How to soundproof a balcony roof from rain.

A glazed balcony is a fairly practical solution than an unglazed one. This is expressed in the fact that you can not only store rarely used things, but also have a pleasant pastime. But good glazing is not complete without creating a roof that not only protects against leaks and the formation of mold/mildew, but can also cause unpleasant noise. Let's look at what can cause noise, and how to eliminate this phenomenon on your own.

Requirements for soundproofing materials

You can make a soundproofing finish for an iron roof using various materials. There is no universal remedy; each case requires an individual approach. Main selection criteria:

- Strength. The product must maintain its integrity under mechanical stress.

- Lack of response to changes in humidity levels and temperature changes.

- Resistance to ultraviolet radiation. The material must not decompose or release toxic substances when heated.

- A product of sufficient thickness will help make the balcony silent.

- A simple and reliable fastening can facilitate the process of soundproofing a roof.

Fulfillment of all conditions will ensure the reduction or complete disappearance of sounds from rain and wind.

Choosing soundproofing material for the roof

When selecting soundproofing materials, the main criteria to be followed are two parameters: the first is the sound absorption index and the second is the dynamic modulus of elasticity. Each of them significantly affects the quality of sound insulation.

Noise absorption index

shows how much of the sound waves were absorbed by the material. Good quality insulated roofing material has a noise absorption index of at least 0.6. For example, the index of wood is 0.08-0.16, foam plastic is 0.16-0.26, but mineral wool has an index of 0.65-0.8. Therefore, mineral wool and ecowool (cellulose insulation) are considered the best soundproofing materials. They create a reliable thermal barrier and at the same time protect the house from extraneous noise. Polystyrene foam cannot be recommended for roof sound insulation.

Dynamic modulus of elasticity -

second parameter. It characterizes the elasticity of the material. The lower the value of this parameter, the higher the sound-absorbing properties of the material. In other words, dense material reflects sounds better than loose material. If you compare, for example, the sound-reflecting properties of fiberglass boards and polystyrene foam, you can see that the first insulators are better than the second.

External sound insulation technology

The work has to be done outside, with all the difficulties that arise. Before starting the operation, it is better to consult with the service organization. If you don’t need permission to change the facade of the building, then you can start. The work order is as follows:

- inspection of the roof’s load-bearing structure and identification of possible deficiencies;

- strengthening or repairing rafters or other roofing bases, if necessary;

- installation of sound-absorbing materials.

As the main material you can use euroroofing felt, soft roofing, bitumen shingles, vibration-absorbing mastics, roofing tapes. If the work on soundproofing a balcony is done correctly, then the inhabitants of the home and their neighbors will be free from noise for many years.

A soft roof will completely eliminate the noise of rain

Floor insulation

The initial stage of insulating the balcony floor is installing waterproofing on the surface. Polyethylene or penofol will do this role perfectly. Be sure to hide all seams between sheets with tape. This way you can be sure that the balcony is protected as much as possible from dampness.

Another popular option for waterproofing balcony floors is bitumen mastic. However, do not forget that such material dries for about 24 hours.

After waterproofing, you should install a frame or, in other words, logs. For this, wood or metal is used. The main thing is to choose the highest quality material that can last for many years.

The beams are laid at a distance equal to the width of one sheet of insulation. As for the height of the beams, it is usually 10-15 cm. To prevent gaps that appear between the logs and the balcony wall, ordinary polyurethane foam is used.

After installing the logs, you can proceed directly to installing the insulation. Make sure that there are no even the smallest gaps between the sheets (or slabs) and the frame. Otherwise, your work will not bring the desired result. In some cases, the insulation is laid in several layers (for greater protection)

Then it is important that the seams between the plates are not in the same place. That is, the material needs to be laid with a slight offset

Additional work on soundproofing the balcony

In addition to the roof and canopy, the source of extraneous sound is often other structural elements that you should also pay attention to:

- Low tides. Even with a slight wind, precipitation is blown under the visor, which, despite its small size, is capable of producing a fairly loud sound;

- Elements of the drainage system passing in close proximity to the window. In most cases, minor noise does not bother the dwellings, but some designs of sediment drainage pipes can produce an unpleasant sound;

- Remote ventilation, air conditioning and heating systems.

The technology for installing sound insulation of the above noise sources does not differ fundamentally from similar work with a roof, however, it should be remembered that some elements carry a functional load and in order for them to work properly, you should choose a sound insulation option that will not interfere with their full operation.

Glazing of an external balcony or loggia involves the installation of a roof for protection from precipitation. One of the popular materials for its manufacture is metal profile sheet, which is light weight, high strength and aesthetic appearance.

But the lightness of the structure and the material of manufacture (galvanized steel) negatively affect the noise characteristics of the shed roof - the presence of birds on it, the roar of rain or water droplets from the air conditioner above often interferes with comfortable living in a residential area. Sometimes the canopy on the balcony rattles, but not everyone knows how to silence it. When deciding what to do in this case, you should bring to the fore not the insulation of an external canopy, canopy or ebb, but its sound insulation using modern building materials.

Reasons for loud sounds from metal balcony railings

An improperly secured balcony canopy makes noise due to gusts of wind.

When glazing and finishing balconies, you need to take the issue of soundproofing the room very seriously. What can cause vibration of metal structures and therefore loud noise?

Improperly secured roofs and canopies of balconies and loggias can vibrate from gusts of wind and precipitation on their surface. It’s not for nothing that in theatrical productions vibration of a sheet of iron is used to simulate thunder. Likewise, with any vibration of the sheet covering, discomfort arises from the occurrence of strong noise.

The canopy must fit tightly to the balcony

The occurrence of loud sounds from metal vibration can have several reasons:

- Lack of correct tilt of the visor, as a result of which the increased windage of the structure will cause noise from the slightest breath of air.

