Building codes and regulations regulate the parameters by which glazing of houses is carried out. This is important to ensure that the windows are safe for consumers. If you incorrectly calculate the area of the sashes, they will be too heavy. This will lead to rapid wear of fasteners and fittings. A glass surface that is too large may simply be unsafe due to its fragility. Such a window will not withstand strong wind gusts. Violation of technology leads to heat loss in the house and deformation of the structure as a whole.

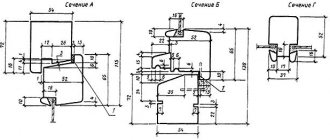

Mounting depth

It is affected by the material, as well as the width of the frame:

plastic - 58-120 mm;

aluminum - 45-125 mm;

wood - 58-165 mm.

The temperature and noise level in the room depend on the installation depth. Manufacturers adhere to standards, but sometimes the minimum values may differ. Priority, of course, is given to Russian GOST. But when the situation requires a non-standard solution, it is better to seek advice from an experienced expert.

Reliability

The profile and fittings are responsible for the reliability of plastic windows. Opening or breaking the window frame is problematic. Steel fittings lock the window, the profile is adjusted to tightly fit the sashes so that a crowbar cannot get through.

A double-glazed window is also a weak point in terms of reliability. For retail and commercial premises, it is worth taking a closer look at strengthened glass - tempered, armored.

Strength, accuracy, integrity are mandatory characteristics. A frankly shoddy product with uneven corners and sloppy seams at the joints will certainly turn out to be cold, damp, and excessive noise will seep through it like water through a sieve.

Number of sashes and their sizes

GOST regulates:

- sash area - 2.5 m2;

- weight - up to 89-100 kg;

- the limit for blind systems in high-rise buildings is 800×400 mm.

Windows with two or three sashes, a balcony with an inactive window and door - a typical design for a panel house. If the opening is larger than 1.5 by 1.5 meters, then a three-leaf window is made. A convenient option is a solid middle one and tilt-and-turn ones on the sides. If necessary, the side sashes can be combined in any way.

The tables below describe window sizes depending on the number of sashes.

1-leaf:

| Opening, mm | Size, mm |

| 500×500 | 470×470 |

| 600×900 | 570×870 |

| 900×600 | 870×570 |

| 900×900 | 870×870 |

| 1200×600 | 1170×570 |

| 1200×900 | 1170×870 |

| 1350×600 | 1320×570 |

| 1350×900 | 1320×870 |

| 1500×600 | 1470×570 |

| 1500×900 | 1470×870 |

2-leaf:

| Opening, mm | Size, mm |

| 600×1200 | 570×1170 |

| 900×1200 | 870×1170 |

| 900×1350 | 870×1320 |

| 900×1500 | 870×1470 |

| 1000×1000 | 970×970 |

| 1200×900 | 1170×870 |

| 1200×1000 | 1170×970 |

| 1200×1200 | 1170×1170 |

| 1200×1350 | 1170×1320 |

| 1200×1500 | 1170×1470 |

| 1350×1000 | 1320×970 |

| 1350×1200 | 1320×1170 |

| 1350×1350 | 1320×1320 |

| 1350×1500 | 1320×1470 |

| 1500×1200 | 1470×1170 |

| 1500×1350 | 1470×1320 |

| 1500×1500 | 1470×1470 |

3-leaf:

| Opening, mm | Size, mm |

| 1200×1800 | 1170×1770 |

| 1200×2100 | 1170×2070 |

| 1350×1800 | 1320×1770 |

| 1350×2100 | 1320×2070 |

| 1500×1800 | 1470×1770 |

| 1500×2100 | 1470×2070 |

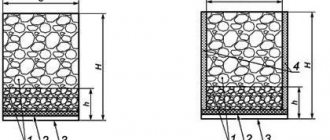

Windows without quarters

When deciding how to measure a window without quarters, you need to do a few simple steps. The width of the future window is calculated after measuring its upper and lower parts. In this case, for the calculation, a smaller value is taken, from which 4 cm is subtracted for the placement of installation seams on both sides - the result is the width of the future product.

