The choice of finishing materials for a cold balcony depends on the presence of glazing. On open and closed balconies, only the temperature conditions remain similar. Of course, in a sheathed and glazed balcony the air temperature will be 3-5°C higher than in an open one, but in severe frosts this does not matter much. But the impact of precipitation and humidity conditions matter a lot.

Introduction

When the balcony is a continuation of the living room, its interior should be fully compatible with its design. If redevelopment is not planned, you can create custom decor, add a touch of originality and unusual touches. For example, stick tiles that imitate natural stone, cover the walls with wood, decorate them with ornate carvings, hang eye-catching roller blinds.

The decor and colors of the cladding play a big role in the interior

Finishing is one of the most important stages of repairing a loggia, on which its final appearance depends.

When purchasing building materials, it is necessary to take into account the microclimate of the room, even if it is insulated. Raw materials must be moisture-resistant, without reactions to increases or decreases in temperature, and fireproof.

The appearance of the skin also matters. To make the walls look well-groomed, you need to choose high-quality materials approved for balcony decoration.

We make liquid wallpaper with our own hands: step-by-step instructions, tips, application techniques, as well as useful ones (85 Photos & Videos)

Which balcony to choose?

Before you start decorating your balcony or loggia, you should think about the purpose for which you are going to carry out the repairs. The materials used for finishing, the need for glazing, and even the installation of additional heating radiators will largely depend on the functional purpose of this room.

Open balcony

If the balcony is not glazed, and you are quite happy with this, you can organize a relaxation area within it to enjoy fresh air and the gentle sun. Naturally, you cannot place furniture on such a balcony. Although garden furniture will do just fine. And you won’t be able to store things on the open balcony, because they will quickly become unusable. As an option, you can install a canopy over the balcony to protect it from rain, as well as walls that also protect it from the wind.

Obviously, an open balcony will need finishing with special materials that can withstand rain, fog, snow, scorching sun and temperature changes. On the other hand, the work required to decorate such a location will be much less than if you decide to glaze and insulate the balcony.

Balcony as part of the apartment space

Most often, ordinary people want to connect a balcony with a living space, thereby expanding the space of an apartment or house. For this, many people demolish the walls separating the loggia from the main room. But there is a catch here, because the balcony is an unheated room, which means you will have to think carefully about how to ensure an optimal microclimate there. Glazing alone will clearly not be enough here, and in winter, in severe frosts, this will become obvious to everyone.

Therefore, when combining a balcony with a living area, it is important to think about installing a “warm floor” system and carry out high-quality insulation of the side walls, as well as parts of the wall under the windows. A huge advantage will be the transfer of heating radiators to the walls of the balcony. In this case, you won’t have to worry about the microclimate!

Balcony as a separate room

This is another option for giving the balcony the status of a useful area. Some people deliberately do not combine the loggia and the living area in order to organize a sports corner, a small but cozy personal office or a comfortable relaxation area in this location.

In this case, it is also quite obvious that the room must be dry and warm, which means that it is impossible to do without wall insulation and floor heating.

Finish options

Let's consider the most common options for interior decoration on balconies - cladding with siding, PVC wall panels and lining.

Siding

Siding finishing is often used for facades and external cladding of balconies, but this material can also be used from the inside, especially if glazing is not planned. Advantages of finishing with siding:

- has good heat and sound insulation qualities;

- does not require additional coating, has an attractive appearance;

- Manufacturers offer various siding options, the range of colors and textures is wide enough to bring your intended design to life;

- Siding finishing is quite easy to do yourself.

The disadvantage of this option is the relatively low mechanical stability of the material; if the surface covered with siding is struck by a heavy object, cracks may appear. It is impossible to restore the panel; it can only be replaced. The siding is attached to the pre-assembled sheathing. Siding cladding is carried out as follows:

- in the corners of the room, special corner strips are installed under which the panels will be placed;

- a starting bar is installed at the very bottom;

- start covering with siding from below, inserting the shelf of the first panel into the groove of the starting profile;

- The strip is secured using self-tapping screws that are screwed into the mounting holes.