- Unreliable fastening of structures will be reflected in its vibration from raindrops and wind hitting the surface.

- The presence of leaks in the places where the canopy adjoins the balcony can cause not only rumbling sounds, but also the whistling of the wind in the cracks of the structure’s fastening.

- Excessive extension of the canopy or roof beyond the balcony fence causes the effect of vibration of a pinched large sheet.

Balconies on the top floors of houses with a concrete top slab do not need soundproofing of their roof.

Noise insulation of a canopy made of a metal profile must be provided at the installation stage

The situation is different with balconies with equipped roofs made of metal profiled flooring, galvanized steel sheets and metal tiles.

Of course, you need to take care of the sound insulation of the iron roof of the balcony during their installation. But what to do when the finishing is finished, and the resulting noise from the metal fence of the glassed room haunts neither the apartment residents nor the neighbors?

What materials can be used to soundproof metal balcony structures? We will try to give answers to these questions in a popular form.

This is interesting: How to make a hip roof and its design: diagram and design of the roof and its rafter system

Selection of required materials

Soundproofing of a balcony roof is carried out using various materials. In each individual case, the optimal noise blocker is determined taking into account all the features and details. Selection parameters:

- Resistance to ultraviolet rays. Heating should not provoke decomposition of the material and make it toxic;

- Strength, the ability to maintain an intact structure under any influence;

- The thickness of the product should be such that the balcony is as quiet as possible;

- Resistance to moisture, temperature changes;

- Simplicity and reliability of fastenings. This will ensure structural strength and noiselessness.

Properly selected materials will help reduce noise or completely eliminate extraneous sounds caused by natural factors.

Building materials used as sound insulation for the roof of apartment balconies.

In practice, the following soundproofing materials are used:

- Izolon. The self-adhesive polyethylene backing makes it easy to attach the tape. The material meets all the requirements to ensure complete noise and heat insulation;

- Titanium tapes based on bitumen are an expensive material, but very durable and of high quality. Soundproofing a balcony is most effective when applying several layers. When carrying out such work in cold weather, the tape must be heated with a hairdryer. To ensure sealing of the roof covering, the joints are treated with sealant;

- For sound insulation, you can use vibroplast (foil material). Despite the fact that this material is used mainly for cars, it has also found its application in soundproofing balconies. It successfully eliminates the sounds generated by rain. However, due to its high cost, few choose it for construction work.

Sound insulation installation options

The roofing material is supplied with a ready-made decorative layer on the front side, and most soundproofing methods involve working on the back side. Sound insulation is installed from the inside and does not pose a danger to the technician.

Despite the fact that roofs with sound-absorbing coating on the outside are most effective, in practice, in the vast majority of cases, you have to deal with an existing problem and look for optimal ways to eliminate it.

The polycarbonate canopy has good sound-absorbing qualities and transmits light

What to use for soundproofing

The choice of sound insulation for a balcony roof is determined by the type of roofing, as well as the exact method in which the process of eliminating excess noise will be carried out. The material can be laid from the inside or outside. The following product options are most often used to solve emerging nuances:

- "Izolon";

- "Vibroplast";

- mineral wool;

- bituminous material.

The first version of sound insulation is made on the basis of polyethylene, which undergoes a foaming procedure. Thanks to this, the base layer is saturated with air bubbles, which do an excellent job of sound insulation. One or two surfaces are covered with foil. This allows you to increase the reflective properties of the canvas. Izolon, which is used for sound insulation, is produced in slab format and in rolls. The product option is selected depending on specific conditions. The thickness of the base can reach 5 cm and the width of two meters. “Izolon” is suitable for internal sound insulation; it is fixed to the surface using an adhesive composition.

The advantages of the material are its long service life, which can reach 80 years. The level of noise reduction depends on the thickness of the material used, the average is 20 dB. The product tolerates temperature changes well. The lower operating limit is -60 degrees Celsius, and the upper limit is +120. Another advantage is elasticity, which simplifies the processing of surfaces of complex shapes. Izolon can act as insulation, reducing heat loss. The disadvantage of implementing sound insulation using such a base is the lack of vapor permeability.

“Vibroplast” is not a completely standard material for household use. This is professional sound insulation, which is used in cars. Nothing prevents it from being used for a balcony roof. There is already a layer of adhesive on the surface of the product, which greatly facilitates the procedure. The material is based on bitumen and auxiliary substances. The product is produced in sheets with a thickness of up to two centimeters. The front side is covered with foil. Some types of Vibroplast require the use of a technical hair dryer for high-quality gluing. Other options are cold glued to the balcony roof. Thanks to its flexibility, Vibroplast fits perfectly onto any suitable surface. The weight of this material is slightly greater than the previous one, so it is necessary to count on an increase in the weight of the roof. The disadvantage is the possibility of peeling off from the metal roofing due to strong heat from the sun.

Various bitumen tapes can be used as external and internal sound insulation for the balcony roof, which often also have a layer of glue applied and therefore do not require additional tools for installation. The disadvantage of such products is the specific smell that appears when heated. Ordinary mineral wool can serve as an insulator for the roof on the balcony. Most often it is used to implement insulation, but due to its density and other characteristics it perfectly absorbs sound waves. The fixation method will depend on the rafter system used and the material from which the roof is made.

Thermal insulation device for “warm floors”

Since water heating of balconies is prohibited in apartments, electric “warm floor” remains the only possible option. Heating cables, heating mats or infrared film emitters are used.