It is worth considering that the greater the error when measuring the width in several places, the greater the number of centimeters that will need to be subtracted to determine the final size.

The size of the seams must be subtracted from the width of the window opening.

Calculating the height of a window product occurs according to the same rules as determining the width, only in this case, about 2.5 cm should be subtracted from the resulting value for the installation seam and 3 cm if a stand profile is installed.

Why do you need a stand profile?

A stand or substitution profile is an element that is placed at the bottom of the window product and has a height of 3 cm. An external drainage system made of powder-painted metal is attached to the stand profile. The ebb prevents the accumulation of precipitation and protects the installation seam from it.

A support profile is needed to secure the drainage system

On the inside of the room, a PVC window sill board is attached to the stand profile, which also hides the installation seam and makes the appearance of the window aesthetically pleasing.

A window sill is attached to the substitution profile from the inside

It is important to know that when installing a PVC window sill, its width will be 5 cm greater than a standard wooden one . At the customer's request, the window sill can be made up to 70 cm wide, but it must be taken into account that the heating radiator does not pass under it, since a wide window sill will prevent the proper circulation of warm air.

It is not recommended to install a window sill that is too wide above the battery

When calculating the width of the window sill, take into account its overhang, which cannot be less than 1 cm. The length of the window sill is equal to the width of the opening with access to the wall on both sides, which should not be less than 5 cm.

Standard window sizes for a private home

The glazing of a private house is no different from an apartment. It is regulated by the same GOST 23166-99. The windows in the room should be at the same height. The distance from the radiator to the window according to SNiPs is 80 mm. The amount of rise of the window sill from the floor depends on the purpose of the room:

- for a dressing room - about 1750 mm;

- bathroom - from 1300 mm;

- kitchen - 900 mm;

- living rooms - approximately 800 mm;

- attic - about 1000 mm.

Thus, when glazing a country house, two factors must be taken into account - whether this part of the building is residential and how much area it occupies.

The largest windows are installed in rooms - the living room, guest room, children's bedroom. In a wardrobe, kitchen, or pantry, it is justified to install a structure with fewer doors.

For a small twelve-meter room, the standard option is suitable - 0.9 by 0.9 m.

Design options

Most often, blocks vertically divided into separate sections are installed in modern apartments and private houses. The number of such sections is determined by the size of the window, its functionality, as well as the specific design of the facade and interior of the room.

The most common are two and three-leaf PVC windows. Structures with one leaf are installed relatively rarely in residential premises. Let's take a closer look at each of the options.

Single-leaf windows

Blocks with one leaf are rightly considered the most affordable, but such savings are not always appropriate. Installing windows of this type is not able to provide comfortable living in spacious rooms.

In most cases, the manufacturer makes the sash openable; blind structures are comparatively less common. Residential buildings of the Soviet period were equipped with windows of this type; now they are practically not installed in apartments. They are often used in country houses, country houses or for glazing small rooms.

Double-leaf PVC windows

Window blocks of this type are divided into two sections by a vertical partition (impost). In most cases, one of the sections opens; designs with two opening elements are relatively less common. A double-leaf system is sometimes implemented without a dividing impost, which, given the significant width of the block, negatively affects the overall rigidity of the structure.

This is the most popular glazing layout option, as it combines ease of use and a relatively low price. Double-leaf plastic windows can be found in almost any type of building: in large and small private houses, cottages, multi-storey residential buildings, office premises and large shopping centers.

Three-leaf PVC windows

The supporting frame in such windows is divided into three sections. Most often, such structures are used for glazing spacious rooms - living rooms, halls, dining rooms, halls.

Any options are possible in terms of the number and direction of opening elements. The most common is the installation of tilt-and-turn fittings on the two outer sashes.

This option is considered optimal in terms of functionality and is relatively cheap. If the developer wants to save more money and this is enough for normal ventilation of the room, only the middle sash is made to open.

