How to cover a balcony with polycarbonate with your own hands

At the moment, various works to improve the appearance of residential premises are especially popular. Moreover, most owners of private houses and apartments prefer to carry out all installation work with their own hands, without resorting to the help of highly qualified specialists.

This approach makes it possible to significantly save the family budget and show others what you are capable of. Some home craftsmen learn something new in this way and at the same time improve the appearance of their home.

Sheathing a balcony with polycarbonate is currently considered a novelty, because such products are mainly used to build greenhouses on a summer cottage.

Preparatory work

The balcony frame must be designed in accordance with the expected loads.

We prepare the room for the installation of polycarbonate. Before starting work, we calculate the permissible loads on the slab, taking into account that a metal structure welded to the wall will transfer part of the load from the slab to the wall.

We prepare convenient approaches to the work site.

If necessary, we carry out major or scheduled repairs of the balcony base. The slab bears the entire load, so it must be in perfect condition; all existing cracks are cleaned of dust, moistened and filled with concrete mortar.

We strengthen or replace metal railings, treat the steel with an anti-corrosion compound. If you plan to use the balcony throughout the year as a living space, replace the railings with a parapet made of foam blocks.

We choose the thickness of the polycarbonate depending on the seasonality of use of the room and the planned functionality.

This is interesting: Do you lay the brickwork correctly? Lessons and Basics of Masonry - Instructions

What polycarbonate can be used for balcony railings?

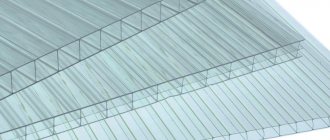

The optimal choice would be cellular polycarbonate. In this case, special attention should be paid to the type of honeycomb material. The type of sheets is often indicated by the manufacturer on the annotation that comes with the building material.

Types are distributed according to the principle of endurance and aesthetic indicators. This can be an elite type of polycarbonate, an economical option, or an optimal one, considered something in between these types. The service life of elite polycarbonate is at least 20 years, economical - 8 years, optimal - 10 years.

Tools and materials for installation

In order to install a roof or balcony glazing using polycarbonate with your own hands, you must have:

- Drill;

- Square;

- Roulette;

- Construction level;

- Electric jigsaw or regular wood saw;

- Screwdriver;

- Self-adhesive poly-protective tape;

- Connecting and end profiles;

- Self-tapping screws;

- Sealing seal washers.

Advantages and disadvantages

The material is considered an innovation; it appeared on the construction market relatively recently. Despite this, polycarbonate is already widely used by builders.

It has a lot of advantages:

A significant advantage is the ease of processing polycarbonate sheets and their further fastening. You can cover your balcony with polycarbonate yourself. No special equipment is needed to operate.

The material has disadvantages. The main disadvantage is low resistance to temperature conditions. When heated, the material expands, and when cooled, it returns to its original state. After such fluctuations, gaps appear into which cold penetrates in winter and heat in summer.

Also, polycarbonate sheets often develop scratches, even with the most careful handling.

What you need to know when working with polycarbonate

When working on a balcony, you need to consider the following material features:

- The finished elements are mounted on the frame so that the side with the protective film faces the street;

- to avoid the accumulation of condensation and the accumulation of dust and small insects inside the honeycomb sheets, the ends are sealed with tape or special tape;

- Removal of the protective film occurs only after the final installation of the entire structure on the balcony. Protection must be maintained to prevent damage to surfaces that have poor abrasion resistance;

- The sheet joint is made with a small gap. The joints are sealed with silicone sealant and masked with a plastic cover;

- for a polycarbonate canopy, choose a material with a thickness that allows you to bend the sheet at the desired angle.

Photos of polycarbonate balconies

In order to understand exactly what polycarbonate looks like on a balcony, you can look at photographs of already completed projects. In this case, polymer products can be used not only transparent, but also colored, which will make the appearance more attractive.

Do-it-yourself polycarbonate installation

We prepare tools and purchase materials. A transparent polymer will let in more light than a matte one. Polycarbonate can be installed in solid parts or in small panels.

