Many consumers put a generalized meaning into the concept of “double glazing”, often using this term to refer to the entire window structure. However, these two concepts should be separated. A window structure is an architectural detail of construction: an opening in the wall that serves to provide a flow of light into the room and controlled ventilation. The window consists of a frame (profile), which can be made of various materials (plastic, wood, aluminum) and the above-mentioned double-glazed window, the glass part of the window.

In other words, a double-glazed window is a structure of several glasses, hermetically connected to each other along the contour with sealant. The function of the double-glazed window frame is performed by a spacer frame, the internal cavity of which is filled with a substance that absorbs moisture that gets inside the double-glazed window during manufacturing and operation.

The importance of double-glazed windows in window construction

The double-glazed window occupies more than 90% of the visible part of the window, so the thermal insulation and sound insulation of the entire structure largely depends on it. Currently, manufacturers offer a huge selection of double-glazed windows, differing in the number of internal chambers, type of glass, and other parameters. In order not to get confused in all this abundance, you must definitely study the offers on the market and formulate your own requirements for double-glazed windows.

For a window to be truly effective, it is not enough to choose a window profile from well-known manufacturers or expensive multifunctional fittings; you must choose the right double-glazed window.

Tips for choosing

We will give some useful recommendations that will be useful when choosing a suitable double-glazed window option.

The first thing you need to decide on is the size. We do not recommend taking your own measurements and ordering a window system based on them. It is best to invite a professional measurer who can competently approach this important operation. By the way, most manufacturers of window systems provide measurement services free of charge.

Manufacturers now provide a large selection of double-glazed windows: you can buy ready-made ones, or you can order them according to individual parameters. It is clear that the second option will cost more, however, it will provide the home with the most suitable windows for it. And for non-standard window shapes, individual ordering is the only option. After delivering the product home, make sure it is intact and free of external defects: stains, cracks, chips, clouding.

When purchasing windows, consider what the weather is like outside. If the temperature outside the window is below 15 degrees below zero, then installation is not recommended - the entire room will freeze.

When choosing a product, we recommend focusing on single- and double-chamber options. A three-chamber double-glazed window is not always justified: it is expensive, and the need for it arises only in Siberia.

We advise you to pay attention to German-made double-glazed windows: here you will find guaranteed quality and purchase a durable, reliable, time-tested product. In addition to German ones, windows from Swedish and Latvian manufacturers, as well as our domestic ones, also deserve attention. Consider Chinese options last, as their low price is more than compensated for by their not-so-high quality.

What type of glass should it be?

From the consumer's point of view, a double-glazed window should be:

- Transparent, without visible distortion;

- Warm, providing a barrier to the penetration of cold air into the room and the leakage of warm air to the outside;

- Quiet, providing sufficient sound insulation for a calm and comfortable environment inside the home.

Particularly sophisticated buyers choose double-glazed windows based on practical considerations and impose additional requirements on them:

- Fire resistance, ability to withstand high temperatures;

- Impact resistance, the ability to withstand significant mechanical loads;

- Sun protection is the most sought-after quality when the window is located on the sunny side.

How many cameras should a double-glazed window have?

The internal space of double-glazed windows (chambers) is filled with dried air or inert gases, which form a heat-protective layer.

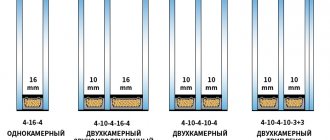

Obviously, the more such layers, the warmer the structure. For example, a standard single-chamber double-glazed window has a heat transfer resistance of about 0.3 m2K/W, a two-chamber one - 0.5 m2K/W, and a three-chamber one - 0.7 m2K/W or more. The most rational from the point of view of energy efficiency is the use of chambers of different widths in one double-glazed window, for example, 14 and 12 mm.

In Russia, the most popular in terms of the number of chambers are double-glazed windows. This is due, first of all, to the climate over a larger area of the country. Double-glazed windows with three or more chambers are recommended to be installed in harsh climates. For central Russia, such a choice is not practical, since a large number of cameras leads to a heavier structure, which needs to be reinforced with an expensive profile.

Single-chamber double-glazed windows are recommended to be installed in unheated rooms, loggias or southern latitudes.

