The loggia, from a constructive point of view, is perfect for becoming a full-fledged room or an extension of the apartment. To make this possible, it is necessary to carry out a number of construction and installation works on insulation, glazing, and finishing. The result will be a cozy relaxation room, a spacious living room, and additional work space.

The result of insulation may differ from the desired one if several factors are not taken into account when choosing materials and technology for insulation work.

The first factor is the further purpose of the room:

- if you plan to have a utility room, then use any single layer of insulation; Basically, only the part directly in contact with the street - the parapet - is thermally insulated;

- the desire to have a separate full-fledged room will require the use of different types of thermal insulation materials, which are laid in two layers over the entire surface of the loggia;

- the option of combining a loggia and a room will also require two-layer insulation, but in this case the main attention is paid to the parapet, and the walls are covered in one layer.

The second factor is the size of the loggia itself, since if it is small, then a type of insulation is selected that, despite its small thickness, has a fairly high thermal protection index. In this case, the usable area will be reduced slightly.

The third factor is taking into account the fact that any material from which the walls of the interior are made allows moisture accumulated inside to pass through. These water vapors, colliding with the colder air from the street, settle on the outside of the wall. If this wall is insulated, it means that the insulation becomes covered with moisture, which leads to its rotting and a decrease in thermal insulation properties. It is necessary that water vapor does not reach the insulation.

Criterias of choice

The main technical characteristics that you need to pay attention to when choosing thermal insulation materials for balconies and loggias:

- heat transfer coefficient - the higher the indicator, the smaller the layer of insulation you need to use, which saves precious space and reduces the load on the slab;

- resistance to mechanical stress - it is easier to apply a layer of finishing material to durable materials;

- vapor and hydraulic permeability - the microclimate in the room and the need to use additional materials depend on these indicators.

It is also worth considering the installation features - the simplicity of the process is especially important if the work is planned to be carried out independently without the involvement of specialists.

Preparatory work

Before you start insulating the loggia with your own hands, you need to clearly plan the future scope of work, costs of materials, missing tools, etc.

If the insulation of the loggia has been detailed on paper, all materials have been calculated and prepared, then we proceed to the next important stage - preparation for installation

- We remove all unnecessary items and furniture from the premises.

- We carefully tidy up the ceiling and floor of the room (sweep away all the debris).

- We remove recesses and cracks in the ceiling; for this you can use polyurethane foam or sealant for interior work.

- Leave the treated surface until completely dry.

- We clean out all the rough edges.

- We provide steam and waterproofing of ceilings. To do this, we use a two-millimeter polyethylene film or a special membrane, connecting all joints using liquid nails or regular construction tape. The vapor barrier oilcloth must fit tightly to the ceiling.

- Take measurements, transfer the markings to the material and prepare the amount of insulation you need.

After high-quality preparation of the loggia ceiling for installation, we proceed to its thermal insulation.

Foam plastic (expanded polystyrene)

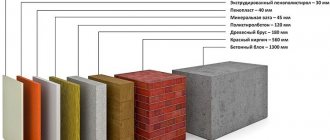

The most common sheet material for insulating balconies. Its composition is a frozen foam, the closed pores of which contain air. 5 cm thick is usually used ; for harsher climates, it is recommended to choose thicker sheets up to 10 cm .

The material has a number of advantages that determined its popularity:

- low thermal conductivity coefficient, which ensures high thermal insulation of the room even without the use of other materials;

- high water absorption rate, which makes it possible not to lay an additional layer of waterproofing;

- sufficient strength makes it possible to use dense and heavy finishing materials;

- environmental friendliness - no dust is generated during operation, no harmful substances are released during further operation;

- hygiene – mold and mildew cannot form in polystyrene foam;

- ease of use and ease of installation - the sheet can be cut into parts of any size;

- low cost compared to other insulation materials;

- service life up to 30 years, subject to compliance with installation technology.

The main disadvantages of polystyrene foam:

- low air permeability – when insulating a loggia with this material, it is necessary to provide additional methods of ventilation, otherwise it will not be possible to ensure a comfortable microclimate in the room;

- poor sound insulation properties;

- insufficient resistance to certain types of drying oils, varnishes and other chemicals based on petroleum products and alcohols - this requires special care when choosing finishing materials;

- high flammability and, accordingly, fire hazard.

To insulate a balcony, you must choose construction foam made by extrusion with a density of 35-40 kg/m3 . Types with an indicator of less than 25 kg/m3 are packaging materials and are not suitable for construction work. To determine the quality of the material, break off a piece from the sheet and look at the structure. Construction foam has cells in the form of polygons, packaging foam consists of easily detachable balls.