Carbonate can be cut well with a grinder or a stationery knife.

Tools you will need:

- electric jigsaw, grinder, screwdriver, drill;

- building level, tape measure, construction knife;

- ladder.

Let's look at how to glaze a loggia and balcony with polycarbonate with your own hands.

Stages of work:

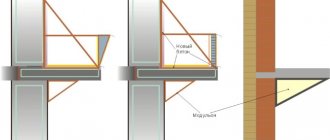

- A metal or aluminum frame is being prepared. The frame is made taking into account the thickness of the polycarbonate sheet. For the economy version, panels with a thickness of 6 to 16 mm are mounted on longitudinal supports in increments of up to 700 mm; for sheets with a thickness of more than 25 mm, the increment can be up to 1050 mm.

- We cut into the required sizes using a grinder or a stationery knife. We take into account that the gap between the sheet and the frame should be 2.5-4 mm. We drill holes in the sheet for fasteners; they should be 1.5 mm larger than the diameter of the screw.

- The ends are covered with a special aluminum tape to protect them from moisture and dust.

- We fasten the polycarbonate to the frame with self-tapping screws or screws on clamps with a pressure head (thermal washer on the leg) with a thickness slightly exceeding that of a sheet of material. This type of fastening protects the raw material from cracking.

- After completing the installation work, all joints are properly sealed with silicone.

- We install the visor. For instructions on installing cellular polycarbonate, watch this video:

Polycarbonate cannot serve as a load-bearing partition. During installation, the sheets are aligned along the top edge. The UV protected side should face the street.

The nuances of installing a structure with arched bends

When installing an arched roof or a curved balcony, take into account the maximum permissible bending radius of the sheet of the selected type of polycarbonate. Purchase material so that the permissible bend radius is slightly larger than what is actually required.

After installing the arched structure, the edges of the connecting profiles are aligned with a jigsaw.

What you need to know when working with polycarbonate

During the work, the following features should be taken into account:

- the sheet is always installed with the protective coating facing out;

- the ends are sealed with a special aluminum tape or covered with plugs;

- the protective film is removed only after completion of work, since the material has low abrasive resistance and can be scratched even with minor impact;

- when cutting sheets and installing them with their ends facing each other, we glue the seam with self-adhesive tape, then cover it with an end profile;

If you install colored polycarbonate, it will play beautifully with reflections in the light of the sun

A polycarbonate balcony looks very beautiful. This material protects from weather influences and retains heat well.

Thanks to the wide range in various color shades, even the most daring design project is easy to implement. Depending on the chosen color of the sheets, from 20 to 90% of natural light will penetrate onto the balcony.

How to glaze a veranda with polycarbonate

The procedure for insulating a loggia

Installation of a canopy on the balcony

Step-by-step insulation of loggia and balcony

Options for external cladding of the balcony

External finishing of the balcony with corrugated sheeting

Which canopy to choose for a balcony

The main disadvantage of a balcony canopy made of thicker polycarbonate is the price, which increases as the thickness increases.

The best option is to use a material with a density of 5 mm for the monolithic type and 10-15 mm for the cellular type. The cellular type is more affordable. This polymer provides enormous opportunities in choosing roofing design. To design a polycarbonate canopy for a balcony that will best harmonize with the exterior of the house, it is recommended to view as many photos as possible. You can see examples of completed work on the website.

The most common forms of canopies are:

- semicircular;

- arched;

- straight inclined;

- gable.

Any of the shapes forms the slope required for the melting of snow masses. In a private cottage with a large balcony or veranda, you can make a combined polycarbonate canopy. By combining arches and inclined sheets of varying sizes, you can make an unusual dome that protects from rain, snow and direct rays of the sun.

The canopy increases the comfort of staying on the balcony even without full glazing. The labor costs of such a solution are much lower than trying to glaze the balcony completely. As with full polycarbonate sheathing, a frame will be required. However, in this case it can be made not from an aluminum profile, but from small diameter pipes.