When covering with siding, you can use panels of different colors if required by the design of the room. The panels themselves can be installed not only horizontally, but also at an angle of 45 degrees.

Plastic panels

If you need to make budget repairs, then one of the best options is interior decoration of the balcony with plastic panels. PVC plastic wall panels can only be installed on closed and insulated balconies, since this material is not resistant to frost.

PVC wall panels are produced in a wide range of colors. However, if the balcony is located on the sunny side, it is better to choose a light-colored option, since bright PVC panels fade quickly.

Installing PVC panels is quite simple, step-by-step instructions for installing them:

- the frame is assembled;

- a starting profile is installed in the corner (for vertical panels) or next to the floor (for horizontal panels);

- the shelf of the first PVC panel is inserted into the groove of the starting profile; after aligning the panel, it is attached to the sheathing using a stapler or self-tapping screws;

- when installing the second and subsequent panels, the shelf is inserted into the groove of the already installed one;

- Before installing the outermost panel on the wall, a finishing profile is installed into which the panel cut to width is inserted.

Wooden lining

The classic design of the loggia is wall decoration with wooden clapboard. To get a high-quality coating, it is recommended to choose premium class or class A lining; using cheaper options leads to a loss in the quality of the coating.

The technology of clapboard cladding is in many ways similar to the installation of PVC panels, the only difference is the absence of profiles that begin and end the cladding. The lining boards are fastened with self-tapping screws or nails.

After completing the cladding work, the wooden planks must be coated with a protective compound. Most often, alkyd or acrylic varnishes are used. To give the wood the desired tone, you can use stain.

Pros and cons of cold glazing of balconies and loggias

The main advantage of a glass partition is good throughput. If you wash the glass regularly, the illumination of the room will remain virtually unchanged.

Cold glazing will be an ideal option if you are not ready to spend too much money on arranging a balcony

Sometimes cold glazing of balconies is the only possible option. In old houses, balcony slabs are quite dilapidated and are not designed for heavy loads. They will not withstand a heavy frame, glass blocks, insulating and decorative cladding even when reinforced with concrete.

A lightweight window structure can be installed even on the balcony of an old building

Another plus is that it saves space; frames and frames are assembled from a narrow profile that does not eat up much space. Thin glass reliably protects from precipitation, wind, dust and dirt. For better sound insulation, lightweight double-glazed windows are used. In terms of variability, cold and warm glazing are practically the same.

A cold balcony is the optimal solution for those who do not plan to use it for living or relaxing during the cold season

The downside of cold glazing is considered to be good thermal conductivity; it is impossible to install an anti-cat or mosquito net on simple, economical structures. You will have to install an additional anti-mosquito frame in the doorway. In terms of sound insulation, cold structures are also inferior to insulated ones.

The mosquito net for sliding windows is installed on a special guide and has a pile that prevents dust from penetrating through technological gaps

Decoration Materials

Materials for finishing balconies and loggias can be divided into rough and decorative:

Rough

Here you can apply the following options:

- Plywood. This is a very easy-to-use material that easily allows you to create a smooth, even base. It is noteworthy that many different brands create very flexible pricing policies. For example, the FK class is quite suitable for interior work, and the moisture-resistant FSF is suitable for more aggressive outdoor conditions. Weight, depending on the type of wood, varies from 0.5 kg to 1 kg per m2;

Wood-laminated board for rough work

- Plaster. It requires the use of water for mixing, so it would be difficult to call plastering a pure type of work. A quick-drying gypsum composition weighs up to 1.5 kg per m3 in a dried state, cement - 1.8 kg per m3, but is cheaper;

Plastering a balcony wall

- Drywall. This material is very easy to process, but is suitable exclusively for interior work and has the following technical characteristics:

- Density of moisture-resistant class – 1400 kg/m3; conventional – 800 kg/m3;

- Moisture absorption – up to 10%;

- Temperature resistance – from -15 to +40 degrees Celsius;

- Frost resistance – 25.

