Plastic windows Salamander (Salamander) - from a popular German manufacturer. They will provide warmth and comfort in the room at different times of the year. In addition, these windows visually make the house more attractive from the outside and inside. Why are Salamander windows so popular, and what advantages does this window profile have?

history of the company

The history of this company stretches for more than 100 years, but their products appeared in our country only in 1999. In European countries, the German company Salamander gained its popularity earlier in 1973.

The company itself was formed from the merger of two large concerns, which were also involved in the production of metal-plastic windows. The “brothers” of the Salamander company can be called Brugmann; it was also created on the basis of the same two large concerns.

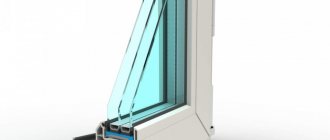

SALAMANDER is a completely sealed and durable window profile

Benefits of SALAMANDER

This brand is known for such qualities as durability, ease of maintenance, environmental friendliness, and high resistance to environmental influences.

259 Reviews | 5 current promotions | 9 advantages of the manufacturer

Let's take a closer look at these benefits:

- high degree of thermal insulation

Achieved due to the fact that the walls of the main chamber do not come into contact with the metal reinforcement. - rapid drainage of rainwater from the rebate.

Ensured by design features. Water does not get under the glazing bead even in the “micro-ventilation” mode. - the presence of fastening bosses on the inner wall of the frame

Thanks to this design feature, the fittings are securely fastened. In general, the design acquires a high degree of protection against burglary in Moscow. - can be equipped with seals made of EPDM rubber

EPDM rubber is a material resistant to weather conditions and has a long service life. - Huge selection of lamination film colors

Excellent conditions for a comfortable life

A correctly selected window determines the microclimate and comfort in your home, so it’s worth contacting specialists. Choose the German SALAMANDER profile.

Plastic windows from our company are a harmonious combination of simplicity, aesthetics, functionality and the achievements of modern technologies.

Finishing work (slopes, window sills, ebbs)

The functionality of a window is largely determined by auxiliary elements that are supplied with the window or purchased separately.

Window sill installation

One of the main elements is the window sill. As a rule, it is also made of polyvinyl chloride and does not differ in color from the window frame. Its width is determined depending on the thickness of the wall.

The window sill extends no more than two centimeters under the frame. The opening underneath is foamed or sealed with mortar, depending on the height of the window sill above the wall. On the inside it is fixed to the window frame or a stand under it, on the outside it lies freely on the sealing layer. If polyurethane foam sealant is used, it is sealed with vapor barrier tape or Stiz B, just like a three-layer seam. On the sides, the window sill should go under the slope by at least 2 cm.

The width of the window sill can be any, but the overhang beyond the inner plane of the wall should not exceed 6 cm. This will allow convection currents from the radiator to flow freely around it and protect the window from fogging. The inclination of the window sill plane from the horizontal towards the floor should be in the range of 5 - 60. This will allow you to install a pot or vase of flowers on it without the risk of them falling off and will prevent the accumulation of dust or water droplets if, for example, you forgot to close the window.

Low tide installation

A drip sill is installed on the outside to drain rainwater flowing down the window from the wall. Installation of plastic windows according to GOST

It also requires proper installation of the ebb. The casting material is also PVC, but aluminum, galvanized steel, and polymer-coated steel can also be used.

In any case, the ebb should protrude beyond the plane of the wall by 3–5 cm, or even more, depending on the wind load. It is also necessary to ensure that the ebb plane is tilted downwards from the horizontal by 5 - 80. The ebb is attached to a special profile on the underside of the window, which provides protection against moisture penetration under the frame. On both sides, the ebb should go under the slopes, which are installed after installing the ebb on the outside and the window sill on the inside.

Installation of slopes

Various slopes are installed on PVC windows (plastic, plasterboard, plaster). The choice depends on the size of the wall, window and type of interior decoration. The installation of slopes can be ordered together with the installation of a window, or performed separately during the general renovation of the apartment. If the installation seam and installation of ebbs and window sills are correctly performed, the slopes perform only decorative functions and have little effect on the tightness and thermal insulation properties of the structure.