The pipes are cut into pieces of the required dimensions and welded together using corner and diagonal joints

It is important to maintain evenness. The formed frame is sanded, primed and then painted.

For installation to the wall, anchor bolts or expansion dowels are used. Before hanging the canopy, polycarbonate is screwed to it with self-tapping screws using thermal washers. The gap between the structure and the wall is sealed with sealant.

Despite the apparent simplicity of the work, installation has a lot of nuances. EliteBalcon specialists will take everything into account.

Why cellular polycarbonate?

Polycarbonate is a transparent plastic that belongs to heat-resistant polymers. A sheet of cellular polycarbonate consists of several thin sheets connected to each other through many ribs, between which there is an air space - a “honeycomb”.

Advantages of the material:

- Sound and heat insulation. Polycarbonate with a thickness of 12-15 mm retains the same amount of heat as metal-plastic double-glazed windows. If you additionally install it instead of ordinary glass, you can increase the thermal insulation by another 2 times.

- Light weight. Polycarbonate sheets are thin - up to 0.7 mm and lightweight, but despite this, they are impact-resistant and ductile. The strength of the structure is also increased thanks to the stiffening ribs.

- Durability. Polycarbonate can withstand sudden changes in temperature, severe frost and heat, and is resistant to hail impacts, strong gusts of wind and snow loads. The warranty period for polycarbonate is 10 years. Under favorable conditions, it lasts up to 15–20 years.

- Light transmission. Depending on the color of the material, polycarbonate transmits up to 86% of light rays, and thanks to its protective UV coating, it blocks harmful ultraviolet radiation.

- Fire safety. Polycarbonate is a non-flammable material. It smolders quickly and slowly and does not spread fire.

All these factors make polycarbonate a suitable material for glazing, roofing and external decoration of balconies. Therefore, it is possible to make the entire balcony out of it and save your money and time. The only thing you need to remember is that polycarbonate is easily scratched and requires careful handling. When cleaning surfaces, movements should be light; rough brushes and aggressive chemical cleaners containing concentrated alkali should not be used for this purpose.

This is interesting: How to cover a balcony with corrugated sheets with your own hands? Step by step

Links to useful videos.

How to cover a balcony with polycarbonate and a roof video:

Profiled polycarbonate has recently begun to be used on a large scale in construction. It is used for the construction of gazebos,…

Any garage space is created to protect the car from rain, wind, snow and other atmospheric…

Strength, durability and moisture resistance directly depend on how correctly the components for polycarbonate are selected...

In December 2022 passed all tests to confirm compliance with the requirements of the Technical Regulations “On...

A carport made of polycarbonate is suitable for a summer house or area near the house. To build a garage...

More and more owners of cottages and country houses are choosing modern, high-quality materials when arranging their territory. For example, for the construction of gazebos...

Polycarbonate is a durable, lightweight and transparent material made from hard polymer plastic. Plasticity, frost resistance, durability and other qualities of cellular polycarbonate...

Not so long ago, greenhouses in summer cottages were used for their intended purpose - for growing...

Today, sheds are often made on summer cottages. The attachment of polycarbonate to the metal frame must be reliable.…

There are many ways to organize an artificial reservoir in a suburban area: starting from budget inflatable models and...

Using profiles during installation

The diameter of the hole in the slab for the screws that secure the material to the bottom of the frame must be larger than that of the bolts. This is done so that when expansion occurs due to high temperature, the integrity of the sheet is not compromised.

After installing the main profile, install the pressure cover. Perform such manipulations with subsequent blocks until the final installation of the structure is completed. After this, remove the plastic film from the outside of each sheet.

Cellular and monolithic polycarbonate are inferior to glass in terms of translucency, but have much less weight and greater reliability. Plastic is also less exposed to environmental factors and has virtually no impact on the environment. Cellular polycarbonate is the best solution for do-it-yourself balcony glazing.

How to glaze with monolithic polycarbonate sheets?

Before glazing the balcony, you will need to make an aluminum frame. If you have experience in installing such structures, you can do it yourself.

