Double-glazed window formula: decoding

The designation is deciphered traditionally - from left to right. Numbers, letters and numbers describe the elements of a double-glazed window sequentially, starting with the outer sheet of glass. The first symbol displays the thickness of the glass in millimeters; sometimes a designation of the brand of glass is added. Then follows the width of the inner frame, then, if available, the thickness of the middle glass is indicated, again the graph paper of the width of the second frame, and finally the thickness of the third glass.

Here is an example of a two-chamber design: 4 10 4 10 4:

- Here the numbers 4 indicate the thickness of the glass. There are three of them: external, intermediate and internal.

- And the number 10, repeated twice, conveys the width of the frames.

This scheme is also called a 48 mm double-glazed window, and this is the usual window standard in Russia and the CIS countries.

And this is the most popular single-chamber concept: 4 16 4:

- As you might guess, in the middle there is a number expressing the width of the frame.

- And on both sides there are indicators of the thickness of the glass.

The given formulas are extremely simplified. In practice, more detailed markings are found. Therefore, it is important to consider the issue in detail.

Window glass formula

The designation of glass thickness with one number is no more common than an expanded one, accompanied by additional symbols. The most common addition in this case is in the form of a glass brand. In the formula 4M1-16-4M1, the material describes the M1 fragment. This means that the glass unit uses standard high-quality colorless sheet glass.

There are other types of notation. So K-glass, otherwise, the common K4 glass, which is energy-saving and has a coating of indium and tin, will be labeled as 4K. Here the number indicates the thickness in millimeters, and the letter K conveys the technological component.

To minimize the risk of injury to people when a double-glazed window is damaged, sheets of tempered glass are used, which, when broken, forms fragments with blunt edges. Such a component in the package is designated ESG. Glass that has been cooled for a long time, has been hardened in a salt solution, is impact resistant, but produces fragments with sharp edges, and is marked TVG. Another fracture-resistant and thermally resistant variety is marked Z or Zak.

Tempered glass is widely used for stained glass. But even more often, multilayer triplex (designated 3.3.1 or 4.4.1 according to the thickness of the layers of glass and film), reinforced (symbol A) or even armored (letter B) glass is used. These are heavy materials that require a high-strength profile for installation.

There are also tinted arrays, variations with soundproofing properties, multifunctional glasses that combine energy-saving properties with sun protection, and many other varieties and varieties.

Moreover, new types of glass with improved technical characteristics are appearing. It is impossible to describe the results of a huge industry in a short article, but the general logic should be clear. Next to the number indicating the thickness of the glass, its additional characteristics may be indicated by markings. You can find out the exact information by searching on the Internet.

The most common types of glass and their symbols

Frames and inter-chamber space

Spacer frames are a traditional glass separator. A part made only of aluminum is not accompanied by any additional markings. Only its size is written in millimeters.

Distance frames

When thermal inserts are included in the frame design, the letters TP (thermal break) or TD (thermal distance) are added to the numerical designation of the width. Some large companies offer their own version of the technology. Then, instead of the abbreviation, the name of the manufacturer is indicated.

The internal space between the glass is occupied by gas. If this is ordinary dry air, no additional markings are applied.

But in the case of filling the chamber with inert gas, the marking suggests the following designations:

- Xe – xenon;

- Ar or A – argon;

- Kr – krypton;

- Sf – sulfur hexafluoride.

Now you can try to read the glass unit formulas that are as close as possible to practice.

Disadvantages and advantages of single devices

Speaking about the advantages, you should pay attention to the low weight compared to two-chamber products. Accordingly, the price of single-chamber units is lower.

Among the disadvantages, the main one is that single bags retain heat less well.

In the standard version, a “4-16-4” double-glazed window retains heat 20–28% worse than a two-chamber “4–14–4–12–4” formula. Accordingly, its noise insulation properties are 20% lower.

Based on this, the use of single-chamber bags is advisable in places where thermal and noise protection factors are not critical. For example, glazing of windows facing a glazed balcony or loggia.

The main thing is that when choosing packages, you need to focus not on the price of the window, but on its consumer properties. The price of a two-chamber device differs slightly from the price of a single-chamber device, and the main characteristics are higher.

Marking of double-glazed windows

The characteristics of the assembly components must be indicated on the sticker. These are the conditions of GOST. Companies often duplicate data by embossing or laser engraving it on visible areas of the frame inside the glass unit.

Here's a random example:

SPD (32 mf) 4M1-10TR-4M1-10Ar-4K

Deciphering in the light of the information presented no longer seems difficult.

