Polycarbonate windows for a gazebo would be an excellent option. Polycarbonate has been successfully cooperating with classic glazing for a long time. This material is easy to process, which allows you to create large window structures in a short time and at a reasonable cost. Polycarbonate is well suited for creating arched windows and other structures of complex shapes.

Main characteristics of polycarbonate windows

Polycarbonate is a polymer plastic that tolerates temperature changes well and is shock resistant.

It is inserted into a wooden or plastic frame. Previously, such windows were used mainly in the construction of greenhouses. Polycarbonate has many advantages over ordinary glass. These include: Table of thickness and bending radius of polycarbonate sheets.

- Excellent degree of insulation of the room from cold and extraneous sounds. This effect is achieved thanks to the pores that are located in the thickness of the polycarbonate. They provide a kind of cushion of air inside, which simply prevents the cold from penetrating into the room. And the polycarbonate itself remains relatively warm.

- Great strength of the material, which allows it to completely replace ordinary glass. The thicker the polycarbonate, the stronger it is. And in many cases, the resistance to mechanical stress is even higher than that of glass. Especially if the carbonate used is also pre-processed using a special technology.

- Very long service life. As a rule, any type of polycarbonate sheets will serve you for quite a long time, provided they are installed correctly in the frame. In this case, the material will not deteriorate due to temperature changes, and condensation will appear on the window much less often.

- Wide selection of glass shades. Polycarbonate is a material that can be used for various purposes. Therefore, you even have the unique opportunity to choose colored glass through which you will have a great view of the street, but at the same time you will not be visible from the street.

And a few more words should be said about the main types of polycarbonate, which is used for window frames. This is cellular and monolithic polycarbonate. In terms of their characteristics, monolithic sheets are much better, since they are of better quality and easier to install. They are also safer because their edges are not very sharp. But cellular polycarbonate is more suitable for greenhouses rather than windows. Accordingly, monolithic sheets are much more expensive, but their price is completely justified.

Types of sliding windows by material

The choice of material is directly influenced by the financial capabilities of the owner, what the house and the veranda itself are built from, as well as a number of other aspects. Below we will talk about the most convenient and reliable ones.

Aluminum

This material is considered one of the most practical; it is often installed on terraces where there is no heating. On sale you can find two options for aluminum sliding windows: with a cold and warm profile. The first is suitable for unheated verandas, used only in the summer, and therefore do not require additional insulation, and the second - for houses that are in use all year round.

Did you know? The first written mention of window glass dates back to 1240

—

it was called “Roman”, and the text itself described the church that was built by Prince Daniil of Galitsky.

- Among the advantages of this material are:

- long service life - the glazing system does not need to be changed for half a century, or even more;

- attractive appearance;

- no need to refresh the color every few years;

- ease of installation and further maintenance;

- tightness;

- no heavy load on the foundation due to low weight.

There are also a number of disadvantages. For example, many may be put off by the high cost of aluminum sliding windows; they heat up quickly in the summer and cool down in the fall and winter. Although tightness is truly considered a plus, there is a frequent need to ventilate the room.

Plastic or PVC

Plastic sliding structures have frames made from multi-chamber PVC profiles. Obvious advantages include relatively low cost, immunity to aggressive weather and atmospheric influences, strength, durability, and ease of maintenance.

Important! At sub-zero temperatures, plastic tends to shrink in size, causing the connection between the valves to become less tight.

There are not so many disadvantages - the massiveness of the frames, which in the event of an open fire do not burn, but melt, emitting an odor unsafe for human health. Unlike aluminum sliding windows, this design has received the second name “warm glazing”, since they are equipped with double or even triple glazed windows that do not conduct cold.

Advantages and disadvantages

The advantages of polycarbonate compared to silicate glass primarily include its weight, strength and price. At the same time, it has the strength of plastic and the transparency of ordinary glass, and can be either colorless or with a shade of the desired color that will fit into the design of the entire house. Due to the fact that the dye is part of the structure of the polymer itself, the color does not lose its saturation over time.

This material has its pros and cons

The disadvantages of both versions of this polymer include low abrasive resistance, that is, the material is scratched, so care must be taken during operation.

If low-quality materials are used or installation technology is not followed, reduced resistance to ultraviolet radiation and damage to the material due to thermal expansion will be observed.

High-quality polycarbonate has a special protective coating that successfully resists the effects of ultraviolet rays.

Popular profiles

The quality of a window is largely determined by the characteristics of the profile, so the buyer should pay attention to choosing a reliable “shell”. Such products should be purchased from trusted companies.

The consultant manager must give comprehensive answers to all questions regarding the profile you are interested in. Having a correct idea of a particular product, you will be able to objectively evaluate its characteristics, compare offers from different companies and choose the most suitable option.

Customers who can afford to install an elite structure should pay attention to frameless glazing

Provedal

Provedal structures have a wide range of applications, including using them to install windows on the veranda. The sliding profile is equipped with one glass.

Provedal aluminum systems are an excellent choice for glazing a veranda. Firstly, this is the most economical option. Secondly, such terrace windows are reliable and durable. Thirdly, the installation of a narrow Provedal profile provides excellent illumination of the room.

The Provedal system is the brainchild of Spanish developers. The profile has not been supplied to our country for a long time. Many companies use Provedal technology to produce their own models, such as Kraus, Alutech, Tatprof and others. In terms of their characteristics, almost all of them are equivalent to Provedal analogues.

Krauss / Kraus

The KRAUS profile is distinguished by its quality and high functional characteristics. It tolerates frosty winters well. The KRAUS profile has the following advantages:

- a special protective coating applied by electrostatic spraying guarantees long service life;

- the profile allows the installation of glass of different thicknesses;

- the price corresponds to the quality, so the buyer does not overpay for this product.

- low weight allows you to glaze any verandas;

- narrow profile lets in more light;

- provides sufficient thermal insulation and is resistant to temperature fluctuations.

The KRAUS company has a good reputation and enjoys the trust of consumers.

The simple design of this aluminum profile allows you to create a winter garden on the terrace or glaze a gazebo in a matter of days.

Vidnal

The Vidnal aluminum profile is manufactured by the Russian company of the same name, which allows us to offer customers products at an affordable price. Production facilities are concentrated in Rostov. The window systems offered by this company are adapted to our climatic conditions.

The Vidnal company supplies its own products throughout the country. The profiles produced by this company are distinguished by their attractive design and high quality. At the same time, they are cheaper than their foreign analogues.

