Author: Alorous

19 October 2022 08:36

Community: DIY!

Tags: balconies DIY repairs DIY tips insulate a balcony photo

16820

15

Insulating the balcony allows you to turn the technical room in the house into a cozy place to relax. Thanks to this, you can spend time on it even in winter. Moreover, any owner of an apartment or cottage can do this with his own hands - you just need to choose the right materials and follow the instructions for performing the work.

0

Source:

See all photos in the gallery

Expanded polystyrene (foam)

0

Source:

The most popular material for insulating balconies. Typically, sheet foam is used with a thickness of 5 cm, or, in harsh climates, 10 cm. Advantages: low thermal conductivity coefficient - i.e. high thermal insulation even without additional materials; satisfactory strength - dense finishing materials can be used; high moisture absorption rate - there is no need for an extra layer of waterproofing; environmentally friendly and hygienic - does not emit hazardous substances, mold will not develop, and dust does not form during operation; ease of installation - sheet foam is easily cut into pieces; long service life - up to 30 years (subject to technology). Disadvantages: poor air conductivity - additional ventilation methods are needed; low noise insulation; poor resistance to chemicals based on alcohol and petroleum products, as well as some varnishes and drying oils; high flammability. Insulation of a loggia or balcony is carried out with construction foam with a density of 35–40 kg/m³. It is easy to distinguish it from packaging by its polygonal cells.

Criterias of choice

The main technical characteristics that you need to pay attention to when choosing thermal insulation materials for balconies and loggias:

- heat transfer coefficient - the higher the indicator, the smaller the layer of insulation you need to use, which saves precious space and reduces the load on the slab;

- resistance to mechanical stress - it is easier to apply a layer of finishing material to durable materials;

- vapor and hydraulic permeability - the microclimate in the room and the need to use additional materials depend on these indicators.

It is also worth considering the installation features - the simplicity of the process is especially important if the work is planned to be carried out independently without the involvement of specialists.

Extruded polystyrene foam (penoplex)

0

Source:

The disadvantage of extruded polystyrene foam is its high cost. There are several types of material on the market (according to their intended purpose): “Foundation” - for insulating structures buried in the ground. “Roofing” - for finishing attic spaces, it is fragile. “Wall” - for cladding external walls and partitions above ground level. “Comfort” - for insulating loggias and balconies (balanced view). Typically, penoplex sheets are fastened with polyurethane foam or “liquid nails.” This material is an improved version of conventional foam - lower thermal conductivity due to its uniform porous structure. Other differences of penoplex include lower fire hazard and greater strength - it can even be laid on the floor. Otherwise, the advantages of the materials are the same.

Preparation and styling

Insulation is preceded by a number of preparatory stages, the sequence of which depends on the general condition of the balcony, the chosen technology for the work and the type of materials used:

- strengthening the concrete base slab;

- dismantling or replacing metal handrails in old houses;

- erection of a parapet from foam blocks in its absence.

Strengthening the parapet with foam blocks

Roll materials (penofol, isolon) are attached directly to the wall. Laying tile insulation (foam plastic, penoplex or mineral wool) can be done in two ways:

- on the wall using glue or dowels - this method allows you to save space on small balconies and avoid additional load on the base;

- on a wooden (metal) sheathing; the material is cut to the size of the sheathing cells (usually about 60*60cm), laid between the beams; It is convenient to fix finishing materials (lining, plasterboard or panels) onto the sheathing.

We fill the cracks with polyurethane foam

Mineral wool

0

Source:

For insulating a balcony, basalt mineral wool is better suited - the most environmentally friendly type of material with excellent technical characteristics. Advantages: low thermal conductivity coefficient - almost like penoplex; waterproofness - if a basalt type of wool is selected; good breathability – formation of a healthy microclimate; excellent sound insulation – noise from the street is reduced to a minimum; sufficient strength - mineral wool can be used for floor insulation; fire resistance – melting point is 1000°C; safety for the environment and health - there are no emissions of harmful substances, the development of mold and fungi is excluded; resistance to chemicals. Disadvantages: high cost; dust formation when cutting; special clothing is required for work. You should not insulate the loggia yourself using traditional glass wool - its particles can become embedded in mucous membranes, skin and hair.

comparison table

For clarity, let's collect all the characteristics in a table.

| Characteristic | Styrofoam | Mineral wool | Expanded clay | Penofol | Penoplex |

| Ease of installation | + | — | — | + | + |

| Environmental friendliness | — | + | + | — | — |

| Fire safety | — | + | + | + | — |

| Thermal insulation quality | — | — | — | + | + |

| Durability | — | + | + | + | — |

| Soundproofing | — | + | — | — | + |

| Vapor permeability | — | + | + | — | — |

| Price (economy option) | From 40 rub. for 1 m2. | From 180 rub. per sheet 60 by 80 cm. | From 30 rub. for 20 liters. | From 70 rub. for 0.6 m2 (self-adhesive). | From 113 rubles per sheet 118.5 by 58.5 cm. |

Foam plastic has the most cons - but it is the cheapest. And most of all the advantages of the most ordinary mineral wool.

