuracy. Therefore, bonding blocks using masonry mixture is more popular.

This method requires accuracy and certain skills, and the technology is similar to ordinary brickwork.

Since glass blocks cannot be cut and sharpened, as is the case with brick, we accurately calculate the entire structure in advance in size, taking into account the width of the seams. If it is not possible to install an even number of blocks, you can use an insert made of ordinary brick, wood or other material.

Blocks cannot be cut, so we adjust the sizes using inserts of other materials.

We start laying from the bottom row. The rows of blocks must lie horizontally, so the base must first be leveled. At a minimum, a stripe with a width equal to the width of the block.

We select the amount of mounting mixture so that it fills the gap between the blocks as completely as possible. To do this, you need to place it so much that it is slightly squeezed out of the seams between the blocks.

To fill a vertical seam, apply the mixture to an already installed block or to the one that we are laying, or better yet, to both. If, however, voids have formed in the vertical seam, we fill them when laying the next row.

To increase the strength of the masonry, we lay reinforcement made of galvanized wire or perforated tape between the rows.

Until you gain experience, check each installed block with a level, as well as the entire row.

The work will be simplified by special masonry crosses. They are placed between the corners of the block, and after the masonry is completed, they are removed or sealed with mortar, filling the seam.

Plastic crosses will simplify the laying of glass blocks, and the reinforcement will make the structure stronger.

Crosses are especially important because they make it possible to lay the entire height of the structure. Without them, laying more than three or four rows without stopping for the mixture to set is undesirable and often impossible.