Sometimes, due to installation features, when finishing the surfaces adjacent to the window, the base width of the main frame profile is not enough - most often this situation occurs when glazing balconies and loggias. In this case, it is possible for plasterboard and other facing materials to overlap glazing beads or even double-glazed windows. This cannot be allowed. It’s even worse when the top trim prevents the sash from opening normally in any of the planes. In all of these situations, it is additional profiles that allow you to get out of a difficult situation without any negative consequences. Before the advent of these universal and very necessary elements, installers and property owners often experienced difficulties, and until the developers of profile systems found a simple and effective solution, the operational and aesthetic characteristics of window structures suffered.

What is an additional profile?

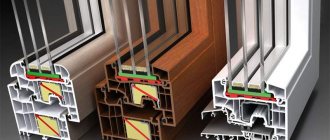

An additional profile for plastic windows

is a molded PVC product that is hollow inside, which is attached to the window frame along its outer perimeter and allows you to increase the total area of the structure. Absolute tightness of the connection is ensured by a special locking connection. The groove-to-groove fixing system makes the extended window structure completely moisture- and airtight. In addition to tightness, additional elements have another important advantage - they are available in models with different thicknesses:

- 20 mm;

- 40 mm;

- 100 mm.

The ability to choose the most suitable size for “extension” provides more options for installers and builders. Some manufacturers of window profiles have decided to expand the range of these additional elements by releasing models with a thickness of 30; 45 and 60 mm. This allows for the “jewelry” integration of window structures in complex situations.

Moldings for window profile systems can also be interconnected, making it possible to extend frames in a wider range of sizes. However, this opportunity should not be abused.

Catalog brands

- home

- Delivery

- Payment

- Contacts

- News

- Dialogue with the director

- Catalog

- PVC waste

- Sawing

- For regular customers

- Guarantees

- Purchase returns

- Our partners

- Working hours:

Mon-Fri: 10:00-18:00, Sat-Sun: closed - Phones:

- Phones:

- OKPO

91412524 - Address:

Moscow, 1st Kotlyakovsky lane, 2

ELITE SET components for plastic windows © 2014 – 2020 LLC “ELITE SET”.

Source: elite-complete.ru

Purpose, types and methods of installing window coverings

A modern window is a complex structure, consisting of several basic and dozens of auxiliary parts. Extensions for windows in a wooden house are auxiliary elements purchased in cases where there is a discrepancy between the geometric dimensions of the window and the window opening.

Such a discrepancy in size is uncharacteristic for wooden houses, but still occurs. The most typical case is the renovation of an old house or the construction of a bathhouse, during which it becomes necessary to install a cheaper double-glazed window, the dimensions of which are smaller than the existing window opening.

Also, you can’t do without additions when arranging glazed verandas and bay windows, where this building element is used to create a load-bearing frame.

Scope of application of additional profiles for windows

There are many situations when an additional profile is extremely necessary, thanks to which it is possible to install windows without problems, as well as to subsequently finish slopes and other surfaces with various building materials. The scope of application of these products is not limited, and they are used wherever, for various reasons, it is necessary to expand the frame. Most often, a plastic additional profile is required when:

- The loggia and balcony are being glazed, and a decision has been made to cover the ceiling with clapboard or plastic;

- it turned out that the dimensions of the window opening are larger than the dimensions of the frame;

- it is necessary to insulate the slopes and also sew them up on the inside with plasterboard;

- it is necessary not only to build up the structure, but also to increase its rigidity.

Extenders, like the main PVC profile, can be covered with decorative films, making them suitable for increasing the area of laminated windows. When connecting such profiles, you must carefully monitor the joining line, since a white stripe may appear at the slightest shift. Usually such flaws are eliminated by painting over with a special marker.

Additional window elements

PVC window cost calculator

Select window type

Price with additional discount: %

Product cost: rub.

Cost of add-ons: rub.

Cost of services: rub.

Select Window Options

Extra options

Accessories

| Commercial offer No. |

| Cost of products and add-ons: | rub. | ||

| Cost of services: | rub. | ||

| Number of products in order: | PC. | ||

| Total without discount: | rub. | ||

| Volume discount: | % | ||

| Total with DISCOUNT: | rub. | ||

| Additional services (Delivery): | rub. | ||

Additional elements for plastic windows are necessary parts that help give the structure rigidity, resistance to various types of influences and make them invulnerable to moisture and mechanical influences. The demand for such parts is explained by operating conditions in which providing additional protection is a matter of functionality and durability.

