Sometimes in everyday life a PVC window itself is incorrectly called a double-glazed window, and this is incorrect, since the latter concept includes many other important elements.

Their dimensions for euro-windows are determined during the implementation of the building project and must ensure sanitary permissible standards determined for a specific type of premises: residential, public or industrial.

The double-glazed window is hermetically installed in the window frame; the shape and number of windows are decisive in creating the composition of the facade. They are considered the main source of natural light in buildings and create up to 50% of all heat loss.

What do the concepts mean?

A double-glazed window is the main component of a window structure, consisting of two or more sheets of glass, interconnected with sealant, installed on special spacers filled with a desiccant to create a sealed interior area. The interwindow space is filled with air or an inert gas - argon.

The purpose of a double-glazed window is to create an energy-efficient translucent window structure to ensure sanitary permissible parameters of the internal space of residential and industrial premises: natural lighting, ventilation, thermal and noise protection.

The size of the double-glazed window is determined during the implementation of the construction project ; in many cases, it is selected on the basis of standard structures depending on the type of building: multi-story or single-story, wall material and standard design solutions.

Sheet window glass is the main building material that is included in a double-glazed window; depending on the chosen project, it can be polished/unpolished, tempered/annealed and reinforced with mesh. Sheets are produced in rectangular shape with uniform thickness and smooth surface.

Industrial sizes of sheet glass come in length: up to 1.5 m; from 1.5 to 3.0 m; over 3.0 m. In the retail chain you can most often find windows with the following dimensions: 1.6x1.3 m; 2.3x1.6 m; 2.5x1.6 m; 3.21x2.4 m, 3.21x2.55m.

Important ! For ordinary double-glazed windows, colorless glass is used; for glazing balconies, colored glass can be installed.

Minimum and maximum dimensions

Double-glazed windows are dangerous products because they are not durable , can be easily damaged mechanically or from vibration and injure nearby people.

Therefore, their maximum dimensions are limited by building codes, so the maximum glazing area should not exceed 6 m2, while the opening sashes should have an area of no more than 2.5 m2.

The maximum number of sheets in a package is not standardized by GOST , however, since this indicator determines the final weight of the structure, you need to treat it with caution, since the maximum weight of the sash according to GOST is 75 kg.

Due to their high fragility, glass with a thickness of less than 4 mm is not used in double-glazed windows for PVC windows in residential buildings. The thickness of the glass determines the main parameters of a PVC window: sound insulation, tolerable temperature range and thermal resistance to heat leakage.

Characteristics of glass depending on sheet thickness per 1 m2 of area:

- 4 mm, weight -10 kg, sound protection - 30 dB;

- 5 mm, 12.5 kg, 31 dB;

- 6 mm, 15 kg, 32 dB;

- 8 mm, 20 kg, 32 dB.

Opening mechanism

Important technical characteristics of PVC windows include the type of sash opening mechanism. The parameter is important because it indicates how convenient it will be for you to ventilate the room and wash the glass. There are five main categories of designs:

- Deaf. They don't open. They are installed on the first floors of private residential buildings and in office buildings. This is dictated by the peculiarities of caring for the outside of the glass. On the ground floor it can be washed from the street, and in high-rise buildings - after calling industrial climbers. When installing, you should also think about fire safety. If the window is located on an escape route, it is better to abandon it and choose an opening option.

- Rotary. Opens inward. The sash rotates along a vertical axis. The window is convenient to clean, and ventilation of the room becomes easier. But if you have small children or pets in your home, during installation you will need to install special fittings, door opening limiters or durable external mesh.

- Folding. Cannot open completely. The lower crossbar is fixed on a horizontal axis. The design has limiters that prevent the sash from being tilted too far. A safe option for families with children and pets - the opening gap is too small to fit through. There will be no problems with ventilation. When installing, you need to think about the convenience of washing glass. A good solution is to place a sash with a turning mechanism next to it.

- Swivel and tilt. Often called combined because they combine the mechanism of the two types of valves described above. Control is carried out by turning the handle. The most convenient solution, but also the most expensive.

- Sliding. They move to the side along the guides. This allows you to save space on opening the sash and use all the usable space in the room.

+7

Call

Order windows at a profit!

Until the end of the week, 30% discount on windows and balconies!

I want a discount

Thickness, width and height

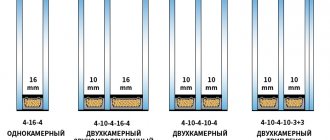

The main dimensions of a double-glazed window are width, height and thickness. The last indicator depends on how many cameras the package will have; its maximum size cannot exceed 80 mm. The single-chamber package has a thickness of 24 mm, the double-chamber one is 42 mm and the three-chamber one is 52 mm.