- SPD – Glass Package Double Chamber

- 32 mf – total width 32 mm (can be written 36, 24, 16 depending on the thickness of the components), with multifunctional glass;

- 4M1 – outer glass of grade M1 with a thickness of 34 mm;

- 10TP – the first spacer frame, made of aluminum, equipped with thermal break inlays, 10 mm wide;

- the following symbols indicate an intermediate glass identical to the first;

- 10Ar – second spacer frame, 10 mm wide, forming a chamber with argon;

- 4MF is an energy-saving glass with solar control properties that has a mirror effect for external radiation.

Characteristics of single-chamber and double-glazed windows, with regular and I-glass, thickness - 24 mm, 32 mm, 40 mm

Labeling of energy-saving double-glazed windows

Filling the cavity between the glasses in the bag with inert gas only makes sense when combined with energy-saving glass. Only then does the effect of heat saving become noticeable. Thus, the argon layer itself provides an advantage relative to dry air of no more than 5 percent. Combined use with glass coated with tin-indium almost doubles the thermal insulation properties.

The previous example shows a double-glazed window in which these conditions are met. So the second chamber is filled with argon, and the inner glass is energy-saving. The ability to read labels will allow you to avoid purchasing products made unprofessionally, without following technological principles.

Thermal insulation characteristics of double-glazed windows GOST-24866-99.

The thermal insulation properties of double-glazed windows are characterized by the reduced heat transfer resistance Ropre.

The higher it is, the warmer the double-glazed window.

The table shows the value of the reduced heat transfer resistance Ropr for the most common double-glazed window designs.

| No. | Number of cameras | Glazing options | Given resistance heat transfer Rdef. |

| 1 | 1 | 0,28 | |

| 2 | 1 | 0,29 | |

| 3 | 1 | 0,30 | |

| 4 | 1 | 0,32 | |

| 5 | 1 | 0,30 | |

| 6 | 1 | 0,31 | |

| 7 | 1 | 0,32 | |

| 8 | 1 | 0,34 | |

| 9 | 1 | 0,47 | |

| 10 | 1 | 0,49 | |

| 11 | 1 | 0,51 | |

| 12 | 1 | 0,53 | |

| 13 | 1 | 0,53 | |

| 14 | 1 | 0,55 | |

| 15 | 1 | 0,57 | |

| 16 | 1 | 0,59 | |

| 17 | 1 | 0,51 | |

| 18 | 1 | 0,53 | |

| 19 | 1 | 0,56 | |

| 20 | 1 | 0,59 | |

| 21 | 1 | 0,57 | |

| 22 | 1 | 0,6 | |

| 23 | 1 | 0,63 | |

| 24 | 1 | 0,66 | |

| 25 | 2 | 0,42 | |

| 26 | 2 | 0,45 | |

| 27 | 2 | 0,47 | |

| 28 | 2 | 0,49 | |

| 29 | 2 | 0,52 | |

| 30 | 2 | 0,44 | |

| 31 | 2 | 0,47 | |

| 32 | 2 | 0,49 | |

| 33 | 2 | 0,52 | |

| 34 | 2 | 0,55 | |

| 35 | 2 | 0,53 | |

| 36 | 2 | 0,55 | |

| 37 | 2 | 0,58 | |

| 38 | 2 | 0,61 | |

| 39 | 2 | 0,65 | |

| 40 | 2 | 0,60 | |

| 41 | 2 | 0,62 | |

| 42 | 2 | 0,65 | |

| 43 | 2 | 0,68 | |

| 44 | 2 | 0,72 | |

| 45 | 2 | 0,59 | |

| 46 | 2 | 0,61 | |

| 47 | 2 | 0,64 | |

| 48 | 2 | 0,68 | |

| 49 | 2 | 0,72 | |

| 50 | 2 | 0,64 | |

| 51 | 2 | 0,67 | |

| 52 | 2 | 0,71 | |

| 53 | 2 | 0,75 | |

| 54 | 2 | 0,80 |

Differences affecting the quality of double-glazed windows

To see other differences, you need to remove the glazing bead (at least one). On handmade double-glazed windows, where the spacer frame is glued with tape (if butyl tape was not used), the frame is visible (Fig. B-D). On factory double-glazed windows, the gluing area is black (Fig. A-D).

This does not apply to fire-resistant double-glazed windows. Their distance frame has a different design.

Features of PVC window markings

The above encodings are borrowed from European manufacturers. Russian regulations have introduced their own abbreviation - based on the first letter of a significant characteristic.