Difference in terms

Before we begin describing the extras, let’s define the terminology.

What are extras

The fact is that in many articles on various Internet resources, wooden and plastic panels that cover the ends of window openings are called extensions. But in generally accepted construction practice, this element is called a “slope”, the purpose and installation methods of which are described in detail in our other reviews.

This discrepancy in names arose after the appearance of the so-called “telescopic” platbands, the side panel of which was “reached” using joined strips of various thicknesses.

Additional types of expanders

Window extensions are not only elements that allow you to extend the frame around the perimeter. Manufacturers of PVC systems also produce other auxiliary profiles that make it possible to assemble complex structures.

Connecting profiles

The PVC window extender is also used for joining frames. These elements are called connecting profiles, since they are designed for the manufacture of a complex enlarged structure from individual blocks located in the same plane. This expander for plastic windows comes in 3 types:

- connecting profile with air chamber or central plate;

- noodles – universal expander;

- H-connector - this addition to PVC windows is a thin strip that looks like an I-beam.

These elements are often used in the manufacture of balcony blocks when it is necessary to connect door and window frames. They are also necessary when performing strip glazing.

In all cases, the extension of structures is carried out by rigidly joining the frames of adjacent blocks using a screw anchor connection.

Stand profile

This PVC extender is a window profile that is fixed in the lower area of the frame. It performs several functions:

- lifts the structure above the lower end of the opening and protects the assembly seams from moisture;

- facilitates the process of installing the window sill and ebb;

- serves as an additional stiffening rib.

In addition, using a stand profile you can extend the frame. This additional profile for plastic windows increases their height by 20-30 mm.

Bay windows and corners

This profile for plastic windows is used for glazing balconies, bay windows and making entrance lobbies, as well as in the process of assembling polygonal structures. The use of bay windows allows for extensions in different planes. Such extensions are also attached to plastic windows using screw anchors. They ensure tightness of the connection and stability of shape. There are 2 types of profiles for making complex joints:

- pipe – consists of an element with a circular cross-section (pipe) and an adapter, which can change the angle of contact until final fixation;

- square - a profile with grooves for connecting two blocks at an angle of 90°.

Using these profiles, massive structures are assembled, so they all have internal chambers for reinforcement. They also have auxiliary elements for high-quality waterproofing, which helps to avoid icing of joints from the inside and damage to connecting seams.

Simplification of fastening of ebb and window sill

There is no need to drill holes directly in the window frame, which, by the way, is prohibited by manufacturers. This can lead not only to water getting inside the frame profile, but also to the appearance of cracks on the frame.

USEFUL INFORMATION: Mixtures for leveling the ceiling: which putty is better?

There are other ways to attach these window elements, for example, by placing a window sill under the frame and screwing the ebb to its outer part facing the street. Also, the drainage and window sill can be installed in special grooves, but there are some nuances and difficulties with the placement of the pads when installing the window block, clearing the foam seam, etc. With a stand strip, the process is greatly simplified.

Professionals recommend mounting the external aluminum window sill on a special profile equipped with a “cap”. It will facilitate installation and protect against leaking water.

Types of add-ons

Depending on the purpose, the following groups of products are distinguished:

- Connecting profiles are used to fasten several elements of window structures together in long openings.

- Expansion elements are used to install PVC windows in old houses with thick brick or steel walls. They cannot be glazed using products of standard thickness, but expansion elements increase the thickness of the window frame to the required dimensions.

Stand products are used when adjusting the installation height of a window structure. Plastic elements are attached to the bottom of the main frame. They raise it to the required level. Often used in old-style houses, where window openings have a quarter of different depths.

- Additional H-shaped elements are designed to increase the load-bearing capabilities of large-sized window structures with sliding sashes. Increased strength characteristics are ensured by the use of metal inserts.

- Corner elements are used to eliminate gaps. They are formed as a result of dismantling used wooden frames. Provides quick assembly of structures.

Based on the shape of finished products, the following groups are distinguished:

- The J-profile has a curved shape. Often used for decorative finishing of a room, it can be combined with spotlights;

- H-profile is a corner element. Typically, such plastic profiles are installed overlapping and joined to the main structure along the entire length;

- F-profiles are widely used. They are used when cashing windows, located in the corners of the opening or used as elements to complete the installation.

