A single-leaf metal-plastic window is made with one swing or tilt-and-turn sash. A blind (without opening) product is installed infrequently - in bathrooms, in dressing rooms or in storage rooms.

A standard single-leaf window, the sizes of which are classified by subtype, requires compliance with the exact ratio of frame parameters. To do this, the project must contain a sketch or sectional drawing for a single-leaf product.

The opening height for a standard single-leaf design varies in the range of 500.0-1500.0 mm. The standard maximum opening width (in millimeters) should be in the range of 500.0-900.0. The height of the PVC product is 470.0-1470.0, width – 470.0-870.0.

A standard single-leaf plastic window has the following dimensions:

| Parameters of a single-leaf design in millimeters | |||

| Opening dimensions (height H, width B) | Standard design parameters (height H, width B) | ||

| H | B | H | B |

| 500,0 | 500,0 | 470,0 | 470,0 |

| 600,0 | 600,0 | 570,0 | 570,0 |

| 600,0 | 900,0 | 570,0 | 870,0 |

| 900,0 | 600,0 | 870,0 | 570,0 |

| 900,0 | 900,0 | 870,0 | 870,0 |

| 1200,0 | 600,0 | 1170,0 | 570,0 |

| 1200,0 | 900,0 | 1170,0 | 870,0 |

| 1350,0 | 600,0 | 1320,0 | 570,0 |

| 1350,0 | 900,0 | 1320,0 | 870,0 |

| 1500,0 | 600,0 | 1470,0 | 570,0 |

| 1500,0 | 900,0 | 1470,0 | 870,0 |

The popular standard sizes of single-leaf plastic windows for a modern high-rise building in millimeters are 1200.0 x 1200.0. The standard size of a PVC product with one window is 1500.0 x 1500.0.

Attention: the width of the window of a tilt-and-turn product with one leaf should be no more than 1000.0 mm.

The advantages of single-leaf PVC structures that builders note are versatility of installation, high sound insulation coefficient, and safety of operation.

What is a plastic window. Product composition.

A plastic window is a chamber window structure consisting of a polyvinyl profile frame, two or more double-glazed windows forming an air-chamber layer of the window frame, which performs a heat-retaining function. The most common type of window communications at present. Budget, reliability, durability and many other advantages, which we will talk about in this article, make plastic windows a universal architectural communication, widely used in both residential and industrial construction.

plastic window

Composition of a plastic window

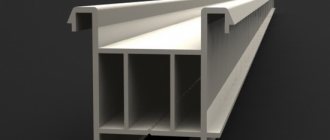

The main material of the frame profile is polyvinyl chloride, abbreviated as PVC. The material contains ethylene and chlorine; stabilizers such as lead, zinc and calcium and dyes are used as additional additives. All additives are presented in small quantities and, according to manufacturers, are safe for health, even under extreme temperature effects on the product.

The structure of the product is built in the same way for each manufacturer and does not differ in variety.

A standard PVC window frame consists of:

- Profile - serves as the basis of a strong frame, with the correct geometry of the window opening. The same type of durable profile is used as when installing wall plasterboard. Read more in the article "Drywall: pros and cons. Composition and structure of drywall"

- Sash - there can be from one to several, depending on the complexity of the design. Necessary for fixing and rotating the movable part of the window frame in the frame.

- Double-glazed windows , in quantities of 2 or more pieces, with a sealed air gap between them. The function of double-glazed windows is to provide access to natural light into the room, protection from humidity and bad weather, and maximum prevention of heat loss in the room. The greater the number of double-glazed windows in a window, the better its protective ability.

plastic window structure

- Fittings are all additional elements of any window that perform practical and decorative tasks. These include: handles, locks, seals, hinges and others.

- External protective and drainage parts. These elements include a metal ebb, the task of which is to remove precipitation in the lower part from the place where the frame is attached to the window opening. Side and top slopes, from the outside and inside the premises, are arranged additionally and perform both protective and decorative functions. Window sill - made of different materials: PVC, wood and others. Its functions are protection from moisture in the lower part, decorative and practical; a reliable window sill greatly facilitates the care of the window and the window area.

Types of plastic windows

The main division of PVC windows is carried out according to their functionality, namely by the number of sashes, by the method of opening and rotating the glass unit, by the number of chambers in the structure.

Windows by number of sashes

Single leaf

This category includes fixed windows or small single-hung windows. This type is often used in bathrooms, bathrooms, baths, utility rooms, balcony glazing, staircases and similar places. This is a budget option for small spaces.

single-leaf plastic window

Double-hung windows

The most common design. One of the doors is usually blind, the second one opens. Such a frame is mounted in living rooms: bedrooms, small living rooms, kitchen rooms, and is installed en masse in multi-story buildings; it is the optimal and quite economical option for country houses. Convenient to use and maintain double-glazed windows.

double-leaf plastic window

Three-leaf plastic windows.

