A balcony parapet is a fence around its perimeter. It can be metal, wooden beams or concrete. Its main function is to ensure security. Therefore, you need to monitor the condition of the balcony parapet. Before performing glazing, it is necessary to strengthen it.

Self-strengthening the balcony parapet

A material such as foam block, sometimes called cellular concrete, is a practically non-flammable material with a universal profile.

Usually it is assigned the role of an element from which a new balcony parapet or roof parapet is erected. It is also important not to forget to treat it on the outside with glassine - this will give the structure additional protection from moisture.

To construct such a structure you will need the following tools:

- hacksaw or circular saw;

- Bulgarian;

- hammer;

- plumb line;

- perforator;

- building level.

Materials required for installation:

- foam blocks;

- primer;

- glue-based block mortar;

- mixture required for plastering;

- zinc treated mesh;

- iron rods.

It is recommended to perform all work according to the following algorithm of actions:

If desired, detailed descriptions of the entire process of strengthening a balcony parapet with videos and photos can easily be found on the Internet.

How to strengthen the balcony parapet in front of the glazing, see details in the video:

Metal reinforcement

Metal reinforcement looks like this:

- If the technical condition of the parapet is acceptable (does not require radical measures), then it can be strengthened by welding metal corners to the areas of old reinforcement necessary for this.

- In case of severe wear and tear, the old metal parapet is carefully separated and then replaced with a new one.

Options for strengthening the balcony parapet before glazing Also, a good option for strengthening the parapet is the use of building foam blocks, the qualities of which perfectly strengthen the balcony parapet.

Strengthening the balcony structure

Insulation of balcony parapet

Most often, it is necessary to thermally insulate not just one part of the balcony (parapet, walls, floor, ceilings), but the entire structure as a whole.

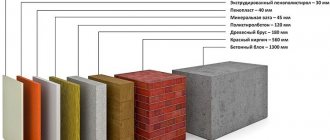

The raw material for this must necessarily be a material that has non-flammable properties, is resistant to moisture and is light in weight, which can be easily attached to balcony elements. In this case, a good option would be to use polystyrene foam (expanded polystyrene) or isolon.

It is known that the coefficient of thermal conductivity of polystyrene foam is very low; moreover, it is an excellent sound-insulating material and can withstand any natural loads. Polystyrene foam is also not susceptible to the formation of any fungi or other harmful substances on it, it is durable, and in addition, there is a wide selection of this material with different thicknesses and overall dimensions. Some categories of polystyrene foam are even fire-resistant; however, it would be better to store the material away from gasoline, solvents and other flammable mixtures.

Materials required for insulating a balcony:

- Styrofoam;

- dowels equipped with caps;

- polyurethane foam;

- a roll of foil tape;

- penofol;

- construction knife.

Balcony insulation process:

Strengthening the balcony parapet with foam blocks

Strengthening the parapet on the balcony can be made of foam block, which has the following characteristics:

- high strength;

- thermal insulation;

- soundproofing;

- fire resistance;

- durability;

- environmentally friendly.

This material is lightweight and easy to cut, so you can strengthen the balcony railing with foam blocks yourself. To do this you will need:

- foam blocks 70-100 mm wide;

- adhesive composition for blocks;

- plaster mixture;

- primer;

- waterproofing material;

- iron rods;

- fittings;

- galvanized mesh;

- Bulgarian;

- circular saw or hacksaw;

- perforator;

- propane torch;

- hammer;

- putty knife;

- plumb line;

- level.

The following procedure is performed:

- Taking measurements of fencing and window openings. The new fence should be 10-15 cm higher than the previous one, this is necessary for installing a drainage system. In a 10-story building its height should be at least 1 m, in a taller building - at least 1.1 m.

- If the screed is of poor quality, it is removed and then a new one is poured.

- The adhesive waterproofing material is spread. To do this you will need a propane torch. Sometimes waterproofing is not carried out. Instead, a U-shaped aluminum channel is laid around the perimeter of the balcony. It is fixed with cement mortar and screwed with dowels. The bottom row of foam block is laid out in this profile.

- The required number of blocks is calculated. If the result is not a whole number of rows, but for example 3.5, then the blocks are cut to the required size and used for the first row, and they are laid with the cut side down.

- Foam blocks are laid along the edge of the balcony slab parallel to the old parapet. The distance between the old and new fencing should be minimal, then there will be more usable area on the balcony. However, you can make a larger gap and place insulation in the gap. The solution for foam blocks is applied with a spatula. When laying, use a plumb line and level.

- Reinforcement and iron rods must be driven into the junction of the wall and the foam block masonry so that one end is in the wall and the other is located exactly on the horizontal masonry seam.

- Foam blocks are laid “in a run” on a special masonry mortar.