Penofol (foamed polyethylene with a foil layer)

0

Source:

The main advantages of the material are the ability to reflect heat and ease of use - it is available in rolls and mats. But it makes no sense to use penofol without other materials, because it does not provide the required level of thermal insulation. There are several varieties of it: “A” - with a one-sided layer of reflection, for combined insulation. “B” - with double-sided reflection, for heated floors, underlays for screeds. “C” is a self-adhesive type with minimal requirements for surfaces. In order for penofol to truly reflect heat flows, it must be laid with the foil (metalized) side towards the inside of the room.

Other insulation methods

It will not be possible to warm up the balcony of a brick house with insulation alone. Therefore, in addition to thermal insulation, heating is carried out.

For heating use:

- "warm floor" system;

- oil heater;

- infrared emitter;

- electric convector.

It is not recommended to heat the balcony of a brick house. If such a need does arise, design work is first carried out and the transfer and installation of an additional battery is coordinated with the BTI.

Most often, infrared heated floors are installed. This system is easy to install. The manufacturer provides each kit with detailed instructions. Following the instructions, lay the heated floor system on the insulation.

There are varieties depending on the finish coating. Before you buy a heated floor, you need to choose the final floor covering - ceramic tiles or laminate.

Izolon

0

Source:

An improved version of penofol, already well suited for insulating loggias and balconies. Also available in rolls and reflects heat flow. Advantages: fire resistance - in contact with fire it breaks down into carbon dioxide and water; good heat and noise insulation; resistance to sudden temperature changes; long service life - more than 100 years; ease of installation - the flexibility of the material allows you to close difficult places; protective properties - can act as a barrier in case of water leakage. Disadvantages: high cost; thinness - the structure is easily damaged and loses its characteristics; the need for strict adherence to installation technology.

Expanded clay

This thermal insulator is made from fusible clay or shale. In fact, this is ordinary ceramics, only granulated.

The clay is mixed with water, loaded into rotating drums and heated to 1300 °C. The material “boils” and pores appear in the granules, which provide expanded clay with high heat-insulating properties.

How to insulate a balcony: preparatory work

0

Source:

Whichever material is chosen as a result, the steps to prepare the room will be the same. And they must be carried out, because if water seeps through the cracks and cracks under the insulation, it will gradually lose its functionality and the sheathing will have to be replaced. Preparatory work before insulation is carried out in a clear sequence: Cleaning all surfaces from traces of cement, old paint, etc. Remove all small debris and dust, preferably using a vacuum cleaner. Plaster with cement mortar and putty all cracks, crevices and gaps. Widening gaps between slabs. Then they need to be sprayed with water and filled with standard installation foam. Cut off excess foam, sealant and other mortars - after all surfaces have dried. Primer coating.

What are the differences between different types of thermal insulators?

Insulation materials are divided into:

- in form: durable sheets, rolls, bulk materials, foaming agents;

- by fastening method: materials are poured, glued, secured with dowels or nails, placed inside the structure, on the outside or on the inside;

- by chemical composition: plastics, minerals, clay.

Sheets are conveniently attached to vertical surfaces. Soft thermal insulators, packaged in rolls, perfectly fill niches in frames. They can be laid very tightly - so that there are no cold bridges left. Bulk materials are universal. You can fill the vertical frame, or you can add it to concrete as a filler and pour the floor.

Foam penetrates into the most inaccessible areas, completely fills niches, leaving no gaps.

The strength, durability and safety of materials depend on the chemical composition.

Common Mistakes

0

Source:

It is important to know not only how to properly insulate a loggia, but also what not to do. No one is immune from mistakes, but recommendations will help prevent them. Placing central heating radiators on a balcony or loggia Such actions will sooner or later be detected and the system will have to be removed. In addition, this is unsafe - the radiators are included in a common network, redevelopment of which can cause serious disruption. Plus there is a fine for this. Read more in the article “moving the battery to the loggia.” Removing a door or window unit from an apartment to a balcony From a legal point of view, this is a redevelopment that requires permission. It follows that in some cases this permission can be legally obtained. Read more in the article “Combining a loggia with a room.” Blind repetition of scenes from television programs about renovations In such programs, a balcony and a room are often combined. Regulatory authorities may recognize this as a violation: for example, for deteriorating heat supply to neighboring apartments. Then dismantling and payment of a large fine will be required. Frameless glazing Visually it looks very interesting. But for insulation you need double and triple PVC windows.