The first 2 types need to be integrated into the cement-sand screed. To do this, EPS sheets are laid on the balcony slab, then foil insulation. The cables are fixed using mounting tapes in increments of 6 to 12.5 cm. If mats are used, they are simply laid out on the surface. The wires are connected to the power supply through thermostats using couplings. A screed with a thickness of 40 mm for cables or 20 mm for heating mats is poured on top. You can turn on the heating only after 28 days. The best flooring for such floors is ceramic tiles.

The heating of the balcony will begin much faster when using infrared heated floors. They are laid on a finished screed, with laminate, carpet or linoleum on top. In terms of energy consumption, such heaters are more economical than cable heaters, but it is not recommended to lay tiles on them.

What to do if the canopy on the balcony rattles

Typically, soundproofing a balcony is carried out together with other sets of work - glazing, insulation and sealing. You need to remember about issues related to the canopy at the very early stage of the above work, because otherwise you will either have to live with noise at the window, or call people to perform high-altitude work (which is quite expensive), or start the process of upgrading the balcony all over again. Here are the following tips with which in certain situations you can solve the problem: a radical, but not very simple solution is to completely replace the iron structure in favor of a plastic one, since this option completely eliminates any extraneous noise. If possible, you can cut the visor so that it does not stick out so much and, accordingly, has a smaller area without a frame.

Troubleshooting options

As a rule, sound insulation is included in a set of measures when glazing a balcony, when the roof is insulated and sealed. A well-organized process provides protection from external sounds in adverse weather conditions. But if the work was carried out poorly and the roof on the loggia or balcony periodically begins to make noise, there is a need for additional sound insulation. The method for solving the problem directly depends on the cause of the extraneous sounds.

The most commonly used measures are:

- The canopy is soundproofed with soft polymers designed to reduce the sound of raindrops.

- In case of poor-quality fixation of the roof, additional strengthening of the structure is carried out.

- Change the angle of the canopy on the balcony.

- Incorrectly selected visor parameters require trimming.

Drastic measures include complete replacement of the metal visor with a plastic structure. It is easier to soundproof a loggia than a balcony. Typically, only the front part needs insulation, and the sides are left unchanged.

Causes of increased noise from a balcony roof

In addition to the material itself for making the external roof, increased noise is caused by some mistakes made by construction workers when installing the canopy; the most common ones include the following:

Small slope

A downpour with raindrops falling at right angles causes a lot of noise; their smooth sliding along an inclined plane is quieter.

Poor installation

Insufficient strength of the canopy fastening with a small number of transverse and longitudinal stiffeners causes increased vibration (windage) during gusts of wind and falling raindrops - all these factors cause increased noise.

Loose fastening

First of all, this applies to joints at joints and along the edges of the structure - savings on mounting foam and fasteners leads to free movement of coating sheets under the physical influence of precipitation and air masses - this causes noise. Wind often gets into the cracks of a loose connection - its whistle can become an additional irritating factor.

Design errors

The desire to better protect the balcony window frame from precipitation leads to an unjustified increase in the coverage area and, accordingly, the level of noise it creates. This often happens when installing a roof covering with your own hands without studying the correct technology for carrying out the work.

Waterproofing a balcony in a house: the need for

Hydroprotection is a set of measures aimed at creating a protective layer (barrier) against the penetration of moisture into the balcony and its structure. High-quality sealing (waterproofing) of an open balcony with your own hands is needed not only on the floor, but also on the walls, partitions, if any, and on the ceiling.

The arguments in favor of finishing the balcony with waterproofing are as follows:

- Not a single owner of an apartment or house with a balcony or loggia would want to live next door to dampness, mold and mildew.

- Wooden structures of open loggias or balconies will very quickly become unusable under the influence of an aggressive natural environment.

Considering the specifics of our climatic conditions, protection must be done.

What materials are used

Our craftsmen work with various types of materials for soundproofing balconies - you can choose any of the available options:

- Mineral wool is an option that was quite common some time ago. As a rule, siding is laid on top of mineral wool. However, this type of insulation has a fairly pronounced drawback - the likelihood of caking and the appearance of sound “bridges”.

- Foam plastic is the cheapest material for insulation and sound insulation. Lightweight slabs are extremely easy to install, and the material is not afraid of fungus and moisture, however, there is one “BUT” - the material crumbles easily and does not perform insulating functions well enough.

- Penoplex is quite expensive, but the most effective method of insulating and soundproofing a balcony. It is thin, easy to cut and install, and still has a high level of protection.

Our specialists have at least 3 years of experience and are always ready to offer you their wealth of experience and give advice on the best solutions in each specific case, based on the condition of your balcony.

Glazing and insulation of a balcony - general concepts

The whole process consists of 5 stages:

- preparatory work;

- sealing cracks with sealant;

- thermal insulation;

- installation of double-glazed windows;

- finishing (lining, drywall).

New PVC double-glazed windows and a thermal bridge are being installed to reduce heat loss. The original appearance of the street facade of the house does not change. If there are thin concrete slabs on the sides of the loggia and a lattice parapet in front, then the walls are first prepared by laying ceramic bricks.

Further:

- double-glazed windows are installed;

- the cracks are hermetically sealed with foam;

- the floor is prepared and leveled with a concrete screed;

- a layer of waterproofing is placed on top;

- finishing of the ceiling, floor and walls is carried out.

With the insulation method, it is important to insulate the walls inside and out. This way, drops of moisture will not settle on the walls of the room, and the dew point will remain outside it

For thermal insulation of walls:

- polystyrene foam boards are glued;

- a reinforcing mesh is applied.

To insulate the walls from the inside, penofol is first attached. On top are polystyrene foam boards. The joints are sealed with aluminum tape.

The ceiling is insulated in the same way. The waterproofing layer is attached. Then foam boards on plastic dowels and reinforcing mesh.