Simple and quick installation of a SALAMANDER window in the insulation area

Suitable for all types of window blocks (aluminium, wood and plastic)

Direct installation through the SALAMANDER window frame into the anchor plate

Quick and safe installation of the SALAMANDER window block into the edge of the brickwork

Protection of brickwork from chipping

Ease of use when modifying or replacing SALAMANDER windows

Fastening a SALAMANDER window in accordance with the burglary resistance class RC2

Maximum bracket load tested by the German Institute for Window Technology IFT Rosenheim test number: 17-000719-PR01

We offer you a load-bearing connection for every installation situation!

SALAMANDER - the profile you were looking for

Since 1973, the SALAMANDER concern has been a manufacturer of high-quality German PVC.

For more than 35 years of experience, the company has opened representative offices in many European countries and large cities in Russia. The most popular series are:

- Design 2D

- Design 3D

- Streamline

Features and nuances

The profile, and therefore SALAMANDER windows, are characterized by high quality plastic, whiteness and gloss of the surface.

The thickness of the load-bearing walls and internal partitions complies with RAL standards for class A. This allows you to create welds with increased strength and extends the service life of the finished product.

Design 2D Series

This is the optimal balance of functionality and classic design. These are three- and four-chamber systems with a mounting width of 60 mm.

Design ideas thought out to the smallest detail in German SALAMANDER double-glazed windows can now be in your home.

High rates of thermal and sound insulation, as well as the ability to carry out all known types of glazing and an affordable price make it in demand on the market.

Design 3D - aesthetic perfection for stylish people

These are five-chamber profiles with an installation width of 76 mm.

The structure uses three sealing circuits, which ensures maximum thermal and sound insulation.

Customer reviews indicate that such windows are the best value for money.

Streamline - profile for modern times

Five-chamber windows with an installation width of 76 mm.

A design feature is the presence of a “labyrinth” of internal partitions, thanks to which static loads are distributed evenly over the entire section. This property is especially important when distributing loads in the area of fastening the handle and hinge group.

The SALAMANDER company positions the Streamline series as inexpensive, but high-quality and functional, therefore, accessible to a wide range of customers.

We offer you to purchase plastic windows with a 45% discount. Just call-1.

A little history and about the company

The German company Salamander Industrie-Produkte GmbH began producing Salamander plastic windows in 1973. During this time, the company acquired the status of a leader in this market segment. And this is easy to explain, because these window systems represent a harmonious combination of innovative ideas and unique design solutions. Even today, among the huge number of PVC windows, Salamander

will stand out not only for their representative appearance, but also for their excellent technical characteristics.

What is the success of Salamander

?

First of all, this is the strictest control over the quality of the profile. The company is very picky in choosing suppliers and places high demands on the source material. The company is constantly looking for new solutions and production technologies, and the introduction of the latest ultra-precise equipment ensures the high quality of its products. The production technology of these window structures involves the use of only patented plastic mixtures. All this together - elite plastic Salamander windows , which have unsurpassed thermal insulation and performance characteristics.

The prices for these windows are high, but even despite this, it is these PVC windows that have a monopoly in the segment of luxury plastic windows and are in constant demand. As for the design, it has distinctive features by which you can easily distinguish these windows from windows from other manufacturers.

Salamander plastic windows have soft lines of profile contours that are rounded with a radius of 5 mm. Another feature is the dazzling whiteness of the perfectly smooth, glossy surface of the plastic profile, obtained through extrusion. And what will especially please housewives is that these windows will not lose their perfect whiteness for a long time. In addition, with these windows you will have the opportunity to decorate them with decorative false frames.

As for the technical and operational features, they include, first of all, the highest quality plastic profile. Here you can add a large profile thickness, which allows you to install double-glazed windows up to 48 mm thick. In addition, the five-chamber Streamline

will provide you and your family with improved thermal protection and sound insulation.