Selection of material for thermal insulation of the balcony

Before choosing how to insulate the balcony from the inside, the materials are carefully studied according to the following main criteria: durability, thermal conductivity, environmental friendliness and cost insulation. Also important parameters are noise absorption, breathability, thickness and ease of installation.

- Durability. The average service life of thermal insulation materials is 5–15 years. Polyurethane foam has the longest service life.

- Thermal conductivity is how quickly or slowly the material will cool or heat up under the influence of the environment. If the insulation has low thermal conductivity, that is, it cools or heats up slowly, then it is a good insulation. The lowest thermal conductivity indicators of polyurethane foam are 0.020–0.041 W/m*C, for comparison the thermal conductivity of concrete is 0.8 W/m*C.

- Eco-friendly. Some insulation materials emit formaldehydes, which are very dangerous substances for health. Therefore, to insulate the balcony, you should choose biologically neutral material, such as ecowool and expanded clay.

- The cost of insulation is calculated based on the area of the balcony, the thickness of the insulation, and the brand of material. Mineral wool and polystyrene foam are considered the most inexpensive.

The microclimate on the balcony or deck will depend on how suitable the material you choose. You should also pay attention to the climate zone in which you live. If the winters are warm, but it will be sufficient to insulate the balcony, for example, with penofol; if the winters are cold, then you will need a multi-layer combination of insulation, for example, double c layer of mineral wool and penofol.

I managed to make a two-room apartment from a one-room apartment

Insulation for a balcony: choosing the best option, installation tips

A good owner will definitely try to turn the balcony in his apartment into the most functional room possible. It is clear that since the balcony is in direct contact with the street, the main problem, in addition to glazing, is its thermal insulation. If we take this issue seriously, then planning such events should begin with studying the characteristics, and then the correct choice of insulation materials.

Insulation for balconies

When choosing insulation for a balcony, you must first take into account the average winter temperature of your region of residence. But, besides this, before purchasing, be sure to compare several different options, comparing their operational capabilities and the degree of safety for humans.

The proposed table presents the main characteristics of most building and insulating materials that can be used to convert a balcony into additional usable area of the apartment.

| Materials | Thermal conductivity coefficient, W/m×°С | Density, kg/m³. | Operating temperature range, °C | Vapor permeability, mg/(m×h×Pa) |

| Polyurethane foam | 0,025 | 40-60 | -100 to +150 | 0,04-0,05 |

| Extruded polystyrene foam | 0,05 | 30-45 | From - 50 to +75 | 0,015 |

| Polyethylene foam | 0,045 | 35 | -60 to +90 | 0,001 |

| Styrofoam | 0,03 | 40-125 | -50 to +75 | 0,23 |

| Stone wool | 0,047 | 35-150 | -60 to +180 | 0,53 |

| Glass wool | 0,056 | 15-100 | -60 to +480 | 0,53 |

| Reinforced concrete | 2,04 | 2500 | 0,03 | |

| Hollow brick | 0,58 | 1400 | 0,16 | |

| Wood (across the grain) | 0,18 | 40-50 | 0,06 |

“Dry” numbers can already say a lot, but it is still necessary to take a closer look at the most commonly used insulation materials. To begin with, it will be useful to understand the criteria that thermal insulation material for a balcony must meet.

Criteria for choosing insulation

Since a completely unheated room that does not have thick walls will be insulated, the following qualities of the thermal insulation material must be provided:

- It should have low thermal conductivity - this will help retain the heat coming to the balcony from heated rooms or from heating devices, preventing it from quickly leaving the room.

Naturally, the lower the thermal conductivity index, the more effective the thermal insulation.

- The thermal conductivity indicator directly depends on the density - if it is high, then one can only dream of good thermal insulation performance. If the insulation has a porous structure, then low thermal conductivity will be ensured.

- It is necessary to choose insulation with low vapor permeability or, in other words, a predisposition to hygroscopicity, since any material saturated with moisture loses its thermal insulating qualities.

- The insulation must be non-flammable or at least self-extinguishing. On the packaging, the flammability of the insulation is marked with the designations G1 to G4. The number “1” means minimal, and “4” means high flammability of the material.

In addition, it is important to pay attention to the smoke production of burning insulation. This indicator is marked with designations from D1 to D3.

Another important fire safety parameter is the rate of spread of the flame. On the packaging of the insulation, this characteristic can be indicated by letters and numbers, from RP1 to RP4. RP1 means that the material will not become a fire carrier, and RP4 indicates the rapid spread of flame after ignition.