The least common designs are those in which all three sections open or, conversely, are completely blind. The main reason for the relatively low popularity of the former is the high cost of the block, because each section must be equipped with a sash and fittings. Blind three-leaf blocks are installed either in rooms with artificial ventilation (supply systems), or in rooms with large internal space together with opening windows.

Standard sizes for an apartment

The openings in panel and brick houses are different.

In Khrushchev-era buildings, the typical value depends on the width of the window sill:

- double doors - 1350×1300, 1500×1450;

- tricuspid - 1359x2040, 1500x2040.

The balcony blocks have the same dimensions - 2070x680, 1350x1100/1340.

The parameters of standard windows in brick and panel Khrushchev buildings are approximately equal - the houses were built according to similar designs.

In five-story Brezhnev buildings, the opening sizes are the same.

| Construction type | Dimensions, mm |

| Double-hung window | 1400×1300 |

| Three-hung window | 1400×2100 |

| Balcony door | 2150×750 |

| Blind window of the balcony block | 1400×1400 |

The dimensions of the balcony glazing of houses built by Brezhnev and Khrushchev are the same.

In nine-story buildings . Most of these buildings have the same opening dimensions.

| Construction type | Dimensions, mm |

| Tricuspid small | 1400×1760 |

| Tricuspid large | 1400×2460 |

| Double-hung window | 1400×1300 |

| Balcony door for bedroom No. 1 | 2150×750 |

| Balcony block window for bedroom No. 1 | 1400×1050 |

| Balcony door for living room No. 2 | 2150×800 |

| Balcony block window for living room No. 2 | 1400×1460/1760 |

Stalin buildings have high ceilings. Therefore, three-leaf blocks are larger than in other types of houses. Another difference is the balcony block. These are two hinged doors and one blind at the top. Size – 2700×1500 mm.

| Type of design | Dimensions, mm |

| Balcony door | 2100×750 |

| Blind sash at the top of the block | 600×1500 |

For better ventilation of the apartment, we recommend replacing the blind sashes.

In houses with a new layout, a single standard was not applied. The most common glazing:

| Type of design | Dimensions, mm |

| Double-leaf block (series 137) | 1420×1150 |

| Three-leaf block (series 137) | 1420×1700 |

| Double door block (504 series) | 1410×1450 |

| Three-leaf block (504 series) | 1410×1700 |

| Double door block (505 series) | 1410×1450 |

| Three-leaf block (505 series) | 1410×2030 |

| Double leaf block (series 600.11) | 1410×1450 |

| Three-leaf block (series 600.11) | 1410×2050 |

PVC balcony doors:

- canvas height - 2150-2160 mm;

- blade width - 670-750 mm.

The width of the windows on the balcony is from 570 to 1400 mm, and the height is from 1400 to 1420 mm.

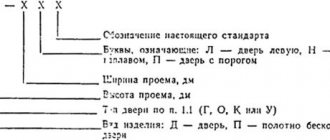

Where to see the requirements

All requirements for dimensions can be found in GOSTs of the construction industry. Each type of window (PVC, aluminum, wood) has its own standards, but, in addition to them, there is a general GOST 23166-99. It regulates the parameters of any window and balcony blocks, regardless of the material from which they are made.

Primary requirements

- The total area of the block cannot be more than 6 square meters. m.

- The area of the opening doors is no more than 2.5 square meters. m.

- The weight of all active elements is no more than 80 kg.

- Deviation from overall dimensions is allowed no more than 2 mm (for diagonal lengths - no more than 4 mm).

- Fixed shutters are allowed only on the first floor (with the exception of small shutters of 40x80 cm and windows between the room and the balcony - they can be used on any floor).

In addition to dimensions, the general document contains standards for wind load and glazing thickness.