When using glass with a low-emissivity coating and filling the chamber with argon, a single-chamber double-glazed window is comparable in thermal insulation to a double-chamber double-glazed window. However, the sound insulation value in such a double-glazed window will be significantly inferior to a double-chamber double-glazed window.

A white window is boring, I want a colored one. Do such things even exist?

Of course there are. There are even solutions that imitate metal or wood. For example, windows from the REHAU Woodec collection are covered with a matte film with a wood texture - they cannot be distinguished from real wood, but they are much easier to care for.

There are several ways to transform a standard white profile. The most obvious (but not the easiest) option is coloring. To ensure that the paint lasts longer and does not fade, it is coated with a special protective layer. The manufacturer here requires high-quality equipment: at the time of applying paint, dust particles are not allowed to settle on the profile, and the coating must lie smoothly, without bumps or sagging.

You can use decorative overlays on the front surface of the profile, for example aluminum. These overlays can be painted in any color, they are easy to care for, but there is a downside. The structure becomes heavier, which means the load on the hinges increases.

What kind of glass is used to make double-glazed windows?

Energy-saving (low-emissivity) glass

is ordinary float glass, which is sprayed with silver ions, which reflects heat waves in infrared radiation and helps to significantly improve the thermal insulation characteristics of the glass unit and, as a result, reduce the cost of heating premises.

Based on production technology, low-emissivity glass is divided into hard K-glass and soft I-glass. In terms of thermal insulation characteristics, I-glass is slightly superior to K-glass, but inferior in mechanical properties, which is why it is recommended to install it by spraying inside the glass unit. The production process of I-glass is very labor-intensive, which is reflected in the cost.

The main advantage of low-emissivity glass is that when choosing double-glazed windows, you can significantly lighten the design by replacing bulky two-chamber or three-chamber double-glazed windows with single-chamber ones, while maintaining the energy-saving properties of the double-glazed window.

To check for low-e coating on glass yourself, light a match or lighter and hold it near the window. The flame color on low-e glass should be different in color.

Solar control glass

indispensable if the windows face south and excess sunlight affects comfortable living in the room.

Based on the type of production, solar glasses are divided into “absorbing” glass, colored in the mass, and “reflective” glass, coated, which reflects part of the solar energy falling on them. In terms of efficiency, coated glass offers better properties at a comparable cost. To provide improved thermal insulation, absorbent glass can be combined in double-glazed windows with energy-saving glass.

Soundproof glass

designed to increase the sound insulation characteristics of a double-glazed window; for this purpose, laminated glass with a polymer inner layer or PVB film is used.

The use of soundproofing glass in the production of double-glazed windows exceeds the noise protection of conventional double-glazed windows by almost 5 times. In addition, the use of soundproofing glass provides increased safety and thermal insulation.

The most effective, according to experts, is the use of one or two glasses with PVB noise-proof film in the design. This solution can not only reliably isolate a room from external noise, but also fit perfectly into most projects without requiring additional costs.

Fireproof glass

– laminated glass, made using a special technology with the installation of a reinforcing metal mesh or a special polymer between the glasses, followed by tempering of the glass in furnaces, due to which the glass acquires heat resistance and can withstand high temperatures.

Tempered glass is the most affordable solution, as it has high consumer characteristics and does not lose translucency, unlike reinforced glass.

Along with well-known types of glass, some manufacturers offer the use of modern “smart glass” that can change the transparency of the glass unit.

Glass with dirt-repellent coating

has become widely popular

, thanks to which there is no need for constant window cleaning.

The choice of glass directly depends on the capabilities and requirements of the customer. It should be remembered that any technology costs money, and before agreeing to the use of efficient glass in the manufacture of double-glazed windows, it is necessary to evaluate the feasibility of using certain solutions in each specific case.

Main problems and problems

The main defect of a double-glazed window is a violation of its integrity, after which moist, cold air begins to enter the room in the winter, the process of condensation begins on important components of the window structure and adjacent walls, which leads to failure of the unit, high heat loss in the house and damage to soundproofing.

Reasons that contribute to the depressurization of a double-glazed window:

- Low-quality design and manufacturing defects;

- incorrectly selected package according to the size of the window opening;

- the package was selected without taking into account real temperature fluctuations for the climatic region of operation of the window system;

- physical defects in the form of chips and cracks;

- poor quality sealing of the package;

- violations of the technology for installing the package in the frame and the window block in the wall opening.