Monolithic sheets come with standard dimensions of 3.05x2.05 m. By correctly calculating the material consumption, you can reduce the amount of waste and even use it up completely. This will also reduce the cost of the aluminum frame itself.

Polycarbonate balcony

You can cut the blades using a circular saw with small teeth (as in the photo). There is no need to connect the sheet covering end to end, since this material tends to expand when the temperature rises. Therefore, the sheet may increase slightly, which will lead to curvature of the surface. If the size of the frame is assumed to be 1.5x1 m, then an indent of 3-4 mm is made from the cut of the polycarbonate sheet to the aluminum corner.

To allow more daylight into the room from the balcony, it is best to purchase transparent material. However, quite often they use a combination of different colors and shades - such finishing significantly improves the appearance of the structure.

"EliteBalcony" - original decoration of your balcony

Do you want an unusual, stylish balcony? We know how to do it. Polycarbonate is a plastic material, so structures of various shapes can be created from it. There are also variations in sizes and colors, allowing you to experiment with designs. In addition to the usual transparent plastic, there is translucent polycarbonate and models in various colors: white ice, bronze, silver, turquoise, pearl. They transmit 20-40% of the sun's rays and create a soft, pleasant glow.

Mirror material looks original, and if you need something brighter, choose polycarbonate in red, yellow or green. You can use a combination of several shades and come up with your own unique style. When covering a balcony with polycarbonate, one of its features should be taken into account: it expands under the influence of heat and contracts when the temperature drops. To ensure that the installation is not damaged during such changes, our craftsmen install the cladding with small gaps - up to 4 mm.

Is it possible to finish the balcony yourself? Certainly. If you have experience working with the material and have the necessary tools, the installation process will go like clockwork. Otherwise, it is better to entrust this task to professionals. The transformation of your balcony will happen in just 1-2 days, and you will save your time and effort.

Do you want to cover your balcony with cellular polycarbonate? Our master is ready to come to you today to take measurements, select color, material texture, and announce the final cost. To place an order, contact our manager by phone.

Features of forged canopies for balconies

Forging capabilities allow the creation of aerial structures with a variety of twisted shapes. This is very attractive from an aesthetic point of view and allows you to create truly original frames for balcony canopies.

Photo:

Forging involves working with a solid metal rod. Compared to hollow profile pipes, such material is able to withstand equal loads with a much smaller cross-section.

Forged frames look much more delicate in appearance.

In terms of reliability, forged structures are also superior to products made by welding or screw connections. Their durability is ensured by high-quality galvanizing or paint coating.

Forged canopy on the balcony of a private house

Note! However, a forged visor can have significant mass. Therefore, before choosing this option, you should make sure that the design of the balcony allows you to securely fasten such a massive structure to it

Return to content

Beautiful ideas

- Open arched balcony. This attractive structure acts as a canopy over the entrance to the house. The semicircular shape prevents the accumulation of snow and water during rain, and the spacious area allows you to organize a good rest.

- Wooden attached balcony. Using this design, you can simultaneously organize two cozy corners for relaxation. The base platform here will act as protection for the terrace from precipitation.

- The semicircular unglazed balcony simply amazes with its magnificence. An interesting solution in this case would be the use of forged fences.

Installation nuances

Procedure for installing a polycarbonate roof.

All preparatory work and dismantling of old fragments must be done first, before finishing the balcony begins. Cellular polycarbonate boards are always mounted with the side on which the protective UV coating is applied. The protective polyethylene film is removed before installation.

Polycarbonate sheets are easily cut with ordinary tools used for woodworking. The slabs are cut according to the required dimensions, the protective polyethylene film is turned around the entire perimeter from the outside of the slab. Then the ends of the slab are sealed with self-adhesive protective tape and closed with end profiles. This is necessary to prevent dust and moisture from getting inside.

The roof of the balcony can be made with a standard canopy or in the form of a canopy, or you can use your imagination and create intricate designs.

Scheme of fastening cellular polycarbonate.