Recommendations for organizing work

You can provide reliable sound insulation to your balcony roof with your own hands. Dismantling the decorative ceiling cladding is the most labor-intensive part. After the completion of the main stage of work, it will need to be returned to its original place.

When the decorative trim of the roof has been removed, a visual inspection of the quality of fixation of the metal roof is carried out. Existing gaps are eliminated with insulating material.

The surface of the canopy or canopy is cleaned of all contaminants. After which it is covered with the material chosen for sound insulation. Organization of work during the warm period does not require additional fixation measures. It is enough to remove the protective film and press the material with the adhesive side to the inner surface of the roof.

A blowtorch or a hair dryer will come to the rescue. If work with open fire is carried out indoors, you should take fire safety measures.

The source of the rumble may not necessarily be raindrops. Excessive width of the canopy is one of the reasons for annoying noise on the balcony. To ensure sound insulation, it is enough to leave a visor 15 cm wide and remove the excess area.

Poor quality fixation of the material on the roof is another reason for the formation of vibration and oscillations. If you seal the cracks and strengthen the fastenings, the sound insulation of the balcony will noticeably increase.

The sound insulation process itself is not difficult, but working at height is associated with a high risk to health and life. Therefore, it is better to entrust the arrangement of the balcony roof to industrial climbers who have the necessary skills and equipment to organize high-altitude work.

How to cover the roof and balcony canopy so that they do not make noise?

The inconvenience is that there is no universal material on our market to solve this problem. As a result of 10 years of work experience, we can say that the most logical and convenient material was one that has the following properties:

- It should be a good, durable roofing material, such as bitumen, so that it can withstand nature's surprises.

- It should have sufficient thickness, provide good sound insulation of the balcony and not be too heavy.

- It should attach well, reliably and simply, ideally stick to any surface.

- This material should be easy to install for the climber, given that the work is carried out in weight and not be massive. For example, something like very flexible meter-long bitumen strips of different widths with increased sound insulation properties, which can be glued in a simple way to different roofs.

Unfortunately, no one has yet come up with such a universal target material, and for soundproofing balconies and balcony canopies, we use various roofing materials, automotive, etc., which are often massive, inconvenient to use, they need to be cut and we have to figure out how to fasten them. Often people do their own research, buy the material they think is best for thermal insulation, and then simply ask climbers to reinforce it on top. Sometimes, when descending along the balconies, you come across other options, like other climbers or the residents themselves did soundproofing. We came across one glued to a canopy or stem :

- Styrofoam

- Linoleum

- Rubber bath mats

- Artificial turf

- Automotive anti-gravel sprayed from a can

- Polyurethane foam poured over the entire extension area

- Expanded clay pebbles sprinkled on some kind of glue

- Just glued pieces of rubber from old inner tubes, etc.

And everyone is happy and says that it helped them. As you can see, there are many options and perhaps you can come up with something better...

Soundproofing of balcony structures is usually carried out during their glazing, when sealing the roof and insulating it. Properly performed work ensures the structure is protected from external sounds during bad weather. If the work was not done well enough, the roof of the structure may periodically begin to “make noise”, and therefore there is a need for sound insulation. When choosing the appropriate way to solve the problem, you should take into account the cause of the sounds that are unpleasant to the ear.

During wind or rain, a balcony canopy often makes sharp sounds that bother the owners, as well as the people living next to them. High-quality soundproofing of the balcony roof allows you to get rid of these loud sounds. Before you start making sound insulation, you need to find out exactly where the noise comes from. Most often they are caused by the following reasons:

- The soundproofing of the balcony roof, necessary to protect against loud sounds, was not made during its installation. Installation specialists with mountaineering skills will help you correct this error.

- The metal roof is weakly fixed at the offset. As a result, the sheets on which raindrops fall begin to vibrate loudly, resulting in annoying sounds.

- A balcony with a slight angle of inclination also needs sound insulation. This can be done by pouring foam for installation under the slope.

- There are too few fasteners or they are poorly secured. In this case, a sound insulation device will help to partially or completely eliminate the sound of raindrops hitting the balcony eaves. During such work, the installation of additional struts is necessary, so the services of high-altitude workers will be required.

- The canopy does not fit tightly to the wall or a gap has formed in the roof cavity.

Requirements for soundproofing materials

To make sound insulation, you can use different materials. When choosing a suitable material for sound insulation, you need to consider the following criteria:

- the strength of the material, which will allow the product to maintain its integrity, adequately withstanding any mechanical impacts;

- protection from fluctuations in temperature and humidity;

- resistance to ultraviolet radiation (the material should not emit substances harmful to health when heated);

- sufficient thickness;

- reliable, simple fastening.

Fulfilling all the above conditions allows you to reduce the loud noise from the balcony canopy during difficult weather conditions or completely get rid of it.

Types of materials for soundproofing a rattling balcony roof

To rid the balcony roof of noise, three types of soundproofing materials are currently used.

- Izolon. Before using such sound insulation, first remove the film, then lean it against a profiled sheet or other surface.

- Tytan ribbons. Manufactured on a bitumen basis. They have attractive performance characteristics that lead to a fairly high price. To achieve the required level of sound insulation, the roof is treated in several layers. When carrying out work in winter, the tape is heated with a construction hairdryer. To ensure the required tightness, the joints should be treated with sealant.

- Vibroplast. This is a foil material, the use of which can improve the performance characteristics of the car. It is also used to eliminate balcony noise during rain. It has a fairly high price.

How can I fix the problem?

Soundproofing of balcony structures is usually carried out during their glazing, when sealing the roof and insulating it. Properly performed work ensures the structure is protected from external sounds during bad weather. If the work was not done well enough, the roof of the structure may periodically begin to “make noise”, and therefore there is a need for sound insulation. When choosing the appropriate way to solve the problem, you should take into account the cause of the sounds that are unpleasant to the ear.