Sheathing with plasterboard sheets

Decorative

On a base that has been leveled and reinforced with rough materials, you can safely mount finishing decorative samples:

- Plastic panels. These are beautiful, moisture-resistant products with a large assortment of visually different models. That is, you can easily choose the desired design. Density of plastic lining – 150 g/m2; seamless polyvinyl chloride sections – 1.5 kg/m2;

Internal lining with plastic panels

- Tree. The main trump cards are environmental cleanliness and an original natural pattern. But such finishing will have a rather serious load:

- Larch density – 700 kg/m3;

- Density of coniferous species – 580 kg/m3;

- Density of birch, beech, walnut, ash, hornbeam, elm - 750 kg/m3;

- Density of poplar, alder, aspen – 550 kg/m3;

Wooden paneling of the loggia

- Porcelain tiles. Not a cheap option, installation work will be especially expensive, but in the end you will get a practical, waterproof and durable finish.

Tiling the balcony

Finishing the balcony with liquid wallpaper

Quite rarely they use such a finishing material as liquid wallpaper for the balcony. The procedure for applying this composition is quite simple.

Decorating the walls of the loggia with liquid wallpaper

Step-by-step instructions for finishing a balcony with your own hands include the following steps:

At the preliminary stage, the walls are leveled with putty or plaster to reduce the consumption of decorative finishing. Although wallpaper for the balcony itself is a leveling material, it is better to get by with cheaper compounds for rough work.

All metal products present in the coating are treated with an anti-corrosion substance and painted over. After this, you need to apply 3-4 layers of waterproofing primer at intervals of 4 hours. Next, start preparing the mixture. This must be done in accordance with the instructions provided by the manufacturer on the packaging, otherwise the result may be disappointing. You need to prepare an amount that is enough to finish the entire wall at once. Stir until all lumps and compactions disappear.

It is necessary to lay out plastic film on the floor inside the balcony, and then immerse the prepared composition on it. It is wrapped and left in this form for 3 hours. Then the wallpaper is mixed again and application begins. The finished mass is scooped onto a special metal spatula or wide spatula, then transferred to the surface and stretched in a thin layer, but so that there are no gaps left

It is important to always press with the same force. After application, it is recommended to roll the wall with a cylindrical trowel or use a bottle for this purpose.

Another idea for finishing a balcony: decorate all but one wall with plaster or clapboard, and treat the last one with liquid wallpaper to create an accent.

How to avoid condensation

This must be taken care of before finishing work begins. This will save effort and money on repairs. Following these rules will help solve the problem:

The boundary of warm and cold air where condensation occurs should be shifted from the inside of the balcony to the outside. To do this, high-quality insulation is carried out on the balcony walls in contact with the street, and, if necessary, on the floor and ceiling. Double-glazed windows are used in the windows. For areas with cold winters, it is recommended to make double-glazed windows. The most effective way to increase the temperature on the balcony is to place a heating device near the outer wall.

The thermal insulation qualities of the insulating material deteriorate significantly when it gets wet, so special attention should be paid to its waterproofing. To protect against humid air, you need to make a layer of vapor barrier. Balcony ventilation plays an important role

Good air circulation avoids rising humidity levels.

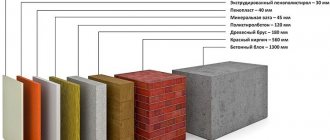

Balcony insulation sequence

To prevent condensation from appearing on the balcony, the installation of insulation materials must be done in the correct sequence:

- The first step should be glazing the balcony, which will protect it from precipitation. High-quality double-glazed plastic windows will be a good barrier to cold and noise. Only after the windows are installed can you proceed to the next stage of insulation.

- All surfaces must be carefully examined for cracks, chips, and rust on metal elements. Damage is repaired and surfaces are treated with antiseptic and anti-corrosion agents.

- To protect against moisture, the surfaces are covered with a waterproofing layer. You can use film materials, but for small balconies the optimal solution is a liquid composition, which is applied with a brush or roller.

- A thermal insulation layer is laid. This can be done in various ways depending on the material chosen. Roll materials are simply attached to surfaces. Polystyrene foam or mineral wool require the construction of sheathing.

- To protect the insulating layer from moisture in the air, a layer of vapor barrier is laid. Such materials remove moisture from the material without letting it pass in the opposite direction.