If you are installing the material taking into account the arched bend of the structure required by the balcony roof, then take into account the minimum permissible radius of cold bending of the slabs applicable to the type of cellular polycarbonate you have chosen. Since in arched structures the bending radius of the connecting profiles is greater than the bending radius of the slabs, they should have a slightly larger size compared to the length of the slab. At the end of the installation of the arched part of the structure, the connecting profiles can be aligned along the edge of the slabs using an electric jigsaw.

The roof of your balcony can have any shape - whatever frame you make, that’s what the roof will be. The polycarbonate roof creates a light and warm atmosphere in the room, and the cellular structure makes this material heat and sound insulating. Depending on the color of the polycarbonate slabs, from 20 to 70% of natural light will penetrate onto the balcony.

Visor options

For a polycarbonate canopy on the top floors, it is recommended to use the following materials:

- multi-colored coating;

- cellular polycarbonate with painting.

In the second option, such a visor will cost slightly less than in the first. The thicker the material, the more reliable it is. But it is not recommended to use a very thick coating, as it is more expensive. The best option for a monolithic sheet is a sheet with a thickness of 0.4-0.6 cm, and for a cellular sheet - 1-1.4 cm.

To prevent dust from getting onto the balcony, snow in winter, and drafts, a special sealant is used, preferably transparent in color, so as not to disturb the overall aesthetics. This product is not expensive, but thanks to it the design will gain additional reliability and will have the most attractive appearance.

Features of the material

Most often, the loggia is sheathed with cellular polycarbonate. The material has high strength qualities, despite the fact that it has a transparent structure. Such a balcony meets the same consumer qualities as loggias made using traditional methods.

Construction boards have a viscous polymer structure that is 200 times stronger than a traditional glass surface and is extremely difficult to break.

Polycarbonate for the balcony prevents harmful ultraviolet radiation from penetrating into the living space in summer. During the winter season, the material can withstand any load from snow and strong winds.

The structure, covered with slabs, scatters light, polycarbonate simply reflects it, so the apartment will not be stuffy in hot weather.

Roof finishing

- Before starting work, the old balcony must be dismantled and all preparatory work must be completed.

- Next, the protective film is removed from the polycarbonate sheets, but this should be done immediately before installation.

- Cellular units must be installed in such a way that the rays of sunlight fall on the side on which there is a protective ultraviolet coating.

- Sheets can be cut with a simple tool that is used in working with wood products.

- The film is removed from the outside of the slab, and the blocks are cut to the sizes needed for installation.

- After this, protective tape is applied to the ends of the slab and closed with a special end profile, as in the photo. This is necessary to prevent dust or condensation from getting inside.

The roof is usually made into a canopy or in the form of a canopy, as can be seen in the photo. But if you have design skills, you can realize any idea. Then the do-it-yourself canopy will be original and unlike all the others.

If the design of the balcony roof is curved, then the permissible bending radius of the sheets must be taken into account, since each type of cellular polycarbonate has individual bending properties. Due to the fact that on such arched structures the bending radius of the slab is smaller than that of the connecting profiles, therefore the profiles must be larger than the length of the slab. After the final installation of the arched structure, the connecting profiles need to be aligned. This can be done with an electric jigsaw.

The canopy can take any shape, it all depends on the design of the frame. The cellular structure is used for sound and heat insulation, thanks to which the balcony will have an aesthetic appearance, provide comfort and safety. The amount of light that gets inside will be from 20% to 70%. Everything will depend on the color of the polycarbonate. Video shows how to make a canopy yourself

Profiles used during installation

When installing polycarbonate, try to align the slabs along the top line of the edge of the structure. The profile, which is located at the base, must be well attached to the frame with special screws or bolts, which must be positioned on the axis of the profile line. The diameter of the hole in the slab for the screws that secure the material to the bottom of the frame must be larger than that of the bolts. This is done so that when expansion occurs due to high temperature, the integrity of the sheet is not compromised.

After installing the main profile, install the pressure cover. Perform such manipulations with subsequent blocks until the final installation of the structure is completed. After this, remove the plastic film from the outside of each sheet. This material is slightly inferior to glass in light transmission, but it is much lighter and more reliable. It also does not adversely affect the environment and is not susceptible to external natural factors. If you want to make a beautiful balcony with your own hands and at the same time spend a little money, then cellular polycarbonate is the best solution.