Depressurization of a window unit can only be eliminated by completely replacing it; if it is determined that the package was damaged during production or installation, then it is replaced at the expense of the guilty party - the manufacturer or installation organization. If the package is mechanically damaged, the owner of the window pays for the replacement.

Additional reasons for poor performance of a double glazed window:

- the appearance of moisture inside due to: depressurization, improper installation, low-quality silica gel or its absence;

- the appearance of stains inside, a violation in the space between the glass, a large temperature difference, a violation of the seal, in the first case a new bag is needed;

- cloudiness of the package, caused by poor-quality assembly, can only be eliminated by completely replacing it by specialists.

Why do bags burst?

If a double-glazed window bursts, this leads to a loss of energy-efficient characteristics of the window, deteriorates its appearance and creates a danger to others. In the first years of installing PVC windows, the situation when glass cracked inside or outside the block occurred quite often and this was due to the fact that many young window companies that were engaged in the production and installation of PVC windows did not have sufficient work experience.

Today, these errors are less common and their causes can be :

Settlement of the structure is especially common in wooden walls or during high-speed construction, for example, shopping centers.- Temperature jumps lead to uneven expansion of the glass, as a result of which zones with different temperature stress are formed in it, which lead to ruptures of the window sheet.

- A narrowed gap between the bag and the frame, which is especially dangerous for aluminum frames, which are pressed closely against the glass and with the slightest vibration, for example, from gusts of wind, the glass begins to collapse.

- Manufacturing defects that are invisible to the naked eye.

If the rupture of the glass unit comes from the bead or is located inside, then the company that produced the glazing is to blame.

The reasons for this are usually overtightened anchors or excessive amounts of construction foam applied when installing the block. Excess foam, expanding, compresses the frame, creating tension in the window sheet. On the contrary, a crack on the outer side of the glass unit indicates violations of operation on the part of the owner.

What does the thickness of the glass unit depend on and what influences it?

The thickness of double-glazed windows for plastic windows is the sum of the thickness of all glasses and the distance between them.

Optimal glass thickness in a double glazing unit

Most often, ordinary float glass with a thickness of 4-6 mm is used in double-glazed windows. Glass with a thickness of 4 mm is the standard solution; thicker glass (5-6 mm) is recommended for use in busy areas and on upper floors, where the wind load is much stronger.

What should be the distance between the glasses

The distance between the glasses in a double-glazed window ranges from 6 to 24 mm and depends on the type of construction. In single-chamber double-glazed windows, the distance between the glasses is usually greater than in double-chamber or three-chamber windows, as it affects the sound insulation of the structure.

For example, increasing the distance between glasses by just 3mm can increase sound insulation by 10%.

In two-chamber and three-chamber double-glazed windows, the distance between the glasses may differ. From the point of view of sound insulation, this technique allows you to achieve maximum efficiency. Usually in such double-glazed windows the distance between the glasses does not exceed 16mm.

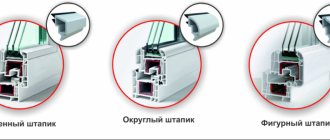

Distance frame and its functions

The function of distancing the glass in a double-glazed unit is performed by a spacer frame, which is a hollow profile filled from the inside with a desiccant. On the surface of the frame you can see perforations through which moisture enters the frame and is absorbed by the adsorbent.

The width of the spacer frame determines the distance between the glasses and can be, accordingly, from 6 to 24 mm.

Traditionally in Russia they use spacer frames made by molding and welding from aluminum. This method allows us to meet the necessary energy efficiency requirements in a modern double-glazed window. In addition, aluminum has excellent adhesion (gluing) to all types of sealants, which makes it possible to produce the most airtight double-glazed windows.

However, for all its uniqueness, the aluminum spacer frame has one significant drawback: due to its very low resistance to heat transfer, it forms a “cold bridge” where condensation can form in cold weather.

In this regard, “warm” frames made of composite materials are becoming increasingly popular. In addition to high heat-shielding properties, a plastic frame can become a highlight in the interior, as it has high aesthetic properties and can be made in various colors. The only drawback of such a frame is the relatively high cost compared to aluminum.