- The final stage after insulation will be finishing. It can be made using any available materials. If the balcony is planned to be used as a living area, it is necessary to provide for heating appliances.

The cause of condensation on the balcony is usually improper insulation. If you carry out the work in accordance with technological requirements and lay down all the necessary layers, you can avoid getting wet and subsequent damage to the finishing materials.

The most economical option is whitewashing

Light whitewash in pastel colors

Whitewashing is one of the traditional methods of decorating walls on a balcony. In addition to the obvious financial benefits, it has many other advantages:

- Simplicity and speed of execution

- Availability of coating in any building materials store

- Lime dries quickly and does not emit unpleasant odors.

- For variety, you can add colors to the composition so that the walls become colored

- Any person without special repair skills can whitewash surfaces.

In order for the walls to look neat and elegant, they must first be prepared. The leveled surfaces are covered with a primer and wait until it dries. Whitewash is applied in two or three layers.

Among the shortcomings is that the coating looks boring and old-fashioned, without any zest. The limestone layer also accepts dust well, so the whitewash will have to be renewed every 6-8 months.

Wall insulation

We already have the waterproofing ready, so we can immediately install the sheathing made of wooden blocks. The distance between them should be equal to the width of the heat insulation, and the height of the bars should be equal to the width of the insulation. For walls, polystyrene foam boards, polystyrene foam or high-quality mineral wool are suitable. As always, we fill the joints between the insulation with foam. A vapor barrier film must be secured over the insulation. As a rule, the wall between the balcony and the room is insulated in one layer, and the remaining walls in two layers, or the thickest heat insulator is used.

Specifics of popular materials used for finishing.

See the plastic finishing of the balcony in 3D.

Plastic

Having decided to decorate the balcony with plastic panels, special attention should be paid to the design of the window. It should be in harmony with the color scheme of the selected PVC panels

In this case, it is not at all necessary to finish the inside of the balcony with a standard white color to match the white color of the window. You can choose a material that imitates the structure and color: wood, stone, etc. Due to the fact that plastic has good resistance to significant temperature changes, a balcony decorated from the inside with PVC panels will retain its original appearance for quite a long time - more than ten years.

Look at the wood finishing of the balcony in 3D.

Tree. Of course, artificial material (PVC) has a lot of positive qualities, but wood can boast of its own unique characteristics. Finishing a balcony with wood (in most cases, lining is used for these purposes) is good because it improves the level of sound insulation of the room and makes its interior safe in terms of countering possible fire.

The fire safety of this natural material is achieved through the use of special impregnating compounds applied to its surface either at the manufacturing stage or directly during finishing work. Another strong argument in favor of finishing a balcony with clapboard is the fact that wood is an environmentally friendly material, which means it does not pose a danger to human health.

See 3D finishing of the balcony with plasterboard.

A special feature of finishing the balcony from the inside with clapboard is the specific color of the wood, which changes over time. After completion of the work, over the course of a year or two, the color of the surface of the building material used will emit a pleasant smell of resin and fill the balcony with forest freshness. Over time, the color of the installed lining will begin to change from the original light with a golden tint towards a darker one.

Remember that finishing the balcony from the inside using both lining and plastic panels is impossible without observing an important condition during installation: the use of sheathing. The lathing acts as a structure onto which the above-mentioned facing material is fixed

Decorative plaster

Finishing using this material is quite common in the repair of balconies.

Surfaces covered with decorative plaster ideally complement the Scandinavian style in the interior.

The walls of the loggia are covered with decorative plaster.

Small living room on the balcony. Plaster was used for cladding.

Advantages of decorative plaster:

- This finish will last a long time (does not rot during use), is resistant to chemicals, mechanical damage, high humidity and sudden changes in ambient temperature;

- The surface is not destroyed;

- Due to its special structure, plaster is used to create various reliefs, patterns on the surface and texture of natural materials;

- The material is absolutely harmless and fire-resistant, has a high degree of vapor permeability.

- Allows you to create a comfortable atmosphere, provides good sound and heat insulation;

- The base for application can be any: brick, concrete, gas and foam blocks, plasterboard;

- The material can be applied in such a way that the surface becomes as smooth as possible or done sloppily, otherwise the plaster will look aged. It all depends on your preferences.