- The masonry is reinforced with galvanized mesh with a wire diameter of 3 mm.

- During the construction of a parapet on a loggia or balcony, the foam blocks are primed with a primer designed for porous materials. Then they are plastered outside and inside with facade plaster.

- The previous point can be omitted if the foam block parapet is immediately sheathed and glazed.

Internal and external editing of the under-rail space, methods of strengthening

Over the years of operation, the balcony and loggia are exposed to weather factors, concrete and iron must be restored. In order to maintain decorativeness, internal and external decoration of the under-rail space is needed. At the same time, when installing windows, the main load falls on it, so it is important to provide the necessary margin of safety for the enclosing structure around the perimeter of the balcony or the facade of the loggia. Each has its own technical subtleties.

For example, a metal parapet on a loggia at the very edge of the slab will not be able to reliably hold a double-glazed window; it must be moved deeper. A collapsing slab can collapse under the brickwork; in Khrushchev and Brezhnevka buildings, a metal frame is often insulated. Loggias are more reliable. Firstly, these houses are relatively new. Secondly, the slab is fixed by the side walls, which allows increasing the static load. Such parapets can be safely strengthened with gas blocks.

Subsequent finishing

Lining is one of the most environmentally friendly finishing materials

After installing all the insulation sheets (plates) into the frame cells, all gaps between them and the frame profile are carefully sealed with sealant, putty or polyurethane foam.

After this, you can begin covering the frame with finishing materials - gypsum board sheets, laminated chipboard, MDF, PVC panels, flooring, etc. On the floors, on top of dense insulation such as penoplex, you can make a cement-sand screed or poured floors, on top of which you can lay tiles.

As you can see, using the instructions for insulating a balcony, doing all the work yourself will not be difficult. To do this, it is necessary to strictly follow the recommendations of the material manufacturer and comply with the requirements of building regulations when carrying out work.

You can increase the living space of the apartment due to the area of the balcony. However, for this it needs to be insulated. Sometimes only insulation saves the apartment from the cold and removes ice from the balcony door.

For a balcony located at a level no higher than the second floor, the best option is considered to be do-it-yourself external insulation. At higher levels it will be necessary to attract specialists with high-altitude equipment.

Let us dwell in more detail on the popular methods of external insulation of balconies.

Main stages

We will write out detailed instructions for insulating a loggia with your own hands. Firstly, glazing. Designs made of plastic are best suited for this.

This stage also includes the installation of additional expansion-type profiles. Before installing double-glazed windows, the parapet is laid, as well as the construction of side walls - foam blocks or light brick (silicate, ceramics).

Before insulating the loggia, you must carefully check the installation seams located around the perimeter of the window block. Inside they should be treated with special foam. Outside - cover with plastic “flashings” or “facade sealant”. All this is necessary to prevent the destruction of the foam surface and the negative influence of moisture from the street. Secondly – direct thermal insulation.

Laying the insulator

Installation of insulating materials is carried out after complete glazing with all preparatory measures. The insulation installation process itself is not too complicated. Plates made of foam plastic or penoplex are glued to the wall, covered with various protective compounds, and doweled. Then it’s time to finish the walls of the loggia.

For finishing in the case of penoplex, materials such as aquapanels, VGKL and GVL are suitable. After installing them, you can cover the wall with wallpaper or perform other work aimed at comfortable and aesthetic living.

Methods for insulating facade glazing

Insulation of façade glazing means carrying out thermal insulation

balcony with installation

of a ventilated facade

. Experts identify several methods that are used to insulate cold facade glazing:

- insulation of existing frames;

- installation of double-layer frames;

- replacement of double-glazed windows.

Each of them has its own characteristics and requires a certain algorithm of actions. When choosing a method, the technical side of the issue (possibility of application in a specific situation), safety, customer preferences, and material resources are taken into account.

Installation of a plastic structure

This term refers to the glazing of a balcony with plastic windows.

. To perform such work, you need to adhere to a certain sequence: dismantling old window frames, installing plastic windows in a pre-assembled frame, eliminating cracks using construction foam, waterproofing. After checking the tightness, installation of the platbands is carried out. This is done for additional protection against low temperatures and to add aesthetics to the room.

Additional circuit

Insulation

façade glazing of a loggia using

a second circuit

is appropriate in cases where dismantling the previous one is technically impossible.

This term means the installation of a second absolutely identical structure. To carry out this type of insulation, it is necessary to obtain permission from the authorities, since the second circuit not only performs the function of thermal insulation

, but doubles the pressure on the balcony slab and load-bearing structures

of the building

. This method has several disadvantages - inconvenience when opening, reduction in usable area.