Types of plastic windows

Before you start choosing a window design, you need to understand their varieties. Types of plastic windows are distinguished according to group distinctive features.

Number of sashes

The number of sashes in a window structure largely depends on the size of the window. Considering the fact that the window must open, the number of sashes can be increased at the request of the client.

The following types of window structures are distinguished:

- Single-leaf – installed in openings of small size and low height. Even if the opening is of a non-standard size, square or rectangular, one sash with the ability to open will solve the problem of window glazing.

- Double-leaf - installed on wider window openings. It is recommended to install double-leaf plastic windows for openings wider than 80 cm.

- Triple-leaf - mounted on large and tall windows, which are often located in living rooms and other large rooms.

We advise you to study - What types of timber are there for building a house?

Separately, there are windows with a door for the balcony opening. In most cases, a blind window is made here with the additional installation of a door in the overall structure.

Opening method

In this category, the following types of plastic windows are distinguished:

- blind window - the sash does not open at all;

- rotating sashes - the window opens in the standard way by turning the sash;

- flaps - they make a special design when the lower part of the sash is attached to the structure, and the upper part is placed inside the room;

- combined - these designs involve combining a turning and tilting window;

- sliding plastic windows - mainly installed on balconies, since such glazing allows you to save an already small and narrow space.

The variety is chosen in accordance with the convenience of the family in subsequent use.

Profile design

A plastic window is a frame or profile that is made of polyvinyl chloride. Polyvinyl chloride is a polymer based on chloride and ethylene.

Additionally, the composition includes stabilizing substances, plasticizers and modifiers. The powder is heated and pressed, resulting in the formation of the base of the window structure - white frames.

A metal profile is inserted inside, and all parts are thermally soldered.

Along with the substances, pigment is added to the composition, which is why interesting colored plastic windows or wood-look plastic windows are obtained.

To make a frame, specialists have to make cuts to make a piece of the required length. The connection occurs by gluing or soldering into straight or spatial structures.

Additionally, cuts are made to ensure air flow into the room and also to remove condensation. The slots are made in the outer chamber, the rest are sealed.

It is recommended to choose a design based on the number of chambers:

- three-chamber structures are recommended for installation in warm regions and warehouses where space heating is not required;

- five-chamber - in mid-latitude regions of Russia;

- six- and seven-chamber designs exist, but it is not recommended to install them, since the quality and thermal conductivity will correspond to five-chamber types, but more money will have to be spent.

It is important to know the exact structure of the profile, since lack of knowledge leads to successful fraudulent actions - careless installers install low-quality products for customers for a lot of money

Differences in glass

There are three types of double-glazed windows - single-chamber, double-chamber and three-chamber. Each has its own advantages and disadvantages:

- single-chamber - have a thickness of 14-32 mm, are considered obsolete and are used only for industrial premises;

- two-chamber - the total depth is up to 58 mm, one glass is used in the cavity, the width of all is no more than 4 mm, used in most cases for the installation of residential premises;

- three-chamber - the width of the double-glazed window is practically the same as for two-chamber ones, so their use becomes impractical.

Three-chamber double-glazed windows have greater weight and slightly increased thermal conductivity and sound insulation values.

What is hidden from the buyer's eyes?

Unfortunately, knowledge about a double-glazed window is most often limited to its visible part, glass and spacer frame. However, the main function of sealing and ensuring physical and mechanical stability in a double-glazed window is provided by elements hidden from the buyer’s eyes.

Sealants for double-glazed windows

These are two layers of sealant that complement each other in their physical properties and, in combination with each other, provide the necessary characteristics.

The primary layer of sealant is the most important, since it is responsible for moisture resistance. As a primary sealant in the production of double-glazed windows, hot-melt butyl sealant is used, which is applied in a thin layer to the side surface of the frame and, in parallel with its main function, serves as a means for gluing the spacer frame to the glass. Replacing butyl with cheaper materials, such as duct tape, does not provide the necessary sealing of the glass unit.

The primary layer of sealant protects from external loads and the secondary rubber-like sealant finally “seals” the glass unit. Most often, a two-component polysulfide sealant is used as a secondary sealant, which is applied in an industrial environment to the contour of a double-glazed window using special equipment.

The use of low-quality products can lead to such undesirable consequences as fogging of double-glazed windows, cracking of double-glazed windows, unpleasant odor and leakage of sealant into the chamber.