The height and width of the glass unit is selected individually, in each specific case during design. At the same time, designers try to adhere to standard sizes, since in this case they are easier to purchase in a retail chain, and in the future they are easier to repair and change if necessary.

Glass

For the production of bags, rectangular window sheets of the highest category and first grade are used; in some cases, grade 2 glass is allowed. Determining sheet dimensions established by GOST No. 111, published in 2014:

- Length from 0.500 to 2.200 m;

- width from 0.400 to 1.600 m;

- thickness from 2.0 to 12.0 mm.

Permissible deviations for window glass are considered to be ±2 mm in width and length, and up to +0.4 mm in thickness . The brand of glass should be of the highest quality - M1, with the least optical distortion and without structural defects.

Select glass by marking, for example, M1-TR-1200x1600x6, the highest quality brand, solid dimensions, 1200 - width in mm, 1600 - length in mm, 6 mm thickness.

Table of PVC window packages

They are limited by GOST requirements for thickness and total weight of the structure.

Thickness is defined as the sum of the thicknesses of the sheet and the inter-glass space ; the thickness of the glass can be from 4 to 12 mm, and the width of the air channels from 6 to 16 mm.

Table of maximum sizes of double-glazed windows depending on the thickness of the window sheet:

| Thickness | Width | Square |

| 3 mm | 1500 x 1270 mm | 1.60 m2 |

| 4 mm | 2420 x 1300 mm | 2.86 m2 |

| 5 mm | 3000 x 1750 mm | 4.00 m2 |

| 6 mm | 3500 x 1980 mm | 5.88 m2 |

| 8 mm | 3500 x 2000 mm | 8.75 m2 |

| 12mm, | 3500 x 2700 mm | 9.45 m2 |

Formula

The glass unit formula is a normatively accepted code, consisting of a set of numbers and letter designations that characterize its configuration and characteristics. The numbers indicate the geometric dimensions of the glass and the distances between them.

For example, the simplest single-chamber package of 2 glasses with a thickness of 4 mm and a distance between glasses of 18 mm will have the formula: 4-18-4. It is easy to calculate the total thickness of the package: 4 + 18 + 4 = 26mm.

A high-quality double-glazed window made from a 5 mm sheet will have the following formula: 5-12-5-12-5, the thickness of the package is 29 mm.

The formulas of modern double-glazed windows have not only digital designations, but also letters, the latter indicating certain characteristics of the product: M - glass quality, energy-saving characteristics: i, “Low”, “Low-e” or “Ar”.

Recommendations for choosing a double-glazed window according to the formula designation:

- two-chamber package 32 mm with M1 4mm float glass: 4M1-10-4M1-10-4M1;

- single-chamber package with energy-saving coating: 4-16-4i;

- single-chamber package with low-emissivity glass “Low” or “Low-e”: 4-16-4Low;

- two-chamber package with 2 energy-saving glasses: 4i-14-4-14-4i;

- two-chamber package with 2 energy-saving glasses and argon: 4i-14Ar-4-14Ar-4i;

- two-chamber package with 2 energy-saving glasses, a thermally insulated spacer frame and argon: 4i-14TAr-4-14TAr-4i.

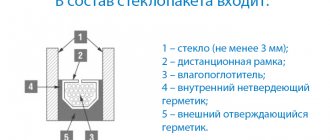

Double-glazed glass design

Some elements of the glass unit are hidden from view. The composition of a two-chamber double-glazed window includes:

- glass – 3;

- chambers (interglass spaces) with air or gas filling – 2;

- distance (dividing) frames – 2;

- desiccant;

- internal (primary) sealant;

- external (secondary) sealant.

Glass can differ in production and processing technology, PVC profile, composition, coating, color, thickness, and it is on their characteristics that the properties of a double-glazed window largely depend.

It is also important to fill the chamber between the glasses; regular moist air must be pumped out of it; the inside of the glass unit must contain a minimum of moisture, otherwise condensation will negate its heat-protective properties.

The spacer frame is a hollow tube with a cross-section close to rectangular, lightweight but durable. Initially, spacer frames were made of aluminum, less often of steel; later, a technology for producing frames from polymers with lower thermal conductivity than metal was developed.

The frame can consist of four straight segments connected by corners, or bend at the corners. In the second case, the structure has only one joint and the likelihood of depressurization through the joints is significantly reduced.