The profile has proven itself well among consumers. It is used to create facade structures, transparent sloping roofs, winter gardens, and greenhouses.

Thanks to the presence of polyamide inserts, the design provides an increased level of thermal insulation. Installing the system does not require any special skills. When installing this profile, brackets are used.

Materials used

Unlike an open or semi-closed canopy, a closed garden gazebo can be used at any time of the year. Such buildings combine the functions of a summer kitchen and a platform for relaxation and pleasant time with the family, so the choice of glazing of the building plays an important role.

Polycarbonate sheets are a synthetic thermoplastic polymer that is produced by the organic synthesis of carbonic acid. Polycarbonate is not hazardous to the environment. Due to its safety and environmental friendliness, polymer plastic is used in the construction industry, the national economy, instrument making and medicine.

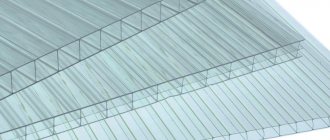

There are two types of polymer plastic: monolithic and cellular.

When choosing window material, do not forget about the conditions of the location where you live

Monolithic polycarbonate is a solid material, the main technical characteristics of which are high impact resistance, resistance to temperature changes and maximum light transmittance.

Honeycomb, or cellular polymer plastic consists of two panels connected by perpendicular jumpers. The degree of flexibility of the material, its strength and endurance is determined by the number of internal ribs.

When choosing a glazing material, it is recommended to take into account its technical characteristics and features. So, for regions with severe frosts and gusty winds, a monolithic fabric is suitable. Cellular polycarbonate retains heat better and has high noise insulation properties.

In this video you will learn how to install polycarbonate windows:

Features and nuances of choosing sliding elements

A veranda is an open or glazed room with no heating. Verandas are widely used in houses with a small number of floors and are used at the entrance. The location is ideal for hallway and corridor options. In the summer, it can be transformed into a bedroom or office.

Since the key expression here is “no heating,” the thermal insulation properties when choosing a material are not given primary attention.

Profile material

A plastic version or sliding windows for a terrace with an aluminum profile are suitable. Summer is also not always warm; the picture is spoiled by wind and rain. Windows must be able to withstand such loads; the best option is profile systems made of wood and aluminum, capable of withstanding high-speed winds - up to 20 m/s.

Number of cameras

It is best for the double-glazed window to be equipped with 2 or more cameras due to the possibility of increasing stability. If the windows face the sunny side, it is worth using energy-saving windows coated with a thin layer of silver oxide, which has a mirror effect and can reflect heat flows. Such windows must have a special orientation and reflect bright sunlight. Using an integrated approach will allow you to achieve a pleasant microclimate on the terrace.

Selection of accessories

The safety of the veranda is one of the key factors in choosing materials. Therefore, it is necessary to choose fittings that can resist burglary and the possibility of opening from the outside. Give preference to handles and other elements that have a durable frame and plastic lining, which will protect the metal rod from corrosion. Glass must also have anti-burglary features. You can choose laminated options or hardened products.

Strained glass

Many people know what tempered glass is, but not everyone has an idea of the basic technology for their manufacture. Tempered glass is durable and cannot break even under heavy load. It can withstand heavy weight and large-scale impacts, so it is not afraid of rain or hail.

Laminated glass

Laminated glass is better known as triplex. The product has a complex design consisting of several glasses, thanks to this, the glass receives advantages: the absence of the likelihood of breaking under heavy loads, a high level of stability.

High-quality laminated glass in plastic double-glazed windows with a sliding mechanism.

Choosing a terrace design

Verandas are usually made of wood, but Art Nouveau styles suggest the use of other materials in accordance. In order for the interior and exterior of the house to be combined as closely and accurately as possible, it is necessary to make part of the terrace from double-glazed windows. But experts believe that the most suitable option in this case is sliding terrace windows. The modern materials market offers two main options.

Parallel sliding structures or re-sliding products

In parallel, there is a sliding glazing structure for the veranda.

The main advantage of the possibility of installing such doors is the large glazing area. As a result of such coincidences, the room will receive a large amount of heat and light.

Sliding wooden windows on the veranda of a beach house.

Thus, sliding windows/terrace doors are the optimal solution for all occasions. Competent and high-quality use of structures guarantees the comfort of owners and guests during their stay in this interesting room.

Cozy panoramic terrace with double sliding windows.

What are you going to glaze: veranda or terrace?

As soon as the owners began to look for ways to glaze their relaxation area, confusion began in two types of buildings, i.e. The concepts of “veranda” and “terrace” are mixed. According to SNiP, only the veranda has walls glazed on several sides, because it should serve not only as a resting place for the owners, but also protect the house from direct exposure to cold from the street. If you glaze your terrace with stationary materials that you do not plan to remove in the summer (for example, PVC windows), then it will automatically become a veranda. This means that you need to look for a suitable glazing option in articles about the construction of verandas.

The terrace was invented as a recreational building without walls

We will consider ways to partially glaze a terrace at the dacha for decorative purposes or make sliding glazing that will be installed only for the winter period.

Using modern technologies in the country

Soft windows for the terrace are quite an interesting solution. This design is lightweight and made of transparent polyvinyl chloride. Your terrace will be protected from weather conditions; if you wish, you can easily remove such windows, for example, for the winter. The design has the following advantages:

- Easy installation and dismantling.

- Small mass.

- Affordable price.

- High transparency, ability to retain heat in the room.

Popular articles Tree hydrangea variety Magical Pinkerbell

However, the disadvantages of this design are also noticeable:

- The material does not allow air to pass through, so in the summer the terrace will quickly heat up; in addition, there is no possibility of natural ventilation.

- The material is afraid of mechanical damage.

- Not suitable for heated rooms.

Soft windows for the terrace

You may be interested in a dormer window as part of the interior. Read a review about the design of dormer windows

Glass entrance doors look beautiful in a private home. This is discussed in detail in our article “Choosing entrance doors - models with glass”.

Another solution for a private home is metal entrance doors with double-glazed windows.

Advantages of polycarbonate glazing

Polycarbonate glazing is an excellent alternative to conventional glass. So, let's look at the advantages and key technical characteristics of polymer plastic:

- the highest possible light transmittance and uniform distribution of solar illumination;

- the presence of a protective coating against UV radiation;

- high levels of resistance to physical and chemical influences and precipitation;

- resistance to temperature changes;

- low thermal conductivity and good noise insulation;

- ability to withstand heavy loads, low specific gravity and excellent flexibility;

- no difficulties with installation and maintenance.