What is the advantage of the material?

Polycarbonate is a material that differs from other materials in its strength and lightness, which makes it more popular than ordinary glass. Also, cellular polycarbonate has a high rate of heat and sound insulation properties. And, even if we compare it with glass again, polycarbonate retains heat much more efficiently, so its use for glazing a balcony can be considered the best option. The advantages of polycarbonate also include good transparency and non-transmission of ultraviolet radiation. The variety of colors allows you to make the balcony more attractive. Well, the most important thing is the ease of installation of this material.

How to choose the right material for balcony glazing

Polycarbonate is selected based on the purpose of the room, in this case, the intended purpose of the balcony. If, for example, the balcony will be used only in the warm season, and in winter supplies will be stored there, then thinner polycarbonate can be used. But if the balcony is set up as a home garden, office, or recreation area, then glazing with cellular polycarbonate with a thickness of at least 1.5 cm, or even up to 3 cm, will be required. After determining the purpose of this room and choosing the material itself , you can start glazing your balcony with polycarbonate yourself.

Where does balcony glazing begin - of course, with preparation.

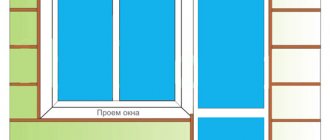

The very first thing to do is to free up the balcony space so that nothing interferes and dismantle the old glazing. Then we proceed to the installation itself. Before installing polycarbonate, it is necessary to create a special aluminum frame, which is necessary to secure the sheets. This stage requires special care, since the final result will depend on it.

The frame is made taking into account the thickness of the polycarbonate sheets. Thus, for a thin polycarbonate sheet (from 0.6 to 1.6 cm), a frame with a distance between longitudinal supports of at least 70 cm is required, but for a sheet with a thickness of 2.5 cm, the distance should be about 105 cm.

Installation of polycarbonate can be carried out in two ways: from solid layers or from cut parts. For example, a polycarbonate balcony in a Khrushchev building can be glazed using parts. Thus, a single sheet of polycarbonate is pre-cut into pieces. In this case, their width should be equal to the width between the frame profiles. Fixing is done to the outer guides. In order to cut a polycarbonate sheet, you can use a construction knife; it will easily cut a sheet with a thickness of 4-6 mm; for thicker polycarbonate, it is best to use a saw with a stop (the teeth should be small and not set apart).

If you make glazing using solid polycarbonate sheets, then the fastening is made to each transverse guide of the frame. The distance between the screws must be at least 30 cm. It is imperative to make the holes in advance, taking into account that their diameter should be half the diameter of the screw itself.

The joints of the polycarbonate sheets and the fastening points must be sealed. Sealing is carried out so that air from the street does not enter the balcony room and moisture does not get inside the polycarbonate. Sealing can be done using silicone filler; it is suitable for the case of installing polycarbonate parts. And when using a solid sheet, you can use special thermal washers that are installed under self-tapping screws (their diameter can be from 2 cm).

Nuances

You should definitely know that decorating a balcony with polycarbonate with your own hands has its own nuances. It should be taken into account that cellular polycarbonate must be mounted on the side where there is a protective layer. In this case, the protective film must be removed before cutting the sheet before installation.

When cutting a polycarbonate sheet, installing them with their ends facing each other, you need to glue the seam with self-adhesive tape, and then cover it with an end profile. This is done to prevent dirt and moisture from getting inside the honeycomb.

If the balcony involves finishing the roof with polycarbonate, then you can make it in the form of a classic canopy or as an inclined canopy, you can also create a unique roof structure according to an individual idea. A polycarbonate roof will create a very bright and comfortable atmosphere on the balcony.

Do you want to use reliable containers for trade or on the farm? Then read our article about the advantages of polymer gastronorm containers, you will find out why this material is good.

Video description

Balcony in Khrushchev with your own hands.