Most often, the following measures can solve the problem:

- sound insulation is performed using soft polymers that reduce the sound of raindrops hitting the visor;

- if the sound is produced by a poorly secured roof, then the structure is strengthened;

- if necessary, the angle of inclination of the balcony canopy is changed;

- If the dimensions of the visor were chosen incorrectly, they are corrected by trimming the excess parts.

In some cases, they resort to a more radical measure, which consists of replacing the steel canopy with a plastic structure. It is easier to protect a loggia from noise than a balcony. On a loggia, only the front part is usually soundproofed, without touching the sides.

Work order

If you wish, you can soundproof the balcony roof from noise with your own hands. The most labor-intensive stage in the manufacture of a soundproofing structure is the dismantling of the ceiling decorative cladding. Having attached the insulating material, the cladding is returned to its place.

After removing the trim, it is necessary to inspect the roof to ensure that it is properly secured. The existing cracks are sealed. The surface of the canopy or canopy is cleaned of any contaminants on it, then covered with insulator. If the work is carried out in the spring-summer period, to attach the material, simply remove the film from it, then press the material to the surface. In late autumn and winter, when it is cold outside, the adhesiveness of the material decreases, so it must be heated before gluing. This can be done using a hair dryer. The noise from the visor can be caused not only by raindrops, but also by its excessive width. Leave the visor fifteen centimeters wide, and remove the unnecessary part. Noise can also occur if the insulating material is poorly fixed, which can lead to trembling and vibrations. In this case, it is necessary to strengthen the fastenings and rid the structure of cracks. The work described above on making sound insulation for a balcony roof is not too complicated, but its implementation is associated with increased danger. Therefore, it is much wiser not to do them yourself, but to order sound insulation from professionals who have the special equipment and tools necessary for carrying out work at height, as well as the relevant knowledge and skills.

Sound insulation of balcony canopy

Causes of noise

Various factors can cause noise. The most obvious of them is the lack of a soundproofing layer, which must be secured when creating a balcony roof. For this purpose, special gaskets are used that can block the penetration of extraneous sounds into the room. If this step was skipped, you need to correct the defect. The services of climbers and installers will be required to protect the balcony from the street side. The measures taken will make the unpleasant sounds quieter or eliminate them completely.

Such coating options have many undeniable advantages. But the inability to ensure silence is a serious disadvantage. Thus, a corrugated roof not only lets all street sounds in, but also makes them several times louder.

In this case, the visor increases, and the strength of the weather conditions also increases. Metal sheets begin to shift and rattle from the rain. You will hear drops falling on them, regardless of the strength and intensity of precipitation. A remote balcony with a small angle of inclination is especially susceptible to sound propagation. To ensure the proper level of silence, polyurethane foam sealant should be poured under the lower slope.

If the problem appeared after the roof was installed, to solve it it may be enough to add fasteners or fix them more securely. High-altitude specialists will install additional elements.

Why is the balcony noisy?

Since the balcony is a room whose surfaces directly border the street, noise can come from various sources - passing cars, children playing on the playground, rain drumming on the roof.

Sound is a physical phenomenon that propagates in a gaseous, liquid or solid medium in the form of mechanical vibrations (waves), which are characterized by amplitude and frequency. A person is able to perceive sound in the frequency range from 16 Hz to 20 kHz.

If the resistance of the surfaces is insufficient, noise easily penetrates into the room and causes discomfort. For example, it is impossible to calmly read a book or work on important documents if there is a traffic highway outside the window or birds have made a temporary shelter on the roof of the balcony.

The roof is the most unprotected place from external noise, which affects not only household members, but also residents of neighboring apartments. There are several reasons:

- installation without the use of soundproofing materials;

- weak fastening of metal sheets, resulting in vibration even with minor mechanical impact;

- small slope angle or its absence.

Lack of sound insulation on the balcony is a common cause of irritation and headaches

Soundproofing of walls and ceilings

Soundproofing of the balcony is carried out both from the outside and from the inside. This gives maximum effect. The interior decoration provides warmth, and the exterior eliminates extraneous sounds directly. As a result, indoor comfort is fully ensured. However, the right approach is required so as not to lose useful footage of the balcony space. Due to the danger of external work, such soundproofing of a balcony with your own hands is not recommended; it is better to entrust this to specialists. Or limit yourself to working from the inside, which will also give results.

Currently, in the age of new technologies and high-quality equipment, the production of modern soundproofing materials is well established, which will make the sounds of flowing water, wind and other irritants almost inaudible.

Insulation and soundproofing of a balcony is carried out using the following products:

- Extruded polystyrene foam. Has good noise insulation properties. It is used to produce hard and soft slabs. They are shaped like grooves, making their installation easier;

- Non-standard foam plastic (PSB-S35, PSB-S50). Widely popular due to the fact that its cost is low and its service life is long. Complete insulation and sound insulation of the balcony cannot be achieved using only this building material;

- Mineral wool. Very popular for these types of repair work due to the combination of low cost, durability and good quality;

- Foil and foamed polyethylene with a density of about 3-10 mm. It will serve as sound insulation and also as insulation. It is compact and suitable for balconies of any size.

You can make a similar purchase at any hardware store in Moscow, as well as throughout the country. The combination of several types of building materials gives a very good effect not only in terms of sound insulation, but also insulating the balcony.

A glazed balcony is more practical than a regular one. This is expressed in the presence of additional space not only for storing things, but also for spending time. High-quality glazing is not complete without a good roof, which in some cases causes trouble due to its noise. The article will discuss what may be causing noise from the roof, as well as ways to eliminate it.