Internal insulation of loggia walls, which material is more reliable?

The loggia, from a constructive point of view, is perfect for becoming a full-fledged room or an extension of the apartment. To make this possible, it is necessary to carry out a number of construction and installation works on insulation, glazing, and finishing. The result will be a cozy relaxation room, a spacious living room, and additional work space.

The result of insulation may differ from the desired one if several factors are not taken into account when choosing materials and technology for insulation work.

The first factor is the further purpose of the room:

if you plan to have a utility room, then use any single layer of insulation; Basically, only the part directly in contact with the street - the parapet - is thermally insulated; the desire to have a separate full-fledged room will require the use of different types of thermal insulation materials, which are laid in two layers over the entire surface of the loggia; the option of combining a loggia and a room will also require two-layer insulation, but in this case the main attention is paid to the parapet, and the walls are covered in one layer.

The second factor is the size of the loggia itself, since if it is small, then a type of insulation is selected that, despite its small thickness, has a fairly high thermal protection index. In this case, the usable area will be reduced slightly.

The third factor is taking into account the fact that any material from which the walls of the interior are made allows moisture accumulated inside to pass through. These water vapors, colliding with the colder air from the street, settle on the outside of the wall. If this wall is insulated, it means that the insulation becomes covered with moisture, which leads to its rotting and a decrease in thermal insulation properties. It is necessary that water vapor does not reach the insulation.

Penoplex (extruded polystyrene foam)

Penoplex is a close relative of polystyrene foam, but with much better properties and characteristics. The special production technology of this material makes it possible to obtain a porous, almost uniform structure with uniform distribution of air in isolated cells. Thanks to this structure, the material has a lower thermal conductivity compared to conventional polystyrene foam and other insulation materials. This is the main advantage of penoplex; in other respects, the material is close to polystyrene foam.

There are several types of penoplex on the market, which are labeled according to their purpose:

- “Foundation” – intended for insulation of building structures buried in the ground; is particularly durable and able to withstand high soil pressure after backfilling;

- “Wall” – used for insulation of external walls, partitions located above ground level;

- “Roofing” is a special type for attic spaces; with a high thermal insulation rate, it is a rather fragile material, therefore it is not intended for areas with increased load;

- “Comfort” is the optimal variety for insulating the walls of balconies and loggias; differs in balanced technical indicators for internal use.

Common mistakes when insulating

Inexperienced craftsmen make mistakes during the work process. This negatively affects the result. We have collected the most common shortcomings and ways to fix them.

Wrong choice of insulation

When selecting material, you must follow the manufacturer’s recommendations. They accurately describe temperature conditions, recommended layer thickness, and operating conditions. Sometimes they choose unusual options; for example, many are interested in whether it is possible to insulate a balcony with foam. This is undesirable since it is intended for other purposes. Foam decomposes from ultraviolet radiation and water and retains heat less well. It is necessary to choose proven modern heat insulators.

Violation of insulation installation technology

Even correctly selected insulation can be damaged by improper installation. For example, if there are gaps between the sheathing elements and the insulating plates, the cold will flow inside through them. All cracks and joints must be foamed. Sometimes craftsmen use putty instead of foam. It is not intended for thermal insulation; it forms “cold bridges” and allows moisture to pass inside the insulating “pie.” This shouldn't happen.

Instagram premium_balcony

Instagram mbm.studio

Mineral wool

There are several types of this insulating material. For a balcony, it is better to choose basalt mineral wool as the most environmentally friendly type with the best technical and operational characteristics.

The material has an impressive list of advantages:

- low thermal conductivity coefficient (only slightly higher than that of penoplex);

- hydrophobicity - basalt mineral wool does not absorb moisture, other varieties (glass wool and slag wool) get wet and change their characteristics;

- good air and vapor permeability - unlike foam plastic and penoplex, this insulation does not interfere with the natural movement of air, due to which a comfortable and healthy microclimate is formed on a closed balcony;

- fire resistance – the melting point of basalt mineral wool is about 1100 degrees; such thermal insulation can stop the spread of fire;

- good sound insulation - mineral wool has a chaotic structure, the air between the fibers effectively absorbs sound waves and significantly reduces the penetration of noise into the room;

- sufficient strength of the sheet allows the use of any finishing materials; some types of mineral wool are suitable for floor insulation;

- resistance to chemicals;

- environmental friendliness and hygiene - no harmful substances are released during use, no biological life in the form of fungi, mold, insects or rodents arises inside the thermal insulation.