This type of insulation is considered radical, as it requires the removal of previously installed wooden frames and windows

loggias. After dismantling, double or triple glazing is installed. This method is effective because the new glazing does not allow cold air to pass through due to its tightness. In this case, it is possible to install heating devices, which allows you to make the loggia a full-fledged room. Insulation of walls, ceiling and floor will be required to prevent heat loss.

Installation of warm aluminum profile

The term “warm aluminum profile” refers to the presence of a polyamide insert in the middle of an aluminum structure. A cold profile does not have a heat-retaining layer. For this method of insulation, a cold balcony facade

replaced with

an aluminum window profile

, in the middle of which plastic elements are built in. This requires a 2nd or 3rd glazing. This type will be the optimal solution for southern latitudes and is not suitable for northern regions.

Installation of plastic windows

In this case, the old cold glazing is dismantled, the frames remain in place. Window blocks are installed on prepared frame structures

with good thermal insulation properties. Before installing decorative cladding, it is necessary to check the tightness.

The use of warm plastic windows allows you to save the area of the loggia or balcony. The advantages of this method include low cost and low labor intensity.

Insulation of single frames

Provided that the previous frames are strong enough, a second layer of glazed frames is installed on the loggia to retain heat. Before installing the frame structures themselves, you need to make supports on which the second layer of glazing will be placed. The disadvantages of this type of window repair

include high material costs and inconvenience in use.

Replacing old fencing

Preliminary dismantling of the old parapet is possible (but not required) in whole or in part. This is done in cases where:

- want to free up additional usable space;

The balcony is expanded along the base of the slab - the old structure has fallen into disrepair and its preservation is inappropriate.

The base is completely rotten

When dismantling the parapet, special attention should be paid to the safety of work at height, as well as to fence off the potentially dangerous area around the house and prevent passers-by from being in it. In some cases, it is advisable to use the services of professional industrial climbers.

Usually they strengthen the existing fence without dismantling it. The choice of method depends on many factors (the general condition of the base, the size of the balcony, the type of old fence, the future use of the balcony).

Strengthening Tips

It is necessary to take a decision from the relevant authorities. All independent work related to changing the appearance of the house entails administrative responsibility. It is worth knowing that if the fastenings are chosen incorrectly, the structure may collapse.

Once you have decided on the type of house, you can get to work.

It is very important to follow several rules that will give effective results. For example, when glazing the balcony part receives additional load, so it is important to strengthen it. This can be done in different ways

First of all, we need to create new support points:

- The first option involves installing supports from below. However, this method is suitable when the balcony is not high. To do this, you need to agree with your neighbors so that they do not complain about you when a similar structure is located in front of their windows. With this method of strengthening, 2 supporting metal structures are used in the lower part, which are concreted in the ground and support the balcony like columns. The supports are best secured using special brackets or screws.

The second method is fixation from above, much more convenient than the first. To do this, you need to drill 2 holes through the wall above the balcony (on both sides) and install strong metal rods (anchors, bolts) or special hooks. If they have threads, then they are secured with nuts and small plates, otherwise they must be concreted on both sides. The part protruding outwards serves to support balconies, which are suspended, for example, with chains.

If the additional structure is outdated, its parapet needs to be strengthened. Metal structures are the best help in this matter. You need to weld a triangular frame, which needs to be attached as rigidly as possible to the wall of the apartment. This option is universal for all loggias, even the oldest.

By using a foam block, you can not only strengthen it, but also insulate the room, but this increases the weight of the structure, which will put pressure on the base of the balcony. Because of this, the method is not suitable for old and narrow balconies.

There is another option for fastening using T-beams. It is very suitable for updating old premises that are in danger of demolition, but you must know exactly the height of the ceiling:

- First you need to cut off the old slab.

- Drill out 1 m long recesses in the floor at 1.5-2 tee heights, if the ceiling allows. Don't forget that there are neighbors below you, and they need a ceiling. It is necessary to make 3-4 such grooves.

- Next, holes are knocked out in the wall.

- Metal rails (brands) 3 m long are passed through them. 1 m remains in the apartment, and the remaining 2 in the outer part.

- Build formwork on the floor and on the protruding part of the rails and fill it with concrete mixture. The level of the slab and the load-bearing covering of the house must completely match.

- Then the frame of the fence is welded from the corners.

- You can build a loggia, decorate and insulate it using special materials.

It is important to know how to properly strengthen it so as not to compromise the integrity of the building and not endanger those who go out onto the balcony. If you realize that you are unable to carry out repairs yourself, contact the experts for help.

Preparation

As already mentioned, in order to properly insulate a balcony and not reap the consequences of incorrectly performed work, you need to act according to a clear algorithm. It starts with preparatory work. You need to remove all unnecessary things from the balcony, remove old frames with glass and take them out, clean the surface for work.