To use a balcony or loggia as a full-fledged living space, it must be insulated. This can be done using various materials, but if you are looking for the highest quality and easiest to use, you should use polyurethane foam. So that you can use it to furnish your own apartment, let’s look at how to insulate a balcony or loggia.

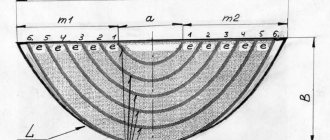

Three-dimensional panorama of PPU balcony insulation

Imagine what your balcony or loggia will look like after insulation with polyurethane foam. At the Customer’s request, our specialists help to correctly plan the thermal insulation system. Pay attention to the spaciousness of the room: the insulation does not take up excess space. More details about the work of the master in our portfolio.

Fire resistance

We use fire retardant coating, thereby ensuring a high degree of safety.

Environmental friendliness

The insulation does not contain volatile components, therefore it is considered an environmentally friendly product.

Economical

Due to high-quality polyurethane foam insulation, we enable the customer to significantly minimize energy costs and save space.

Advantages of polyurethane foam for thermal insulation of balconies and loggias

- Effective thermal insulation when applied in thin layers

. In terms of insulating properties, 5 cm of polyurethane foam corresponds to 15 cm of mineral wool. Such high efficiency, even when applied in a thin layer, helps to ensure a comfortable temperature on the loggia or balcony, maintaining maximum free space. - Resistance to biological threats and other external factors

. Polyurethane foam is not covered with fungus and mold, and is not damaged by bugs. It is also resistant to dampness, temperature changes and other influences, which together ensures a long service life.

- Low moisture absorption and high vapor barrier properties.

PU foam absorbs only 2–4% of water (for comparison, for mineral wool this figure reaches 18%). It also provides good vapor barrier. These properties make it possible to avoid the use of additional moisture-proof materials, which reduces the cost and simplifies the work. - Safety in operation

. Polyurethane foam does not contain formaldehyde and other similar substances that are harmful to health. It is slightly susceptible to combustion, which helps ensure fire safety and allows the material to be used in residential buildings (houses, apartments).

VIDEO: The process of insulating a balcony with polyurethane foam.

Insulation of PPU loggia: pros and cons

Polyurethane foam is a modern, exceptional, special insulation material of the 21st century, which has a minimal thermal conductivity rate compared to other materials made from synthetics.

Advantages of spraying polyurethane foam

Internal thermal insulation of a balcony requires a competent approach to the selection of materials. They must be breathable, non-toxic, occupy a minimum of space, and have high heat-saving characteristics. According to these and other indicators, polyurethane foam is successfully ahead of its competitors:

- the possibility of applying a thin layer with minimal heat loss - 5 cm of polyurethane foam provides the same thermal insulation as 8 cm of expanded polystyrene, 12 cm of mineral wool, 1.5 m of brickwork;

- absence of joints and cold bridges - when the sprayed material hardens, it turns into a single monolith covering the walls, floor, and ceiling;

- saving on parabarrier - with a thickness of 5 cm or more, polyurethane foam itself acquires vapor barrier properties;

- there is no need to install a windproof film - thanks to the structure with closed air cells, the polyurethane foam is not blown by the wind.

Installation of polyurethane is carried out in 2 stages:

- thermal insulation;

- sealing holes and cracks.

The insulation process always begins with the surface of the floor covering. It must be covered with a thin layer of adhesive, on which the insulation should be laid. Thermal insulation panels can optionally be mounted end-to-end or with bandaging, and the joint must be glued. And after completing the previous work, the floor covering is applied using a cement screed with reinforcement.

PPU ceiling insulation

The ceiling and walls are insulated using three-layer construction technology, which guarantees excellent thermal insulation of the room. Using dowels and PPU glue, the panels are attached to the insulated plane. After this, they are covered, for example, with finishing plasterboard, using special glue. At the final stage, all cracks are closed.

Why should you choose polyurethane foam as a heat insulator:

- environmental friendliness;

- small thickness;

- excellent adhesion to other materials;

- low level of water absorption;

- Compared to classic insulation options, they have minimal thermal conductivity.

Material characteristics

Forms made from this material have good flexibility and reliability, and due to special fillers, excellent wear resistance. Frames will allow you to create products from all kinds of building materials.

Advantages of polyurethane foam:

- Long-term operation.

- Low viscosity.

- Slight shrinkage.

- Does not deform.

- Increased strength.

- Immunity to high and low temperatures.

- Immunity to acid and alkali.

Characteristics of polyurethane Structures made from liquid polyurethane foam are characterized by performance for 2 years. Among the advantages it should be noted:

- Products made from this material are distinguished by their increased imitation of natural coatings.

- There will be an option to use materials that perfectly imitate the relief of natural surfaces.

- Due to the internal surface of the products, different shades of the product are obtained, creating a blurred effect.

- The finished product has a clear geometry and low weight, which makes for design and easy installation.