Practicality of polycarbonate windows

An excellent replacement for glass is polycarbonate. This is a worthy alternative to plastic double-glazed windows, as it has quality characteristics:

- Increased impact strength and strength. Polycarbonate is distinguished by its increased impact strength

- Low specific gravity allows the foundation to be lightweight.

- Fire and environmentally safe.

- Temperature changes do not affect the quality of the material.

- High heat and sound insulation properties.

- Transparency and tintability expand the options for implementing design ideas.

- Plasticity promotes the flexibility of a material without heating.

- High resistance to aggressive environments and sunlight.

- It does not transmit ultraviolet rays, but it blocks infrared rays.

- Costs less than glass.

Flaws:

- Weakly resists abrasives. Easily scratched.

Despite its many advantages, polycarbonate is susceptible to abrasion - It reacts to the effects of low and high temperatures with a significant change in its size. This factor should be taken into account during installation, planning in advance the place for the thermal gap.

Design options

The glazing of the veranda can be made solid or with windows. Openable polycarbonate windows can be made:

- swing;

- sliding;

- removable.

Hinged windows resemble ordinary windows; they have one or more sashes, hinges and a frame. In the same way, you can implement doors leading from the veranda to the courtyard. In this case, polycarbonate can occupy both the entire area of the doors and some of them.

When opened, the sliding window moves to the side and must have guide rails. The same principle of operation as that of sliding wardrobes. Also, sliding windows will be frameless and fixed only at the top and bottom. The joints of such windows, instead of a massive frame, will be connected by inconspicuous aluminum plates.

The design of removable windows makes it possible to easily unscrew and remove part of the material, thus creating the necessary open opening. This is the easiest way to make windows that open.

Window installation algorithm

After installing the supporting frame, we begin installing the windows:

- Anchors are screwed into pre-marked areas of the window frame, forming a suspension. One anchor is located on the frame at the top, the other two are on the sides. A special profile is inserted into the window opening of the frame where the frame will be installed, which is secured with dowels inserted into holes with a diameter of 8 mm. An anchor is used to create a canopy

- Using a plumb line, a building level and wedges for greater installation accuracy, the window frame is attached to the profile on the frame with anchors.

- The correspondence of the window sill and frame seats is determined. Using a file and a hacksaw, mutual adjustment of the mating elements is performed.

- A board is fixed under the window sill on brackets or wedges to create rigidity.

- Plugs are installed along the edges of the window sill.

- The construction level checks the correct installation of the frame.

- Polyurethane foam is used to seal all gaps. Excess hardened foam will be removed with a utility knife.

Sliding

With a sliding design, the frames move along guides, saving space, but reducing the tightness due to wear of the contacting elements.

Sliding polycarbonate windows will save space

The glazing process consists of the following operations:

- The frame is mounted on a profile fixed to the frame.

- The part of the sheet intended for longitudinal movement is inserted into guides mounted on the frame together with the profile.

- The installation accuracy is checked by level.

- The frame is attached to the frame with anchors.

- Window sill installation.

- Gaps are eliminated using polyurethane foam.

- Remaining foam is removed.

- Slopes are installed.

Swing

The design of casement windows is traditional - it is a frame consisting of sashes that rotate on hinges.

Hinged windows made of polycarbonate are considered the most common among the population

The installation technology is as follows:

- A metal profile is attached to the frame.

- Hinges for the sashes are screwed to the profile.

- The frame elements and polycarbonate sheet are assembled.

- The sashes are mounted on hinges in the frame opening.

- The accuracy of the installation of the sashes is checked by a level.

- Window sill installation.

- Gaps are eliminated using polyurethane foam.

- Remaining foam is removed.

Deaf

Fixed windows are simple in design. Installation is easy:

- The frame is mounted on a profile fixed to the frame. Fixed polycarbonate windows are the easiest to install among analogues

- The installation accuracy is checked by level.

- Anchors secure the frames to the frame.

- Window sill installation.

- Gaps are eliminated using polyurethane foam.

- Remaining foam is removed.

- Slopes are installed.

To the listed types of windows you can add removable ones, which are removed for the winter.

But no matter what design of carbonate windows you choose for installation on the veranda, the appearance of the construction is aesthetic, and the pleasure of working with such material is guaranteed.

Preparatory stage

If the main factor is weight, price and thermal insulation, the obvious option would be to use cellular (cellular) polycarbonate for glazing the veranda, which is 13 times lighter than ordinary glass of the same thickness. If strength and transparency are important to you, the choice lies with the monolithic option. The monolithic version is more expensive and heavier than its cellular counterpart, but still several times lighter than regular glass.

Preparation of the glazing of the veranda begins with measurements of future windows and the acquisition of the required number of polymer sheets. Next, in accordance with the selected type of window, related parts are purchased: aluminum tape, runners, hinges, self-tapping screws, thermal washers. Then you can start marking and cutting. Polycarbonate at home, depending on the thickness, is cut with a stationery knife, jigsaw or grinder. Do not forget that the cellular polymer is sensitive to orientation in space and should be positioned so that the cells are located along the window opening with the protective anti-ultraviolet coating facing outward.

When installing such windows there are some nuances

Don’t forget that you need to drill 10–15 mm more holes for the thermal washer to compensate for the thermal expansion of polycarbonate panels.

Features of polycarbonate doors

Polycarbonate, due to its advantageous technical characteristics, has become one of the most popular materials. It is used to construct interior partitions, screens to delimit the internal space of a room, furniture parts and much more. It is now especially often used for assembling doors.

The polymer does not break into sharp fragments, which makes it a very safe material for doors

Such models have a number of advantages:

- The installation process is simple and convenient;

- the sheets are quite durable, which helps both during installation and during further use of the structure;

- high safety, because even when broken, the polymer does not form traumatic fragments;

- flexibility and a wide color palette, which provides great opportunities for design solutions.

Polycarbonate doors can come in several variations. Depending on the opening mechanism, they are divided into hinged and sliding.

With a hanging structure, the canvas is attached to the jamb using special awnings. The sliding version provides for opening and closing parallel to the wall, for which a special guide mechanism is used.