A material correctly selected according to these criteria will probably save the life and health of apartment residents if a fire suddenly occurs.

- The environmental friendliness of the material is no less important for the health of people living in the apartment. Over time, many modern insulation materials begin to emit substances harmful to humans, which can cause various diseases.

- The durability of the material will affect the service life of the insulated balcony without repair. It should be borne in mind that some of the insulation materials tend to decompose over time.

- It is necessary to take into account the complexity of installing the material - insulation technology can vary significantly. It is advisable to choose an option that will be easier to implement, especially if you plan to carry out the installation yourself.

The soundproofing qualities of insulation will also be useful, as they will help protect the apartment from street or yard noise.

The most commonly used materials for insulating different parts of the balcony are mineral wool and polystyrene foam in one modification or another, penoflex, expanded clay and others.

Expanded polystyrene

Probably the most popular thermal insulation material in recent decades is polystyrene foam, or, as it is more often called in everyday life, polystyrene foam. They insulate balconies and apartments, roofs and walls of houses, both outside and inside. However, is it really that good for such purposes? To find out this, it is necessary to take a closer look at its characteristics, since the material, in addition to numerous positive qualities, also has its significant “disadvantages”.

Expanded polystyrene is one of the most popular insulation materials

Expanded polystyrene can be ordinary foamed and extruded. The characteristics of these types differ from each other, so you should not think that they are practically the same thing.

Extruded polystyrene foam

Extruded polystyrene foam is designated by the letters EPS and XPS. It differs from ordinary polystyrene foam in its manufacturing technology, which largely determines some of its qualities.

Extruded polystyrene foam panels are usually given a specific shade

Its positive characteristics include:

- Low water absorption, which allows the material to remain almost always dry, which means this quality will not allow it to lose its main purpose - to keep the room warm.

- The low thermal conductivity of properly installed extruded polystyrene foam will give the balcony room good protection from the cold. Even at a temperature outside the walls of the house of -25 degrees, thermal conductivity is only 0.05 W/m×°C.

Balcony insulation with extruded polystyrene foam panels

- The low specific weight of the material facilitates its installation and lifting to the height of the building. The density of extruded polystyrene foam is from 35 to 45 kg/m³.

- The resistance to compression and deformation of EPS is much higher than that of conventional foam, and it is excellent for floor insulation. The force at linear deformation of 10% is about 0.25-0.4 MPa, and the bending strength is from 0.4 to 1 MPa.

- Resistance to inorganic solvents, such as alkalis, acids and salts, allows the use of water-based paints for painting this material.

- The material is characterized by sufficiently high durability - the service life can be calculated at 50 years or more, of course, with proper installation and covering of polystyrene foam from ultraviolet rays with cladding or coloring compounds.

- When closed, expanded polystyrene is almost non-toxic and does not emit harmful substances during operation, therefore, without exposure to certain factors, it is completely safe.

The “disadvantages” of extruded polystyrene foam include the following:

- Expanded polystyrene is not resistant enough to high temperatures and their sudden changes - the upper limit at which it can lose its given shape and performance characteristics is only about 75 degrees.

Although not actively, extruded polystyrene foam can still burn

- Its markings are usually G3 and G4. Class G3 materials contain fire retardant additives, and this increases the cost of the insulation. If the packaging bears the designation G4, then this expanded polystyrene has a fairly high degree of flammability and is considered an economy-category insulation material. When burning, polystyrene foam produces strong smoke, and the combustion products are very toxic, as they include fumes of formaldehyde and other substances hazardous to health and life.

- The material has low vapor conductivity, that is, it is not breathable. Therefore, in rooms that are insulated with it, it is necessary to provide good ventilation.

- Another disadvantage can be considered low resistance to adhesives and solvents made on an organic basis. This quality must be taken into account when choosing compositions for installing insulation. Polystyrene can melt and dissolve on contact with organic acids and alcohols, as well as ethers and hydrophobic solvents, so they should not come into contact with EPS boards. If this condition is not met, polystyrene foam may “float” over time, shrink, and the insulation will come to naught.

Video: example of insulating a balcony with extruded polystyrene foam

Regular foam

Most often, ordinary polystyrene foam is used for insulation, since it has a lower price. However, you need to remember that almost always the price determines the quality of the material. The characteristics of this insulation are in many ways similar to extruded polystyrene foam, but they also have significant differences.

A cheaper option is panels of ordinary polystyrene foam (foam)

Polystyrene foam has a more porous structure, consisting of 98% air and only 2% polystyrene foam. Its structure consists of individual granules ranging in size from 4 to 15 mm, which are glued together during the manufacturing process of the blocks.