Important: in November this document will cease to be valid and will be replaced by GOST 23166-2021. It will add requirements for window and balcony blocks with fixed glazing. It will be possible to use them above the first floor if the width of the block is no more than 400 mm for partially non-opening sashes and no more than 800 mm for fixed glazing in the central part of the structure. The height of inactive elements cannot be more than 400 mm. The overall dimensions, area and calculated weight of openings will be based on manufacturers' recommendations.

More detailed information on different types of profiles can be found in the following GOSTs.

- 30674-99 - plastic profiles.

- 24699-2002 - wooden profiles.

- 21519-2003 - aluminum profiles.

- R 56926-2016 - balconies in houses built in 2016 and later.

Instagram @polyakova.biz

Instagram @design_denis_serov

Instagram @homevcube_

Standard window sizes for a summer residence

A PVC window is an excellent solution for a country house. It will be warm and quiet. The micro-ventilation mode will prevent the formation of mold or mildew. Single glazing is an option for a gazebo, veranda, or summer cottage. If you come in autumn or winter, then go for a double.

It's no secret that holiday villages are an attractive place for criminals. Anti-burglary window fittings will make it difficult for burglars to gain access to your home. If the window is approximately two-thirds the size of the floor area, then the room will be cozy and bright.

In house designs, window openings are standardized. This means that choosing the right option will not be difficult. And there will be no problems during repair or replacement either.

The importance of correct measurements

The manufacturer usually offers the services of its own measurer. This service is free. The product is manufactured on the basis of a measurement sheet, where the measurer indicates all the necessary parameters. If, when installing a window, difficulties arise due to an incorrectly manufactured product, the manufacturer will bear responsibility.

As a rule, window measurements are carried out by the manufacturer

If the customer provides the dimensions himself, then at the stage of signing the contract for the provision of services for the manufacture and installation of plastic windows, he signs the measurement sheet, which is drawn up by the manager based on the provided dimensions.

With his signature, the customer confirms the correctness of the dimensions indicated in the measurement sheet, in his words, which means that if the window does not fit during installation, the customer will bear responsibility and all financial costs for remaking the product will fall on his shoulders. When taking measurements yourself, it is important to approach this matter extremely responsibly.

Prices and window sizes

The cost of glazing depends on many factors. In addition to the size of the opening, it is influenced by the type of profile, double-glazed window, fasteners, the presence of a door closer, indicators, and roller shutters.

| Type of components | Cost surcharge |

| Energy-efficient double-glazed windows instead of conventional single-chamber ones | 10-15% |

| 5-chamber PVC profile instead of 3-chamber | 10-15% |

| Wooden beams instead of PVC profiles | from 100% |

| Window automation | from 50% |

The favorable price of standard PVC windows offered on sale is not an indicator of their low quality. Companies often sell off excess product from a large order. Before purchasing standard systems, invite a measurer and make sure that the “standard” profiles suit you. This way you will avoid unnecessary expenses and be confident in the optimal choice of glazing.

Selection of profile depending on manufacturer and class

When choosing a suitable window profile, in addition to its characteristics, you should take into account its brand and class. Regarding the manufacturers of this type of product, it can be noted that today on the domestic window market you can find a fairly large number of brands that produce various models of plastic windows, differing in their constituent elements and, accordingly, characteristics.

Important! This issue was most fully covered in our previous materials, entitled “Manufacturers of PVC windows” and “Rating of the best plastic windows - top 3 profiles of companies producing PVC structures.”

Now a few words about choosing a profile class. There are two classes of such products:

- A

- B

Class A profile can be used both in residential buildings and geometrically complex facade structures. It has a long service life and has a wall thickness of at least 3 mm.

Class A profile. Click to enlarge.

Due to the design features, the class B profile is usually classified as a budget solution. The main factor influencing the price is the presence of a thin wall of the product. It is precisely because of the savings on the thickness of the material used for the chamber wall that manufacturers of Class B were able to keep prices for their products extremely low. Price comes at a price, however, the buyer should remember that such a marketing ploy cannot but affect the service life of a plastic window equipped with such a profile - the service life of the system will be significantly shorter.