Molecular sieve

Another important element hidden from the buyer’s eyes is a molecular sieve or adsorbent poured inside the spacer frame. The main function of a molecular sieve is to absorb moisture that enters the glass unit during production and operation. Saving on high-quality adsorbent can also significantly affect the performance properties of a double-glazed window.

If you are faced with such consequences as corrosion of the spacer frame, the formation of white crystalline deposits at the site of the perforations, rest assured, this is the result of savings from a careless manufacturer.

To protect yourself from such troubles, you should purchase windows only from reliable manufacturers who provide a guarantee on double-glazed windows and can advise on the quality and materials used for production.

The service life of double-glazed windows is established in the technical documentation. According to the warranty, it must be at least 5 years from the date of shipment of the products by the manufacturer.

Specifications

The design, production, installation and operation of window systems is strictly controlled by the state standardization system for residential, public and industrial, which is associated with ensuring energy-efficient characteristics and creating safe operating conditions.

Compliance with state standards at all stages of the creation and use of structures is a guarantee for the effective and safe operation of PVC windows throughout the entire standard service life determined by the manufacturer.

If these requirements are not met during transportation or window installation, the buyer has the right to free warranty service or even a complete replacement of the package if violations are identified during the warranty period.

The basic document for double-glazed windows is GOST No. 24866, published in 1999, which defines the general specifications for them; in addition, the requirements for them are placed in separate regulations: SNiP, GOST and SP for wooden, aluminum and PVC windows.

Current GOST standards for double-glazed window systems:

parameters of PVC windows - No. 30674, 1999;- general requirements for window structures for buildings for various purposes - No. 23166, 1999;

- standards for sound and heat protection and ventilation characteristics: No. 26602.2; 26602.1 and 26602.3, issued in 1999;

- Specifications for wooden windows with double-glazed windows - No. 24700, 1999;

- Specifications for PVC windows with double-glazed windows - No. 30674, 1999;

- Specifications for aluminum frames with double-glazed windows - No. 30674, 1999;

- types, design and dimensions for low-rise residential buildings - 26601, 1985.

How to read the glass unit formula?

The glass unit formula must necessarily contain the following information:

- brand and thickness of glass;

- distance between glasses;

- type of filling of internal chambers;

- parameters of height, width and thickness of the glass unit;

- type of double-glazed window (Ud - shock-resistant, E - energy-saving, S - sun-protective, M - frost-resistant, Sh - noise-proof);

- designation of the standard (GOST 24866-99).

As an example, let's look at the following formula:

SPO 4M1 –20Ar – 4M1 1500x750x24 GOST 24866-99

Single-chamber double-glazed window: the first glass of the M1 brand is 4 mm thick - the distance between the glasses is 20 mm, the chamber is filled with argon - the second glass is M1 4 mm - the dimensions of the double-glazed window are height 1500 mm, width 750 mm, thickness 28 mm - general construction use.

What determines the cost of a double-glazed window?

The cost of a double-glazed window is set by the manufacturer per square meter of the product and depends on the following factors:

- Number of chambers in a double-glazed window

. The more there are, the more expensive the double-glazed window. On average, increasing the number of cameras from one to two in a double-glazed window without additional options leads to an increase in the cost of the double-glazed window by 30%. - Glass type

. The use of one glass with a low-emissivity coating in the design increases the cost of a double-glazed window by another 30%. - Gas filling

. Argon is most often used as gas filling. The cost of filling depends on the size of the double-glazed window and increases the cost of the double-glazed window by at least another 10%. - Decorative elements

. The use of decorative elements, tinted film, and fire-resistant glass can increase the base cost of a double-glazed window by two or more times.

Filling the inter-glass space

Three main substances are used as air chamber fillers:

- An inert gas or mixture of gases - the most commonly used are argon (Ar or A) and krypton (Kr).

- Dehumidified air.

- Sulfur hexafluoride (sulfur hexafluoride, SF6) is an inorganic compound, a heavy gas, the mass of which is several times heavier than air.

links to materials supplementing this article: Mirror plastic windows. Types and characteristics

Plastic double-glazed windows with built-in blinds inside. Already reality?

Choosing a plastic window for the kitchen. Which one is better?