Loose foam granules

The thickness of the material blocks can be from 20 and even up to 1000 mm, and the size of the slabs usually varies in multiples of 500 mm: 1000 × 500, 1000 × 1000, 2000 × 1000 mm.

The advantages of conventional polystyrene foam include its following qualities:

- The low thermal conductivity of polystyrene foam can be called its main advantage over many other insulation materials, including extruded polystyrene foam. Typically this indicator is around only 0.03 W/m×°C. This quality is achieved due to the extremely porous structure, which is able to protect the room from the penetration of cold from outside and retain accumulated heat inside.

- Properly installed polystyrene foam can protect the balcony from the wind and from the penetration of street sounds.

- Polystyrene foam is almost non-hygroscopic, as it is able to absorb a minimal amount of moisture. This may be explained by the fact that the granules, which overwhelmingly predominate in the total volume, are completely sealed and do not absorb water - it can only seep into the small channels between them.

Foam panels between the joists and sheathing guides on the balcony

- Simplicity of installation and ease of lifting the material to any floor of the building. Polystyrene foam is easy to install and fix on any surface, it is easy to cut and adjust to the desired size.

- During normal processing (without the use of thermal cutting), this material does not emit any odors or harmful substances, so those working with it will not require protective equipment.

- Polystyrene foam, like extruded polystyrene foam, is resistant to aggressive alkaline and acidic environments, cement, lime and gypsum, salts and water-based paints.

The negative qualities of polystyrene foam include:

- Low fire resistance. Most often, such foam is labeled as a flammable material - G4. Less often, it is given the low flammability of G3 - in this case, the insulation is more expensive, since fire retardants were used in their manufacture. If the packaging does not indicate flammability at all, or the material is designated as completely non-flammable (which cannot be trusted), then you should not purchase such polystyrene foam, since it is not known what can be expected from it.

Burning foam plastic poses an extremely high danger.

When burned, the foam melts and flows, releasing gases that are very dangerous for humans, which can cause chemical and thermal burns of the respiratory system. In addition, highly toxic substances are released into the air along with smoke, which quickly lead to serious poisoning of the body.

- Foam made using factory technology must withstand temperatures up to + 75 degrees without losing its qualities - the threshold, as you can see, is not too high.

- Over time, polystyrene foam begins to chemically decompose and release into the room a significant amount of substances hazardous to humans, which can penetrate even through brick walls.

- The material should not be left open for a long period of time, as ultraviolet rays contribute to its rapid decomposition.

- The material is exposed to many technical liquids, such as turpentine, ethyl alcohol, acetone, gasoline, etc. When in contact with these substances, ordinary foam simply dissolves in them.

- Polystyrene foam, unlike extruded polystyrene foam, can hardly be called a particularly durable material, therefore, if it is used to insulate a floor, it requires additional reinforcement in the form of wooden logs or concrete screed. Fixed to the wall and then sheathed with decorative material, such insulation should last about 15 ÷ 20 years without loss of heat-insulating qualities.

Mineral wool

The second most popular insulation for balconies is mineral wool, which has excellent thermal insulation properties. There are several types of this material, made from different raw materials, and they differ somewhat in some technical characteristics.

One of the best thermal insulators is mineral wool

| Name of parameters | Slag | Glass wool | Stone wool |

| Limit temperature of use, °C | up to 250 | from -60 to +450 | up to 1000 |

| Average fiber diameter, µm | from 4 to 12 | from 5 to 15 | from 4 to 12 |

| Hygroscopicity of the material in 24 hours (no more),% | 1,9 | 1,7 | 0,095 |

| Taunting | Yes | Yes | No |

| Thermal conductivity coefficient, W/(m×°C) | 0,46-0,48 | 0,038 -0,046 | 0,035-0,042 |

| Sound absorption coefficient | from 0.75 to 0.82 | from 0.8 to 92 | from 0.75 to 95 |

| Presence of binder, % | from 2.5 to 10 | from 2.5 to 10 | from 2.5 to 10 |

| Flammability of the material | NG - non-flammable | NG - non-flammable | NG - non-flammable |

| Heat capacity, J/kg×°C | 1000 | 1050 | 1050 |

| Vibration resistance | No | No | No |

| Elasticity, % | no data | no data | 75 |

| Sintering temperature, °C | 250-300 | 450-500 | 600 |

| Fiber length, mm | 16 | 15-50 | 16 |

| Chemical stability (weight loss), % in water | 7,8 | 6,2 | 4,5 |

| Chemical stability (weight loss), % in alkaline environment | 7 | 6 | 6,4 |

| Chemical stability (weight loss), % in acidic environment | 68,7 | 38,9 | 24 |

So, mineral wool has the following positive qualities, which determine its convenience for insulating balconies and loggias:

- Low thermal conductivity - mineral wool creates an excellent barrier to the penetration of cold or heat.