- impact resistance - U;

- noise protection - Ш;

- sun protection - C;

- frost resistance - M;

- energy saving - E.

On the Internet, along with the markings of plastic windows, their significant characteristics are often searched for. The request can be formulated as follows: “single-chamber solar-protective glass unit” or “4-16-4E”. To avoid mistakes, call the managers of Window Technologies. We will advise you on the choice of profile and glass unit and recommend an option for your home.

Differences that do not affect the quality of the glass unit

On a makeshift double-glazed window, the spacer frame is assembled from cut aluminum profiles connected by plastic corners. Therefore, the angle looks more even (Fig. A-B). On factory-made double-glazed windows, usually the spacer frame is bent in the corners using automated equipment. As a result, the corner looks jammed (Fig. B-C).

The joint on the frame of a factory double-glazed window can be anywhere, and not in the corners, as on a makeshift one. The manufacturer's mark is usually applied to the frame of a factory-made double-glazed window. It is absent on hand-made double-glazed windows.

How to order?

- Call or leave a request on the website.

- In a few hours, meet the technician who will perform diagnostics and measurements.

- Production at the factory will take 1-7 days.

- The technician’s return visit and work will take up to 1 hour.

| We also use other special glasses during assembly. | |||

| AND | Low emission glass is low emission and energy saving glass, hard coated with silver oxide particles. (Pilkington Optitherm S1 and S3, ClimaGard N, CLGuN, Top-N, Top-N+, I-glass, i-glass) | ||

| M.F. | multifunctional glass with heat-saving properties and protection from solar radiation, as well as a mirror effect. (SunCool, SC70/40, GuSolar ClimaGard Solar, StopReyNeo, StRNeo) | ||

| 3.3.1 / 4.4.1 | triplex, created from several layers 3 (4) mm thick, using one-millimeter polyvinyl butyral film, provides impact resistance. (Stratobel Clear and Optilam Clear) | ||

| Zach (D) | glass tempering is used for high-security structures. If such glass breaks, it is impossible to cut yourself on the fragments | ||

| A (Active Clear) | have a self-cleaning option, which allows you to wash windows less frequently | ||

| Satin, SatMat | frosted glass, produced by chemical etching or sandblasting | ||

| Krizet | patterned glass, classified as decorative, contains a relief pattern on the surface | ||

| Planibel | colored tinted in mass, painted in a certain color | ||

| Stopsol Classic | reflective glass, has a mirror effect Stopsol Classic Bronze (where Bronze means the color of the glass) | ||

| Colored glass comes in a varied palette. The name of the color is written into the formula after the name of the glass itself. | |||

More details with prices

What does a plastic double-glazed window look like?

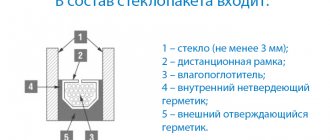

Actually, a blind PVC double-glazed window, not yet inserted into the profile, is a glass block usually in the shape of a parallelepiped, the width and height of which significantly exceed the thickness.

There are also double-glazed windows of more complex shapes. Visually, the third glass, located in the middle of the glass unit, is practically indistinguishable. Therefore, from a distance, a double-glazed window gives the impression of an all-glass monolith inserted into a window block.

Up close you can see that this design has glass at the front and back, spacers around the entire perimeter inside, and sealant along the entire contour outside (at the ends, top, bottom).

If the glass unit is already installed in the sash, the sealant and the main part of the spacer frame are hidden from view, only the glass and the side of the spacer (dividing frame) facing the inside of the glass unit are visible, which is visually perceived as a metal (less often polymer) strip with small perforations - diffusion holes.

Without a profile, in the edge zone of the glass unit, the sides of the spacer frame are visible, glued to the glass with a thin layer of sealant.

The easiest way to visually distinguish a double-glazed window from a single-chamber one is to turn off the overhead light in the evening and go to the window with a lighter or flashlight.

What is the difference between manual and conveyor-assembled double-glazed windows?

It will not be a discovery for anyone that many manufacturers of plastic windows order double-glazed windows to size from specialized companies.

It is difficult to answer unequivocally what is better, double-glazed windows made by yourself or factory-made. If the technology is followed, both can last for many years. But the weakest point of most handicraft double-glazed windows is the primary sealing.

That is, in order to save money, the glass is glued to the spacer frame not with butyl tape, but with double-sided transparent tape. Scotch tape is much cheaper, which makes the product cheaper. If you use a low-quality product (adhesive tape), yellow streaks may appear on such double-glazed windows over the years.

In fairness, it is worth noting that the use of adhesive tape does not always lead to similar results.