Mineral wool also has its disadvantages:

- work must be carried out in protective clothing - when cutting sheets, dust is generated, which causes skin irritation;

- high cost of material.

Is it possible to insulate a balcony with panoramic glazing?

How to insulate a panoramic balcony depends on the type of glazing. It may be cold, in which case heat loss can only be slightly reduced by insulating the ceiling, floor and wall. The optimal result is obtained when installing heat-saving window systems. But for their installation you need to obtain permission, since the weight of the structure is much greater than that of a “cold” analogue. An effective solution for a loggia can be combining it with a room. But this is considered a redevelopment, so obtaining permits will be required. And complete unification is still impossible, except perhaps with the installation of sliding doors. In this case, it is better to use underfloor heating systems for heating. The optimal solution is infrared film.

Instagram mbm.studio

Instagram mbm.studio

Penofol

This is a universal material with moisture, sound and heat insulation properties.

It is a thin layer of polyurethane foam with an aluminum coating that has the ability to reflect heat. Available in roll form, it is easy to install. Usually used in combination with other materials.

To ensure the level of thermal insulation required for residential premises, the use of penofol alone is not enough! Depending on the purpose, several varieties are available:

- type “A” – has a one-sided reflective layer, used for internal combined insulation;

- type “B” - material with two reflective surfaces for arranging a substrate for a screed or heated floor;

- type “C” is a self-adhesive type, characterized by ease of installation and minimal requirements for surfaces; It is enough that the concrete walls are smooth and clean.

Izolon

Its composition is polyethylene foam with a foil layer. A lightweight universal material, most often produced in roll form and is an excellent choice for insulating a balcony:

- service life – more than 100 years;

- does not support combustion, upon contact with an open flame it breaks down into water and carbon dioxide;

- resistance to temperature changes without changing properties;

- high rates of heat and sound insulation;

- flexible roll material allows you to effectively and easily insulate the most inaccessible places;

- It is used not only as an insulating layer, but also as a protective layer against leaks when pouring floors.

Main disadvantages:

- high price;

- it is necessary to strictly follow the installation technology;

- thin material breaks easily, and damage to the structure leads to loss of characteristics.

Advice from professionals

To save money, you can do some of the work yourself. Thus, decorating the inside of a loggia with your own hands is accessible to any adult. Please note important points:

- Protect insulation and frame elements from moisture. Install a vapor barrier membrane from the inside with taped seams. From the outside, protect the balcony from atmospheric moisture. Do not neglect the window sills, they will allow you to divert rain from the parapet.

- Polyurethane foam is destroyed by exposure to UV radiation. Protect foam seams with sealants or decorative caps.

Insulating the loggia will increase the size of the usable area of the apartment and increase its climatic comfort.

Preparation and styling

Insulation is preceded by a number of preparatory stages, the sequence of which depends on the general condition of the balcony, the chosen technology for the work and the type of materials used:

- strengthening the concrete base slab;

- dismantling or replacing metal handrails in old houses;

- erection of a parapet from foam blocks in its absence.

Strengthening the parapet with foam blocks

Roll materials (penofol, isolon) are attached directly to the wall. Laying tile insulation (foam plastic, penoplex or mineral wool) can be done in two ways:

- on the wall using glue or dowels - this method allows you to save space on small balconies and avoid additional load on the base;

- on a wooden (metal) sheathing; the material is cut to the size of the sheathing cells (usually about 60*60cm), laid between the beams; It is convenient to fix finishing materials (lining, plasterboard or panels) onto the sheathing.

We fill the cracks with polyurethane foam

Is it legal to insulate a balcony?

Following the letter of the law, only the loggia can be insulated; the balcony room cannot be insulated. The reason is the structural difference between these rooms. Thus, the loggia rests on the walls, and accordingly, it can withstand almost the same load as living rooms. The balcony is a platform with a fence located behind the facade. The load on it should be much less.

The structures are insulated from the inside with mandatory glazing. The heat-saving window system has significant weight, which the balcony slab simply cannot withstand. Therefore, permission must be obtained before installing windows. Some new buildings already have glazing. In this case, permission will be required only if you plan to change the type of windows or their appearance. For buildings of historical value, obtaining permission for glazing is mandatory.

The law prohibits the installation of double- or triple-glazed windows, electrical wiring, relocation of heating radiators, or demolition of the partition between the room and the balcony area without an examination and obtaining permits. All these actions are dangerous due to overloading the balcony slab, and redevelopment and relocation of the battery will provoke disruptions in the operation of the heating system of the entire building.

Instagram mbm.studio

Instagram antei.by