Types and purpose of products

The company's assortment includes various additional elements for PVC windows:

- connecting ones are used to obtain a solid structure of a window frame;

- expansion ones are useful when you need to change the geometric parameters of the profile;

- shulpovye are necessary for blocking the gaps between individual sashes in multi-leaf structures;

- bay windows (PVC pipes) are used to create window frames of complex geometry;

- sealing agents are used to give windows the required thermal and sound insulating qualities;

- substitution profile for fastening the window sill;

- finishing - J-profiles and platbands are used as door and equestrian overlays;

- shaped are used for finishing corners and joints;

- slopes - for finishing surfaces around the window frame;

- drainage and cornice strips - for draining water from the outside of the windows.

Advantages of ordering products from us

The main advantages of ordering additional elements for PVC windows from the manufacturer are as follows:

- parts are made from materials that are the same or very similar in aesthetic and physical characteristics to those used for the manufacture of the profile;

- the manufacturer, concluding direct contracts with suppliers, offers the best prices;

- the manufacturer provides a guarantee for the entire window structure as a whole, and therefore if any part fails, it is restored free of charge;

- the company offers manufacturing, delivery and installation services using appropriate additional elements.

Source: www.plastikovokna.ru

Rehau additional profiles

Additional profile (extension, extension) is an additional profile element for increasing the dimensions or strengthening the frame structure.

Dimensions of additional Rehau profiles

Dobory Rehau

are produced for each type of profile with the corresponding installation depth - 60 mm (

Blitz Design

), 70 mm (

Sib

,

Delight

,

Brilliant Design

).

Step height

— 10, 20, 40, 60 and 100 mm additional profiles provide ample opportunities for implementing installation tasks. If necessary, additional profiles are joined together in various combinations.

Installation of additional Rehau profiles

The profiles are fixed to the frame or to each other by simply snapping them into place.

Depending on the size of the additional profile and installation conditions, clamps or other tightening devices are used for connection.

To ensure airtightness, the joint between the profile elements is sealed with silicone.

To avoid thermal convection, the inside of the joint cavity is filled with polyurethane foam, PSUL or other suitable material. It is also necessary to completely seal the ends of the additional profiles.

To increase the static characteristics of the Rehau

reinforced with a U-shaped, closed or strip steel profile with a wall thickness of at least 1.5 mm. Reinforced additional profiles are screwed to the frame with screws with a minimum diameter of 5 mm through two metal walls.

Rehau additional profiles: design

The front surfaces of the additional profiles are extremely smooth.

They are made from the same type of RAU-PVC

, which determines high resistance to solar radiation and precipitation.

Additional Rehau profiles do not change color and shape for a long time. The service life is comparable to window profiles.

Rehau additional profiles

laminated with colored structural films to ensure visual uniformity with window and door structures.

Application of additional profiles

Additional profiles are used:

- to compensate for the width of quarter openings and reduce the gaps between the structure and the slope - to increase the width of the frame and install various window equipment, such as door closers or remote transom control - to increase the width of the frame and compensate for the thickness of adjacent elements, such as insulating boards - to increase structural rigidity

EXAMPLES OF APPLICATION OF EXTRA PROFILES:

Design without additional profile

The size of the structure is determined taking into account the required visibility of part of the frame from the street.

Design with additional profile

Additional profiles are used to achieve the required technological gap.

Junction of various elements

Extensions are used in cases where various structural elements are adjacent to the frame.

When to use?

Often, the angle is used for glazing gallery spaces, especially if further actions are aimed at insulation. In this case, the norms are taken into account; if something is missing, then extras are added. They are attached to the top or side so that the doors can move smoothly. This option requires following all technological rules.

In addition, the elements allow for interior finishing of walls with plasterboard, clapboard and other materials. Installing a tension surface will not be a problem.

Price of additional Rehau profiles

| Extension height | Rehau profile 60 mm | Rehau profile 70 mm | Rehau profile 86 mm |

| 10 mm | from 450 rub/meter | No | No |

| 20 mm | from 380 rub/meter | from 390 rub/meter | from 460 rub/meter |

| 40 mm | from 480 rub/meter | from 460 rub/meter | from 760 rub/meter |

| 60 mm | from 830 rub/meter | from 522 rub/meter | from 920 rub/meter |

| 100 mm | from 1000 rub/meter | from 1460 rub/meter | from 1730 rub/meter |

Installation of additional profiles

Installation of additional profiles is carried out by slotting and fixing with connecting screws.