Balcony terrace. The special atmosphere is set by the texture of the plaster and the careless application of the material.

Non-standard options

If the balcony is combined with a kitchen, then the best solution would be to move the dining area to the “street”, where you can have breakfast at dawn or dinner by candlelight in the dark of the night. However, for this solution it will be necessary to properly insulate the balcony so that this possibility is present in the winter season.

Another such solution could be an individual workspace - an office, where your mind will always be fresh to work. The whole point, again, is in the interior design, on which 100% of success depends.

In any case, no matter what you choose, finding a place for a table and a few chairs on the balcony is always possible, and the issue of decor will be resolved on its own as soon as you attach importance to the future space.

Cold glazing installation options

Two types of window structures are installed on a cold balcony. Sliding ones move along guides, hinged ones open outward. For better sealing and less ventilation, hinged and sliding modules are alternated with blind inserts. In the version of panoramic frameless glazing, the blocks are mounted on a base. The results are aesthetic designs that increase the level of illumination in the room.

Hinged sashes require free space in front of the window to open.

Sliding doors slide along the frame, so they are more practical in terms of saving space

If desired, the systems can be combined, for example, make the main glazing sliding, and cover the sides with hinged windows

Double and single glazing is possible; often cold and warm options differ only in the absence of insulation.

In winter, sliding sashes freeze to the guides and opening becomes impossible.

To prevent snow from getting inside the balcony in winter, when choosing sliding glazing you should pay attention to additional sealing

Wallpapers and photo wallpapers

Wallpaper on the loggia looks nice and neat

This is an option for an insulated balcony, inside which room temperature is constantly maintained. The wallpaper should be in harmony with the walls in the room itself. You can paste the same copies so that the loggia looks like an organic continuation of the room.

Decorative photo wallpapers will help you decorate a small space in an original way. They can be used to cover part of a wall or ceiling. For the wallpaper to stick well, the surface must be smooth and dry.

The disadvantages of finishing are low tolerance to changes in humidity and fading of the design in the sun. The latter becomes especially noticeable when the same wallpaper is pasted inside the room.

DIY Christmas tree decorations: beautiful, original, with soul! Master classes and step-by-step instructions | (75+ Photo Ideas & Videos)

Photos of examples of decorating balconies and loggias with cold glazing

Balcony structures with extensions along the base or railings are practical and are used for storing winter supplies and sports equipment. Cold loggias and balconies have built-in wardrobes and perimeter storage systems. A summer loggia with frameless glazing looks laconic and protects from wind and precipitation.

The photo shows an example of panoramic glazing of a loft-style balcony

Design option for a cold balcony in a modern style

A cozy place to relax on a loggia decorated in Provence style

Summer room on the balcony in country style

Relaxation room on the balcony in neoclassical style

Do-it-yourself interior lining of the balcony

Among the most available materials that are used for cladding the inside of balconies are the following:

Plastic PVC panels. This is definitely an affordable option that you can implement with your own hands. This is a rather labor-intensive task, but quite understandable for those who have never encountered this. Extreme accuracy, attentiveness and patience are important here. The reward for such complex work will be the money saved, which you did not have to pay to professional craftsmen for the work.

Before moving on to lining the balcony from the inside with this material, it is important to carry out insulation and sealing work.

Wooden-aluminum windows

The best way to reliably insulate a balcony and adapt it for comfortable use in winter is to install wooden-aluminum windows. They are divided into two types:

- aluminum profile with wood trim placed on the inside of the window;

- wooden frames decorated with aluminum overlays on the street side.

The first option is absolutely not suitable for apartments, since its thermal insulation properties are the same as those of an aluminum window. As for the second option, wooden frames with several layers of double-glazed windows and aluminum trim on the outside not only give the window an unusual style, but also protect the wood from the harmful effects of precipitation.

The profile width of such windows will differ from the cold version with classic glazing. At the same time, you will have the opportunity to perfectly match the color of the powder enamel that is used to paint the outside of aluminum windows. In this case, your balcony will be practically no different in appearance from its “neighbors” in the house.