A less popular variety, used in rooms and rooms with a large area, living rooms. It is represented by several types of structures, which can consist of one blind and two movable sashes, two blind and one opening sashes; it is not advisable to manufacture all three opening sashes from an economic point of view and is not always practical.

three-leaf plastic window

Multi-leaf frames

They are complex frames, consisting of several fixed and movable sashes, which may include windows, retractable and hinged elements, and unique design structures. Made to order for a specific object or project. It requires more labor-intensive work, both during manufacturing and installation; a reinforced profile is used to counteract windage, therefore it is a more expensive type of plastic window frames. Such frames are used for glazing verandas, balconies and viewing platforms.

multi-leaf plastic window

By type of sash rotation

Rotary

Standard double-glazed windows that open into the room along the vertical axis of the window frame. The disadvantage of this design is that the window sill space in the opening area of the sash must be free of foreign objects. Windows with wooden frames have always been made of this type.

pivoting plastic window sashes

Tilt&Turn

A combined design that combines a rotary method of opening the sash vertically and horizontally (the so-called window mode). A slightly more expensive modification, but it allows for ventilation and aeration without fully opening the window. In the upper part, horizontally, the sash opens to a distance of 2 cm or more, in several modes. This allows you to control the rate of air cooling in the room and reduce the draft effect.

folding frames

tilt and turn window

PVC sliding windows

Convenient design for rooms with a small area, balconies, verandas, indoor partitions. When opened, the glass unit moves along a guide profile along the adjacent glass unit.

sliding plastic windows

accordion plastic windows

By the number of double glazing chambers

Single chamber

The classic and most popular design of any window frame. It consists of two glasses with a single sealed space between them (chamber), which serves as a protective barrier for heat loss. They are used everywhere: in residential and non-residential premises, for economic and industrial purposes, balconies and verandas. The most affordable option in the price category.

single chamber plastic window

Double chamber

They consist of three glass sheets and, accordingly, two chambers between them. They are characterized by improved thermal insulation properties and better sound absorption. There are no restrictions on installation; they are installed depending on the feasibility for each individual room.

double-chamber plastic window

Three-chamber

The design provides for three sealed chambers and four glass sheets. Such windows are characterized by increased thermal insulation and strength. They are used in areas with harsh climates, where low temperatures prevail, and in places with extreme wind and noise loads. In temperate climates, three-chamber frames are used for glazing the upper floors of high-rise buildings and in buildings near objects with high noise levels: highways, airports and others.

three-chamber plastic window

Double-leaf PVC construction

The design has become widespread because it is cheaper than other translucent products, not counting the single-leaf version. A popular solution is a double-leaf window with one blind half and one opening. Occasionally you can find a double-leaf design with both movable halves.

A double-leaf window, which has a plastic profile, is quite easy to maintain and repair. The fittings for windows of any design are unified and differ only in the quality of workmanship. The installation area ranges from residential buildings to industrial, administrative and public facilities.

The type and series of a residential building affects the choice of window sizes (in millimeters):

- In the “brezhnevka” window with 2 sashes has a size of 1300.0 x 1400.0;

- In high-rise buildings with a new layout - 1780.0 x 1430.0;

- In the “Khrushchev” - 1208.0 x 1340.0 x and 2040.0 x 1500.0;

- In “Stalin” – 1500.0 x 1900.0;

- In houses with a Czech layout - 1300.0 x 1400.0.

The double-leaf design is simplified and lightweight; the fittings must have a high degree of reliability. The principle for choosing fittings is the same: it is easier to replace the mechanism than the entire window. In terms of operation, a window with two sashes is simpler and more comfortable. The window sill will be half free, while the window can be opened for micro-ventilation on an ongoing basis. Therefore, the decision about which window is better, single-leaf or double-leaf, will obviously be in favor of the second option. In this case, the size of the product itself or the individual sashes does not matter.

Advantages of plastic windows in the house

Durability

The manufacturer states that the average lifespan of a PVC double-glazed window is at least 30 years, even in harsh climates. Of course, subject to the purchase of high-quality material manufactured in accordance with GOST. Because. When counting on the durability of the installed window frames, you should first of all make sure of their quality and the integrity of the manufacturer.

Good sealing

All plastic windows, from single-chamber to multi-chamber, have absolute tightness. This quality can be obtained using polymer materials. Unlike wooden frames, which change their volume as a result of changes in humidity. Therefore, you will not be bothered by cold drafts, the need for additional insulation and pasting over possible gaps in the frame, as is the case with natural wood.

plastic windows are sealed

Easy to maintain and maintain

PVC frames do not require periodic painting; it is enough to wipe them with a wet cloth to wash off any dust deposits. Once a year or two years, it is necessary to lubricate the fittings with ordinary technical oil, and sometimes treat the seal between the glass and the frame with silicone sealant. When washing plastic windows, it is not recommended to use abrasive and acid-base solutions, which may have corrosive properties.

easy to maintain and clean

Good sound insulation

The hermetic chamber of the glass significantly reduces the degree of penetration of sound from the street. Two-chamber and three-chamber frames almost completely eliminate the penetration of external sounds into the room, even if these sounds come in the immediate vicinity of the window. Therefore, for people who especially value silence in their own home, plastic double-glazed windows are an ideal option.