- Molded products do not require various auxiliary facing works.

In terms of its own quality parameters, such a material will be superior to metal and rubber. Brittleness occurs at a temperature of -60 degrees. The material is destroyed during heating above 100 degrees (a number of brands at + 150).

Preparatory work

Initially, you should clean the surface of the ceiling and walls from old coatings. This stage of balcony insulation is extremely important, because to perform high-quality work you need an ideal foundation. To remove old putty or paint, you can use a spatula or other sharp tool.

Remember, you should never leave remnants of plaster or paint on the surface, because... it will crumble during operation. And if the wall and ceiling are cleaned thoroughly, then excellent adhesion of polyurethane foam is guaranteed.

Insulation of the loggia with polyurethane foam

Benefits of use

As an insulation material, polyurethane foam has no equal. Apartment buildings and private buildings emit heat into the atmosphere all the time. An examination with a thermal imager - a device that records thermal radiation - showed that balconies, loggias and walls of modern buildings lose up to 35% of the heat received as a result of heating. Insulation with polyurethane foam can reduce these losses to 5-7%.

Considering how quickly current homes are acquiring heating meters, the undoubted benefits are obvious. It is estimated that owners of private houses who used polyurethane foam as insulation recovered its cost in 8-10 years, saving on heating costs.

Installation of lathing for insulation

Sheets of extruded polyurethane foam have significant dimensions, so to securely and correctly fix them, it is necessary to install a supporting frame made of wooden slats or a special metal profile.

- To make the sheathing, we use beams with a height corresponding to the thickness of the selected polyurethane foam sheet. They are attached to the base surface of the walls and ceiling in increments of no more than 50 cm.

- Using a building level and wooden spacers, it is necessary to align the beams in the same plane to prevent the wall from getting “wavy” during finishing.

- The wooden elements of the supporting frame are fixed using quick installation or small dowels.

How to insulate a balcony with your own hands - step-by-step instructions

- Clearing the premises. It is impossible to do quality work if you have to constantly move things from place to place.

- Sealing cracks. We assume that high-quality double-glazed windows are installed on the windows. In any case, there are gaps between the balcony and the wall, where the ceiling and floor meet. So they need to be sealed using foam, sealants or solutions. Large gaps are sealed with pieces of polystyrene foam.

- Waterproofing of balcony/loggia. It is necessary to prevent water from getting inside. Moreover, it can enter through micropores in concrete. For this purpose, you can use a deeply penetrating primer.

- If cotton wool is used, it is necessary to install a waterproofing film. It is overlapped and secured with tape.

- Installation of insulation. There are two methods here:

- Frame method. In this case, you must first equip the frame from antiseptic-treated wooden boards or galvanized profiles. Boards are more popular because they are cheaper and allow you to adjust the thickness of the frame. The most commonly used timber is 50x50. Insulation is inserted into the resulting cells.

- Frameless method. More preferable, but suitable only for rigid insulation. This is due to the fact that the frame material with the frame method remains uncovered with insulation. That is, wood or metal serve as cold bridges and conduct heat well. Therefore, in the vast majority of cases, rigid insulation is installed without constructing a frame.

- Laying penofol, vapor barrier film or superdiffusion membrane.

- The floor is insulated.

- The final stage is decorative finishing of the balcony with wooden paneling or plasterboard.

Ceiling insulation

It is advisable to start work on insulating a balcony using PPU from the ceiling. It is recommended to carry out them in the dry, warm season - during this period the waterproofing dries faster and better.

If you decide to use polyurethane foam as thermal insulation, you need to purchase or rent special equipment for its installation. Such an installation can be purchased at any hardware store. It consists of two connected cylinders equipped with a spray gun. This installation always includes several attachments that can be used to perform various types of work.

Insulation of walls and parapets

The technology for insulating a PPU balcony is not complicated. The owner of the apartment needs to prepare the surface for applying polypropylene foam, remove all old plaster, and treat the walls with a primer (especially if the humidity level in the room is high). Then you need to install the sheathing and spray polyurethane foam evenly over all the walls. After this, you will need to wait for the material to dry completely and install the topcoat. At the last stage, sockets, baseboards, and trims should be installed on the walls.

There are no requirements for the thickness of polyurethane foam when finishing walls and balcony parapets. You can make it the same as when insulating the ceiling - 4 cm. On loggias you can make a thinner layer of material - only 2 centimeters.

Finishing interior decoration

Decorative or finishing does not always serve simply as a finishing coating or interior decoration. Some materials also act as insulation.

The difference is easy to understand if you compare two materials for wall decoration: acrylic paint and cork panels. The first simply changes the color of the wall covering and, possibly, protects it from moisture, corrosion, and mold. Cork is good heat and sound insulation.

Let's consider the most popular options for a balcony, which ideally hide the insulation and themselves, at least partially, insulate the room from the cold.