How to cover a balcony outside

Exterior finishing of a balcony places slightly different requirements on materials. In addition, it must be strong and reliable, wear-resistant. To understand the best way to cover the outside of a balcony, let’s look at the main options.

Vinyl siding

It is available in two versions - traditional in the form of long boards with a tongue and groove fastening, which is often used to sheathe houses, and facade in the form of slabs with uneven edges, imitating stone or masonry. Both materials are mounted on the sheathing using self-tapping screws, but the frame is assembled slightly differently, adapting to the geometry of each material.

You can cover the balcony with siding. Regular or base (right)

Metal siding or corrugated sheet

Although vinyl is considered durable among plastics, it can’t compete with metal.

If for high-lying balconies how durable the material is is not critical, then for lower floors it is very important. That’s why downstairs balconies are often sheathed on the outside with metal siding or corrugated sheets

Whether it is better to cover a balcony with siding or corrugated sheets is a matter of personal preference. Both have a high degree of reliability. Siding is made of aluminum or galvanized iron, on the front surface of which a polymer film is applied. Profiled sheet is a shaped sheet of roofing iron coated with polymer or paint. The service life is stated to be from 15 to 25 years.

You can inexpensively cover the outside of a balcony with metal siding or corrugated sheetsThe main difference is the installation method. A part of the desired shape is cut out of the corrugated sheet and a large piece is attached to the sheathing with special self-tapping screws with a painted head. Siding is also assembled like lining: there is a tenon on one side and a groove on the other. Along the edge of the strip there is perforation for fasteners. Self-tapping screws are screwed into it (in the middle of the hole, slightly short of the cap - leaving the ability to move with temperature changes in the materials).

How to decorate a house with siding is written in the article “How to cover a house with siding with your own hands.” If you choose this material, you will need to know the features and installation rules...

Wood paneling

Houses are built from wood, so why not cover the outside of the balcony with it? Not a bad option, but the wood requires maintenance

Therefore, special attention should be paid to the impregnation of the material used. Take antiseptic and protective compounds for outdoor work

The treatment is carried out before installation begins - then it will be problematic. When finishing, do not forget to process the ends of the boards cut to size. Otherwise, the entire installation is the same.

You can sheathe the outside of the balcony with wood - clapboard, for example

Just keep in mind that without proper care, attractive cladding will turn into something unattractive. A fragment of a tree left without care can be seen in the photo below on the right.

Selection of materials for cold glazing

Profiles for cold balcony glazing are made of polymer-coated steel or aluminum alloys. Wood, plastic, and metal are used in the manufacture of frames.

Classic wooden windows are not very popular these days. They are close in cost to plastic ones, but they rot quickly and require constant maintenance.

Plastic windows are more suitable for warm glazing of a balcony

It is possible to install small-chamber double-glazed windows made of metal-plastic, if the condition of the slab allows. Light PVC profiles and aluminum corners are most often used. Combined options are possible: metal contour, polymer seal.

If the slab collapses, a new screed is made on the concrete. It is imperative to check the condition of the railing structure; they also often require replacement.

Aluminum glazing

Aluminum is a good alternative to wood and steel. When using a lightweight, durable profile, the load on the balcony slab is reduced. Aluminum glazing is relevant in “Khrushchev” buildings and old “Brezhnevka” buildings, where the condition of reinforced concrete is cause for concern.

Aluminum windows are lightweight and able to withstand temperature changes

Aluminum has a number of advantages:

- looks decorative;

- without additional coating it is not subject to corrosion;

- paints well with polymer compounds;

- more reliable than plastic analogues, more economical than wooden ones.

Aluminum profile fits into any facade design; it is a practical, durable material.

A loggia with aluminum windows looks modern and attractive, both from the inside and outside

On the south side, the glass is covered with reflective film; it will become much cooler on the loggia or balcony on hot days.

Materials for finishing the balcony inside

A closer acquaintance with each of the building materials for interior decoration will make future choices easier.

The appearance of the listed products has much in common; variations are natural or synthetic materials.

The use of different types of linings will make finishing the balcony simple, and the appearance will please the eye for many years.