The frame for polycarbonate sliding doors should be made of lightweight and durable materialsThey can also be framed or frameless. The first option is distinguished by the presence of a special frame for glazing. Such a frame can be made of metal, plastic or wood; its main task is to ensure the strength and rigidity of the structure, although it itself should be light.

The frameless model is assembled without a frame. With this method, all hanging parts and fittings are connected directly to the polycarbonate plate.

To assemble a structure, especially a frameless type, monolithic polycarbonate is usually used. Unlike cellular, it will provide greater strength and add weight, and a door made of monolithic carbonate will add rigor and solidity to the design. However, this option is more expensive and has less soundproofing properties.

Assembly

So, let’s finally deal with polycarbonate windows with our own hands:

- Sealant is carefully applied to the frame using a construction gun;

- Then a cut-out sheet of polycarbonate is attached;

- If you can, carefully remove excess sealant;

- And on top - secure the position with glazing beads.

And you can now easily carry out installation on anchor plates.

So, the polycarbonate window is ready with your own hands!

Work plan

In both cases, polycarbonate sliding windows for the gazebo are installed in the following sequence:

- The intended location of the window is pre-planned and the number of sashes is determined.

- To install the structure, you will need a frame (or a frame, like a door). It is made from ready-made sets of aluminum profiles made in the factory, or wood, plastic, metal-plastic and various combinations of these materials are used.

- Having the dimensions of the box, we begin to work with the sashes. A polycarbonate sheet of the required dimensions is placed in an aluminum, wooden, plastic or metal-plastic frame. Instead, edging fragments can also be made only at the top and bottom.

- Special fittings for sliding windows made of polycarbonate are selected - roller, locking, locking, pressing elements.

- They assemble and install the window structure. If necessary, install a window sill and ebb.

Assembly of frames and sashes

When wondering how to make sliding frames from polycarbonate, a related question often arises about where to get the components for making frames for the sashes. produces a wide range of components designed specifically for polycarbonate sheets of any type.

These include connecting (HP, HCP, GCP) and end profiles, hardware, sealing and perforated tape for cellular polycarbonate, metal and heat-resistant washers made of polycarbonate. Components are selected for specific brands of sheets based on thickness, type, and color. Full size compatibility guaranteed.

Frame installation procedure

Do-it-yourself sliding polycarbonate windows are installed according to the following scheme. The frame is inserted into the prepared opening and leveled relative to the horizon vertically and horizontally using a plumb line or spirit level. For long structures, it is convenient to use wedges, through which the frame is wedged and firmly fixed in a given position until finally secured.

If windows on a polycarbonate terrace are used for partial glazing, the frame is attached to the fence and ceiling using self-tapping screws or anchor plates. When the opening is completely filled, the structure is more bulky, monolithic and fixed to the floor and ceiling. Fasteners are selected depending on the type of base. For concrete ones, anchors and anchor plates are used, for wooden ones, rather large self-tapping screws are used.

Popular articles Feeding irises in spring and autumn

Installation and adjustment of sashes

The cracks and gaps between the base of the opening and the outside of the box are filled with polyurethane foam. Sashes are inserted into sliding windows for polycarbonate verandas. Their horizontal movement is ensured by guides and rollers. The first ones are fixed on the frame, the second ones are installed on the sash frame.

The window can be locked using a special locking mechanism. Finally, for normal rebate and opening, the position of the valves is adjusted using bolts on the roller mechanisms. Cheaper glazing options do not involve any mechanisms at all. The sashes are simply inserted into the grooves of the guides and, due to their low weight, easily slide along them.

Video on installing a polycarbonate window:

Installation of polycarbonate windows

Diagram of the structure of a polycarbonate sheet.

So, now is the time to get to work.

First you need to make all the necessary markings and prepare the main material - polycarbonate sheets and frame.

To do this, it is advisable to vacate a large room or area on the street, having previously fenced it off so that the appropriate degree of safety for others is maintained during work.

Preparation of materials and opening

Great attention must be paid to the temporary storage of polycarbonate until it is finally installed on the windows. As a rule, when purchased, polycarbonate is covered with a protective film, which prevents it from being exposed to various types of external influences. Therefore, this film should not be removed yet. It is also not recommended to prepare sheets in direct sunlight.

First you need to carefully prepare the frame for installing sheets into it. Regardless of which window you choose - plastic or wooden, the frame is made to order in advance, so you will not need to adjust the dimensions. If the frame is made of plastic, then it is enough to wipe it with a soft cloth to remove dust and degrease the areas of future joints with polycarbonate sheets with acetone or another similar product. This is a necessary measure to ensure that in the future the sealant adheres as firmly as possible to the materials.

If you have given your preference to a frame made of natural wood, then you need to make sure that it is impregnated with special antiseptic agents against rotting and premature deformation of the wood. Degreasing is also recommended as described above.

Scheme for fastening a polycarbonate window.

Next we work with the frame fasteners. In total, it is recommended to make 2 anchors on the sides and one on the top and bottom of the frame. This will allow the window to hold as securely as possible. After fastening, the anchors should be visible both from the outside of the frame (their heads) and from the inside.

Now you need to prepare the opening for installing the frame. First, dust is removed from the opening using a stiff brush, after which holes are drilled in the opening using a hammer drill to install the profile. You need to drive dowels into the drilled holes, and then work with the profile. It is a simple metal frame that is mounted on self-tapping screws.

Installing the profile and frame into the opening

After this, the frame itself is mounted on the profile. It is attached to the profile in a comprehensive manner - using special wedges and self-tapping screws. During work, it is important to constantly monitor the evenness of the installation using a building level and plumb line. When the frame is finally fixed in the opening, proceed with the installation of the window sill. It is installed in the same way - on screws, secured with wedges. But this must be done from underneath so that the front part of the window sill remains perfectly smooth. This applies to both wooden and plastic structures.

Window frame installation diagram.

Polycarbonate windows for the veranda

Since the veranda is attached to the house and is essentially its addition, it must be warm enough, and the glazing must be airtight and thermally insulating. Therefore, the polymer is perfect for these purposes. Among the advantages of such a window for a gazebo, in addition to its insulating properties, weight also stands out - such a system will weigh significantly less than metal-plastic or glass, therefore the load on the structure is reduced.

When purchasing polymer for future glazing, the seller will package the material in roll form. You cannot store purchased material in this form for more than a day - the material is quite flexible and can take shape. Therefore, at home, the sheets are laid out on a flat surface, one on one, it is advisable that the surface with the protective film is on top, even if sunlight does not enter the storage room. You cannot store polycarbonate vertically - a crack may appear along the entire length of the sheet.