Finishing the loggia yourself: simple instructions

A loggia or balcony is another room that must be carefully finished and decorated. Upholstering an interior can cost a lot of money, but doing it yourself can help you save money.

Step-by-step instruction:

- The entire perimeter is covered with a frame made of metal or wood. The interior upholstery will be attached to these elements in the future. They are selected individually depending on what materials will be used later at the finishing stage.

- The next stage is glazing the balcony. This will be discussed in more detail in a separate paragraph.

- The third step is the interior upholstery of the room.

- The final step is the final decorative work.

Do-it-yourself balcony finishing is done from the following materials:

- Siding - this material is used for interior and exterior decoration. It is durable, reliable, and has a wide color palette. But it can fade quickly in the sun, and it doesn’t always smell nice in a closed space.

- Plastic panels - they look neat and beautiful on the walls, but create a sealed effect of the room. Also available in different colors - from shades of color to rich textures.

- Wood – wooden lining is the most common material for cladding loggias. It looks neat and beautiful, and if properly treated with varnish, it does not fade in the sun, does not break, or crack. The material is also simple and convenient to work with. The only negative is that it is quite expensive.

- Drywall - a moisture-resistant material is installed on the sheathing. The top of the slabs can be covered with paint or wallpaper. An inexpensive and easy-to-work material, but it looks less impressive than wooden lining.

You can trim the inside of the balcony yourself.

First, make sure that you have all the necessary tools and materials for the work:

- facing material;

- insulation;

- dowel nails;

- wooden slats;

- jigsaw;

- self-tapping screws;

- waterproofing material;

- polyurethane foam;

- drill;

- screwdriver

Do-it-yourself balcony finishing: step-by-step instructions:

- Preparatory stage - at this step it is necessary to clear the room of unnecessary things, remove the old covering if any, inspect the walls for cracks, seal them, and also carry out cleaning.

- Installation of the sheathing - the final material will be attached to it. The frame is made from durable wood beams, then mounted on the walls.

- Insulation - after installing the sheathing, the free cells are filled with insulating material, which allows you to keep the room warm and comfortable even in cold weather. Penoplex is the most commonly used insulation, which is attached to cells and has the form of slabs. It is fixed with glue or foam, and the material must fit very tightly in the cells. Mineral wool is also used for insulation, but when installing it, waterproofing films must be used.

- Waterproofing is a very important stage that comes immediately after insulation. Moisture penetrating onto the balcony leads to gradual deterioration of the material, constant leaks from the ceiling and the appearance of mold. Repeated repairs will require large time and financial investments. Waterproofing is done using polyethylene film, roofing felt or other membranes.

- Installation of cladding - the lining begins to be attached to pre-installed plastic elements. The panels are fastened using self-tapping screws or staples.

- Ceiling repair – without ceiling cladding, the room will have an unfinished look. You can make the same coating on top as on the walls, whitewash it, cover it with decorative plaster, or even install a suspended ceiling. Before starting cladding, it is necessary to make good waterproofing so that moisture does not penetrate from neighbors or from the roof and spoil the view.

- Lighting is the final, but not mandatory, stage. You can provide light to a balcony or loggia using insulating channels made of white plastic or buy battery-powered lamps.

Balcony finishing with plastic panels

Causes of Unwanted Noise

Part of the house structure is exposed to the environment. This is wind and precipitation - the inevitable natural conditions for operating a house. The right solution will reduce the noise level and make your stay more comfortable and cozy. The immediate causes of sound are:

- A material that transmits vibration well and converts the potential energy of precipitation and wind into sound. It is advisable to choose roofing coverings that have an initially high sound absorption coefficient. These are soft roofing, tiles, slate and other similar materials. If, for a number of reasons, corrugated sheeting or metal tiles are chosen, then the noise will probably be significant. It will annoy not only homeowners, but also neighbors.

- Errors during installation of the supporting roof structure and laying the roof. Poorly secured sheets of metal or other material make sounds when they hit each other and the load-bearing frame. In addition, a carelessly assembled structure under the influence of wind and resulting vibration has a tendency to further destruction, which is unsafe for both homeowners and surrounding people.

- Insufficient roof slope. The most unsuccessful design can be considered a straight roof. Rain and hail fall on it at right angles, transferring the accumulated energy to the coating. A sloping roof reacts much more softly to precipitation. Even metal sheet material, with a protective factory-made polymer layer, is practically silent at a sufficient angle of inclination of the roof.

A well-thought-out project and correctly selected materials with high-quality installation do not require additional measures, and soundproofing the balcony roof will not be a mandatory operation. However, this is not always possible to implement in practice and additional efforts have to be made to eliminate this shortcoming.

Roof installation steps

The roof over the balcony is designed individually.

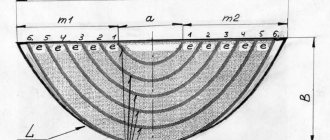

For this purpose, a frame is designed that will be made of metal. The level of roof slope depends on the chosen frame model. Remember, the larger it is, the less problems with snow there will be, because it does not accumulate at the top. Anchor bolts are used to secure the frame to the wall. The roof will be laid on the timber sheathing; other finishing samples will be used on the inside. The roof on the balcony can be made of ondulin or metal tiles. On the inside, special components are used for sound and heat insulation.

The top of the balcony, made of ondulin, is a lightweight, durable and environmentally friendly design. The element perfectly absorbs the sound of rain, so the usual “drum” sound will not be heard. Any shade of the roof can be chosen, which cannot be done with slate. A common option is metal tiles, which are represented by galvanized sheets coated with a special material. This sample perfectly protects against corrosion while maintaining a beautiful appearance.