- The material has a fairly strong and at the same time plastic and elastic structure.

- During installation and during operation, the insulation is absolutely non-toxic.

- Mineral wool not only has excellent thermal insulation, but also protects the room well from extraneous noise.

- Any mineral wool is marked NG, that is, the material is not flammable.

- The material is practically not susceptible to the destructive effects of chemicals.

- Mineral wool is available in rolls or in the form of slabs, which adds comfort during installation.

General negative qualities of mineral wool include:

- Hygroscopicity - for some types of mineral wool it may not be too high, but it will still require a coating with a water vapor barrier material during installation.

- The material is caustic, which causes inconvenience during installation and will require the use of skin and respiratory protection. The exception is stone wool.

It is better to consider other advantages and disadvantages characteristic of each type of mineral wool separately, since they differ somewhat.

Glass wool

Glass wool consists of fibers made from sand or broken glass, which are melted at a temperature of 1450 ÷ 1500 degrees. The fibers have a thickness of only 5 ÷ 15 microns and a length of 15 ÷ 50 mm - they are what make this insulation elastic and durable.

Glass wool is a good insulation material, but installation requires special precautions

Glass wool has excellent resistance to chemical influences, as well as to the development of any forms of biological life in its structure. When installed correctly, it is not susceptible to rotting, and in addition, mice and rats do not live in it, which is very important for balconies located on the ground floor.

Glass wool in a balcony insulation system

The disadvantage that appears when installing this insulation is the fragility of the fragile fibers. The debris has sharp edges so it can easily penetrate thin clothing, stick into skin, get into eyes, and can be easily inhaled, causing respiratory damage.

To avoid these troubles, you need to carefully prepare for insulation work by purchasing clothes made of thick material, gloves or mittens, safety glasses and a respirator. You should also know that after completing the installation of glass wool, used clothing and mittens will have to be thrown away, since it will not be possible to clean them.

Basalt (stone) wool

Stone wool is made from gabbro-basalt and similar groups of minerals. The insulation has low thermal conductivity and excellent resistance to high temperatures. Stone wool fibers can withstand temperatures up to 800 ÷ 1000 degrees, but binders are designed only for temperatures up to 200 ÷ 250 degrees, so when they burn, the stone fibers disintegrate. However, for the conditions of the balcony this is not decisive.

Stone wool - there are practically no disadvantages

This type of cotton wool is easy to work with as it has no brittle fibers and is therefore safe for the skin, eyes and respiratory tract.

Stone wool is a “breathable” material, which is especially important when insulating external walls.

This material can be called environmentally friendly, since it does not contain or emit substances harmful to the human body.

Balcony walls insulated with mineral wool

It is basalt insulation that fully corresponds to the name “mineral wool”, and it can be called the best option for insulating a balcony. Moreover, today stone wool is produced with a foil layer, which enhances the insulating effect.

Slag

Slag is made from blast furnace slag. It has a fairly high hygroscopicity, that is, it easily absorbs moisture, which leads to a rapid loss of its original insulating qualities.

Slag wool fibers are not as brittle as glass wool, but the caustic effect is present, so its installation should also be carried out with appropriate equipment.

It is better to avoid using slag wool in apartment conditions

Another significant disadvantage is that blast furnace slag is not always environmentally friendly, transmitting this “trail” to the materials based on it. All this suggests that it is still not worth using slag wool for insulating residential premises.

Prices for mineral wool

Mineral wool

Expanded clay

Expanded clay is a bulk material that is perfect for insulating the floor on a balcony. It has remarkable qualities, and the main one is the absolute environmental friendliness of the insulation. It is made from low-melting clays by cleaning them, thoroughly mixing, molding and quickly firing at high temperatures, reaching 1250 ÷ 1300 degrees.

Expanded clay of various fractions

This table will tell you in numbers about the characteristics of the material:

| Indicators | Fraction size | ||

| 10-20 mm | 5-10 mm | 0-5 mm | |

| Bulk density, kg/m³ | 280-370 | 300-400 | 500-700 |

| Strength under pressure, N/mm² (MPa) | 1,0-1,8 | 1,2-2,0 | 3,0-4,0 |

| Frost resistance 20 cycles, gravel weight loss in % | 0,4-0,2 | 0,2-1,2 | Not regulated |

| Thermal conductivity W/m×°C | 0,0912 | 0,0912 | 0,1099 |

| Water absorption,% | 10 — 15 | 15 — 20 | up to 25 |

But in order to understand how suitable it is for insulation operations on the balcony, you should consider all its qualities in more detail.