Another feature of Salamander plastic windows is the sagging on the inner walls of the profile. It is they who ensure reliable fastening of the fittings, and also guarantee high protection of the entire structure.

The company's developers never cease to improve the best, so in the Streamline

labyrinth

has appeared , with the help of which static loads are evenly distributed across the profile cross-section, which especially effectively protects the areas where the handle and hinges are attached.

OOO " Windows SALAMANDER"

", having at its disposal more than 15 years of experience in the production of metal-plastic windows, we are ready to offer you products from the elite German

Salamander

.

All products « Windows SALAMANDER

"represents the best examples on the Russian market of PVC windows.

GU

and

MACO

fittings .

" SALAMANDER Windows

" has its own production base, equipped with modern equipment, which allows us to produce high-quality windows of any configuration.

Products « SALAMANDER Windows

"was highly appreciated by the

Salamander

and is proudly displayed at the

Salamander

during the annual

Windows-Doors

, which in itself distinguishes our products at a qualitative level from other

Salamander

.

Warranty provided by " SALAMANDER Windows"

“also highlights our products and confirms the reliability and quality of each design element: the warranty on the assembled product

is 3 years, the warranty on fittings is 10 years, the service life of the Salamander profile is more than 45 years.

Since 2005, Proizvodstvennaya has been offering its customers the option of offering windows at an even more affordable price.

Installation of plastic windows

Recommendation from Windows Salamander

Metal-plastic windows are designed for long-term use for 40 - 50 years. To avoid problems with them, it is necessary to be very careful in choosing the design itself and performing installation operations. Sometimes more depends on the method of window installation and the qualifications of the installers than on the quality of the structure itself.

Manufacturers of windows and other metal-plastic structures have developed certain installation technologies in walls made of various materials, which must be adhered to without fail. It will be quite annoying if the wall begins to freeze around a five-chamber profile with a two-chamber energy-saving double-glazed window or mold spots appear.

In Europe and Russia, special standards have been adopted that regulate the number, type and sequence of operations when installing plastic windows. In particular, GOST 30971. 2002 and GOST R52749 are in force in Russia. 2007 It is difficult to meet all the requirements of the standards, but it is absolutely necessary to focus on them - only in this case will the window serve properly throughout the entire stipulated period.

- Preparing the window opening

- Installing and aligning the window in the opening

- Formation of a three-layer assembly seam Gluing PSUL

- Filling the seam with foam

- Formation of the inner layer

- Window sill installation

Preparing the window opening

Work begins with preparing the window opening.

THIS PROCESS CONSISTS OF SEVERAL STAGES:

- Dismantling old windows.

- Removal of all types of seals and insulation.

- Construction waste removal.

- Aligning the walls of the opening.

Correct installation of plastic windows according to GOST is possible only if they are manufactured using industrial equipment and fully comply with previously taken measurements. Even at the stage of preparatory work, it is necessary to take into account the fact that the opening must be 2–5 cm wider and higher than the window structure, so that a full-fledged installation seam consisting of 3 layers can be formed there.

The easiest way is that if windows are installed in new buildings, one of the most difficult stages - dismantling - is eliminated. But in case of window replacement, it is mandatory. Removal of the old window begins with the removal of the sashes. As a rule, there are no difficulties at this stage if the frame is not completely rotten. In this case, you must first remove the glass so that it does not fall out when removing the sash.

The frame itself can be removed in several ways, including some that are very gentle, but time-consuming, allowing you to keep the frame intact and suitable for further use, for example, in a country house or as a load-bearing element of a greenhouse. Most often, the old frame is simply cut with a circular saw and removed piece by piece.

The opening is thoroughly cleaned of debris and remnants of old sealant. If there are recesses, potholes and cracks with a diameter of more than 2 mm on the walls of the opening, then GOST requires them to be sealed with plaster or putty mortar. Few people adhere to this point due to the fact that the plaster completely dries within 5 - 8 days, which is not entirely convenient. All this time the opening will be open. But you can use quick-drying gypsum or polymer mixtures, which will reduce the waiting period to several hours.