Roof installation

The design can be in the form of an arched canopy or in the form of a direct canopy. It is more practical and reliable to glaze the balcony with monolithic polycarbonate. All roof options are created on the basis of a frame, with a slope for the descent of snow and water.

Transparent plastic bends well, so the raw material can be used to cover a curved visor. When bending, you will have to take into account the maximum degree of deformation, otherwise the structure will burst. If you lack experience, it is better to entrust the non-standard glazing procedure to professionals.

For a balcony made of monolithic polycarbonate, the roof is installed on a frame made of plastic pipe with a diameter of 20 mm. The skeleton is mounted on additional hooks, which ensure uniform placement of the structure above the room. The areas adjacent to the walls are protected with a waterproofing strip.

The transparent canvas on the frame is installed whole or divided into 2 or 3 parts. The more experience the master has, the easier it is to glaze balconies with polycarbonate. Fasteners are inserted into the holes on the surface of the plastic. If the structure is assembled from different parts, then the elements are tightened together with bolts.

How to cover a balcony

A polycarbonate balcony is a durable and warm structure that will decorate the facade. The durability and decorativeness of the material depends on compliance with installation rules. To make it easier for craftsmen without experience to understand, the technological process was divided into several stages.

Preparatory work

Glazing a balcony with polycarbonate sheets begins with a schematic image. The future project with dimensions is recorded in the drawing. On paper, the degree of closure of the structure and additional details (visor) must be provided. Before work, you need to carefully measure the parameters of the loggia with a tape measure, and cut the canvas to the specifications. For cutting, it is better to use a circular saw with fine teeth.

The polycarbonate balcony is based on a frame to which polymer sheets are screwed. The skeleton is assembled from a metal profile or wooden beams. Due to their low weight and strength, it is better to use aluminum models rather than steel. If a wooden structure is used, the parts are coated with a protective compound.

The thickness of the frame panels depends on the parameters of the polycarbonate. Thin sheets (6-16 mm) are installed on a skeleton with a cross-section of 70 cm. For material with characteristics from 2.5 cm, the step is 105 cm.

The transparent material is fixed to the structure using self-tapping screws and sealing washers. You will also need connecting and end profiles, which are used when assembling plastic elements. For waterproofing, self-adhesive poly-protective tape is useful. The canvases are measured with a square, and the correct installation on the balcony is checked with a building level.

When choosing polycarbonate, pay attention to the tasks that the material must perform. For insulation and sound insulation, it is better to give preference to cellular raw materials. To make the room brighter, take monolithic sheets. Both types are suitable for visors, but the latter is more reliable and safe.

The thickness of the sheet depends on the characteristics of use. For families with small children and animals, it is better to use a balcony with options with maximum density. If people periodically stay in the room, you can take medium or thin sheets.

Loggia cladding

Polycarbonate for finishing balconies is attached to the frame using bolts. Holes are pre-drilled in the sheets for self-tapping screws. The diameter of the holes should be 2 mm larger than the cross-section of the screws. To prevent microscopic cracks from appearing on the material, be sure to use special fasteners with a thicker clamping head.

The ends of the elements are protected from debris and moisture with plugs or aluminum tape. Professionals mount transparent raw materials onto thermal washers. The thickness of the element must match the characteristics of the sheet. Details reduce deformation processes in plastic and reduce heat loss through holes.

A gap (up to 4 mm) must be left between the frame and the cellular material. A small gap will not allow the sun and cold rays to penetrate into the room. When the temperature changes, the hole will protect the structure from deformation during expansion and compression.

If the balcony is sheathed with polycarbonate sheets, the material cannot be used for load-bearing structures. Despite its strength, the raw material will not withstand the pressure of the partitions. The canvas should complement the facade, and not strengthen it. The plastic is placed with the protective coating facing out. The film is removed from the surface only at the end of installation work.

After installation is completed, the structure is inspected for areas with broken seals. Professionals advise sealing the seams and joints of the sheets with silicone sealant. The adhesive composition is selected to match the color of the material or preference is given to transparent types.