The spacer is filled with a desiccant (absorbent, desiccant - a substance with a large number of pores), and there are small diffusion holes along the top of the frame. Through them, moisture molecules penetrate from the air in the chamber into the frame and are absorbed by the absorbent. The following are used as a desiccant:

- molecular sieve;

- silica gel;

- a mixture of them.

Primary sealant - butyl mastic or tape, which retains elasticity after hardening, is used to firmly connect glass and frames into a single structure and to protect against water vapor contained outside.

After gluing the glass and frames, a secondary, external sealing is carried out to give the structure additional strength and moisture-vapor resistance. For external sealing, plastic masses based on:

- polysulfide;

- silicone;

- polyurethane.

Read: which double-glazed window is better: single-chamber or double-chamber.

Why is it important to identify and choose correctly?

As a rule, this data is needed in order to qualitatively replace double-glazed windows in an existing PVC window.

This replacement may be due to mechanical damage, seal failure, or the need to install a new energy-efficient package.

The correctly selected size will help to efficiently install the new package while maintaining the functionality of the main window components.

Knowing the size, you can determine the acceptable glass formula for selecting it on the market, and you can strengthen its protective characteristics, for example, by replacing the glass thickness from 4 to 6 mm, or replacing a two-chamber glass with a three-chamber one, if the thickness of the old package allows. If you cannot find a three-chamber package based on this indicator, you can simply install energy-efficient glass.

How to measure yourself?

There are several options by which you can quite accurately determine the size of a double-glazed window, without disassembling the PVC window:

- Measure the distance between the width and height of the package along the glazing groove exactly to 1 mm and subtract 10 mm from the resulting value. This size determines the deformation gap between the glass and the PVC frame. To prevent the package from breaking due to temperature expansion. For example, the width along the groove is 485 mm, then the double-glazed window will have a width of 485-10 = 475 mm.

- Next, measure the thickness of the bag; the easiest way to do this is by looking at the window passport or contract; this characteristic will be indicated there, for example, for a 32 mm two-chamber bag.

In most cases, this characteristic is indicated on the spacer bar.

You can also measure the width of the PVC frame and calculate the width of the double-glazed window using the formula:

Ш st = Sho - Asn - Asi,

Where:

- W st - width of the glass unit in mm;

- W o - window width in mm;

- Asn - distance from the frame to the glass outside, mm;

- Asi - distance from the frame to the glass from the inside, mm.

For example:

- W st - width of the glass unit in mm;

- W o - window width 40 mm;

- Asn - distance from frame to glass outside, 4 mm;

- Asi - distance from the frame to the glass from the inside, 4 mm;

- W st = 40 - 4- 4 = 32 mm.

Almost all serious window companies have a laser device for determining the thickness of a PVC window. The glass unit size determined by the instrumental method will be the most accurate.

Triple glazed windows

The concepts of “three-chamber double-glazed window” and “triple glazing” are often confused. Triple glazing is called glazing, which uses 3 glasses, and in a three-chamber package there are 4 of them. There are several possibilities for triple glazing a window:

- Installing a double-glazed window consisting of three glasses is the most common, simple and rational option with the best price.

- Install a single-chamber double-glazed window (2 glasses) plus a single glass. In this case, a special two-frame design is needed, where a double-glazed window is installed in the inner frame (profile), and single glass is installed in the outer frame. This technology is used mainly in wooden and wood-aluminum euro-windows.

Number of cameras in profile

The word “chamber” means not only the air compartment in the glass unit, but also special voids in the profile. They are separated by partitions.

The greater the number of cameras, the better the protective performance will be. The width as well as the weight of the profile will increase significantly. The most budget-friendly solution remains the option with three chambers, but to improve thermal insulation it is best to use models with five or six voids.

To make the multi-chamber structure stable, the profiles are reinforced. Reinforcement of REHAU profiles is carried out in accordance with TU 1108-001-02068195-2008.

No. 6. Distance frame

Literally everything is held on to the spacer frame in the glass unit. It holds the glass and sets the required distance between them. It is better to choose a double-glazed window with a frame made not of aluminum, but of steel , because its thermal conductivity is lower, but it is even better to use a completely fiberglass or plastic frame .

The glass is connected to the spacer frame using butyl and thiokol based sealants, which insulate the entire structure and give it the necessary physical properties. In fact, all well-known manufacturers of double-glazed windows use a similar joining method, but there are also unfortunate companies that glue the entire “pie” together with double-sided tape.

Additionally, thin decorative frames can be installed inside, which form an interesting layout.