PVC windows have good sound insulation

sound absorption PVC windows

Humidity resistance

The polymer materials from which all plastic frames are made are absolutely non-hygroscopic, they do not accumulate or transmit moisture, do not change their geometry, do not swell or shrink as a result of changes in humidity both inside and outside the room. This property is a significant advantage over expensive wooden windows.

plastic windows are resistant to humidity

Resistance to temperature changes, fire safety

They can withstand low temperatures up to 600 degrees, aim below zero and in the hot season, when the temperature rises, they retain their density without damage and do not emit harmful substances. The mixture of materials used to make the window frame does not support combustion. Direct, prolonged exposure to an open flame will of course damage the window and can completely destroy it. However, with short-term exposure to fire, the material will not suffer significant damage due to its self-extinguishing property.

Budget and accessibility

Plastic windows are available in a variety of price categories; almost every homeowner can afford the purchase and installation of such frames. The difference in price depends on the size, multi-chamber and the presence of additional fittings. A standard, single-chamber and single-leaf double-glazed window will cost much less than the same wooden window frame.

Why do we need standard glazing sizes?

In this diagram you can see how a plastic single-leaf window and three-leaf PVC glazing differ from each other

Why are the dimensions of a three-hung window the same, but the dimensions of analogues with one or two sashes are different?

Standardization of glazing sizes is dictated by the following factors:

- Construction time and price, since installing a window unit in an opening of a suitable size is easier and cheaper than adjusting the frame to the location;

- Correspondence of the glazing area to the wind load;

- The weight of the elements in the frame structure and, as a result, the load on the fittings;

- The distance from the opening sash to the opposite edge of the static frame and, as a result, the possibility or impossibility of cleaning the glass yourself;

- Light transmittance;

- Energy efficient design.

Let's consider the above points in more detail.

In this table you can choose plastic single-leaf windows by size and approximate cost

The standard size of a double-leaf or three-leaf window was not chosen by chance, since openings are made in accordance with these standard sizes during the construction of a building. Thus, a responsible contractor can order glazing from third-party organizations and, at the same time, be confident that the manufactured structures will fit into the openings like a glove.

Thanks to this table, choosing a double-leaf plastic window unit will be easy

When calculating glazing area standards, among other things, the wind load characteristic of certain regions was taken into account.

Therefore, a blind single-leaf PVC window without lintels is installed in some openings, and frames with several lintels are installed in openings with large dimensions. That is, the more jumpers, the more resistant the glass in the frame is to mechanical loads.

The table shows the standard sizes of plastic three-leaf windows and their average cost

An important point is the load on the fittings, which is also determined based on the dimensions and configuration of the glazing. That is why the standard size of a double-hung window in typical apartments was calculated in such a way that ordinary rotary hinges could support the weight of the sash without the need for frequent adjustment of the fittings.

The energy efficiency of the structure also depends on the glazing area, since glass has greater thermal conductivity compared to a plastic or wooden profile. Therefore, correct calculation of the number of sashes, their sizes and frame configuration will make your house or apartment warmer.

Single-leaf wooden frames are installed in small, mainly utility rooms, where light transmittance is not so important

Light transmittance also depends on the dimensions of the installed frame. The standard parameters for the optimal glazing area were calculated taking into account that there would be enough light during the daytime from both the sunny and shady sides of the house.

This parameter also takes into account the geographic location of the object. That is, the further north the region is located, the greater the light transmission parameters of the openings in the wall of the house should be. And vice versa, the further south the region, the smaller the glazing area will be sufficient for normal lighting of the living space during the daytime.

And finally, by installing not a blind window, but a full-fledged three-leaf window, you can wash the outer part of the glass almost completely with your own hands and using a special scraper. Will you be able to do similar work if your house has fixed, non-opening windows?

Light transmission coefficient and calculation of glazing area

Quadruple glazing is installed on balconies and loggias to allow more light into the room

In accordance with GOST 11214-86 and GOST 23166-99, the maximum size of a single-leaf, double-leaf and three-leaf window corresponds to the standard sizes of openings made during the construction of standard series buildings.

The standard dimensions specified in the regulatory documentation regulate the dimensions and configuration of the following types of window units:

- Single;

- Double;

- Triple;

- Terraced and bay windows.