Installation of a sliding structure

In the process of installing a window profile and its glazing, you will need the following materials, tools and working equipment:

- polycarbonate sheets;

- protective perforated tape and end profiles;

- connecting detachable profiles;

- self-tapping screws with thermal washers, roofing screws, screws and anchors;

- insulation, polyurethane foam;

- construction tape, level, marker;

- a circular saw, electric jigsaw or fine-toothed wood saw for cutting material;

- drill with drills of various diameters, hammer drill;

- screwdriver, screwdrivers, pliers;

- saw, mounting knife, sandpaper;

- silicone glue and a gun for applying it.

To install a parallel sliding window system, it is recommended to make a drawing. Having a detailed diagram will help you avoid common mistakes in construction. The drawing is made based on the measurements taken and taking into account the design features of the sliding system.

Don’t forget about the material that will be needed when installing windows.

Now let’s move on to the algorithm for installing polycarbonate sliding windows:

- Clean the work surface from dust and debris. Cut the polymer fabric, taking into account the material’s tendency to thermal expansion.

- Then clean the embedded structure to install the window frame. Treat the surface with special protective agents.

- Using anchors, attach the profile to the frame and install the window frame on it. Using a level, level the structure in horizontal and vertical planes.

- Install the window sill, which is fixed under the bottom of the frame. Attach the window sill with metal anchors.

- Adjust individual elements. Recheck the horizontal and vertical lines. Fill the gaps between the frame of the gazebo and the window frame with foam.

- Treat the ends of the polymer plastic with perforated tape and end profiles.

- Install the split profile base. Install the polycarbonate, secure the sheet with self-tapping screws and thermal washers.

- Close the profile with a protective cover.

Polycarbonate glazing of the gazebo requires minimal maintenance. Timely cleaning of panels from dust, debris and various types of contaminants will significantly extend the service life of the window. The warranty period for polycarbonate glazing of garden gazebo windows is 10–15 years.

Construction of sliding windows

When glazing a gazebo with polycarbonate, you need to accurately determine the dimensions of the frames and other measurements, according to which you need to calculate the number of sashes and material consumption. For clarity, you can make drawings. You should also decide on the type of materials - wood or aluminum profile, two-layer or monolithic polycarbonate. The sliding system itself can be designed for a cold or warm room, since in the presence of heating it has certain technical features.

According to the principle of operation, such systems are divided into:

- lift-and-slide;

- parallel-sliding;

- folding (“accordions”).

All systems consist of a supporting and movable frame, and also have running rollers. Some of them can use a sliding mosquito net. The “accordion” consists of several doors and is installed for unheated rooms, since it does not insulate it well. When assembling such windows with your own hands, it is best to buy ready-made kits for such systems and install them on the frames.

Find out how to properly install polycarbonate on a greenhouse.

In addition to the material itself for sliding systems, it is necessary to purchase related tools:

- polyurethane foam;

- protective tape;

- sealant (silicone);

- fasteners (anchors, screws and self-tapping screws);

- washers.

Equipment required for work:

- screwdriver;

- drill;

- hacksaw or jigsaw;

- pencil;

- measuring instruments (tape measure, square, level);

- construction knife;

- circular or hand saw.

Assembly of frames and sashes

First, the supporting frame is installed according to the principle of window frames. Then the canvas is assembled and a roller system is attached to it. Using a construction knife, cut the polycarbonate according to the markings and insert it into a wooden frame. Cutting can also be done with a circular saw. Before installation, the ends of the polycarbonate sheet are sealed with a special tape or covered with an end strip, which is secured with silicone. The frames are inserted into the grooves and nailed with glazing beads, and then sealant is used.

Important! When marking and cutting polycarbonate sheets, you need to take into account that they must be installed so that the air channels are located vertically. Otherwise, liquid from condensation will clog in them.

Frame installation procedure

The wooden supporting box is mounted depending on the existing frame of the gazebo.

You can nail it in two ways:

- with self-tapping screws - to the wooden perimeter;

- anchors - to concrete, stone or brick.

All cracks are sealed with polyurethane foam. In its lower part, guide strips are pre-cut to the size of the rollers using a jigsaw or hacksaw. After installation, they are attached together with other elements of the sliding system and inserted into ready-made window panels. Seals can also be used along the edges of a sliding window.

Installation and adjustment of sashes

The position of the shutters is adjusted using bolts located on the roller mechanisms. If rollers are not provided, but a simple mechanism is used, then the moving structural elements should move well along the pre-cut grooves. You can also install a locking mechanism on the sashes.

Did you know? Primitive sliding doors were used in ancient Rome. This was evidenced by excavations in the city of Pompeii.

Small veranda design

You can create a chic interior of a glazed veranda with your own hands. This does not require much effort or specific skills. All you have to do is use your imagination and you can turn to the Internet for help. Only a harmonious combination of shapes, configurations, and color schemes of the design can create an incredible atmosphere of comfort and warmth in your room. Light ceilings and individually colored walls give the room an incredibly chic feel.

Advice ! The design of a glazed veranda must, first of all, correspond to the general style and design of the house itself.

Flowers will be an excellent decoration. Bright green vegetation will transform the room. You can place the bouquet on the windowsill, decorating not only the window, but the entire room. Thanks to their presence, there will be a lot of oxygen on the veranda, so while you are there you can truly enjoy the relaxation process.

In order for your creation to look cozy and look truly dignified, you need to make maximum physical efforts, efforts and limitless fantasy and imagination. Warm, delicate color shades that combine harmoniously are perfect. For example, a snow-white color with a delicate yellowish tint will give the room an incredible appearance, and the space will become much larger.

Installing sliding systems yourself

Owners of plots outside the city are accustomed to doing everything themselves. Insulation of various structures is not a complex, impossible task. Often the material used is polycarbonate sheets. For a person who is familiar with construction tools, insulating a veranda or gazebo by installing windows is not difficult. The structure can be assembled without outside help.

Related article: Tint windows in an apartment

Before you begin, you should decide on the method of opening the windows. This determines what fittings will be used when installing polycarbonate structures.

There are two ways to open windows:

For installation, you can use sheets of cellular and monolithic polycarbonate. These materials are light, safe, easy to process, and do not transmit harmful ultraviolet rays. The choice depends on the wishes of the owner of the site. The use of cellular polycarbonate will reduce the cost of the process and darken the room; the monolithic version is more expensive, but is transparent like glass.