Expanded clay is produced in the form of granules of different sizes - these can be pellets up to 40 mm in size or a smaller fraction - up to expanded clay sand. The material is light and durable, moisture resistant, which is very important for a balcony floor, has low thermal conductivity and good sound insulation properties. Expanded clay is durable; it can be used for at least a hundred years without losing its positive qualities.

Its light weight will not weigh down the balcony structure, and bulk bags with insulation can be easily lifted to a high floor. In addition, it is easily distributed over the surface of the base using a rake or a regular wooden mop.

To protect the floor on the balcony from moisture, it is recommended to lay expanded clay as the first layer, since even if condensation occurs from a temperature difference on the base of the balcony, the expanded clay layer will not allow it to penetrate into the insulation laid above.

There are several ways to insulate the floor on a balcony with expanded clay. The material can be used either as a sole thermal insulator or in combination with other materials.

- The first method is to pour expanded clay onto the prepared surface between the joists, and cover this insulating layer with floorboards or thick plywood.

Dry filling of expanded clay between the insulated floor joists

- Another option is carefully leveled expanded clay concrete, laid between wooden beams. After it hardens, the insulation can be enhanced with extruded polystyrene foam or other insulation, increasing the logs to the required height.

Expanded clay is often mixed with cement mortar for greater stability of the layer.

- The third option could be a loose floor, which is often otherwise called a “dry screed”. This is done using fine expanded clay and gypsum fiber boards.

Fine expanded clay is the main insulating element of the “dry screed”.

Detailed information about the construction of an insulated floor using the “dry screed” can be found by referring to a special article on the portal by following the link.

Prices for expanded clay

Expanded clay

Spray polyurethane foam

Recently, many owners have resorted to a new, modern way to insulate a balcony - spraying polyurethane foam on the walls. This is extremely convenient - since the application process takes only one day. The only drawback of this insulation method is that it is almost impossible to do it yourself, since applying liquid foaming material to the walls will require special equipment and practical skills. But the cost of such services remains quite high.

Thanks to its fine-porous structure, polyurethane foam has excellent insulating qualities

Sprayed polyurethane foam has a significant number of advantages. And the first of them is that after creating such a layer, you don’t have to think about additional insulation - you can install decorative trim directly on top of it after drying.

Thanks to its insulating qualities, speed, reliability and uniformity of application, polyurethane foam can be called the most effective way to both insulate and soundproof a balcony:

- When polyurethane foam is sprayed on the surfaces of walls, floors and ceilings, a monolithic seamless coating is created that covers absolutely all cold bridges that are quite possible when laying other thermal insulation materials. The balcony turns into a kind of thermos, which keeps the inside warm in winter and cool in summer.

Balcony insulated with sprayed polyurethane foam

- The thermal insulation qualities of this material depend on the thickness of the spraying; still, the thermal conductivity coefficient is minimal, amounting to only 0.020÷0.027 W/m×°C. This super-indicator is achieved due to the unique fine-cell, air-filled structure of the material. Even the smallest layer of sprayed polyurethane foam can give the effect of much thicker layers of other materials.

To compare the thickness, you can refer to this diagram. It clearly shows how thick different materials should be laid in order to achieve the same thermal insulation efficiency of the room.

Comparison of thermal insulation qualities of various materials

- Such thermal insulation has a very wide operating temperature range - without compromising its qualities and human health, from - 150 to + 150 degrees.

- To spray polyurethane foam on any surface, you do not need to prepare them in any way - attach lathing, create waterproofing, etc.

- The insulation is highly resistant to chemical attack and is not a breeding ground for any forms of life.

- Protected from ultraviolet rays, polyurethane foam does not decompose into its components. and retains all its thermal insulation qualities and physical characteristics for 50 years or more.

Unfortunately, it is impossible to call polyurethane foam an absolutely non-flammable material.

- We must not forget about such an important quality as the flammability of the material. In its characteristics you can often find the designations G1 and NG, but, unfortunately, this is not entirely true. With prolonged exposure to an open flame, polyurethane foam can catch fire, and combustion products also pose a danger to human health. However, in terms of fire safety, it is “head and shoulders above” any type of polystyrene foam.

More information about insulation technology using polyurethane foam can be found in the article posted on the pages of our portal

There are other thermal insulation materials, both manufactured using modern technologies and those that have been tested for decades. Thus, the insulation of a balcony is almost never complete without the use of thin rolled material - polyethylene foam with one- or even double-sided foil (for example, penofol).