Soundproofing visor

An extremely pressing issue. In apartment buildings, roof soundproofing is done only by residents of the upper floors. For others, this problem does not exist. But in order to protect the facade and windows, many homeowners on all floors install canopies.

In order for the desired design to bring satisfaction, and not irritation, with every, even slight rain, it is important to comply with certain requirements. It’s better to do this at the planning stage if there is no visor yet

If it already exists and causes a lot of trouble, then the installation technology becomes more complicated.

The technology for fixing the sound-absorbing layer is not fundamentally different from a similar procedure with a roof. Difficulties may arise if you want to use mineral wool as the main sound insulator. The need to completely seal it makes the operation labor-intensive and costly, so the method is practically not used.

The most acceptable method should be the installation of sheet, rolled waterproof materials, or special vibration-damping compounds. The small coverage area allows you to purchase products used in cars for similar purposes without much expense.

Interior work

Soundproofing the balcony from the inside also effectively dampens the noise from falling rain. This method is used more often than others; it does not present any particular difficulties, since there is no need to go down onto the roof.

Before starting work, probable causes of noise are excluded. Be sure to tighten the fasteners and double-check the roof rafters. If the roof serves as a floor covering for the loggia, then you need to discuss with your neighbors the possibility of jointly performing sound insulation.

Bitumen tape is glued to the ebbs on the back side, the space between them is blown out using polyurethane foam. The sound insulation is fixed closely. The material must cover the entire surface - this will allow you to achieve optimal results. Mineral wool is attached between the elements of the rafters, and not on the flooring. If the sound insulator is hygroscopic, the surface will need to be covered with a vapor barrier membrane once the installation work is completed.

During installation, care is taken not to damage any component of the waterproofing layer.

Glazing selection

Balcony glazing protects from wind and prevents precipitation and dust from entering. By providing reliable thermal insulation, your home will be protected from the cold in winter. Glazing can be done independently. Successfully selected materials for glazing and knowledge of all the intricacies of the process itself are a guarantee of the quality of the work done. Windows from the Rehau Intelio profile will help ensure silence in the apartment, as they are one of the quietest.

Nowadays, balconies are glazed with the following materials:

- Wooden frames. They are very different in quality from traditional windows. They are more durable, resistant to moisture and are not afraid of fluctuations in air temperature due to the use of so-called laminated timber technology. Their service life is quite long, since they are coated with special protective materials. Wood is characterized by low thermal conductivity and excellent sound insulation properties;

- Metal-plastic frames are most often used in the production of windows. Such structures can last more than 40 years. They are resistant to corrosion and rotting. They do not require any additional processing or coating renewal. Thanks to the presence of drainage and micro-ventilation elements, the optimal air temperature is maintained in the room;

- Aluminum windows are very widely used on old balconies. Due to their light weight, they do not load the balcony structure. However, such material must be used with heat-insulating inserts to ensure comfort in the cold season;

- Frameless glazing. Such structures transmit light well and reliably protect from precipitation and wind. However, this option does not completely eliminate the noise, but only muffles it. The glass is attached to aluminum frames. The measurements must be as accurate as possible: any misalignment and the design will lose its functionality.

We glaze the balcony with our own hands

Developers initially did not glaze the balconies in their houses, leaving an open area. Due to unfavorable weather conditions and the desire to store some things there or create a recreation area, people began to order a glazing service.

A glazed and insulated balcony becomes a full-fledged part of the living space, because it is as comfortable to be in as in an apartment. Rocking chairs, cabinets and bedside tables, small sports complexes, flowers, etc. are installed here.

You can glaze a balcony yourself if you have basic knowledge in the field of construction. There are 3 types of installed double-glazed windows:

Wooden frames - they are of high quality and durability, completely different from their old counterparts. These double-glazed windows perform the function of sound insulation and thermal insulation, and also look stylish on balconies. The design also has disadvantages - moisture can get into the sliding frames, and a large accumulation of it has an adverse effect on the wood. Also, during winter periods, when the temperature outside the window is sub-zero, drops can freeze and prevent the windows from opening.

- Metal-plastic frames are one of the most popular options for double-glazed windows. Average service life is 40 years or more. In addition, the material is not exposed to moisture or cold, is equipped with drainage systems and is made from high-quality raw materials.

- Frameless windows - this glazing option has appeared recently. The developers thought that massive frames take away some of the glass, and less sunlight penetrates into the apartment. Then frameless double-glazed windows were invented, which are not inferior in quality to their frame counterparts, and look harmonious on the balcony. However, in such a room it will be quite cold, a little warmer than outside, so it can only be considered residential in warm weather.

There are 2 main types of glazing:

- Cold is a more economical method, because... Single-glazed windows and lightweight frames are used in the installation. During the cold season it will be really cold here, so the balcony can only be used for storing things that are not afraid of frost.

- Warm - in this case, full-fledged frames and double-glazed windows are installed, taking into account all the requirements that do not let the cold in and do not let the heat out.

Getting rid of possible condensation:

- provide controlled ventilation;

- install double glazed windows and high-quality frames;

- provide moisture insulation of the floor covering;

Preparing the balcony for glazing:

- The metal parapet is insulated before installing the frames;

- All measures for finishing the balcony are carried out after the installation of double-glazed windows;

- The brick parapet is leveled with cement mortar;

- Dismantle the top of the old fence if it is not horizontal.

Installation of wooden frames:

- The lower beam of the wooden box is installed at the level of the railing, and the upper beam at the ceiling level. The connecting points are fastened with brackets to the wall.

- Lathing is installed for further finishing.

- Treated and, if necessary, pre-painted frames are installed.

- Canopies are installed outside the balcony to protect against moisture.