Polycarbonate sheets are produced in various colors, which allows your imagination to run wild and make your site special. But you should choose a material that is produced by a trusted company so that the created structures serve for a long time and without failure.

How do English windows with vertical rise work?

One of the most attractive features of this type of glazing is that the sash is broken down into relatively small rectangular sections. Windows with this type of paneling have a strict, classic look, which corresponds to their name.

The design of a classic English window includes an external frame and two internal sashes. To open the window, you need to move one of the sashes in the vertical direction, and then secure it with special latches. As a rule, the lower part of the window is made movable, while the upper part does not open.

Movement is carried out through special grooves in the frame and corresponding guides in the moving part. Guides can be made either in the form of rollers or operate on the sliding principle.

To make opening easier, the blocks are equipped with special counterweights that compensate for part of the load when lifting the sash. The counterweights are located in the voids between the opening and the outer part of the frame, which makes them invisible to others and ensures a smooth ride.

Video “Closing the veranda with polycarbonate”

From this video you will learn how to cover a veranda with polycarbonate with your own hands:

When glazing a veranda, if you want to have transparent windows, install sheets of monolithic polycarbonate, and if you want to be in a warm room, choose cellular polycarbonate.

At the preparatory stage:

1. Select the design of the veranda windows:

- opening or swinging;

- sliding;

- deaf.

2. Decide on the type of polycarbonate sheet - structured or monolithic.

3. Find out the sizes of the sheets you will purchase. For glazing, a material with a thickness of 8–10 mm is preferable.

Before using polycarbonate as windows, you should determine the thickness of the polycarbonate sheet

4. Knowing the dimensions of the veranda, the dimensions of the polycarbonate sheets, make a sketch with the dimensions of all elements of the structure: foundation, roof, racks, lintels, window frames, etc.

5. Prepare materials:

- sheet polycarbonate;

- tape or adhesive tape to protect the surface of the material;

- connecting profiles for polycarbonate as elements of the supporting structure;

- special washers for self-tapping screws and screws;

- fasteners;

- polyurethane foam.

6. Prepare your tools:

- hammer drill or drill;

- pliers;

- screwdriver;

To install polycarbonate glass you will need a screwdriver

- screwdrivers;

- stationery knife;

- building level;

- jigsaw;

- file;

- hacksaw for wood and metal;

- roulette

Glass verandas: a lot of light and warmth!

SmaltaGroup is a leader in the production of translucent structures of various types. Our specialists are ready to take on the production of products such as glass terraces and verandas of any style and type, using only high-quality materials from the best domestic and foreign manufacturers. We have a lot of profitable solutions that we are ready to put into practice. We create terrace and veranda glazing from durable and extremely transparent glass of a completely new class. SmaltaGroup guarantees its clients high quality and affordable prices throughout the region!

To create frameless glazing of the veranda, only high-strength materials are used. Thus, steel is used as a raw material for the manufacture of metal profiles. The design also includes high-strength glass or double-glazed windows. From us you can order veranda glazing for a country house, choosing your own architectural design style, or give preference to those developed by our qualified professionals. From us you can buy ready-made standard design solutions, choosing from a large assortment the best option suitable for your home. And the professional development of an original and unique style for frameless glazing of a terrace or veranda will not take much time and will not cost much.

Glazing with extension (extension)

The best option when deciding to set up a winter garden on the balcony. The permissible extension is up to 35 cm. Unlike standard glazing, you will need:

- strengthen the parapet (especially in old houses), because this type of glazing will exert the greatest load;

- equip a strong and large canopy.

Double-glazed windows are installed on a metal structure, which is mounted additionally. The glazing is placed along the window sill, due to which the balcony area will increase.

The design with the offset is complex. First, the base of the parapet is prepared, metal corners are installed in the form of a kind of shelf or metal profiles. Wooden blocks are first attached to the floor and parapet.

Outside the parapet, to give the frame the greatest rigidity, triangle-type brackets or corners are attached. Then they are fastened to the structure of the protruding part, onto a load-bearing wall along the height of the entire loggia. With aluminum glazing, the frames are attached to the top.

Selecting polycarbonate by type and properties

Having an idea of how to make sliding windows from polycarbonate, you need to decide on the type of polycarbonate. It is this material of the window structure that is responsible for the amount of light penetrating into the gazebo or veranda. The correct choice determines how cold the room will be in winter and hot in summer. produces polycarbonate of two types:

- Cell phone. It looks like multilayer slabs with partitions and voids, inside of which there is air. Thanks to this, glazing a gazebo with polycarbonate with your own hands allows you to create a durable structure with high levels of thermal insulation, weather resistance, and heat resistance.

- Monolithic. Solid extruded material with increased parameters of impact resistance, heat capacity, and temperature stability. Outwardly, it is difficult to distinguish it from ordinary glass, but in comparison with it, a gazebo with opening polycarbonate windows is much cheaper in terms of glazing costs, and the window structures themselves are lighter, more reliable and safer.

Light transmittance and translucency

Important features of polycarbonate, as well as other translucent materials, are their ability to transmit varying amounts of light depending on the parameters of light transmittance and transparency. Before you make removable polycarbonate frames, you need to consider where exactly the building is located.

For warm areas and regions with long and hot summers, it is recommended to glaze with cellular or monolithic polycarbonate with reduced light transmittance within 35%. This will create such conditions that in hot weather less solar heat will penetrate into the gazebos and verandas through transparent polycarbonate windows, but at the same time a sufficient amount of daylight will enter.

Which double glazed window to choose

Single-chamber and double-chamber double-glazed windows are in greatest demand. One chamber means that the window structure consists of two glasses, between which there is an air gap. It prevents the penetration of cold air. Single-chamber glass can be installed in a gazebo that will not be used in winter.

If you plan to create a year-round gazebo, then it is best to use double-chamber glazing. Such canvases include three glasses, between which there are two air spaces. It is this design that will provide the best protection from the cold.

Such a gazebo with sliding windows will be functional and comfortable.

Gazebo made of plastic windows

A gazebo with plastic windows may involve the use of such windows as a frame. This means that the structure will not have classic support pillars. All its walls will be represented exclusively by plastic windows. Sliding windows into this type of gazebo are also possible.