Installing and aligning the window in the opening

Correct installation of plastic windows according to GOST is possible only if they are manufactured using industrial equipment and fully comply with previously taken measurements. Even at the stage of preparatory work, it is necessary to take into account the fact that the opening must be 2–5 cm wider and higher than the window structure, so that a full-fledged installation seam consisting of 3 layers can be formed there.

The easiest way is that if windows are installed in new buildings, one of the most difficult stages - dismantling - is eliminated. But in case of window replacement, it is mandatory. Removal of the old window begins with the removal of the sashes. As a rule, there are no difficulties at this stage if the frame is not completely rotten. In this case, you must first remove the glass so that it does not fall out when removing the sash.

The frame itself can be removed in several ways, including some that are very gentle, but time-consuming, allowing you to keep the frame intact and suitable for further use, for example, in a country house or as a load-bearing element of a greenhouse. Most often, the old frame is simply cut with a circular saw and removed piece by piece.

The opening is thoroughly cleaned of debris and remnants of old sealant. If there are recesses, potholes and cracks with a diameter of more than 2 mm on the walls of the opening, then GOST requires them to be sealed with plaster or putty mortar. Few people adhere to this point due to the fact that the plaster completely dries within 5 - 8 days, which is not entirely convenient. All this time the opening will be open. But you can use quick-drying gypsum or polymer mixtures, which will reduce the waiting period to several hours.

The frame is fastened to the wall using anchors or special mounting plates, if provided. Naturally, before fixing the frame, it is necessary to dismantle the double-glazed window and remove the sashes. This will make aligning the frame and installing it much easier. Usually, a PVC window correctly manufactured on industrial equipment is very easy to disassemble into its component parts (except for the frame) and then put back together, having the necessary skills, of course.

For fastenings in the frame, holes for anchors are made from the inside using a drill - three on the vertical walls and two on the horizontal. Their diameter is 8–10 mm, depending on the hardware used. When drilling, a regular hammerless drill is used; a hammer drill is needed when preparing holes in wall material. If the wall is wooden or made of cellular concrete, then you can only use a drill.

The sequence of fastening is the lower anchors on both sides (not screwed in completely), then the upper and middle ones. At each stage, the plumbness of the structure is rechecked. When tightening the anchors, moderation should be observed - the frame is very easy to deform, especially in the middle part.

After fixing the frame in the opening, the supporting pads from the bottom are not removed; they act as a holding structure, partially relieving the load on the anchors. During installation, support pads must be installed along the edges of the frame and at the point of contact of the vertical middle post (impost) with the horizontal lower part of the frame.

Formation of a three-layer assembly seam

Professional installation of plastic windows in accordance with GOST requires a three-layer seam between the wall and the frame cut, which should ensure:

- thermal insulation

;

- noise protection

;

- vapor permeability

;

- waterproofing

.

1. Polyurethane foam

.

2. PSUL - vapor permeable layer

.

3. UGK - hydro-steam insulating tape

.

4. Stand profile

.

5. Support pads

.

6. Silicone

.

Several types of materials are used to form the seam - steam and waterproofing tape PSUL

(or sealant type

STIZ-A

), polyurethane foam, vapor barrier tape.

Pasting PSUL

Seam formation begins even before installation begins if PSUL

. It is glued around the perimeter of the frame or opening using a self-adhesive compound applied to the surface of the tape rolled into a roller.

This will achieve two goals at once - to create reliable protection against moisture penetration into the seam from the outside and to prevent the polyurethane foam from being squeezed out of the frame cut. The tape is produced in accordance with GOST 30971-2002 and was created specifically for arranging ventilated seams when installing metal-plastic structures. It is used only in combination with polyurethane foam. PSUL is made of polyurethane foam impregnated with special hydrophobic components and covered with a self-adhesive layer.