Roll of foil polyethylene foam - penofol

Whatever type of main insulation is used, it is recommended to lay a layer of penofol on top of it for greater effect, which, in addition to the fact that it itself has a porous structure, also has the property of reflecting heat flows back towards the room (this was clearly shown in the video above) . In some cases, when too much insulation is not required, such material can even act as the main thermal insulator. More information about the characteristics and use of rolled foil insulation can be found in the corresponding publication of the portal.

Penofol can be used as both additional and primary insulation

The insulation materials mentioned in the article are the most popular of those sold in hardware stores and offered by construction companies involved in insulation work. To choose one of them or create a complex of several materials, you need to carefully study not only their advantages, but also their negative qualities in order to protect the family from possible negative consequences.

And in conclusion, a fairly detailed video about insulating a balcony, which will also help you understand the choice of thermal insulation materials.

Prices for thermal insulation materials

Thermal insulation materials

Video: Insulating a balcony or loggia. The easiest way. Warm balcony

First priority

Before you start insulating the balcony, you should glaze it

Why is glazing important? Old or low-quality windows will produce colossal heat losses, so it makes no sense to insulate the balcony if the windows will blow out. It is better to entrust the installation of windows to professionals who will carry out the installation using modern technologies.

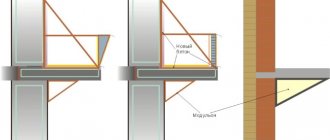

After installing the windows, you should decide where it is best to install insulation. Of course, it is recommended to insulate the outer walls of the balcony, which will prevent the development of problems such as moisture settling on the walls and the appearance of fungal mold. But insulating a balcony if it is at a high altitude is not easy. To do this, you will need to call steeplejacks-builders, who will ask for a considerable amount of money for the services. And one more important point - in order to insulate a balcony from the outside, you will need approval from the authorities, since by your actions you plan to change the design of the facade of a residential building.

As a result, the last option remains - to insulate the balcony from the inside. Moreover, such work can be done independently if you have the necessary tools. Many apartment owners do not want to pay a lot of money for balcony insulation, so in order to save money, they decide to insulate the balcony themselves. This article will tell you how to insulate a balcony yourself, what material to choose for this, and what are the main steps to complete the work.

The floor is not properly insulated

In order not to overload the floor slab (for example, with a concrete screed or leveling mixture), it is better to make the floor covering from lightweight modern materials. On top of the vapor barrier - foil or polyethylene film - mats made of penoplex or mineral wool are laid in two layers. On top is waterproofing, which can be used, for example, hydroglass insulation. The rolls are placed on top with an overlap of about 10-20 centimeters. Using a blowtorch, the mastic-based strips are fused together, and if the use of open fire is for some reason impractical or dangerous, then the sheets are fastened mechanically. Then a layer of plywood, and only then carpet or laminate.

Finally, the “classic” method of floor insulation is also not bad: wooden logs are laid on the slab, between which modern insulating materials are located.

Installing a new radiator on the loggia or moving the old one

I want the new attached living space to be warm, and the solution seems to be moving the heating radiator from the living room or kitchen to the loggia. This is a gross mistake that you shouldn’t even think about: moving the heating radiator outside the external (load-bearing) wall is strictly prohibited. This is fraught with heat supply accidents (for example, freezing of pipes), and you will never receive permission for such arbitrariness. But if you do change it this way, then you will have to return the pipes and radiator to their original position at your own expense. Is there a way out? Of course, there is electric floor heating. Modern technology allows for efficient and safe floor heating by installing a special electrical cable. Moreover, for maximum heat transfer, the laying step can be varied depending on the planned heating temperature. I do not like? Instead of a water radiator, you can hang an oil electric heater in the same place, which will do the same job.

Production technology

Today, the question of insulating your living quarters is quite relevant, so every homeowner is faced with the question: what is better to choose for insulating a balcony - penoplex or polystyrene foam? The differences between these building materials lie in production technology.

Polystyrene foam is produced using polystyrene foam technology, without the use of pressure. The production technology provides for an increase in pentane and polystyrene granules by 50 times. The output is polystyrene foam consisting of 2% polymer and 98% air. Thanks to this production technology, the building material has high thermal insulation properties. Penoplex is a derivative of polystyrene foam, only the principle of its manufacture is slightly different. Penoplex is obtained as a result of the extrusion method. This method involves exposing polystyrene granules to pressure and high temperature. The result is a durable and solid material with a uniform consistency. It is also called expanded polystyrene. Compared to polystyrene foam, expanded polystyrene has a higher density and therefore has worse vapor permeability. But due to its high strength, such insulation can be subjected to various types of mechanical loads.