Wooden frames

Installation of plastic frames:

- Support posts are installed from wooden beams.

- The support posts are attached to the ceilings and parapet using self-tapping screws.

- Double-glazed windows are removed from the frames before installation.

- The doors are removed using pliers.

- A support profile is fixed at the bottom of the frame.

- The double-glazed windows should include anchor plates; they are installed in the grooves of the frame.

- The frames are installed in the openings and fixed using self-tapping screws and anchors.

- Double-glazed windows and sashes are attached in place.

- After this, the window sill is installed and the grooves are sealed with foam.

Plastic frames

Basic materials for sound insulation of balcony iron roof

To insulate balconies and loggias from noise, materials are used that are glued to the inner surface of a metal sheet - the close contact of the insulating material, in addition to dampening sound due to its structure, causes an increase in the total mass of the covering sheet, and this additionally dampens sound vibrations.

Sound insulator Izolon

Isolon (PPE) is a material based on polyethylene foam with a foil side to improve insulation; fixation to a metal surface is carried out using an adhesive layer applied to one of the sides. Soundproofing Izonol is available in slabs (1×1.1 m and 2×1.4 m) and rolls up to 200 m long, 1 – 50 mm thick, width varies in the range of 0.55 – 2 m. To cover the roof from the inside with a noiseless material, cut off pieces of the required size, remove the protective film from the adhesive surface and press the insulator tightly against the steel sheet, covering the joints with construction tape.

Izonol has the following technical characteristics:

- Shelf life – up to 80 years.

- The reduction in impact noise depends on the thickness, the average value is 20 dB.

- The specific heat capacity is 1.95 kJ/kg*s.

- Material density 26 – 45 kg/m3.

- Water absorption no more than 0.1%, vapor permeability 0.001 mg./m.Pa.

- Reflection of thermal energy by the foil surface is up to 97%.

- The operating temperature range is -60 C – +120 C.

- Isonol is elastic, the indicator is 130% with a relative elongation of 250%.

- The material does not support combustion; in the presence of fire retardants in the composition, its flammability belongs to class G2-G4.

- Isonol is a non-toxic material; the polyethylene foam, aluminum foil and water-based acrylic adhesive included in the composition are inert substances.

Vibroplast

Sometimes, to reduce the noise of metal balcony roofs, expensive materials are used to dampen vibrations in cars, which stick to the surface due to the adhesiveness of the components in the composition. Vibrating paste consists of bitumen and mastic and is produced in small sheets up to 20 mm thick. with one-sided foil coating. Typically, such sound insulation is applied by applying a sheet to a metal surface and then heating it, but there are also types with cold application.

Vibroplast increases the weight and reduces the noise characteristics of the roof, while having low thermal protection, so the use of thick sheets is more effective. Also, the disadvantages include the possibility of the sheet peeling off when the roof is very hot.

Bitumen based tapes

Not too expensive bitumen-based roofing tapes are made from oil, coal and shale; they are waterproof, chemically resistant and do not lose their properties in the temperature range from -40 to +90 C.

The disadvantages of bitumen coating include flammability and softening under the influence of high temperatures.

Sound insulation of an iron roof on a balcony is made by materials glued to its surface from the inside or outside - sound absorption occurs due to the properties of the material and the increase in the mass of the sheet.

At the same time, insulating a room from sound with your own hands using popular rolled stone wool insulation is not very rational - due to the loose fit to the roof sheet, its effectiveness is lower, and installation requires the installation of a complex profile frame with further cladding.

Roof over the top floor balcony - self-installation

When constructing a roofing covering, whether it is independent or dependent, it is better to immediately do everything to the maximum. Then you won’t have to work at heights at the risk of your life after each season. It is advisable to seal the joints using polyurethane foam, sealant or dry building mixtures

When building, it is important to take into account the direction of the prevailing wind. If strong winds constantly blow onto the balcony, the roof must be installed so that water does not flow between the sheets of covering

Preparing for work

Before starting construction, you need to purchase high-quality materials. This is especially true for wood; it is better to buy first-grade bars - without cracks, knots, or chips. Otherwise, weather conditions will quickly render the building unusable. Drilling brick walls may not work with a conventional electric drill; you will need a powerful hammer drill.

If the necessary tools are not on the farm, you can rent them or from friends.

You will need a powerful cordless screwdriver, since working with a drill with a wire at a height is inconvenient. Metal trusses should be ordered from a specialized company. It is not recommended to weld them on site; this is a fire hazard. You will also need a wood saw with large teeth. It is necessary to purchase consumables - screws, dowels, anchors.

To create an independent balcony roof from corrugated sheets over a standard 2-meter-long balcony, the following materials will be required:

- triangular trusses made from steel angle – 3 pieces (placed at a distance of 80-100 cm);

- sheathing – timber 20-40 mm;

- anchor bolts 100 mm long;

- screws with sealing gaskets, standard self-tapping wood screws;

- anti-corrosion primer for metal;

- antiseptic impregnation for wood, for example, Pinotex;

- corrugated sheets;

- cement mortar.

Step-by-step instructions for installing an independent structure

The procedure for creating an independent roof on the balcony is as follows:

- Attach the prepared trusses to the wall using anchors. Deepen the anchors to a depth of 70-80 mm.

- Treat the timber with Pinotex and wait until it dries completely.

- Secure the wooden sheathing with screws. It is necessary to prevent the sheets from rattling in windy weather.

- Using metal scissors, cut the corrugated sheet into pieces of the required size.

- Using screws with seals, attach the metal sheets to the sheathing.

- There remains a small distance between the roof and the wall. This gap must be filled with foam. If necessary, after hardening, excess foam can be cut off with a knife.

- The joint treated with foam is covered with sealant on top.