Important! Read about how long plastic windows can last here:.

To summarize all of the above, I would like to draw attention to a very obvious fact: all the elements of a plastic window are interconnected. When choosing a warm double-glazed window, you should also take care of purchasing a warm window profile. Otherwise, the design, due to significant differences in technical characteristics, may turn out to be unbalanced.

Consequences of the wrong choice

Not every owner of a residential property knows how to choose the right profile for making PVC windows. In case of errors, a number of negative consequences may occur during the operation of the installed structure:

- Inconsistency between the thermal characteristics of the product and the required climatic parameters in the room.

- Deformation of heavy sashes when torn off.

- Vibration of a window structure under the influence of the pulsation component of wind loads at a height of over 30 meters.

- Vibrations and insufficient sound insulation due to the small number of closed chambers inside the product.

- Unjustified expenses when purchasing a profile with maximum characteristics.

Before placing an order, you should consult with a professional, present him with architectural plans of the premises, and also draw up technical specifications so that he can select the optimal profile at a reasonable price.

Advice from professionals

If all the windows on the facade are to be replaced, then everything must be measured at once. Their height may be almost the same, but their width may differ. For manufacturing, you need to take the smallest value of the measured window.

To determine the location for installing the window unit, the thickness of the wall must be known. From the inside, the structure should be mounted to a depth equal to 2/3 of the width of the wall, while you can take into account the width of the external insulation and install it further.

If you add 5 cm to the width of the opening for the bend and 4 cm for the protrusion, then the required value of the drainage width will be known. If the wall is sheathed, then this thickness must also be taken into account. The width of the slopes is measured only after installing the window unit.

Why is it important to know the standards?

Knowledge of the standard nomenclature for the dimensions of window openings in brick houses is very important for the following participants in the construction and installation industry and the home owners themselves:

For designers:- Drawing up a correct masonry plan.

- Linking the order on facades to brick dimensions.

- Preparation of specifications using standard sizes, which contributes to the unification of products.

- For installers and masons:

- Possibility of laying bricks in each row with exact observance of the brickwork dimensions.

- Correct design of dimensions of walls and window openings.

- Installation of quarters on the side and top edges of a structural element to fill translucent structures.

- For window block manufacturers:

- Production of standard structures tied to brickwork.

- Unified installation of blocks along the entire wall plane.

- Minimizing production costs, which affects the cost of production.

- For the owner of the property:

- Accurate cost estimate to determine the required investment.

- Possibility of saving money by ordering standardized window units.

- Ease of maintenance of structures.

- Use of standard fittings.

- Acceleration of the installation process, which affects the timing of commissioning of the facility.

If the dimensions of window structures and openings are not observed during the construction of brick masonry, there is a risk of increased investment in construction, as well as a significant increase in installation time.

In addition, if, during the operation of a facility with non-standard design solutions, any of the windows fails, its repair will cause certain difficulties and increased costs.

What it is?

The profile of a plastic window is the main structural element of a translucent structure, which serves as a supporting frame and frame for a double-glazed window. The part is manufactured by extrusion from polyvinyl chloride mass in a factory. The thickness, number of chambers, as well as the presence of reinforcement are determined by the requirements of regulatory documentation and the operating features of the future structure.

Profiles for PVC windows can be fixed - mounted directly at the ends of the opening in the wall, or opening - on loop hangers or on roller supports. Opening doors are equipped with handles and locks for ease of operation, increasing user comfort and safety.

Briefly about the main thing

Knowing how to correctly measure the opening for a plastic window, you can do it yourself, saving time on having a technician go home. But for this you need to take into account many nuances: the type of opening, the material of the walls, the presence of finished slopes and window sills, the possibility of shrinkage of the house. And if the shape of the window block is non-standard, everything becomes even more complicated. Problems that arise as a result of incorrect measurements are compensated by the one who made them, so it is better to save not time, but your own money, entrusting this matter to professionals.