It is produced in a wide range of standard sizes, after gluing it expands on its own and completely fills the seam, sealing it.

Characteristics of PSUL:

- UV resistant;

- not afraid of frost and heat (temperature range for maintaining basic properties is 45 0C ... +85 0C);

- chemically inert;

- does not harden over time;

- water-repellent;

- not susceptible to biological damage (fungus, mold, mosses);

- has good vapor permeability (more than 0.15 mg/(m*m*Pa).

The tape is sold in rolls, ready for immediate use after unwinding. The adhesive layer has excellent adhesion to PVC and most wall materials, which must be dry and free of dust. It is recommended to treat porous materials with deep penetration primer.

The expansion rate of the tape depends on temperature. At + 30 0C it expands completely in 30 minutes, at zero temperature - within 48 hours. Therefore, when installing windows in autumn or winter, it is necessary to use a hair dryer at the minimum position of the heating regulator.

Filling the seam with foam

After installing the protective tape, the seam is sealed with polyurethane foam (polyurethane foam sealant). It is advisable to use professional PRO foams, which are sprayed using a gun. They provide proper material density after expansion and excellent thermal insulation, while their consumption is lower than household sealants sprayed from aerosol cans.

Manufacturers offer universal foam sealants in winter and summer versions. This definition refers only to the minimum air temperature at which they can be applied. Summer ones are used at temperatures above +5 0C, and winter ones can be sprayed at several (up to -10) degrees below zero. After polymerization (contrary to popular belief), they are no different in either mechanical or thermal properties.

When working with foam, it is necessary to take into account that polymerization occurs only upon contact with moisture. Before filling the seam with foam, all surfaces must be moistened, and after finishing, spray a little water around the perimeter. But it must be remembered that the foam expands up to 40% of the original volume (this means professional material), so it is not necessary to fill the seam tightly. If too much sealant is blown into the gap, then when it expands it can deform the frame.

In order to partially neutralize the loads arising during the polymerization of foam, it is necessary to fill the seams with it after installing all the sashes and double-glazed windows and moving the opening parts to the closed position.

When using foam sealant, you should remember that, regardless of whether it is professional or household, it is afraid of exposure to ultraviolet radiation and moisture from the air. In direct sunlight it deteriorates faster, in the shade - more slowly. But if you do not protect the thermal insulation layer from external influences, then after 2–3 years it will collapse and the cold will certainly penetrate inside the house along the perimeter of the window.

The external PSUL tape does not allow moisture or ultraviolet radiation inside, so nothing threatens the thermal insulation. At the same time, the structure of the tape allows excess water vapor to leave the thickness of the seam, it dries naturally, which also has a beneficial effect on durability. If there is no PSUL tape, then you can use special acrylic-based sealants.

One of the most popular and widespread is Stiz A, specially created for installation seams of metal-plastic structures. It is produced in white and brown colors and can be matched to any design. It has the same high vapor permeability as waterproofing tape and approximately similar other characteristics.

The composition hardens to sufficient strength that it can be painted or plastered, but also retains a sufficient level of elasticity to withstand temperature deformation and shrinkage within 15% of the joint thickness. Adhesion to aluminum, glass, plaster, concrete and other materials is not inferior to the adhesive layer of the tape. But only a completely dry seam can be sealed.

The thickness of the sealing coating is not less than 2 and not more than 6 mm. The sealant can also be used in the cold season, but before applying it it must be kept for several hours at room temperature. The composition is sold in completely finished form and is not diluted with water or other solvents. If there is a partial loss of plasticity, it must be heated.

Formation of the inner layer

The inner surface of the seam, from the room side, is sealed with SAZILAST 11

(

StizV

). It is created on the basis of polyacrylates and, after drying, forms a vapor-proof layer similar to soft rubber. It protects the seam from penetration of moisture from the room. The sealant has excellent adhesion to putty and plaster compounds; installation of slopes will not cause problems.

