When ordering and installing plastic windows, you need to take into account many characteristics.

The weight of the structure is one of them. The product exerts a load on the walls of buildings, which should be taken into account at the earliest stages of placing an order.

This is especially important for old-type buildings in order to strengthen the opening in a timely manner. Also, such information is necessary when glazing balconies or loggias, where several products are installed.

Documents establishing requirements

More than 20 GOSTs have been installed on plastic windows, regulating the parameters, characteristics, properties of products, as well as manufacturing and installation processes.

To determine the permissible weight of the product, you will need to refer to the regulatory documents:

- GOST 30674-99. The interstate standard defines all parameters of window blocks made of PVC profiles.

- GOST R 56926. Describes all requirements for window and balcony structures.

- GOST 23166-99. The text is devoted to the general technical characteristics of window units.

- GOST 24866-99. This document contains technical specifications for double-glazed windows for construction purposes.

- GOST 30673-99. Text about technical conditions for polyvinyl chloride profiles.

Each of these documents contains the information necessary to calculate the correct weight of PVC windows.

Weight of plastic windows

Most consumers are well aware that plastic windows are quite heavy. It is generally accepted that this only matters for movers and installers. However, the weight of windows and their elements is important not only for them - this parameter is necessarily taken into account during the production process of structures, and such information is also important for those who plan to install and operate PVC windows.

What does it depend on?

The weight of a PVC window directly depends on the weight of the profile. But the weight of the profile depends on the parameters of many functional parts , for example, the thickness of the partitions and the design of the chambers; the lighter the window profile, the less the entire structure weighs.

The period of operation of the window depends on the strength of the profile. In addition, other design components also influence the mass.

Frame

This is the frame of the entire window on which the crossbars, sashes, and transoms are supported. In a plastic window, the frame is made of PVC. But plastic can be of different types. It differs in thickness and, accordingly, in weight. The weight of the window depends on the thickness of the frame wall. If it belongs to class A, the thickness is fixed within 3 mm. Class B has a limit of 2.7 mm, and Class C is not adjustable. Therefore, the weight of a plastic window is directly dependent on the thickness and strength of the profile.

Profile

The mass of the profile increases with each added partition and chamber - the air compartment.

But the thickness of the profile is more important. The thicker the product, the stronger and more reliable the window, and the heavier it becomes. Therefore, this indicator has to be documented, especially for residential premises and offices.

The reinforcing profile contains metal and further increases the weight of the structure. Most plastic products are produced with such a reinforcing element. It makes the product durable and prevents the sash from sagging. It is also good when the window is equipped with additional stiffening ribs. But they also add weight. Other factors that increase the mass of the profile :

- Thickness of outer walls . Therefore, in the technical specifications for building glazing there are requirements to limit the thickness of profile systems.

- Reinforcement type . For example, an L-shaped frame type is lighter than a closed one.

In addition to the reinforcement configuration, the profile material also influences the weight. The finished plastic profile can have a weight from 1.8 kg to 3 kg (depending on the chamber size).

Double-glazed window

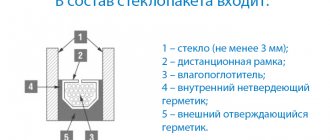

This element weighs much more than the profile. The package consists of :

- glass;

- primary and secondary sealant;

- distance frame;

- desiccant.

Important ! When calculating, only glass parameters should be taken into account; other elements do not have a significant influence.

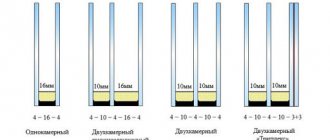

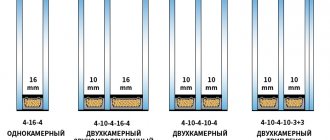

The weight of a window is easy to calculate if you know the number of glasses in the package. Glass area is 1 sq. m with a thickness of 1 mm is 2.5 kg . The weight of a double-glazed window depends on the number of glasses. For example, a single-chamber weighs 20 kg, a double-chamber weighs 30 kg. The mass of the product is calculated using the formula.

Accessories

Another factor that influences the weight of the window.

When making fittings, manufacturers do not consider it right to reduce the weight of parts or simplify the design. The weight of the fittings indicates the quality and reliability of the elements.

The reliability of all parts of the fittings depends on the quality and strength of the metal elements mounted inside the handles, latches or pins.

Due to steel inclusions, the fitting mechanism weighs from 2 kg to 2.4 kg (the figure depends on the manufacturer).

Doors

The operation of the valves depends on compliance with the sequence and accuracy of each stage of the installation technology. Also from unsuitable quality of fittings or heavy weight. To avoid this, there are restrictions on the mass of the sashes . According to the standards on standard PVC windows, the weight of pivoting sashes should be limited to 60 kg. Some manufacturers reduce this figure to 50 kg in order to extend the life of the product.

Important ! The load of blind sashes is not regulated.

The mass of the sash is 0.5 kg.

Five-chamber double-glazed window: description

PVC windows have become widespread due to their technical characteristics. They protect homes well from extraneous noise and have excellent thermal insulation properties. The price of plastic double-glazed windows has decreased significantly, which makes it possible to install them everywhere.

Five-chamber windows are metal-plastic glass packages that have excellent technical parameters compared to others. Sections in the window frame are hollow compartments filled with air, protecting the room from extraneous sounds and cold.