Photo gallery:

A more detailed examination of the main materials used for interior decoration of the loggia:

Wooden lining

Natural building material made from wood of various species (oak, ash, alder, pine, birch).

The appearance and sanitary characteristics of natural wood make lining a design and operational leader among materials for interior decoration of balconies.

Photo of wood:

Among the undoubted advantages of wooden lining are:

- aesthetically high class - the balcony will be filled with comfort, the interior looks expensive and high quality;

- environmental benefits - natural building materials have hypoallergenic properties;

- durability - wood will not lose its external properties for many years.

Flaws:

- high cost - wood is a very expensive material;

- certain nuances in installation - the lining can only be mounted on absolutely flat walls or additional slats;

- The finished wooden surface needs final treatment with varnish or paint.

Plastic lining

Plastic panels are the simplest material for interior decoration of a balcony. This product has more advantages than disadvantages.

The substance from which the plastic lining is made - polyvinyl chloride - is a synthetic product, but experts say that it is a hypoallergenic and environmentally friendly product

Main advantages:

- low cost - finishing even a large balcony will not cost you a pretty penny;

- ease of installation - plastic panels of the lining type are installed according to the principle of wooden relatives, but without the requirement of necessarily smooth walls;

- a wide variety of color and stylistic solutions - synthetic material allows you to experiment with colors and textures;

- resistance to external factors and moisture allows plastic lining to serve for a long time.

Drywall

This material itself looks like a wall.

Pressed gypsum, processed with thick paper, is a convenient material for interior decoration of a loggia.

A surface suitable for further finishing will allow you not to abandon design solutions due to the curvature of the walls.

The advantages of drywall are:

- affordable price - the sheet will cost less than the amount of plaster required;

- environmental friendliness - plasterboard contains a maximum of natural products;

- ease of installation - the sheets are fastened to a pre-installed metal frame;

- space for ideas about further finishing;

- high sound insulation properties.

MDF lining

The material is the “golden mean” between expensive wooden lining and uncomfortable plastic.

The product is obtained by pressing wood chips, and the outside is treated with synthetic films.

The visual characteristics of MDF lining are very high; the wide variety of types of wood, which the material is stylized into, will not hold you back in interior solutions.

Advantages of the material:

- adequate cost;

- MDF service life is from 25 years;

- good sound insulation;

- visual appeal, resemblance to natural wood;

- does not require additional processing.

Minuses:

- the need for certain skill during installation;

- lack of moisture-resistant properties - if the loggia is not protected from external factors or there is an accumulation of condensation on the walls, the MDF will deform and lose its appearance.

We insulate the floor

First, it is necessary to lay a waterproofing layer of polyethylene or penofol on the floor so that dampness does not bother us. Craftsmen advise laying penofol with the reflective side up. At the same time, we can attach the waterproofing material to the walls. It is better to glue the joints between the sheets of waterproofing with foil tape.

Another good waterproofing agent is bitumen-based mastic. It dries for about a day; surfaces treated with it should not be touched.

Then we install logs - wooden beams or metal beams that serve as the basis for floors, platforms and other surfaces. Wooden logs are suitable for floor insulation. You should choose logs made from high-quality materials: the moisture content in the wood should not exceed 12%. Also, in order to prevent fungus and rotting, the beams are treated with an antiseptic or primer. The distance between the logs should be equal to the width of the insulation, and builders recommend making the height of the beams 10-15 centimeters - this is necessary to reliably protect the floor from frost. To seal the holes between the joists and the wall, and also to secure the beams in the desired position, use polyurethane foam. Don't worry about being careful: excess foam can be cut off with a knife after it dries. Next, a thermal insulation layer, slab or fiber, is laid. Make sure that there are no gaps between the heat insulator and the joists: “cold bridges” will negate all your insulation efforts. If you are laying insulation in several layers, be sure to move each new layer so that the seams between the insulation sheets are not in the same place. To protect the floor from condensation, you will need a layer of vapor barrier. Using self-tapping screws, attach a “sub-floor” made of boards, sheets of plywood, fiberboard or chipboard to the joists. This is the last step before finishing a floor such as laminate, linoleum or carpet.