In addition to sealant, for the internal coating of the seam, you can use one of the varieties of special vapor barrier tapes, both foil-coated and polymer-based. If the slope will be formed using plaster compounds, then before purchasing the tape you need to study the instructions for it, determining the level of adhesion to them.

True German VEKA quality

Premium German brand on the Russian market since 1995. With VEKA you get true German quality from a company with a 48-year history around the world.

- ALL profile systems of the highest class “A”

- ALL are made frost-resistant and marked with the letter “M”

- ALL have maximum 4-sided steel reinforcement

- Uniform quality standard regardless of country of production

The more air chambers, the less air exchange and, accordingly, the higher the thermal insulation.

The wider the profile and the greater the installation depth, the higher the thermal insulation.

Salamander 3D (Salamander 3D)

This class “A” system, which is called, has an installation depth of 76 mm and 3 sealing circuits.

Window blocks made from Salamander 3D profiles can be used in regions with harsh climatic conditions. Their heat transfer resistance coefficient, provided energy-efficient double-glazed windows are installed, is 1.2 W/m²×°C, and the third sealing circuit reliably protects against blowing even in strong winds. Since the rebate is ventilated through a separate and completely insulated chamber, which also drains water, the frames are additionally protected from freezing. Although the basic Salamander 3D system was developed back in 1998, this line is still in demand among consumers. Rounded external contours give the windows elegance and make them stand out from the general background. Perfectly smooth profiles are very easy to care for, since dirt does not accumulate on their glossy surface. Thanks to the availability of two modifications of the Salamander 3D systems, you can order 5 or 6-chamber windows with rounded or semi-offset sashes.

Profiles ONLY of the highest class “A”

According to GOST 30673-99 “PVC profiles for window and door blocks” in terms of the thickness of the internal walls, ALL of our profiles are the highest class “A” - the thickness of their front wall is at least 3 mm.

GOST standards for different classes:

- class “A”: front wall not less than 3.0 mm

- class “B”: front wall not less than 2.5 mm

- class “C”: wall thickness is not standardized

Please note that 80-90% of the Russian market are classes “B” and “C” and only 10-20% are class “A” profiles. At the same time, VEKA’s assortment includes ONLY class “A” profiles.

We fundamentally DO NOT use profile systems of classes “B” and “C” (with a front wall width of less than 3.0 mm).

Salamander SL (Salamander Streamline)

Systems from this series are used to assemble windows with a modern technological design.

The installation depth of StreamLine profiles is 76 mm, and the burglary resistance class of structures made from them belongs to category C4/B4. These systems are suitable for the production of large blocks that are equipped with wide sashes. They are used to assemble tilt-and-turn, swing and tilt windows. In addition to the basic white color, the profile manufacturer Salamander Streamline offers many options for painting and lamination. The thickness of the outer walls of these systems belongs to class “A”, so it is 3 mm. Salamander Streamline windows can have 2 or 3 sealing contours made of gray or black elastic seals. The SL series profile is suitable for the manufacture of heavy sashes weighing up to 120 kg. According to the manufacturer’s classification, these systems are assigned the “Comfort” status.

ONLY frost-resistant profiles

According to GOST 30673-99 “PVC profiles for window and door units” for resistance to climatic influences, ALL of our profiles are “frost-resistant” - for areas with an AVERAGE monthly air temperature in January BELOW minus 20°C.

GOST standards for different classes:

- normal version “N”: the average temperature in January is minus 20°C and above

- frost-resistant version “M”: the average temperature in January is lower than minus 20°C

Our assortment includes ONLY frost-resistant profile systems marked with the letter “M”.

Heat transfer resistance (thermal thermal resistance) is the main thermal insulation coefficient. It is determined by the ratio of the temperature difference between the outside and inside the room to the heat flow passing through the window. The higher this number, the better the insulation performance.