- Such buildings have certain features that need to be specified in more detail:

- Plastic gazebos need a foundation. After all, plastic windows themselves with a PVC or aluminum profile cannot serve as support for the entire structure. They cannot simply be installed on the ground or secured in any other way;

- The configuration of gazebos with glazing can be any - rectangular, square, with six corners, and so on. But creating a round gazebo will not work, since the profiles will inevitably create many angles. But outwardly such a design will be very similar to a round one;

- Plastic windows must be installed on a solid foundation. For this you can use a wooden beam. Such logs are laid directly on the foundation. They are strong enough to support the weight of the structure;

- When constructing such gazebos, it is necessary to make the foundation correctly. The durability of the building and its stability will depend on its strength.

You need to know that the base for the gazebo must be larger than its boundaries. That is, the dimensions of the base should exceed the dimensions of the gazebo by 50 cm on each side. At the same time, gazebos made of plastic windows are very beautiful. They let in a lot of light and leave room for decorating the interior space with decorative elements. At the same time, a gazebo with sliding plastic windows retains heat perfectly. If you build a hearth or stove inside, the building can be used in any weather.

Installation of windows in a polycarbonate gazebo

The glazing can be continuous. In this sense, the use of polycarbonate should be noted. This material can simultaneously act as glazing and as the walls of the gazebo.

The construction principle will be standard. It is necessary to attach polycarbonate fragments that were made in advance to the support pillars.

Such gazebos have a number of significant differences. They need to be described in more detail:

The important elements will be the floor and foundation. To construct the foundation, you must use columnar technology. They consist of erecting low brick columns, on which wooden logs are subsequently laid

The columns should be raised above the ground level by 30 - 40 cm; In addition to the foundation, serious attention should be paid to the construction of the floor. The basis will be horizontally laid timber logs

Boards and moisture-resistant plywood are laid on the indicated logs; Supports for fastening polycarbonate are attached to horizontal joists using angles and brackets.

Installation of windows taking into account the roof

Since plastic windows or aluminum profiles cannot withstand high pressure, heavy roofing materials should not be used. It is not recommended to use metal tiles or natural tiles.

Polycarbonate or soft roofing is ideal. If you plan to install natural tiles, you should make a strong top trim from timber. It will be able to withstand the load of a heavy roof and protect the frame made of plastic windows from damage.

In this case, glazing can be combined with wooden fencing. It can reach one and a half meters in height. An aluminum profile or plastic windows are installed on this fence as a frame.

Windows are installed using construction foam. This is a universal option for such designs.

Polycarbonate glazing in winter

If the task is how to make a sliding window from polycarbonate and at the same time retain maximum heat in winter, then it is important to understand that cold glazing systems, which include polycarbonate translucent structures, will help solve the issue only with an integrated approach.

In practice, this means that when using premises year-round, it is necessary to equip them with heating sources of sufficient power. They compensate for the shortcomings of cold glazing, and the gazebo or veranda will be cozy and warm even in severe frosts. Another way to preserve heat is to make polycarbonate frames with your own hands in such a size that the glazing area is small.

Sources

- https://1pooknam.ru/ustanovka/okna-iz-polikarbonata-svoimi-rukami.html

- https://besedka.guru/postrojka/okna-iz-polikarbonata-dlya-verandy.html

- https://besedka.guru/postrojka/okna-iz-polikarbonata-dlya-besedki.html

- https://okna-veka64.ru/okna/samodelnye-iz-polikarbonata.html

- https://1prookna.ru/ustanovka/okna-iz-polikarbonata-svoimi-rukami

- https://polygalvostok.ru/razdvizhnye-okna-iz-polikarbonata/

Methods of finishing with light-transmitting structures.

Based on the purpose of the terrace and veranda, completely different options can be used for their glazing, such as:

- frameless.

- windows made of wood.

- PVC windows.

- aluminum profile.

- wooden single frame.

If the room is unheated, in this case, as a rule, glazing with an aluminum profile or wooden single frame is used.

Currently, aluminum sliding-type structures are extremely popular. Such designs allow for functionality and maximum ease of use. However, the features of this glazing method do not guarantee perfect tightness in the places where the sliding window sashes are joined, especially in winter, when ice and snow form.

It should also be noted that single-frame glazing is by far the simplest and most inexpensive way to improve additional square meters. At the same time, quite stringent requirements are imposed on the durability and quality of the frame. But with regards to frameless glazing, this option is more often used to implement original architectural solutions.

A heated veranda can be converted into a full-fledged living room, so the main requirement for its glazing is maximum tightness and excellent thermal insulation ability of the installed structure. PVC windows can solve this problem. However, today most owners of their own homes choose wooden windows due to their multiple advantages.

Pros and cons of using

The popularity of sliding window designs among consumers is only growing every year, thanks to many positive aspects :

- effective protection of the cold circuit from precipitation;

- a reliable barrier from gusty winds;

- slight enhancement of thermal properties;

- improving the appearance of the facade of the house;

- giving the extension a finished look;

- reducing the risk of unauthorized entry;

- the possibility of transforming the exploited space.

At the same time, some users note a number of negative factors when operating these structures :

- the need for periodic maintenance of mechanisms;

- risk of corrosion or failure of roller bearings;

- high cost of products;

- complexity of installation and adjustment;

- window units are practically not required in the summer.

Note. Despite some subjective disadvantages, translucent sliding systems are in stable demand and always find their buyer.

Creation example

To create sliding windows mounted on a terrace or veranda, you must adhere to the following technological map :

- A drawing of the future structure is being developed, based on pre-taken dimensions.

- The bars are fixed on the workbench with a vice.

- Using a milling cutter, the required grooves are selected on the bars until a cross section with the desired geometry is achieved.

- After processing, the profile is cut by a cross-cutting machine to the required length.

- At the ends of the profile, grooves are selected to form a junction of mutually orthogonal elements using the “groove-tenon” method.

- The bars are covered with a layer of paint.

- The frame elements are mated to each other with preliminary gluing with epoxy glue.

- Leave for 24 hours until the glue is completely polymerized.

- To increase rigidity, the structure is reinforced with steel corners.

- The glass is marked according to the internal contour of the frame, and then cut with a glass cutter.

- The finished glass is installed in the frame, after which it is fixed with glazing beads.

- Runners with roller supports are attached to the ends of the movable sashes, and rail guides are installed in the seats of the window sill and lintel parts of the opening.