To ensure airtightness, the joint between the profile elements is sealed with silicone, and the internal cavity is filled with polyurethane foam, PSUL or other heat-insulating material. The ends of the additional profiles are sealed.

Rehau additional profiles have a smooth, high-quality surface that is resistant to solar radiation and precipitation. The service life is comparable to window profiles.

Requirements for additional profiles

The thickness of the external and internal walls of any PVC window profiles is regulated by special GOST standards, which can be found in a separate thematic review on OknaTrade. The same standards regulate the main operational characteristics of polyvinyl chloride for the manufacture of auxiliary moldings.

In addition, the additional profile for windows must be reinforced. The presence of steel reinforcing liners is necessary not only to increase the overall rigidity of the window structure, but also to ensure the reliability of the connection. After all, expanders are attached to frames using special self-tapping screws, so metal elements in adjacent profiles allow for high-quality joining of individual elements of the window structure.

Color of auxiliary profiles

Expanders and connectors of blocks made of PVC profiles are painted and subjected to lamination, so they do not differ in appearance from the main structures. The additions to plastic windows, photos of which show decor options, can be white or colored in the paste. In standard situations, cream or brown profiles are recommended for applying wood-like films. However, in the case of extensions, you can choose a less expensive white base, since all visible parts of the auxiliary profiles will in any case be covered with films.

How to choose a manufacturer

The quality of the installed window structure is undoubtedly influenced by accurate measurements and installation carried out in accordance with GOST by qualified employees.

After all, it is during the process of measuring the window that the required dimensions and quantity of the additional profile are calculated, and during the installation process the elements are hermetically sealed. When choosing a manufacturer, it is recommended to give preference to reliable companies with extensive experience in this field.

Sizes and manufacturers

The standard length of the window sill profile is 6 meters. But other sizes may vary depending on the model and manufacturer.

As a rule, the width ranges from 2 to 4 cm, the height is 2–3 cm.

The largest manufacturers of plastic windows complete their products with supplied profiles. So the need to purchase them separately usually arises in two cases:

- in case of loss or breakage of a part;

- when the product included in the kit is not satisfactory in terms of characteristics, for example, the number of cameras.

The most common models on the Russian market:

- KBE. For the plastic window system, this company produces profile models 343, 342 and 342R, as well as 142 and Expert.

- Rehau. The Rehau profile model 561013 and 561570 is widely used. It consists of 5 independent chambers - thermal modules. This German company also offers modifications Blitz and Delight.

- Veka. Produces Softline and Euroline models.

The window sill profiles of the following companies have proven themselves well:

- Wintech;

- Brusbox;

- Enwin;

- Montblanc;

- Wds;

- Novotex.

Products of the Russian brands Brusbox and Novotex look more attractive in price than their Western counterparts, but cannot always compare with them in quality.

Recommendations for measuring window and door openings

When measuring window openings in rooms where there are “old windows”, you must adhere to the following recommendations: add 1 cm per side to the external dimensions of the opening (to allow the future window structure to fit into the facade of the building). You also need to remember that the “old window” is in a box, and until it is dismantled, the real size of the opening will not be known. Therefore, the external dimensions of the opening must be compared with the internal ones.

When measuring a “clean” (empty) opening, subtract 1 cm from the dimensions in order to fit the future window structure onto polyurethane foam and spacers.

When measuring the height, you need to remember that if the window has a window sill, then you need to subtract 6 cm from the height of the opening (6 cm is the height required to install the structure on the stand profile).

Also, when measuring the window sill, you must add:

• 3 - 5* cm to width;

• 10* cm to length;

* - provided that the window sill protrudes from the wall.

When measuring ebb tides, it is necessary to start from the depth of installation of the window inside the building (its length = window width + allowance for slopes).

Why do you need a support profile for plastic windows?

The architectural features of modern and old buildings are such that in the area of the lower border of the window, air is pumped under the external tides. In Soviet times, they combated this by placing heating radiators directly under the windows. Now they are often trying to remove them from prominent places, so special attention should be paid to the window sill area and eliminate the possibility of cold bridges appearing there. To solve this problem, a stand profile is installed.

The presence of internal air chambers improves the thermal insulation of the window, and the design of the strip makes it easier to solve several issues at once.