Summary table for comparing the main parameters of Salamander windows

To order the most suitable Salamander PVC windows for specific operating conditions, we recommend that you study and compare the main parameters of the systems in detail. This will help not only to choose the optimal model, but also not to overpay for unnecessary characteristics.

| Profile type | Installation depth (mm) / Number of chambers | Maximum glass thickness (mm) | Heat transfer resistance coefficient with steel liners in profiles (W/m²×°C) | Achievable sound insulation level (dB) |

| Salamander SL | 76/5 or 76/7 | 48 | 0,91 | 46 |

| Salamander 3D | 76 / 5 | 48 | 1,2 | 46 |

| Salamander BluEvolution 82 | 82 / 6 | 52 | 1,09 | 47 |

| Salamander BluEvolution 92 | 92 / 6 | 60 | 1,25 | 47 |

In order for windows from Salamander profile systems to have the characteristics declared by the manufacturer, the owners of the German brand recommend equipping them with MASO fittings. These Austrian opening mechanisms are able to withstand the weight of heavy sashes and make structures difficult to break into.

Evolutionary double-glazed windows SmartGlass 2.0

Our multifunctional double-glazed windows work for you both in winter and summer. In winter, the spraying of silver particles retains up to 90% of the thermal energy of heating devices, and in the summer, a double-glazed window reflects 25% more solar heat than conventional plastic windows.

- 42% more HEAT in winter (energy saving properties)

- 25% less HEAT in summer (sun protection properties)

All our double-glazed windows contain special energy-efficient glass. We DO NOT use regular glass even in the most basic configurations.

Salamander bluEvolution 82 (BluEvolution 82)

Energy-saving systems BluEvolution 82 Premium class have 6 chambers and an installation depth of 82 mm. Windows assembled from these profiles are recommended for glazing private houses and country cottages, since their use reduces heating costs. The possibility of freezing of frames is eliminated by the increased installation depth of the profiles. BluEvolution 82 is suitable for the production of active sashes with the following parameters:

- maximum height – 2300 mm;

- maximum weight – 120 kg;

- maximum width – 1400 mm.

This Salamander window profile is equipped with frost-resistant seals in black and gray. Two sealing circuits are enough to prevent blowing and moisture from entering the premises. The grooves in BluEvolution 82 systems are designed to accommodate thick double-glazed windows, which increases the level of sound insulation of structures and makes them even warmer. Salamander plastic windows with energy efficiency class A++ are assembled from such profiles.

AirDrive I, II and III climate control systems

Optimal ventilation mechanisms are built into the windows - the sashes open slightly by 1-5 mm, depending on the selected mode.

These are NOT external devices (combs or valves), but BUILT-IN ventilation fittings. Three options:

- AirDrive I: slot ventilation (1 mode)

- AirDrive II: discrete multi-stage ventilation (3 modes)

- AirDrive III: discrete multi-stage ventilation (5 modes)

We try not to place combs based on their appearance (only at your request). In principle, we do not use valves due to the fact that they violate the integrity of the window, reduce its tightness and strength (since the profile and its reinforcement are drilled through).

Reviews about Salamander windows

When choosing windows, it is useful to study not only the thermal characteristics of the systems, but also to get an expert opinion about the products.

To better understand what the Salamander profile is, reviews should be considered from both professionals and ordinary consumers. Such an assessment will be the most complete and objective. Vasily Nikolaevich Stoychenko (driver):

“

Several years ago I was replacing old plastic windows, and on the recommendation of a security guard from our company I chose the Salamander 3D profile. Absolutely everyone liked the windows from it. They look beautiful and solid and convey a feeling of reliability. The apartment has been warm and quiet for 3 years now. The windows don’t blow through, and we don’t know of any problems with fogging.” Igor Yurievich Pristavkin (builder): “Our company is engaged in the construction of country cottages. We have been installing Salamander windows for a long time, reviews about them have never been negative. This is the reason why we always prefer this popular German brand. Due to the peculiarities of operation in the private sector, windows must be very warm and quiet at the same time, so the best system was chosen for their assembly - bluEvolution 92.” Image source – Salamander official website