Five-chamber plastic windows

Unlike other metal-plastic glass packages with a smaller number of sections, in the 5-chamber set the metal reinforcement from the inside of the profile is located further from the hinges. This makes it possible to block air entering from the street in the most vulnerable places.

Frames with 5 sections - PVC construction, consisting of several compartments, the central section plays the role of the basis for the metal profile, providing rigidity to the double-glazed window. On the side of the central compartment there are 2 additional chambers, which increase the thermal insulation characteristics and protect against extraneous street noise.

The main section of the metal profile with five compartments is made of high strength material; it prevents possible deformation and damage to the window system. Five-chamber double-glazed windows are practical, durable, and more suitable for residential premises.

Calculation

Before starting the calculations, you should take into account that the main area of the window is occupied by a double-glazed window. Therefore, before calculating the weight of the structure, you must first find the mass of the glass unit.

To do this, you need to measure the height and width of the glass to find its area. You also need to know the thickness of the glass, for example 1 mm or 2 mm.

1 square meter

The standard glass thickness is 4 mm . The mass value is taken from the reference book. For example, glass 1 mm thick has a mass of 2.5 kg/sq. m. So, 1 sq. m of glass 4 mm thick has a mass of 10 kg/sq. m.

One square meter of a single-chamber double-glazed window weighs 25 kg, where 20 kg is the weight of the glass + 3 kg (profile weight) + 1.5 kg (fittings weight) + 0.5 kg (sash weight).

Total products

In this case the formula is used:

3 x window height x window width x glass thickness x 2.5 = weight

The first number 3 means the number of glasses in the bag (there are 3 pieces in a two-chamber bag).

An example for a two-chamber standard double-glazed window with a width of 1.4 m, a height of 1.8 m and a glass thickness of 4 mm.

The area is 1.8 x 1.4 = 2.52 square meters. m. Calculate weight - 3 x 2.52 x 4 x 2.5 = 75.6 kg

The result is indicative. This is due to the installation of various fittings options.

If glass of different thicknesses is installed in a double-glazed unit, then the weight of chambers with different thicknesses should be calculated separately. The results need to be summarized.

Due to incorrect calculation, the following problems appear::

- sagging and rubbing of the sash;

- fogging and freezing of the window;

- deformation of the frame structure;

- depressurization of the glass unit.

Particularly dangerous is the fact that problems cannot be noticed immediately after installation . Most often, they appear after some period of use.

Therefore, it is necessary to calculate in advance the approximate weight of the plastic window and the compliance of the results with the requirements of regulatory documents.

Triple glazing: characteristics

A three-chamber window is a closed glass structure consisting of glass of different or equal thicknesses separated by frames and air-tight chambers formed between them, as well as spaces filled with gas or air gel.

Three-chamber sets have 3 cameras and 4 glasses. Triple glazing is suitable in the following cases:

- harsh climate;

- good thermal insulation is needed;

- protection from the penetration of extraneous sounds.

Attention! When they say plastic windows with 4 or 5 chambers, they mean their number in the supporting profile, but not in the light transmitting elements.

3-chamber double-glazed windows are not suitable for old wooden houses, frame-type cottages, for filling large structures and finishing balconies and loggias.

Why do you need to know how much a structure weighs?

Such information is very important for engineers of companies producing plastic structures.

It serves as the basis for calculating the loads on all related parts - profile, building facade, load-bearing wall. This indicator is also something that installers need to know.

The degree of complexity of installation and the cost of transportation or replacement of double-glazed windows depend on it .

The weight of a plastic window affects a number of design characteristics and properties of the product:

- Operational . Sagging of the sash is most often observed with excessive or maximum weight of the part. Adjustment measures or installation of a microlift will be required. To achieve ease of opening/closing, it is necessary to install expensive fittings.

- Load parameters . This primarily applies to load-bearing walls in old structures. The walls of new houses are characterized by good strength and load-bearing capacity, so the weight of the window will not have a strong impact.

- Installation process . Installation of a lightweight product is much simpler and does not require much experience. If the structure is bulky and heavy, the physical costs increase not only for installation, but also for the design of slopes and the number of necessary materials and tools.

- Total construction cost . The amount and type of material used depends on the weight. Reliable, durable, high-quality materials have considerable weight.

Important ! The weight of a plastic window is determined by all the components and the quality of the material.

If the mass is calculated incorrectly, this leads to adverse consequences.

When replacing a double-glazed window with an improved version in terms of sound insulation, there may be an excessive increase in the weight of the double-glazed window and financial investments. A heavy frame will lead to rapid wear of the fittings .

When selecting elements, the maximum load on each of them is calculated. If it is exceeded, problems will arise during operation. Therefore, the weight must be known before installation.

What does the weight of the window affect?

Most often, the consumer is interested in how the double-glazed window works and what its weight is. As a rule, the manufacturer does not hide information and immediately reports the weight of the product. Why do they even pay attention to this indicator?

- This parameter is important when you need to strengthen the floor and walls. For example, installation is planned in an old home.

- Weight affects further window maintenance. Heavy sashes can sag over time, which means the safety margin of the fittings is slightly lower than that of lighter sashes.

Important

Do not order an overly wide or high sash. Try to make the design lighter by dividing it into several parts.