Image gallery

Photo from

Wooden lining and boards

Plastic lining or panels

Sheets of moisture-resistant plasterboard

Decorative stone or tile

In addition to the listed facing materials, cork panels are used, which are easily and simply mounted with acrylic glue.

A laminate is suitable for the floor, which also creates a thin, but heat-insulating layer. Ceramic tiles, on the contrary, cool the surface if they are not heated from below by a “warm floor” electric cable.

The following article will introduce you to the specifics of carrying out work on thermal insulation of a loggia, which we highly recommend reading.

Finishing work

The next day after treatment, they begin laying the concrete screed over the reinforcing mesh, and install a cable or infrared heated floor on the concrete.

Perform finishing operations:

- installation of ceramic floor tiles;

- covering the frame with plasterboard or clapboard;

- gypsum board putty or lining varnish;

- gluing wallpaper on drywall (or painting it);

- grouting tile joints;

- installation of skirting boards;

- installation of sockets and switches.

A distinctive feature of thermal insulation of a balcony or loggia by spraying polyurethane foam is the speed of the procedure. Professionals perform it in no longer than an hour, and the surface is ready for further finishing within a day.

Preparation

Before carrying out work, it is necessary to prepare the balcony. The number of preparation stages is determined by the state of the building, the building materials used and the selected installation technology.

Preparatory work includes the following steps:

- Cleaning things and furniture from the balcony.

- Removing or installing new fencing is usually required in older buildings.

- Construction of a parapet or its strengthening. It is convenient to use foam blocks for construction.

- Sealing cracks. In most high-rise buildings, the loggias are not initially glazed, but even after glazing there are many gaps left. They can be located at the junction of the slabs, between the floor and the wall. They should be sealed with foam.

- Strengthening and leveling the concrete slab.

After completing the above operations, installation begins. This may require preliminary installation of waterproofing.

Laying the insulating layer

When insulating the walls of a balcony, a layer of foiled polystyrene foam is first laid on the outside. Pre-cut sheets are fixed using disc-shaped dowels and polyurethane glue. Metal hangers are attached on top of the heat-reflecting layer, and they additionally fix the insulator to the wall surface. All seams and holes are covered with metal tape.

Next begins the careful laying of a thicker layer of heat insulation - extruded polystyrene foam. Holes for aluminum hangers are pre-made in the foam sheets. It is necessary that the gaps between the sheets be minimal.

After installation is completed, in which the foam sheets are attached simultaneously using glue and fastening materials, all joints are carefully treated with polyurethane foam. The same goes for the holes around the hangers. You can further enhance the seal by covering the foam, after removing its excess, with a layer of metal tape.

Next, another layer of heat-reflecting foil foam is laid on the outer wall of the balcony. All seams and holes are again covered with aluminum tape. When thermally insulating the internal and side walls of a balcony, you can limit yourself to just two layers: foil foam and extruded thick polystyrene foam.

Balcony insulation by spraying polyurethane foam

Most apartments in apartment buildings have balconies or loggias, which are skillfully used as additional space for storing equipment, things or vegetables.

They are connected to living rooms and expand the kitchen space. In each case, the requirements for room temperature determine the conditions of thermal insulation, however, it is almost impossible to insulate a balcony from the outside; this is hampered by many restrictions that require official approval for changing the facade on a single balcony.

The installation of thermal insulation from the inside from slab or roll materials takes up a significant area due to the need for lathing to fix the insulation and fastening, but the biggest problem arises during operation.

The penetration of warm air through leaky joints and abutments of insulation sheets causes the formation of condensation and wetting of the insulation, which inevitably entails a loss of heat-insulating properties. The funds have been spent, but it doesn’t get any warmer, as if there was no insulation at all.

Spraying polyurethane foam is the right solution for insulating a balcony

The technology of spraying polyurethane foam (PPU) is an effective alternative to a multi-layer insulation system made from roll and sheet materials with high labor costs.

For comparison, a 20 mm thick polyurethane foam coating is equivalent in thermal conductivity to 500 mm brickwork. Today, none of the existing thermal insulators has such a low thermal conductivity, an average of 0.025 W/Mk.

The uniqueness of sprayed insulation

The uniqueness of polyurethane foam lies in the technology of forming a seamless protective coating when sprayed directly onto the insulated base. The foam mass with excellent adhesion fills all irregularities and voids, hermetically adhering to the insulated surface. Its universal properties eliminate the need for moisture-proof insulation and provide additional noise and wind protection properties.

Main advantages

PPU insulator is not an allergen, has no impurities and is an absolutely safe material. A durable and very light material with low density, it replaces all types of joint insulating coatings, which eliminates the risk of making balcony structures heavier and makes it economical to use.

Seasonal temperature and humidity fluctuations do not affect the properties of PU foam insulation and do not destroy its structure and shape.

Insulating a balcony or loggia using Ecotermix polyurethane foam spraying will save your money and create additional conditions for a comfortable stay. Information about the cost of work and materials can be obtained by calling the numbers at the top of the site.