However, in addition to the regulated dimensions, there are parameters according to which you can independently calculate the dimensions of openings and frames for your home. When calculating the glazing area when arranging residential buildings, we are guided by the requirements listed in SNiP 2.08.01–89 “RESIDENTIAL BUILDINGS”.

These requirements say the following:

- The ratio of glazing area to floor area in residential premises should be no more than 1:5.5 and no less than 1:8;

- For upper floors equipped with attic windows, the value of this coefficient is 1:10.

As an example, let's try to calculate the sizes of openings and frames for country buildings.

Calculation for a summer house or small village house with a floor area of no more than 65 m²:

- Taking into account the coefficients listed in SNiP 2.08.01–89, we divide 65 by 5.5 and 8, and we get that the maximum glazing area for such a room should be no more than 11.8 m², and the minimum - no less than 8.12 m²;

- Now we calculate the area of the opening - to do this, we multiply the height by the width, namely 1850 mm × 1500 mm = 2.78 m² and 1500 mm × 1500 mm = 2.25 m²;

- We add up the results to find out the total size: 2.78 × 2 + 2.25 × 2 and we get 10.06 m².

10.06 m² is a normal result that meets regulatory requirements.

Calculation for a country house with a total floor area of 81.5 m²:

- Taking into account the coefficients listed in SNiP 2.08.01–89, we divide 81.5 by 5.5 and 8 and get 14.8 and 10.1.

- The house will use frames with the following dimensions: 2060 × 1420 = 2.9 m²; 1670 × 1420 = 2.3 m² and 1460 × 1420 = 2.07 m².

- We calculate the total glazing area as 2.9 × 2 + 2.37 × 2 + 2.07 × 2 and get 14.6 m².

The size of 14.6 m² just fits into the maximum coefficient, and therefore the light transmission will be optimal, but not excessive.

When calculating the glazing area, the resulting result is rounded down - this will be an adjustment for the thickness of the profile in the frames.

As you can see, calculating the window area in accordance with the light transmittance is not difficult. This means that using this method, you can calculate the number and dimensions of windows when designing your home.

How does the weight of the sash relate to the mechanical load on the fittings?

The photo shows a non-standard double-glazed window in a PVC profile with an increased width of the sashes

Externally, plastic three-leaf and double-leaf windows are perceived as almost weightless. But these are just features of our perception, since the combination of glass and window frames is guaranteed to be heavy. Therefore, it is so important to calculate and select the weight of the sashes at which the hinges will not sag and will not need to be replaced.

The standard weight of a swing door for a set of modern hinges is 50 kg. That is, if the sash installed on rotary hinges weighs more than 50 kg, it is necessary to use reinforced fittings.

An example of how a double-leaf PVC window becomes unusable if the dimensions of the sashes are chosen incorrectly

The calculation of the permissible glazing area, in this case, is carried out based on the fact that the weight of glass with an area of 1 m² and a thickness of 1 mm is 2.5 kg. Since the manufacture of modern windows uses glass with a thickness of 4 mm, the weight of 1 m² will already be 10 kg.

Considering that double-glazed windows are widely used when arranging residential properties, the weight of 1 m² will have to be multiplied by 2. As a result, the weight of 1 m² will be 20 kg and to this you can add 3-4 kg - the weight of the profile. Thus, it is easy to calculate that the maximum permissible area of the hinged sash should not exceed the weight of 2 m².

Cons of plastic windows

High tightness

It is both an advantage and a disadvantage. The presence of high-quality, plastic windows in the house also requires the presence of a good ventilation system. The lack of additional air flow through the window can create a greenhouse and vacuum effect, which is especially noticeable in the hot season and in damp weather. Often, the dew point shifts into the room and you can observe the appearance of traces of liquid on the slopes and glass, and subsequently fungus.

Not repairable

A damaged frame and glass unit cannot be replaced as a separate element. In this case, the window will have to be replaced completely. Scratches cannot be painted over or filled with putty.

if damaged, the plastic window will have to be completely replaced

Questionable environmental friendliness

Plastic frames are made entirely of synthetic materials, which, when exposed to high temperatures, and especially at combustion temperatures, under the influence of an open flame, release substances that are toxic to humans. Therefore, in extremely hot climates and fire-hazardous regions, the use of such materials is not recommended.

Acquisition of marriage

Currently, many manufacturers do not comply with GOST requirements for the production of PVC windows, which affects their durability, thermal protection and environmental friendliness. Therefore, you can find many unsatisfactory reviews regarding the use of plastic windows. Purchasing double-glazed windows from a reliable manufacturer with a good reputation can guarantee that you have received the proper quality of the product.

defective plastic window

When choosing plastic windows, you should weigh all the advantages and disadvantages of the material from which they are made, whether their technical characteristics are suitable for a specific room, whether they can cause harm or, on the contrary, whether they are the most practical and expedient option

plastic window