- At the final stage, handles are installed on the vertical imposts to control the movable sash.

Note. If it is necessary to manufacture several structures of the same type, experts recommend pre-assembling a jig or slipway, with which you can prepare modular parts with identical geometric parameters.

Prices for finished products

Considering that sliding window structures for terraces and verandas are on the market from many competitive manufacturers, prices for identical products are approximately the same :

- Cold structures with single glass made of PVC profile – from 5 – 7 thousand rubles. for 1 m2.

- Wooden profiles with single-chamber double-glazed windows - from 9 - 11 thousand rubles. for 1 m2.

- Aluminum sliding systems – from 8 – 10 thousand rubles. for 1 m2.

- Warm translucent blocks with a complex mechanism – from 12 – 15 thousand rubles. for 1 m2.

The final cost depends on the popularity of the manufacturer, as well as the presence of positive reviews about the company’s products on online forums.

Specialist services

When ordering the installation of sliding window systems for verandas and terraces, the consumer will be offered the following prices :

- Installation of window blocks of standard height up to 1800 mm, with sash weight up to 70 kg - from 700 - 1000 rubles. for 1 m2.

- Installation of strip glazing with heavy sashes with a height of 2 m or more - from 1500 - 2000 rubles. for 1 m2.

- Installation of “book” or “accordion” type structures in an aluminum or wooden span – from 1500 – 3000 rubles. for 1 m2.

- Replacement of windows with dismantling of old structures, preparation of the opening and installation of new windows - from 2,500 rubles. for 1 m2.

Important. The final cost of installation is determined on the basis of an estimate, which takes into account the base price list of the enterprise, as well as correction factors.

Purchase of consumables

When creating window structures of this category with your own hands, the home craftsman will face the following expenses :

- Wooden blocks 40 x 40 – 70 x 70 mm – from 150 – 300 rubles. per m.p.

- Single window glass with a thickness of 4 to 6 mm - from 400 to 700 rubles. for 1 m2.

- Single-chamber double-glazed window - from 1000 rubles. for 1 m2.

- Fittings for sliding sashes - from 1500 - 2500 rubles. for 1 set.

- Fastening elements – from 500 rub. for 1 set.

- Wooden glazing beads made of slats 20 x 20 mm - from 70 - 100 rubles. for 1 m.p.

- Handles for ease of opening – from 300 – 500 rubles. for 1 piece

- Paint and varnish coatings to protect the surface of wooden profiles - from 200 - 300 rubles. for 1 l.

To purchase the required amount of material, it is recommended to draw up a detailed specification for the project, as well as a materials consumption sheet .

Preparing polycarbonate for decking

The first thing you need to do before starting work is to determine the back and back side of the polycarbonate. High-quality polycarbonate is sold either in rolls or in standard sheets. In any case, the manufacturer of the material glues a protective transport film on the front surface to protect it from scratches and impacts. It is removed at the last stage, usually before installing a polycarbonate sheet in a frame or covering the ceiling with it.

Cutting polycarbonate, whether cast or cellular, is quite simple, the material is soft, and often, before closing a section in the frame, the edge is trimmed with a knife if necessary.

To cut sheets, you can use a handsaw or a jigsaw; a high-speed knife with a rotating blade, used for cutting frozen meat, is very convenient. Its round nickel-cobalt disc cuts polycarbonate like butter, allowing you to cut and close a window opening of the most complex curved configuration.

After the sheets are cut to size, the ends of the honeycomb will need to be covered with an edge profile, and burrs and sharp edges will be removed from the cast polycarbonate.

What to consider when glazing

Polycarbonate sheets come in different thicknesses. For glazing, the best material is a sheet thickness of 8–10 mm. So, for verandas and terraces it is better to use a two-layer honeycomb material or a monolithic analogue equal to 10 mm in thickness.

If you decide to make windows for the veranda yourself, then we suggest you familiarize yourself with some useful tips:

- Prepare well for the glazing process. It is better to first develop a drawing that will indicate the dimensions of sliding and monolithic windows on the veranda. So, you can determine in advance the type, quality and quantity of material.

- Since the windows for the veranda at the dacha must provide enough light in the room, it is important to select a glazing system in advance.

- If you install sashes, they must open inward. This way, you can provide a large flow of clean air into the room.

Installation process

The frame or frames for the windows are ready. You can start installation:

- Hinged windows. We insert a sheet of material onto the sealant into the finished frame, not forgetting to observe the thermal expansion gaps. We fix it with glazing beads, just like regular glass.

- Sliding. The top guides are installed first. Then the lower runners are marked and installed along a plumb line. Then we insert the panels and attach the necessary fittings to the material itself.

- Removable. Fittings are screwed around the opening to hold the removable window. The structure is screwed on from the inside with convenient handles for quick dismantling.

It is quite easy to glaze a veranda with polycarbonate at home, regardless of whether it is monolithic or cellular. You just have to follow the general building codes and rules when constructing a frame or frame, and also follow the instructions of the polycarbonate manufacturer.

Keep in mind that unscrupulous manufacturers make a lightweight version of polycarbonate and do not indicate this in the description. This significantly reduces the service life of the polymer. Panels are made lighter due to thinner internal partitions for the same sheet thickness, so if you are not sure about the company that manufactured the material, it is better to check the weight of the polymer sheet.

Tips and tricks

In order to protect a beautiful veranda or terrace area, you just need to follow a few simple rules:

- Regularly inspect the polycarbonate glazing of the terrace; if deep scratches or even cracks are found, it is necessary to rub the surface with a special cleaning agent for transparent plastic. If the damage is significant, then it is best to replace the material, cover it or seal it with a thin transparent RET film;

- When preserving for the winter, it is best to cover the polycarbonate glazing of the dacha veranda with thick plastic film. If you don’t have one at hand, then an old bag or even paper glued to a soap solution may work.

A polycarbonate sheet, no matter whether it is cellular or cast, must stand in the frame with a fairly large gap, 2-3 mm for every meter of sheet. If there is no heating on the veranda in winter, then the joints and cracks must be covered with soft silicone. You can take any plumbing compound, for example, Ceresit 15CS.

For your information! According to reviews, the bulk of damage occurs at the end of February - beginning of March. With the beginning of the period of strong spring winds, the frequency of cases of polycarbonate damage doubles or triples.

Therefore, with the first days of spring, it would be right to once again visit the dacha to close the veranda and check the condition of the glazing.